Retrofitting a 1986 Maho MH400E

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

16 Mar 2019 21:15 #128774

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Unfortunately, when I got the Boley, it only had the fine feed mechanism and the associated two change wheels. The rest of the change wheels, the pinion for the spindle and the banjos were lost.

madmodder.net/index.php/topic,7884.msg147233.html#msg147233

I did bodge up a spindle encoder and stepper mount to drive the leadscrew...

madmodder.net/index.php/topic,7884.msg129525.html#msg129525

... but only hooked up a temporary drive and PC to use it to make the first back plates. I have been torn between CNCing it properly, like you did your Holbrook with two jog wheels on the apron to still do manual turning, or getting a set of change wheels and making the banjos. I rather enjoy manual turning on a lathe.

Now that you have you Holbrook finished for a couple of years, do you find you use the jog wheels like a manual lathe for those quick 5 minute jobs where specific dimensions aren't critical?

Mark

madmodder.net/index.php/topic,7884.msg147233.html#msg147233

I did bodge up a spindle encoder and stepper mount to drive the leadscrew...

madmodder.net/index.php/topic,7884.msg129525.html#msg129525

... but only hooked up a temporary drive and PC to use it to make the first back plates. I have been torn between CNCing it properly, like you did your Holbrook with two jog wheels on the apron to still do manual turning, or getting a set of change wheels and making the banjos. I rather enjoy manual turning on a lathe.

Now that you have you Holbrook finished for a couple of years, do you find you use the jog wheels like a manual lathe for those quick 5 minute jobs where specific dimensions aren't critical?

Mark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

16 Mar 2019 21:35 #128777

by andypugh

No, pretty much never as it is easier to use my turn / face / thread macros.

I do use the X mpg for parting, but I will probably make a macro for that at some point.

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

Now that you have you Holbrook finished for a couple of years, do you find you use the jog wheels like a manual lathe for those quick 5 minute jobs where specific dimensions aren't critical?

No, pretty much never as it is easier to use my turn / face / thread macros.

I do use the X mpg for parting, but I will probably make a macro for that at some point.

Please Log in or Create an account to join the conversation.

- Mccartymachine1

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 2

17 Mar 2019 00:03 #128787

by Mccartymachine1

Replied by Mccartymachine1 on topic Retrofitting a 1986 Maho MH400E

I used two different configs for my maho. One horizontal and one vertical. Working great. Only annoying thing is switching between them in the same setup.

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- hanmon

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 23

17 Mar 2019 19:19 - 17 Mar 2019 19:20 #128848

by hanmon

Replied by hanmon on topic Retrofitting a 1986 Maho MH400E

Hi,

nice thread milling video Mark !

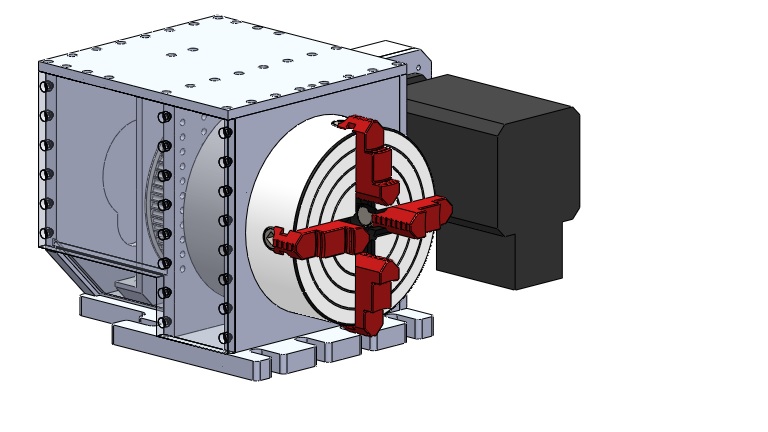

At the moment I'm working on this project which will be documented in Peter's CNC-Ecke :

Hanno

nice thread milling video Mark !

At the moment I'm working on this project which will be documented in Peter's CNC-Ecke :

Hanno

Attachments:

Last edit: 17 Mar 2019 19:20 by hanmon.

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

17 Mar 2019 20:09 #128850

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Setting different machine configs for slow and fast spindles is a great option. I don't know how much you'd have to pay for a proprietary controller to be able to program that. But when it comes to spindle orientation (horizontal vs vertical) I thought you'd just use G17/18 and program the parts in CAM with the setup you want. At least that's the standard practice described in the Philips manual and the same codes are available in LinuxCNC as well.

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

17 Mar 2019 21:21 #128859

by drimaropoylos

John

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

I thing you are right, g17,g18,g19 is a better way compared to separate configurations.But when it comes to spindle orientation (horizontal vs vertical) I thought you'd just use G17/18 and program the parts in CAM with the setup you want. At least that's the standard practice described in the Philips manual and the same codes are available in LinuxCNC as well.

John

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

19 Mar 2019 13:50 #128969

by andypugh

Most CAM systems assume that the tool is aligned along Z (and, in fact, LinuxCNC assumes that for canned cycles) to having the spindle aligned along the system Y can often be annoying.

I will quite often MDI stuff that way anyway, but if using CAM then I have to change config.

And then there is the question of arbor-cutters . I am not sure if any of the CAM systems are very good at that...

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

I thing you are right, g17,g18,g19 is a better way compared to separate configurations.

Most CAM systems assume that the tool is aligned along Z (and, in fact, LinuxCNC assumes that for canned cycles) to having the spindle aligned along the system Y can often be annoying.

I will quite often MDI stuff that way anyway, but if using CAM then I have to change config.

And then there is the question of arbor-cutters . I am not sure if any of the CAM systems are very good at that...

The following user(s) said Thank You: drimaropoylos

Please Log in or Create an account to join the conversation.

- R2AIV

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

20 Mar 2019 23:29 - 21 Mar 2019 13:35 #129124

by R2AIV

Replied by R2AIV on topic Retrofitting a 1986 Maho MH400E

Hi All! Today I successfully started all 3 axis and setting axis zero position. But I can't configure PID's to work normally. Axes works with rough FERRORs, up to 1 mm.Can you share your PID settings of your machines? And i have trouble with gearbox. When i trying to set spindle speed gearbox motor 1 moves and mechannicaly stops at end CW position. Reverse don't works. All connections is correct. What could it be? Thanx.

Last edit: 21 Mar 2019 13:35 by R2AIV. Reason: mistypes

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

21 Mar 2019 23:28 #129228

by andypugh

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

There is no point sharing PID settings, they will be unique to each machine.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

22 Mar 2019 13:16 #129254

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Is your machine also a 400E? Here is the axis set up part of my INI, to give you a starting point.

#********************

# Axis X

#********************

[AXIS_0]

TYPE = LINEAR

HOME = 100

FERROR = 0.5

MIN_FERROR = 0.2

MAX_VELOCITY = 45

MAX_ACCELERATION = 50

P = 6.5

I = 0

D = 0

FF0 = 0

FF1 = 0.22

FF2 = 0.0021

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 10

ENCODER_SCALE = -1000

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -1

MAX_LIMIT = 400

HOME_OFFSET = 0

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = -10

HOME_FINAL_VEL = -1

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

#********************

# Axis Y

#********************

[AXIS_1]

TYPE = LINEAR

HOME = 200

FERROR = 0.5

MIN_FERROR = 0.2

MAX_VELOCITY = 40

MAX_ACCELERATION = 50

P = 5.5

I = 0

D = 0

FF0 = 0

FF1 = 0.228

FF2 = 0.0015

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 10

ENCODER_SCALE = -1000

OUTPUT_SCALE = -10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -1

MAX_LIMIT = 251

HOME_OFFSET = 250

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 8

HOME_FINAL_VEL = 40

HOME_USE_INDEX = YES

HOME_SEQUENCE = 1

#********************

# Axis Z

#********************

[AXIS_2]

TYPE = LINEAR

HOME = 370

FERROR = 20.0

MIN_FERROR = 1.0

MAX_VELOCITY = 45

MAX_ACCELERATION = 50

P = 7.5

I = 0

D = 0

FF0 = 0

FF1 =0.218

FF2 = 0.002

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 10

ENCODER_SCALE = 1000

OUTPUT_SCALE = -10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -1

MAX_LIMIT = 376

HOME_OFFSET = 375

HOME_SEARCH_VEL = 0

HOME_LATCH_VEL = 10

HOME_FINAL_VEL =15

HOME_USE_INDEX = YES

HOME_SEQUENCE = 0

The following user(s) said Thank You: DoWerna

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.334 seconds