Retrofitting a 1986 Maho MH400E

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

30 Apr 2019 07:05 - 30 Apr 2019 07:09 #132331

by rodw

Its never let me down and the batteries last forever. The correct part number for a Mesa config is ATWGP01-6BB-3.

That is a 5 volt compatible encoder with coded binary signals for the scale and axis selection switch to save pins. It can control 6 axes so there are a couple of extra MPG outputs. I was thinking of using one for reverse run...

The only thing I've found is that by default the estop is enabled so you need to switch it on or off or hit the estop on startup. I thin that is by design. I use estop_latch to merge the stop chain in HAL.

Replied by rodw on topic Retrofitting a 1986 Maho MH400E

That looks really nice. How reliable is the wireless connection?

Mark

Its never let me down and the batteries last forever. The correct part number for a Mesa config is ATWGP01-6BB-3.

That is a 5 volt compatible encoder with coded binary signals for the scale and axis selection switch to save pins. It can control 6 axes so there are a couple of extra MPG outputs. I was thinking of using one for reverse run...

The only thing I've found is that by default the estop is enabled so you need to switch it on or off or hit the estop on startup. I thin that is by design. I use estop_latch to merge the stop chain in HAL.

Last edit: 30 Apr 2019 07:09 by rodw.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Apr 2019 10:46 #132341

by pl7i92

Replied by pl7i92 on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

30 Apr 2019 13:34 #132350

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Doing things the hard way come naturally to me

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

30 Apr 2019 14:10 #132352

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I am also very good at starting projects, and very patient at letting them mature.

I was given a tool holder with a broken off carbide jamming the hole.

Picked up some offcuts of an industrial plastic. (something harder but still insulative would be better)

Scrap endmills provide 6mm carbide shafting. These ones I bought as scrap, although I have a talent for produing scrap end mills.

Six balls from bearing

And a slug of Meehanite.

You can probably guess where this is going.

I was given a tool holder with a broken off carbide jamming the hole.

Picked up some offcuts of an industrial plastic. (something harder but still insulative would be better)

Scrap endmills provide 6mm carbide shafting. These ones I bought as scrap, although I have a talent for produing scrap end mills.

Six balls from bearing

And a slug of Meehanite.

You can probably guess where this is going.

Attachments:

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Apr 2019 14:36 #132353

by pl7i92

Replied by pl7i92 on topic Retrofitting a 1986 Maho MH400E

i am pretty shure that there are Holders like you need

from older shops on low cost

most upgrde there stuff regular and sell the old stuff

from older shops on low cost

most upgrde there stuff regular and sell the old stuff

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

30 Apr 2019 15:12 - 02 May 2019 08:16 #132356

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Attachments:

Last edit: 02 May 2019 08:16 by RotarySMP.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

02 May 2019 08:26 - 02 May 2019 08:27 #132496

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

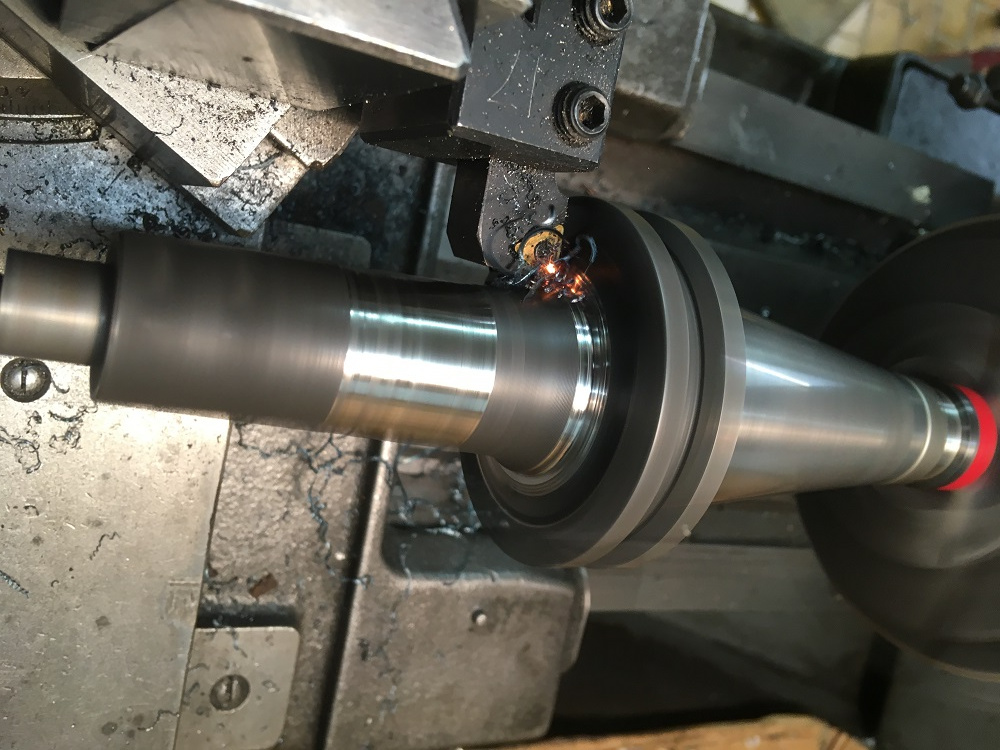

Yesterday I felt more like turning than milling. Switched from the Meehanite to a 50CrMo4 drop I got from the scrappies. The finishing pass was a fresh TMCT090402 insert at 1800rpm, very shallow cut and low feed. The swarf came off as sparks, but it looks pretty.

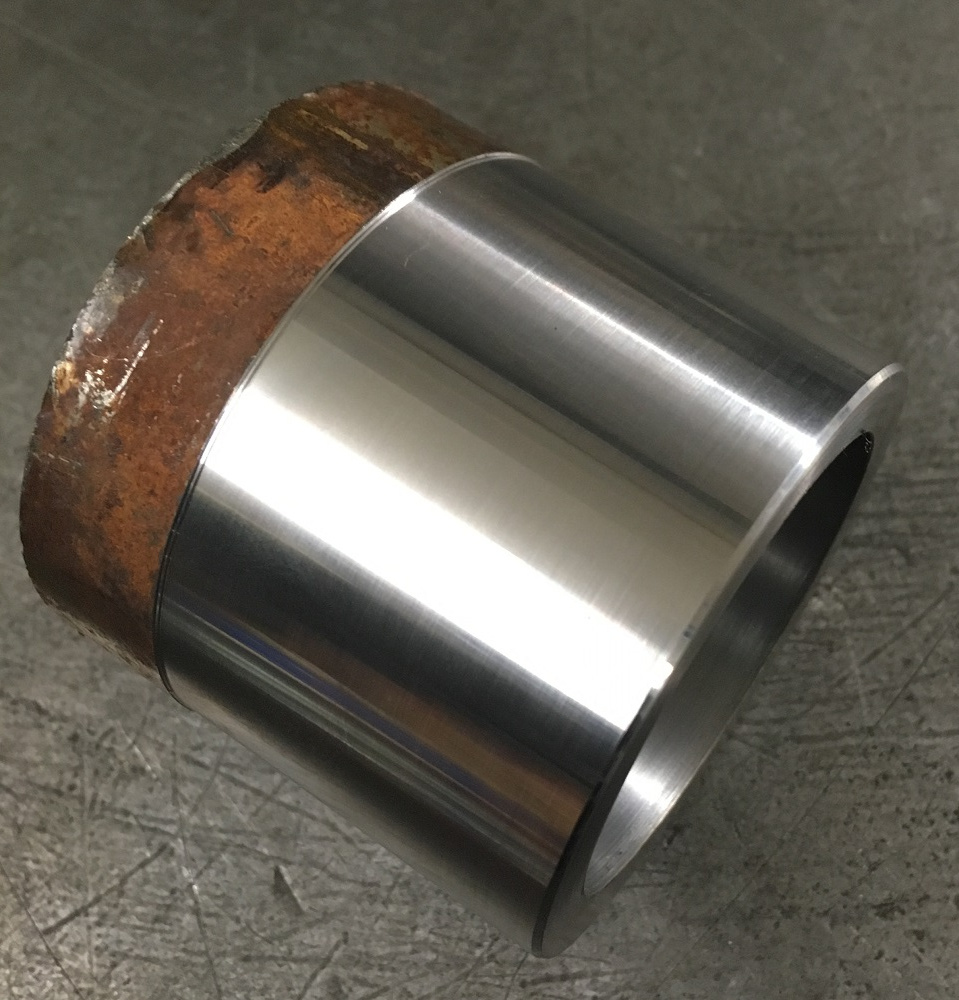

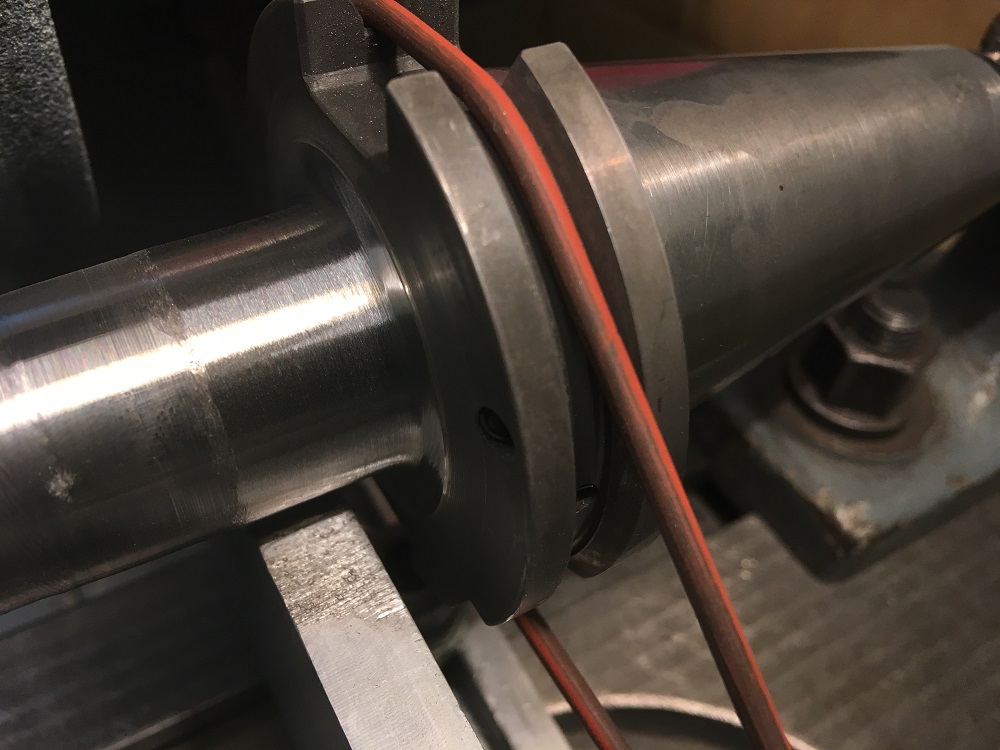

Ground the mounting boss round on the SK40 tool holder, and then ground in an alignment goove using a cut off disc, before parting it by hand.

My grease press arrived so I filled it with Kluber NBU15 and lubed the angle gears of the MAHO.

I've been thinking about how unenjoyable engraving is at 16mm/min with the MAHO screaming away at 4000rpm. Decided to add yet another project, and ground up an old carbide endmill for a drag engraver bit, and then started making a holder for it.

Mark

Ground the mounting boss round on the SK40 tool holder, and then ground in an alignment goove using a cut off disc, before parting it by hand.

My grease press arrived so I filled it with Kluber NBU15 and lubed the angle gears of the MAHO.

I've been thinking about how unenjoyable engraving is at 16mm/min with the MAHO screaming away at 4000rpm. Decided to add yet another project, and ground up an old carbide endmill for a drag engraver bit, and then started making a holder for it.

Mark

Attachments:

Last edit: 02 May 2019 08:27 by RotarySMP.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

02 May 2019 12:16 - 02 May 2019 12:21 #132522

by andypugh

I keep looking at this:

www.ebay.co.uk/itm/New-Kollmorgen-KBM-43...-Motor-/323752695811

(1.2kW, 4750rpm) www.kollmorgen.com/en-us/products/catalo...-selection-guide-uk/

And only 36mm long: www.kollmorgen.com/sites/default/files/p...20%28KBM-43%29_0.pdf

It seems like it would fit nicely around a set of bearings and ER collet mounted in a 40-taper tool.

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

I've been thinking about how unenjoyable engraving is at 16mm/min with the MAHO screaming away at 4000rpm.

I keep looking at this:

www.ebay.co.uk/itm/New-Kollmorgen-KBM-43...-Motor-/323752695811

(1.2kW, 4750rpm) www.kollmorgen.com/en-us/products/catalo...-selection-guide-uk/

And only 36mm long: www.kollmorgen.com/sites/default/files/p...20%28KBM-43%29_0.pdf

It seems like it would fit nicely around a set of bearings and ER collet mounted in a 40-taper tool.

Last edit: 02 May 2019 12:21 by andypugh.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

02 May 2019 14:16 #132538

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

A lot of work for only 750rpm more, and engraving wouldn't need 1.2kW, wouldn't it be better to go with the little frame size ten, and 20K rpm. You could probably fit the tool inside an ER 32 collet

I have an ER-16 collet chuck with 20mm shaft, and a set of P4 AC bearings stashed away in my future projects treasure trove, waiting to be turned into an engraving spindle. There wasa really good one made on CNCZone years ago, where the maker used the rotor and stator from a BLDC model motor as an itegrated motor/spindle. Not sure whether the is much of a benefit now that the chinese HF spindles are so cheap.

It looks like drag engraving works very well on aluminum. Probabaly can't do a useful depth on steel. At least I won't be thrashing the MAHO at full rpm for hour doing that.

Mark

I have an ER-16 collet chuck with 20mm shaft, and a set of P4 AC bearings stashed away in my future projects treasure trove, waiting to be turned into an engraving spindle. There wasa really good one made on CNCZone years ago, where the maker used the rotor and stator from a BLDC model motor as an itegrated motor/spindle. Not sure whether the is much of a benefit now that the chinese HF spindles are so cheap.

It looks like drag engraving works very well on aluminum. Probabaly can't do a useful depth on steel. At least I won't be thrashing the MAHO at full rpm for hour doing that.

Mark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

02 May 2019 14:53 #132541

by andypugh

Yes, but there isn't one of those on eBay at the moment.

At 60mm dia the KBM(S)-10 is too fat to fit inside anything smaller than a 50 taper, but is fairly short so might still work.

Replied by andypugh on topic Retrofitting a 1986 Maho MH400E

A lot of work for only 750rpm more, and engraving wouldn't need 1.2kW, wouldn't it be better to go with the little frame size ten, and 20K rpm. You could probably fit the tool inside an ER 32 collet

Yes, but there isn't one of those on eBay at the moment.

At 60mm dia the KBM(S)-10 is too fat to fit inside anything smaller than a 50 taper, but is fairly short so might still work.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.518 seconds