Retrofitting a 1986 Maho MH400E

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Jan 2020 15:44 #155553

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

@Mark: literally ROFL

I'm really excited.

Put everything back together and the Axis works like a charme.

It runs MUCH smoother than before and even the 1/1000 digit doesn't wobble anymore.

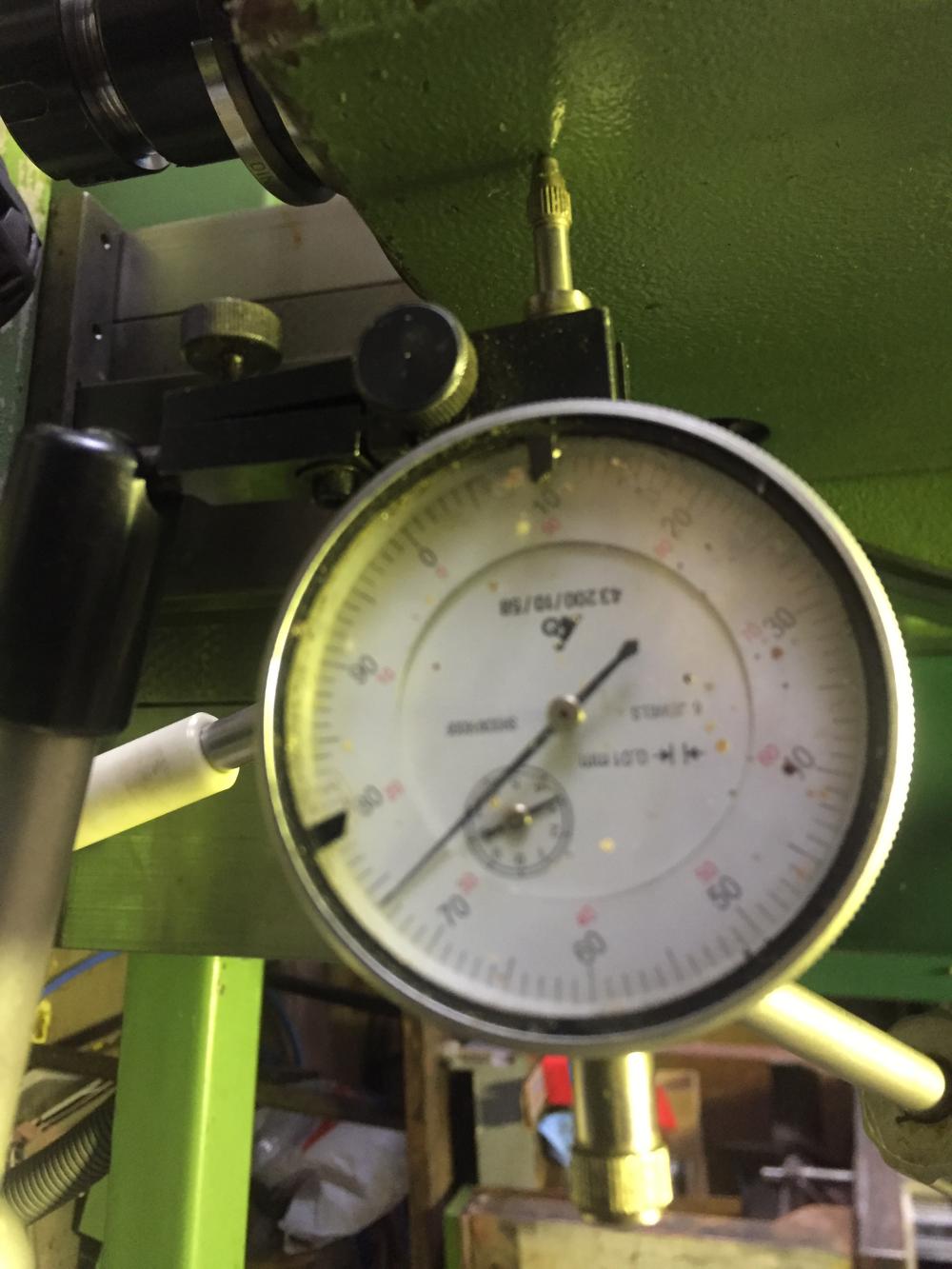

Of course, here are the pics.

Do NOT lose the soft inserts (Aluminium):

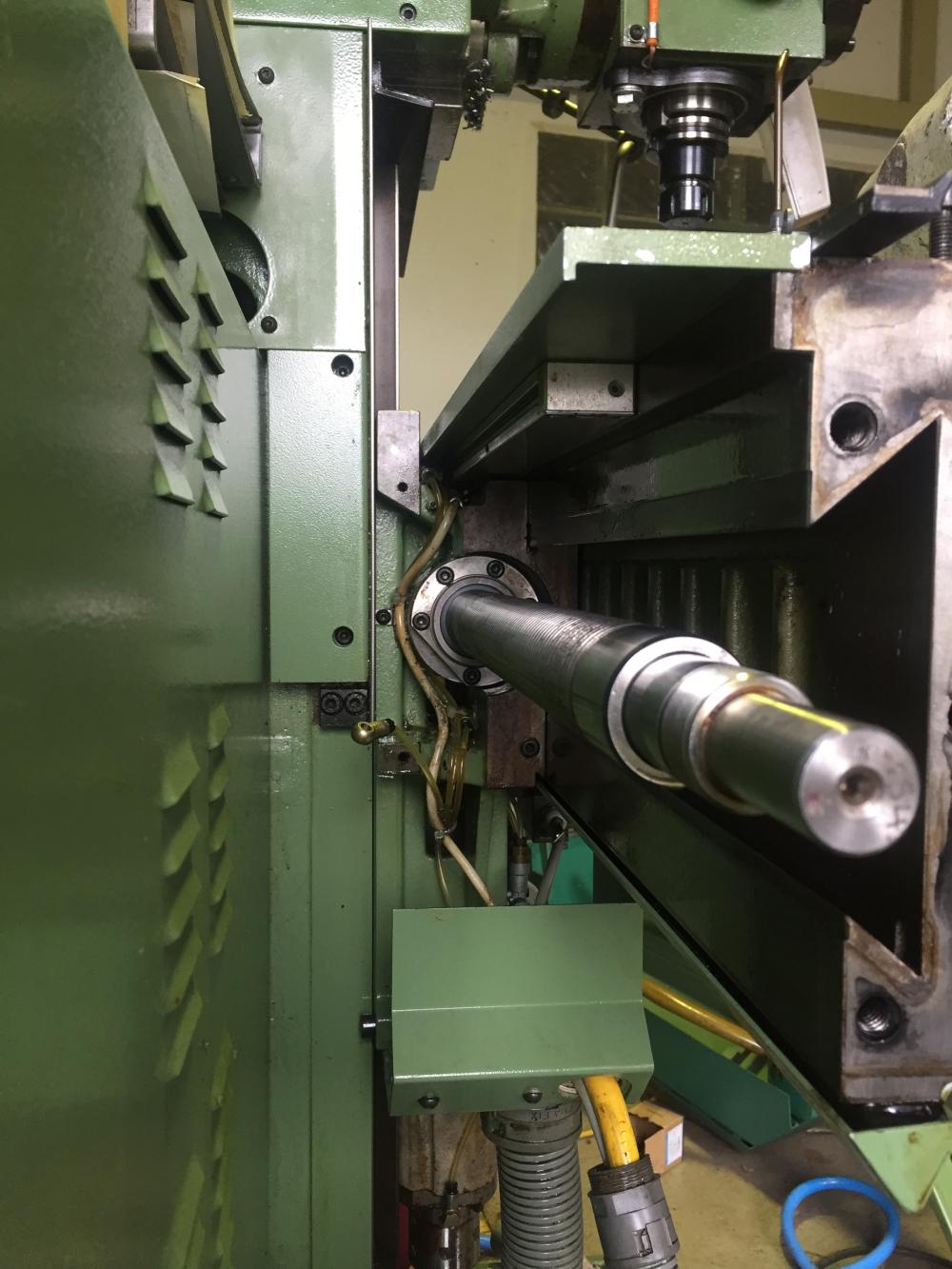

Ballscrew back in place:

A LOT of oil pured out of the cable-tube:

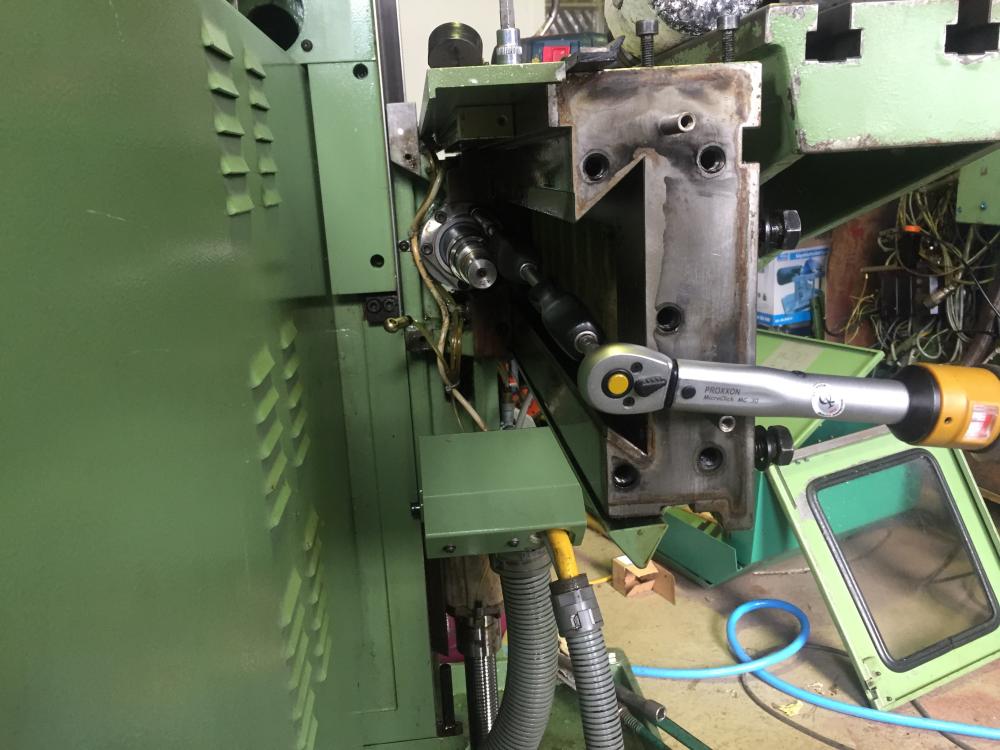

Torque-wrenched the screws to 15Nm,

I don't trust the regular 10Nm for M6 8.8 :

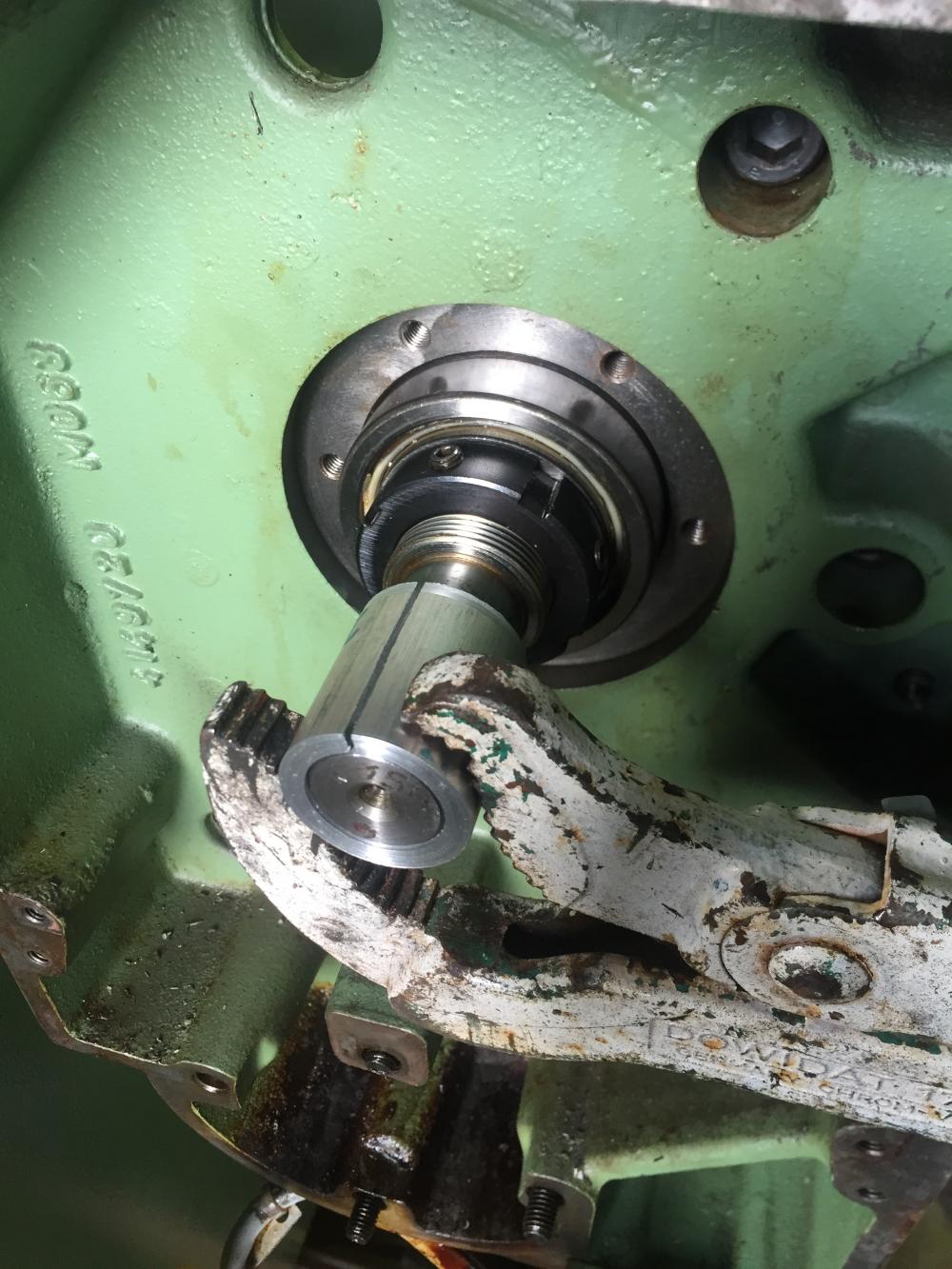

Turned an Aluminium protection bushing:

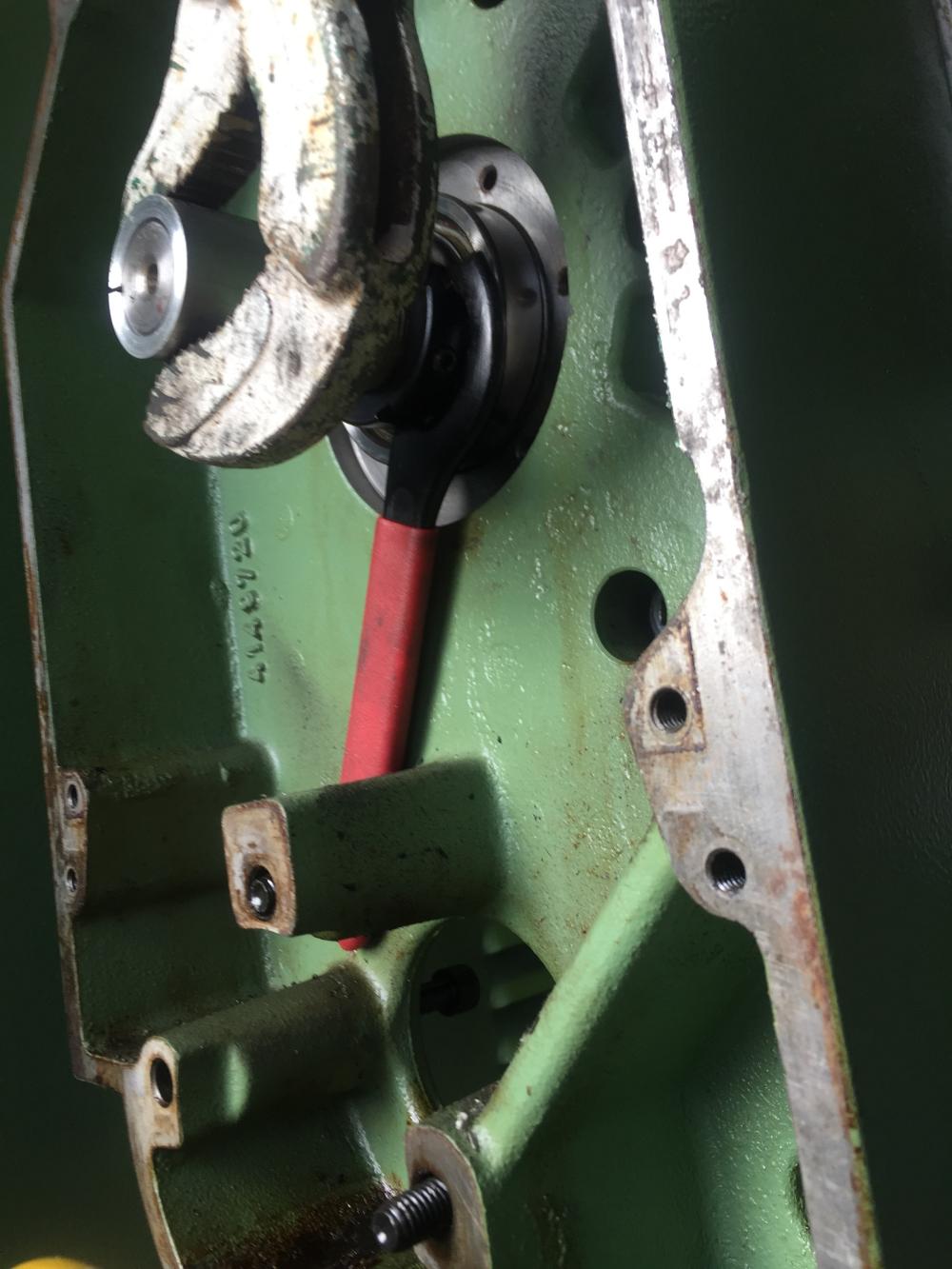

Scratched a marking:

I'm really excited.

Put everything back together and the Axis works like a charme.

It runs MUCH smoother than before and even the 1/1000 digit doesn't wobble anymore.

Of course, here are the pics.

Do NOT lose the soft inserts (Aluminium):

Ballscrew back in place:

A LOT of oil pured out of the cable-tube:

Torque-wrenched the screws to 15Nm,

I don't trust the regular 10Nm for M6 8.8 :

Turned an Aluminium protection bushing:

Scratched a marking:

The following user(s) said Thank You: RotarySMP, J Green

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Jan 2020 15:48 #155554

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Attachments:

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

23 Jan 2020 16:00 #155556

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

I'm seriously considering changing the balls in the other spindles, too.

I will check and adjust the wedges, measure a lot and then decide how to go on.

For now I'm really happy !!!

Cheers

I will check and adjust the wedges, measure a lot and then decide how to go on.

For now I'm really happy !!!

Cheers

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1570

- Thank you received: 576

23 Jan 2020 16:05 #155557

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Stop screwing around already

But seriously, it is is cool to see a successful tranformation of a probelmatic machine to one running correctly.

Mark

But seriously, it is is cool to see a successful tranformation of a probelmatic machine to one running correctly.

Mark

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

23 Jan 2020 18:27 #155563

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi Mark

The manual rotary table will also tilt front to back and swivel side to side . They came with 2 dial indicators for resetting the tilt and swivel . The tilt and swivel is of a limited amount compared to the table rotation.

Tilt - swivel - rotate sure helps preserve usable part volume machining capacity and allows clamping a part on the table to be much easier. Compared to the rigid / straight table there is a reduction in X axis table length. The rotary swivelling table can reduce interpolation machining cusp.

Do you have any suggestions about how to incorporate a ROD 271 into Linux CNC. What is needed for the INI an HAL files? The reference mark would need a way to incorporate a fixed - constant offset from a zero position reference. MAHO just dialed the zero point reference offset into the machine constants.

Thanks

Bob

The manual rotary table will also tilt front to back and swivel side to side . They came with 2 dial indicators for resetting the tilt and swivel . The tilt and swivel is of a limited amount compared to the table rotation.

Tilt - swivel - rotate sure helps preserve usable part volume machining capacity and allows clamping a part on the table to be much easier. Compared to the rigid / straight table there is a reduction in X axis table length. The rotary swivelling table can reduce interpolation machining cusp.

Do you have any suggestions about how to incorporate a ROD 271 into Linux CNC. What is needed for the INI an HAL files? The reference mark would need a way to incorporate a fixed - constant offset from a zero position reference. MAHO just dialed the zero point reference offset into the machine constants.

Thanks

Bob

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

23 Jan 2020 22:45 - 23 Jan 2020 22:53 #155586

by drimaropoylos

linuxcnc.org/docs/2.6/html/config/ini_config.html

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

HOME_OFFSET = 0.0 - The axis position of the home switch or index pulse, in machine units. When the home point is found during the homing process, this is the position that is assigned to that point. When sharing home and limit switches and using a home sequence that will leave the home/limit switch in the toggled state the home offset can be used define the home switch position to be other than 0 if your HOME position is desired to be 0.Hi Mark

Do you have any suggestions about how to incorporate a ROD 271 into Linux CNC. What is needed for the INI an HAL files? The reference mark would need a way to incorporate a fixed - constant offset from a zero position reference. MAHO just dialed the zero point reference offset into the machine constants.

Thanks

Bob

linuxcnc.org/docs/2.6/html/config/ini_config.html

Last edit: 23 Jan 2020 22:53 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

23 Jan 2020 22:50 - 23 Jan 2020 22:55 #155588

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

In your ini_config.txt you have to set that parameter.

John

John

Last edit: 23 Jan 2020 22:55 by drimaropoylos.

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

24 Jan 2020 01:41 #155614

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi John

Thank you for the answer.

Bob

Thank you for the answer.

Bob

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1570

- Thank you received: 576

24 Jan 2020 09:12 - 24 Jan 2020 09:17 #155637

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Assuming you will be wiring in the rotary tables ROD encoder into the fourth axis encoder input of the MESA 7i77 connector TB4 pins 1-8, and configuring the GUI to display the fourth axis. Not sure how happy the GUI and LinuxCNC is going to be about diplaying a manual axis, especially, whether it will error out if you hit the GUI's C AXIS jog button, although there is no motion control connection?

I am pretty crap at the HAL/INI config stuff but let me throw out my ideas, and maybe Andy or one of the other HAL Jedi's can correct this...

In the INI:

[DISPLAY]

GEOMETRY = xyzc

[TRAJ]

AXES = 4

COORDINATES = X Y Z C

[AXIS_3]

TYPE = ROTARY

HOME = 0

ENCODER_SCALE = 1000 ; or whatever it is.

OUTPUT_SCALE = 10 ; You'll have to work all these values out for your machine.

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -1

MAX_LIMIT = 400

HOME_OFFSET = 0

HOME_USE_INDEX = YES

HOME_SEQUENCE = 2

; So after LINUXCNC homes the linear axis's it'll sit and wait till you home the C Axis.

In the HAL:

loadrt hm2_pci config=" num_encoders=4 num_pwmgens=0 num_stepgens=0 sserial_port_0=300xxx"

#*******************

# AXIS C

#*******************

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 1

setp hm2_5i25.0.encoder.03.scale [AXIS_3]ENCODER_SCALE

net c-pos-fb <= hm2_5i25.0.encoder.03.position

net c-vel-fb <= hm2_5i25.0.encoder.03.velocity

net c-pos-fb => axis.0.motor-pos-fb

net c-index-enable axis.3.index-enable <=> hm2_5i25.0.encoder.03.index-enable

net c-pos-rawcounts <= hm2_5i25.0.encoder.03.rawcounts

# ---setup home / limit switch signals---

net home-c => axis.3.home-sw-in

net c-neg-limit => axis.3.neg-lim-sw-in

net c-pos-limit => axis.3.pos-lim-sw-in

I am pretty crap at the HAL/INI config stuff but let me throw out my ideas, and maybe Andy or one of the other HAL Jedi's can correct this...

In the INI:

[DISPLAY]

GEOMETRY = xyzc

[TRAJ]

AXES = 4

COORDINATES = X Y Z C

[AXIS_3]

TYPE = ROTARY

HOME = 0

ENCODER_SCALE = 1000 ; or whatever it is.

OUTPUT_SCALE = 10 ; You'll have to work all these values out for your machine.

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -1

MAX_LIMIT = 400

HOME_OFFSET = 0

HOME_USE_INDEX = YES

HOME_SEQUENCE = 2

; So after LINUXCNC homes the linear axis's it'll sit and wait till you home the C Axis.

In the HAL:

loadrt hm2_pci config=" num_encoders=4 num_pwmgens=0 num_stepgens=0 sserial_port_0=300xxx"

#*******************

# AXIS C

#*******************

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 1

setp hm2_5i25.0.encoder.03.scale [AXIS_3]ENCODER_SCALE

net c-pos-fb <= hm2_5i25.0.encoder.03.position

net c-vel-fb <= hm2_5i25.0.encoder.03.velocity

net c-pos-fb => axis.0.motor-pos-fb

net c-index-enable axis.3.index-enable <=> hm2_5i25.0.encoder.03.index-enable

net c-pos-rawcounts <= hm2_5i25.0.encoder.03.rawcounts

# ---setup home / limit switch signals---

net home-c => axis.3.home-sw-in

net c-neg-limit => axis.3.neg-lim-sw-in

net c-pos-limit => axis.3.pos-lim-sw-in

Last edit: 24 Jan 2020 09:17 by RotarySMP.

The following user(s) said Thank You: J Green

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

24 Jan 2020 18:21 #155663

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi Mark

A Big Thank You !

Being able to display the manually positioned rotary table will be extremely useful. I can't think of any other MAHO accessories where this is needed , but feel people will be making some neat stuff that can benefit.

Maybe the boat building kiwi will find this useful .

Cheers

Bob

A Big Thank You !

Being able to display the manually positioned rotary table will be extremely useful. I can't think of any other MAHO accessories where this is needed , but feel people will be making some neat stuff that can benefit.

Maybe the boat building kiwi will find this useful .

Cheers

Bob

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.731 seconds