Retrofitting a 1986 Maho MH400E

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

22 Jan 2020 20:22 #155449

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi,

even if it was under Water it may be still intact.

Mine had a film of coolant inside, everywhere.

I washed it with brake cleaner and it's perfect again.

Cheers

even if it was under Water it may be still intact.

Mine had a film of coolant inside, everywhere.

I washed it with brake cleaner and it's perfect again.

Cheers

The following user(s) said Thank You: Azzrael

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 Jan 2020 20:54 #155450

by drimaropoylos

My old y axis ball screw with only 3 rows of balls left on it. I can measure 37 balls on every row.

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Hi there,

counted my balls today

240, exactly. As the ballscrew nut has 7 ball returns I expected the Number to be a multiple of 7 minus one or two cracked balls. I don't know how to interpret that result.

Cheers

My old y axis ball screw with only 3 rows of balls left on it. I can measure 37 balls on every row.

Attachments:

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

22 Jan 2020 21:00 #155452

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi hanmon

If you are referring to the ROD 27? - could you go into more detail about removing it from the rotary table? I have two rotary tables an the servo driven one looks as if the coolant turned the cog belt pulley into swiss cheese. Was trying to get the steel ball to release on the ROD to table shaft without success - just squirt it with super thin oil every time I walk pass it. Thanks for mentioning "Brake cleaner" as I forgot about that.

What is the latest about the ball screw adventure?

Bob

If you are referring to the ROD 27? - could you go into more detail about removing it from the rotary table? I have two rotary tables an the servo driven one looks as if the coolant turned the cog belt pulley into swiss cheese. Was trying to get the steel ball to release on the ROD to table shaft without success - just squirt it with super thin oil every time I walk pass it. Thanks for mentioning "Brake cleaner" as I forgot about that.

What is the latest about the ball screw adventure?

Bob

Please Log in or Create an account to join the conversation.

- J Green

- Offline

- Elite Member

-

Less

More

- Posts: 164

- Thank you received: 24

22 Jan 2020 21:07 #155453

by J Green

Replied by J Green on topic Retrofitting a 1986 Maho MH400E

Hi drimaropolos

What size is your MAHO ? For some reason I thought you machine is a MH500E.

Bob

What size is your MAHO ? For some reason I thought you machine is a MH500E.

Bob

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 Jan 2020 21:13 #155454

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

It is a MH600E, the new ball screw is from a MH400E x axis. Exactly the same dimensions for y axis of MH600E

John

John

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

22 Jan 2020 21:20 #155457

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

I remember that I had to turn the table to a certain position where I could loosen the then lined-up allen-wrench screw through a hole in the mounting flange.

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

22 Jan 2020 21:26 - 22 Jan 2020 21:36 #155459

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi drimaropoylos,

thank you for that info.

I read somewhere that the gap on a line should be within the size of 1-5 balls.

Do you still have that ?

If I calculate your number for the seven lines, almost 20 balls are missing.

I will fill the nut an see how many balls it will take.

I adjusted the wedge on the X-axis.

Measured the original unmachined spacer to have 10,48mm.

Made a second test-spacer out of a tube and turned it down to 10,40mm and 10,32 which was enogh.

Turned the original spacer down to that 10,32mm then.

According to the manual a spacer reduction of 0,13mm minimizes the play about 0,001mm,

whatever that means and how they measure that.

thank you for that info.

I read somewhere that the gap on a line should be within the size of 1-5 balls.

Do you still have that ?

If I calculate your number for the seven lines, almost 20 balls are missing.

I will fill the nut an see how many balls it will take.

I adjusted the wedge on the X-axis.

Measured the original unmachined spacer to have 10,48mm.

Made a second test-spacer out of a tube and turned it down to 10,40mm and 10,32 which was enogh.

Turned the original spacer down to that 10,32mm then.

According to the manual a spacer reduction of 0,13mm minimizes the play about 0,001mm,

whatever that means and how they measure that.

Last edit: 22 Jan 2020 21:36 by hanmon.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 Jan 2020 21:44 #155463

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

It may be true, I haven't open and see the new one. The deflectors in the old ball-screw are loose and more than one ball space may lead to jamming.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

22 Jan 2020 21:56 #155465

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

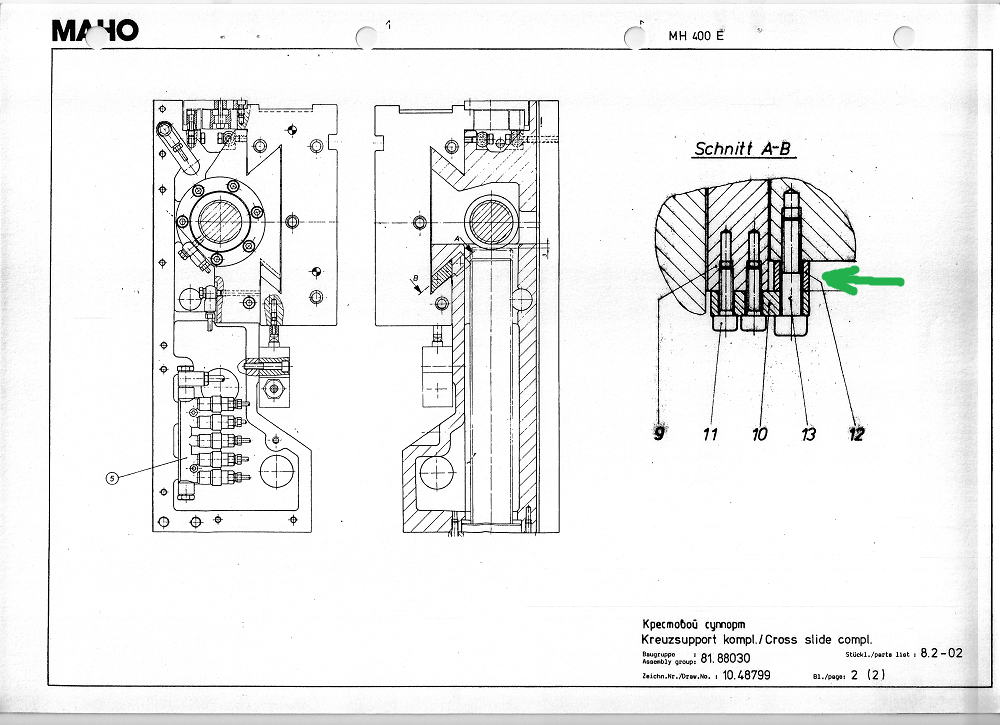

This is what you have adjusted?Hi drimaropoylos,

I adjusted the wedge on the X-axis.

Measured the original unmachined spacer to have 10,48mm.

Made a second test-spacer out of a tube and turned it down to 10,40mm and 10,32 which was enogh.

Turned the original spacer down to that 10,32mm then.

According to the manual a spacer reduction of 0,13mm minimizes the play about 0,001mm,

whatever that means and how they measure that.

Attachments:

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

22 Jan 2020 23:26 #155476

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

yes.

The drawing looks different in my documents.

Will post a picture tomorrow.

The drawing looks different in my documents.

Will post a picture tomorrow.

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.210 seconds