Schaublin 125-CNC retrofit.

- smc.collins

- Offline

- Platinum Member

-

Less

More

- Posts: 718

- Thank you received: 138

27 Nov 2025 05:08 #339286

by smc.collins

Replied by smc.collins on topic Schaublin 125-CNC retrofit.

Personally, I'd just buy a servo and rip oit all the crap on the spindle, you can get a 5kw spindle and drive on Alibaba for $400 shipped or less. That'll give you what you're after for a lot less hassle. Pull out the pulley system and all and just direct drive. Get a 5000rpm servo that should give you way more cut powe than you have.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1566

- Thank you received: 573

27 Nov 2025 13:23 #339319

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Pick your excuse :

1/ That requires more effort than my inherent laziness allows

Everything is already in there.

2/ I don't see a deal like that. The best deal offered here for a 5KW servo and driver from AliExpress is at least €1000, so will cost more like €1500 delivered, with tax and customs.

3/ I only have 16A feed at 400V. The required supply varies, but those 5KW servo drivers seem to require supplies which can peak above 20A.

But it is basically what Schaublin did on the follow on 125-CCN model. Since my collet closer limits the spindle to 3000rpm, a 1:2 reduction to the spindle would work, as those servos seem to be 6000rpm.

1/ That requires more effort than my inherent laziness allows

Everything is already in there.

2/ I don't see a deal like that. The best deal offered here for a 5KW servo and driver from AliExpress is at least €1000, so will cost more like €1500 delivered, with tax and customs.

3/ I only have 16A feed at 400V. The required supply varies, but those 5KW servo drivers seem to require supplies which can peak above 20A.

But it is basically what Schaublin did on the follow on 125-CCN model. Since my collet closer limits the spindle to 3000rpm, a 1:2 reduction to the spindle would work, as those servos seem to be 6000rpm.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

27 Nov 2025 15:58 #339330

by spumco

Replied by spumco on topic Schaublin 125-CNC retrofit.

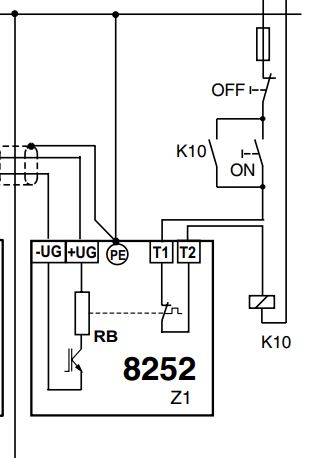

One thing I didn't notice in the vid or the thread discussion is that there is a separate manual for the braking module. It's referenced on page viii (Part G - 11) of the VFD manual.

The braking module manual shows a "T1" and "T2" connection on the module.. but those aren't shown in the main VFD manual.

Based on the diagram, I suspect those need mains power to 'activate' the braking module.

I'm sure there are some parameters to change as well, but this might be a possibility. Maybe have a look?

And yes...dogshit manuals.

The braking module manual shows a "T1" and "T2" connection on the module.. but those aren't shown in the main VFD manual.

Based on the diagram, I suspect those need mains power to 'activate' the braking module.

I'm sure there are some parameters to change as well, but this might be a possibility. Maybe have a look?

And yes...dogshit manuals.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1566

- Thank you received: 573

27 Nov 2025 16:21 #339331

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Those are the thermal overheat switch, which with that wiring will cut power to the main VFD in the case that the brake module overheats. To test it, that connection is not necessary.

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

27 Nov 2025 21:51 #339349

by tommylight

Replied by tommylight on topic Schaublin 125-CNC retrofit.

OFF topic/rant ):

):

I have that in every room in the house, that is 3 phase, each capable of 400V at 16A!

And in the shops there are everywhere 3X400V/32A sockets, so yes we can charge electric cars very fast at home, but we do not have many of those cars. I would like one that can do about 50-100KM on a single charge as that is sufficient for my daily use, but i would need another car for longer distances, so i am sticking to my diesel for now...until i build one with some drone batteries and some servo motors i have around the shop!

Just to make Americans green with envy (i was granted American citizenship but i never went there3/ I only have 16A feed at 400V.

I have that in every room in the house, that is 3 phase, each capable of 400V at 16A!

And in the shops there are everywhere 3X400V/32A sockets, so yes we can charge electric cars very fast at home, but we do not have many of those cars. I would like one that can do about 50-100KM on a single charge as that is sufficient for my daily use, but i would need another car for longer distances, so i am sticking to my diesel for now...until i build one with some drone batteries and some servo motors i have around the shop!

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

27 Nov 2025 22:00 #339350

by spumco

Are the LED's on the brake module illuminated? Green for ready, yellow for braking active? Just trying to work out if your #2 (dead component) theory is true.

Replied by spumco on topic Schaublin 125-CNC retrofit.

Makes sense now that I look at the diagram more closely.Those are the thermal overheat switch, which with that wiring will cut power to the main VFD in the case that the brake module overheats. To test it, that connection is not necessary.

Are the LED's on the brake module illuminated? Green for ready, yellow for braking active? Just trying to work out if your #2 (dead component) theory is true.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1566

- Thank you received: 573

27 Nov 2025 23:15 - 27 Nov 2025 23:16 #339351

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Okay, I think I understand why it is doing what it does.

The brake is working, but only during a speed change. So with C13 = 0.5S, and C023 at 110% current, the spindle speed change from 70 Hz to 20 Hz is braked (nicely). So that solves my decel between CSS facing cuts.

But switching spindle off, makes the spindle coast down. Since I am commanding the VFD with analog 0-10V, I thought spindle off just meant 0V commanded, but now I think about it, I sort off remember being surprised that is not the way LinuxCNC works. I suspect the spindle stop actually deactivates the spindle drive enable signal which I have connected to VFD Pin 28, and therefore the VFD is disabled every stop.

Since I controlling the VFD with a 0-10V analog signal, what can I do to have LinuxCNC set that analog signal to 0V when I command a spindle stop?

I thought I was only only using Pin 28 it for machine start up and shut down, and E-Stop. It looks like I need to put a delay onto that disable to give the VFD time to be braked down to stop with the analog speed command, before the VFD is disabled.

The brake is working, but only during a speed change. So with C13 = 0.5S, and C023 at 110% current, the spindle speed change from 70 Hz to 20 Hz is braked (nicely). So that solves my decel between CSS facing cuts.

But switching spindle off, makes the spindle coast down. Since I am commanding the VFD with analog 0-10V, I thought spindle off just meant 0V commanded, but now I think about it, I sort off remember being surprised that is not the way LinuxCNC works. I suspect the spindle stop actually deactivates the spindle drive enable signal which I have connected to VFD Pin 28, and therefore the VFD is disabled every stop.

Since I controlling the VFD with a 0-10V analog signal, what can I do to have LinuxCNC set that analog signal to 0V when I command a spindle stop?

I thought I was only only using Pin 28 it for machine start up and shut down, and E-Stop. It looks like I need to put a delay onto that disable to give the VFD time to be braked down to stop with the analog speed command, before the VFD is disabled.

Last edit: 27 Nov 2025 23:16 by RotarySMP.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

27 Nov 2025 23:19 #339352

by tommylight

Replied by tommylight on topic Schaublin 125-CNC retrofit.

Try in MDI

S0

Before

M5

S0

Before

M5

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

28 Nov 2025 01:40 #339361

by spumco

Replied by spumco on topic Schaublin 125-CNC retrofit.

Mark,

My spindle drive enable pin is tied to a 'machine-is-on' signal, and not to the M3/M4/M5 0-10v signal. The drive isn't disabled at M5.

Check your HAL file (and watch the VFD enable pin in halshow) to see if you've got something connected funny.

My spindle drive enable pin is tied to a 'machine-is-on' signal, and not to the M3/M4/M5 0-10v signal. The drive isn't disabled at M5.

Check your HAL file (and watch the VFD enable pin in halshow) to see if you've got something connected funny.

The following user(s) said Thank You: RotarySMP

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1566

- Thank you received: 573

28 Nov 2025 12:42 - 28 Nov 2025 12:51 #339369

by RotarySMP

Replied by RotarySMP on topic Schaublin 125-CNC retrofit.

Well, we now know what I did to set the VFD into "coast down" mode. I pinned the drive enable to spindle on, and just disabled the drive to stop it. Doh! No wonder I didn't document it.

Now I know that, I have a few options.

1/ Use ladder to react to a spindle stop command with an S0, wait a second, and then disable the drive. I had the VFD set for min 20 hz, max 70 Hz, so this would only brake down to 20, and coast down from there. It has the advantage that the spindle is not sitting on an enabled drive with an analog input, which could cause rotation from EMI induced voltage.

2/ Add a 24VDC output, wire that to Pin E3, and command the VFD to brake to a stop. I would probably still add a delay and disable the drive after a couple seconds. That would seem to be the proper way.

3/ But if I am adding another relay to to get me an extra 24VDC out, I may as well add more. Then I can also wire up the electro-mechanical brake, and have both VFD braking and mechanical braking commanded. This would also give me an option to add some ladder logic to use the mechanical brake on an E-stop.

Ideally, I would add the extra outputs with a second 7i84, as I maxed out the current one due to needing one I/O bank on 5V (for the Hall sensors for homing and tool change). I ended up scavenging a few extra outputs by using the unused axis enables on the 7i85, still ran out of 24V outputs, and put in a cheap relay board to use the excess 5V outputs to control 24V loads. I have an 8 relay card floating around, and could bodge that in instead of the 4 relay card to try this all out.

I will make a video to feedback what I actually do.

Cheers,

Mark

Now I know that, I have a few options.

1/ Use ladder to react to a spindle stop command with an S0, wait a second, and then disable the drive. I had the VFD set for min 20 hz, max 70 Hz, so this would only brake down to 20, and coast down from there. It has the advantage that the spindle is not sitting on an enabled drive with an analog input, which could cause rotation from EMI induced voltage.

2/ Add a 24VDC output, wire that to Pin E3, and command the VFD to brake to a stop. I would probably still add a delay and disable the drive after a couple seconds. That would seem to be the proper way.

3/ But if I am adding another relay to to get me an extra 24VDC out, I may as well add more. Then I can also wire up the electro-mechanical brake, and have both VFD braking and mechanical braking commanded. This would also give me an option to add some ladder logic to use the mechanical brake on an E-stop.

Ideally, I would add the extra outputs with a second 7i84, as I maxed out the current one due to needing one I/O bank on 5V (for the Hall sensors for homing and tool change). I ended up scavenging a few extra outputs by using the unused axis enables on the 7i85, still ran out of 24V outputs, and put in a cheap relay board to use the excess 5V outputs to control 24V loads. I have an 8 relay card floating around, and could bodge that in instead of the 4 relay card to try this all out.

I will make a video to feedback what I actually do.

Cheers,

Mark

Last edit: 28 Nov 2025 12:51 by RotarySMP.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.122 seconds