Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

09 Mar 2019 21:27 #128180

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

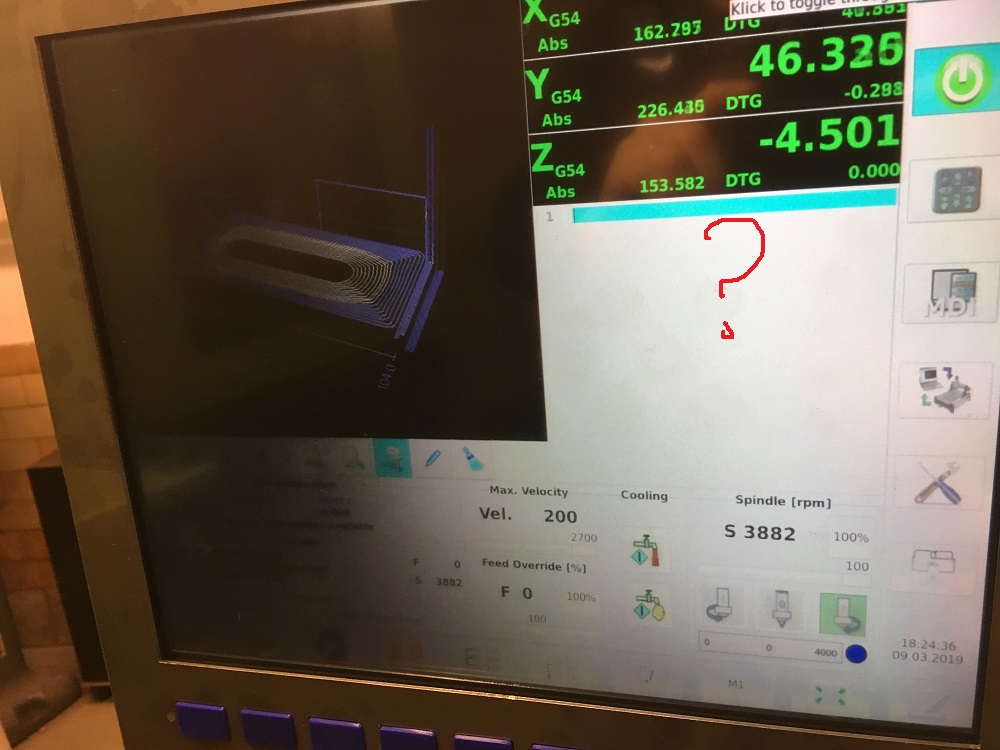

This is the first tool path I have generated with CAM.

As you can see I screwed up the tool material setting, and number of flutes, and left it as 2 flute HSS, when it was an 8mm carbide four flute, explaining the 1/4 feedrate it should have had.

I used a FANUC 11m PP to generate the code. Then edited it on a PC in wordpad to delete some of the initial codes which LinuxCNC doesn't have (G23?), and also edited the code in mousepad. It ran fine, but the code part of the window only shows a line one, the rest is blank.

I have attached the gcode file. I would appreciate if anyone could please point out what LinuxCNC is being tripped up on.

As you can see I screwed up the tool material setting, and number of flutes, and left it as 2 flute HSS, when it was an 8mm carbide four flute, explaining the 1/4 feedrate it should have had.

I used a FANUC 11m PP to generate the code. Then edited it on a PC in wordpad to delete some of the initial codes which LinuxCNC doesn't have (G23?), and also edited the code in mousepad. It ran fine, but the code part of the window only shows a line one, the rest is blank.

I have attached the gcode file. I would appreciate if anyone could please point out what LinuxCNC is being tripped up on.

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

09 Mar 2019 23:03 #128184

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi Mark,

my first gues, the comment probably?

I can try to run the code on my machine tomorrow.

my first gues, the comment probably?

I can try to run the code on my machine tomorrow.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

10 Mar 2019 08:15 #128208

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Thanks Hanno, I did delete that G01 from the header, as LinuxCNC doesn't like a G01 without an F.

Mark

Mark

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

10 Mar 2019 20:42 #128271

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

This time I hand coded this tool path, as I wanted to get a better feel for spiral paths. The feed rate is the correct 700mm/min for the 8mm 4 flute carbide this time.

Mark

Mark

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

11 Mar 2019 11:59 #128310

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Looking good Mark, though after milling that pocket and outer contour I'd use your large facemill to take off the top. Take advantage of that hydraulic-assisted tool changing

By the way, I finally ordered all the Mesa parts for the retrofit over the weekend. I ended up buying them from Portugal because they had everything in stock apart from the DB25M to IDC26 cable. Since I have to make the cable myself, do you maybe know what the pinout is between the two connectors?

Gonna have to finally buy that soldering 3rd arm for this project, otherwise I'm likely to kill myself with my iron

By the way, I finally ordered all the Mesa parts for the retrofit over the weekend. I ended up buying them from Portugal because they had everything in stock apart from the DB25M to IDC26 cable. Since I have to make the cable myself, do you maybe know what the pinout is between the two connectors?

Gonna have to finally buy that soldering 3rd arm for this project, otherwise I'm likely to kill myself with my iron

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

11 Mar 2019 12:13 #128313

by andypugh

Maybe use a IDC to DB25F back-panel then a DB25M-M cable?

www.amazon.co.uk/Nacpy-Parallel-Header-A...acket/dp/B07BQ2KJDQ/

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

everything in stock apart from the DB25M to IDC26 cable.)

Maybe use a IDC to DB25F back-panel then a DB25M-M cable?

www.amazon.co.uk/Nacpy-Parallel-Header-A...acket/dp/B07BQ2KJDQ/

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

11 Mar 2019 12:33 #128316

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

That's a good idea!

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

11 Mar 2019 12:53 - 11 Mar 2019 12:58 #128319

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I used the face mill on the other side, but was playing around and decided to see what the finish looked like with that 8mm carbide. I need to set up a tool table and the manual tool changing comp, so I don't have to touch off after changing tools.

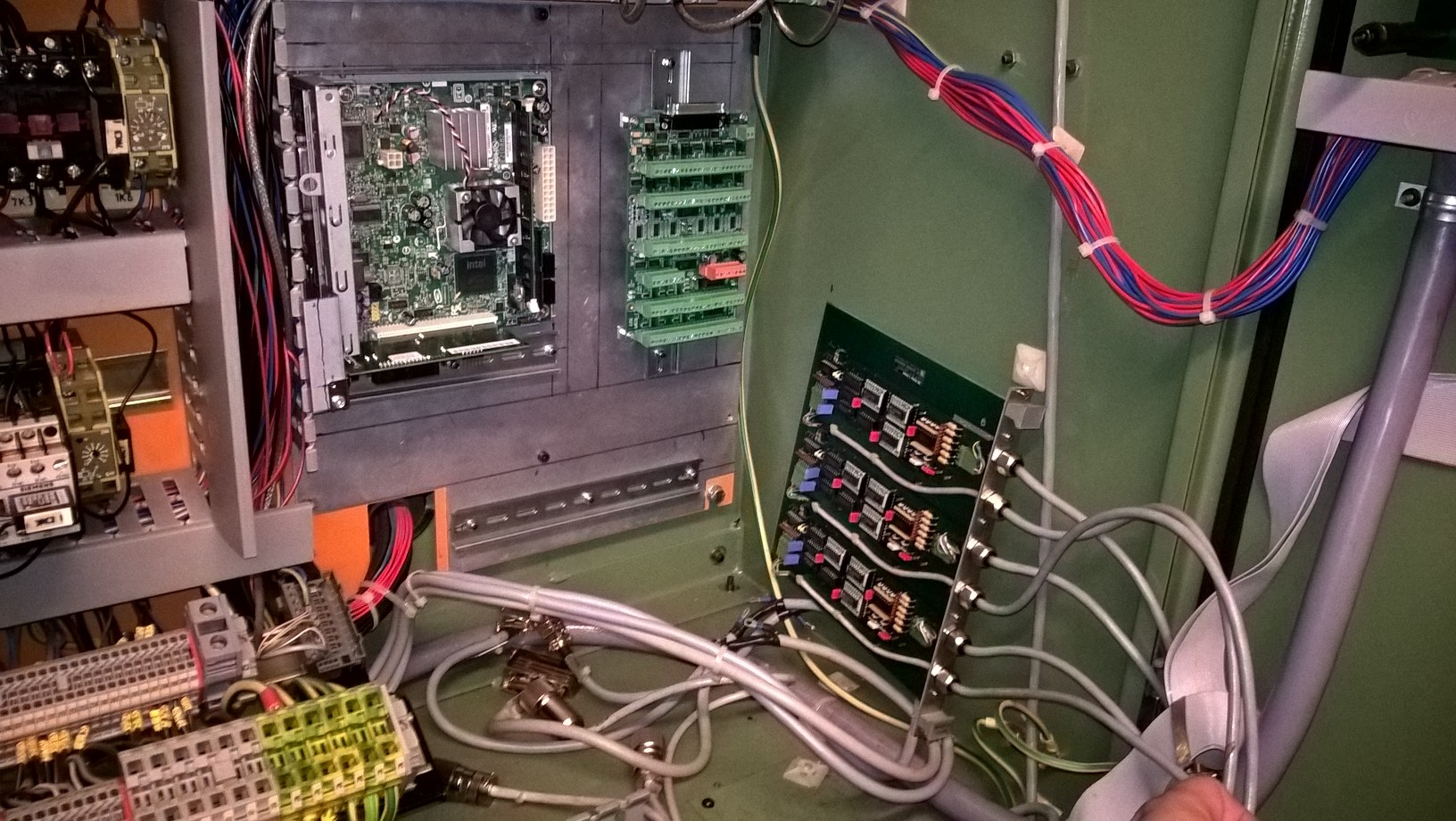

I bought Mesa's IDC26 - IDC26 cable to connect the 5i25 with the 7i77. Not the most practice solution, especially since I have the ITX MoBo edge connectors pointing left and far to close to the cable tunnel, so the conenctors end up crammed into the tunnel. Rotating the MoBo to put the edge connectors down would have made for easier access.

This link is a photo I previously posted in this thread showing my MoBo and 7i77 layout.

Mark

I bought Mesa's IDC26 - IDC26 cable to connect the 5i25 with the 7i77. Not the most practice solution, especially since I have the ITX MoBo edge connectors pointing left and far to close to the cable tunnel, so the conenctors end up crammed into the tunnel. Rotating the MoBo to put the edge connectors down would have made for easier access.

This link is a photo I previously posted in this thread showing my MoBo and 7i77 layout.

Mark

Last edit: 11 Mar 2019 12:58 by RotarySMP.

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

12 Mar 2019 12:52 #128432

by pl7i92

Replied by pl7i92 on topic Retrofitting a 1986 Maho MH400E

Question why dident you add a 7i92 so it is all of the eternet

and you can go with the newest software OS and Aplication guis

and you can go with the newest software OS and Aplication guis

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

12 Mar 2019 14:58 - 12 Mar 2019 15:01 #128442

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Good question. Because I had no clue what I was doing back then and didn't know the 7i92 existed  The Plug'n'go 5i25+7i77 kit from Mesa was well known on the forum and works. I dont think the choice between 5i25 or 7i92 makes much of a difference. The connection between the FPGA (whether 5i25 or 7i92) to the 7i77 is DB25, and that is the bulky cable which is more differcult to fit into cable channel. My MoBo has a PCI slot, so it saves space to use the 5i25 rather than a remote mounted 7i92.

The Plug'n'go 5i25+7i77 kit from Mesa was well known on the forum and works. I dont think the choice between 5i25 or 7i92 makes much of a difference. The connection between the FPGA (whether 5i25 or 7i92) to the 7i77 is DB25, and that is the bulky cable which is more differcult to fit into cable channel. My MoBo has a PCI slot, so it saves space to use the 5i25 rather than a remote mounted 7i92.

I didn't really under stand the why the Mesa Lego fits together. I did think it was weird that they had me cut the end off a CAT 5E cable from the 7i84 and terminate it in screw connections on the 7i77. That section of the 7i77 manual could be improved with a note that the 7i44 exists.

I think Hanno was the first to point out the 7i44 to me. If I did it today, I'd use the 5i25+7i77+7i84 again, but add the 7i73 at the user interface, and tie the Ethernet cards to the 5i25 with a 7i44 through a ribbon cable.

Mark

I didn't really under stand the why the Mesa Lego fits together. I did think it was weird that they had me cut the end off a CAT 5E cable from the 7i84 and terminate it in screw connections on the 7i77. That section of the 7i77 manual could be improved with a note that the 7i44 exists.

I think Hanno was the first to point out the 7i44 to me. If I did it today, I'd use the 5i25+7i77+7i84 again, but add the 7i73 at the user interface, and tie the Ethernet cards to the 5i25 with a 7i44 through a ribbon cable.

Mark

Last edit: 12 Mar 2019 15:01 by RotarySMP.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.319 seconds