Retrofitting a 1986 Maho MH400E

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Apr 2019 05:16 #130546

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

You need to power off the pc from the bouton before closing the main switch, so you need a bouton from the motherboard to control panel face.

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Apr 2019 05:33 #130547

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

09 Apr 2019 12:42 - 09 Apr 2019 12:45 #130550

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I'll make a video of my start and shut down sequences.

Start up

I set bios to power up automatically, as Tommylight suggested.

I turn on the big main power switch on the back of the cabinet. The PC boots, as do the MESA cards (only one of three 24V DC buses is powered at initially power on. The Mesa cards need to be hung on that bus).

Sergei set Linux to autostart LinuxCNC, but I have a timing issue there, as it sometimes errors out, and I have to start it manually.

Once LinuxCNC is up and Gmoccapy running, I push the top soft key to release E-Stop, and at the same time, the second from top button to latch it on.

Then use Gmoccapy soft keys to home all axis.

Shut down.

The top soft key of Gmoccapy drops the machine into E-Stop, powering off the drives etc.

Then I push the Exit softkey in Gmoccapy, which shuts down LinuxCNC.

Then I use the standard Debian shut down button to shut down the PC (no need for a Physical PC off switch)

Finally I switch off the main power switch on the back of the cabinet.

For testing I did connect a momentary switch on the MoBo's reset pinhead, but haven't seen any need to have a PC on/off switch like the Haas has.

Photos or it isn't happening

I don't think CNC controls need much processor power. My 400E's Phillips 432 only had an 8088, not even an x86 processor (although it was only 2.5D). It seems to me that any Celeron or more has than sufficient processing power for LinuxCNC. You choose the PC more for latency performance than for processing grunt. The ITX board I use had pretty good latency numbers.

I just bought a tiny Gigabyte Brix BRACE-3150 which will be the brain of my lathes controller.

I have also come around to Glemigobles point that packing the PC into the original MAHO user control module could be a great solution. You'd need a monitor smaller than the 15" I used, but I really don't think you need anything bigger than 13" for gmoccapy. There is plenty of space in that MAHO user module. If you do it that way, you should really add a 7i73 to interface the user panel buttons. I am short of shed space (who isnt?) and figured I could make the user module more compact.

Mark0

Start up

I set bios to power up automatically, as Tommylight suggested.

I turn on the big main power switch on the back of the cabinet. The PC boots, as do the MESA cards (only one of three 24V DC buses is powered at initially power on. The Mesa cards need to be hung on that bus).

Sergei set Linux to autostart LinuxCNC, but I have a timing issue there, as it sometimes errors out, and I have to start it manually.

Once LinuxCNC is up and Gmoccapy running, I push the top soft key to release E-Stop, and at the same time, the second from top button to latch it on.

Then use Gmoccapy soft keys to home all axis.

Shut down.

The top soft key of Gmoccapy drops the machine into E-Stop, powering off the drives etc.

Then I push the Exit softkey in Gmoccapy, which shuts down LinuxCNC.

Then I use the standard Debian shut down button to shut down the PC (no need for a Physical PC off switch)

Finally I switch off the main power switch on the back of the cabinet.

For testing I did connect a momentary switch on the MoBo's reset pinhead, but haven't seen any need to have a PC on/off switch like the Haas has.

Bob wrote: So it would be a 6 axis control-- XYZ = 3 and spindle =1 and B an C axis = 2 . Plus a 20 tool tool changer for me!I don't think CNC controls need much processor power. My 400E's Phillips 432 only had an 8088, not even an x86 processor (although it was only 2.5D). It seems to me that any Celeron or more has than sufficient processing power for LinuxCNC. You choose the PC more for latency performance than for processing grunt. The ITX board I use had pretty good latency numbers.

I just bought a tiny Gigabyte Brix BRACE-3150 which will be the brain of my lathes controller.

I have also come around to Glemigobles point that packing the PC into the original MAHO user control module could be a great solution. You'd need a monitor smaller than the 15" I used, but I really don't think you need anything bigger than 13" for gmoccapy. There is plenty of space in that MAHO user module. If you do it that way, you should really add a 7i73 to interface the user panel buttons. I am short of shed space (who isnt?) and figured I could make the user module more compact.

Mark0

Last edit: 09 Apr 2019 12:45 by RotarySMP.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

09 Apr 2019 15:36 #130558

by pl7i92

Replied by pl7i92 on topic Retrofitting a 1986 Maho MH400E

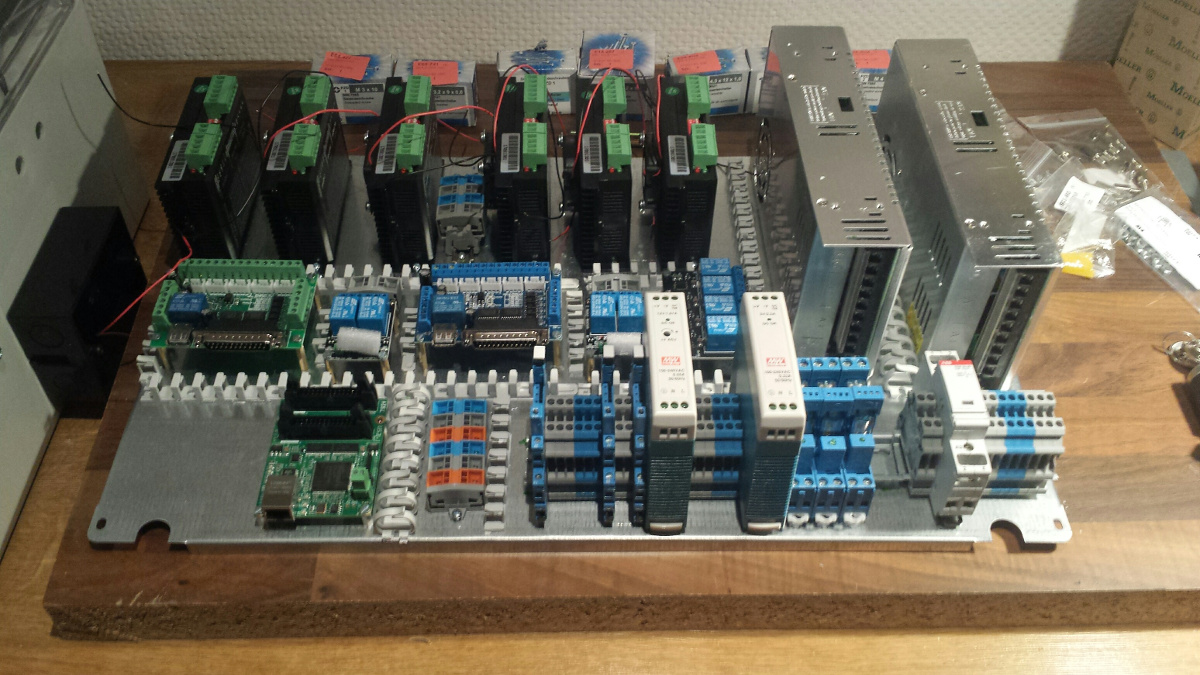

Attachments:

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

09 Apr 2019 15:38 #130559

by pl7i92

Replied by pl7i92 on topic Retrofitting a 1986 Maho MH400E

isent the USB post from the HAS control under the ROUND CAP at the side

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Apr 2019 17:26 #130564

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Please Log in or Create an account to join the conversation.

- drimaropoylos

- Offline

- Elite Member

-

Less

More

- Posts: 265

- Thank you received: 40

09 Apr 2019 17:41 #130565

by drimaropoylos

Replied by drimaropoylos on topic Retrofitting a 1986 Maho MH400E

Something like this, I thing is more practical.

www.ebay.co.uk/itm/Neutrik-NAUSB-W-USB-A...c:g:I-sAAOSwZ8ZW2XIk

www.ebay.co.uk/itm/Neutrik-NAUSB-W-USB-A...c:g:I-sAAOSwZ8ZW2XIk

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

09 Apr 2019 17:55 #130567

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

Here is the start/stop procedure for my machine...

The following user(s) said Thank You: Glemigobles

Please Log in or Create an account to join the conversation.

- Glemigobles

- Offline

- Elite Member

-

Less

More

- Posts: 201

- Thank you received: 18

09 Apr 2019 20:53 #130574

by Glemigobles

Replied by Glemigobles on topic Retrofitting a 1986 Maho MH400E

Thanks a lot Mark, now everything is clear to me!

Another idea I had for organizing computer parts in the MAHO is removing the printer receptacle and RS 232 port on the side of the electric cabinet (they're both bolted on) and replacing them with a couple of USB and Ethernet ports. I'm going to use the AMD parts that don't work with the Mesa card to make another computer for the workshop and I'm considering connecting the two with a cable for easy program transfer without worrying about having a USB stick. I could install Windows on the other computer and use Fusion360 for CAD and CAM in the workshop, saving myself a lot of hassle (the workshop is in a detached garage).

Another idea I had for organizing computer parts in the MAHO is removing the printer receptacle and RS 232 port on the side of the electric cabinet (they're both bolted on) and replacing them with a couple of USB and Ethernet ports. I'm going to use the AMD parts that don't work with the Mesa card to make another computer for the workshop and I'm considering connecting the two with a cable for easy program transfer without worrying about having a USB stick. I could install Windows on the other computer and use Fusion360 for CAD and CAM in the workshop, saving myself a lot of hassle (the workshop is in a detached garage).

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1568

- Thank you received: 574

10 Apr 2019 06:26 #130588

by RotarySMP

Replied by RotarySMP on topic Retrofitting a 1986 Maho MH400E

I also removed those ports from the side of my cabinet (you remind me that I was going to make a blanking plate.

Having a local network between the MAHO and the CAD/CAM station could be really nice. If you have the PC/MoBo mounted in the user module, with USB ports on the opposite side of the cabinet, you will exceed the 5m recommended cable length limit for USB. I had the same issue in the other direction, which I why I used a powered USB hub.

If you do that, I'd still recommend putting at least one USB port on the user interface module. It is very convenient to be able to plug in a thumb drive there.

I added three external USB ports to the user module for:

1/ File transfer with thumb drives

2/ the USB keyboard

3/ USB mobile internet stick which gets used for connecting the MAHO to the internet when I need to update anything. Normally it is offline.

Two ports there would have been sufficient, but I used dirt cheap chinese extensions to the Logitech powered hub which had four ports.

The fourth port is using internally to connect the touch screen.

These are the ones used...

www.ebay.at/itm/60cm-USB-2-0-A-Male-to-A...?hash=item23b798f043

Mark

Having a local network between the MAHO and the CAD/CAM station could be really nice. If you have the PC/MoBo mounted in the user module, with USB ports on the opposite side of the cabinet, you will exceed the 5m recommended cable length limit for USB. I had the same issue in the other direction, which I why I used a powered USB hub.

If you do that, I'd still recommend putting at least one USB port on the user interface module. It is very convenient to be able to plug in a thumb drive there.

I added three external USB ports to the user module for:

1/ File transfer with thumb drives

2/ the USB keyboard

3/ USB mobile internet stick which gets used for connecting the MAHO to the internet when I need to update anything. Normally it is offline.

Two ports there would have been sufficient, but I used dirt cheap chinese extensions to the Logitech powered hub which had four ports.

The fourth port is using internally to connect the touch screen.

These are the ones used...

www.ebay.at/itm/60cm-USB-2-0-A-Male-to-A...?hash=item23b798f043

Mark

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.362 seconds