7i76e and opto ancoder TCST2103

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

10 Mar 2020 23:01 - 10 Mar 2020 23:21 #159709

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Attachments:

Last edit: 10 Mar 2020 23:21 by alkabal.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

10 Mar 2020 23:08 - 10 Mar 2020 23:09 #159712

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Attachments:

Last edit: 10 Mar 2020 23:09 by alkabal.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

10 Mar 2020 23:33 - 10 Mar 2020 23:48 #159714

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Regarding to my old hardwar i see one difference

old 24v kill switch + 24v PWM + Ena + 24V + 5v + Gnd + free wire + encoder in the same shielded harness (isolated by DAC and Opto inside spindle box)

now 5v Kill switch + Analog signal + Ena + Com (+unused 15v) + 5v + Gnd + encoder in the same shielded harness

both have shield to Gnd

It is possible EMI from unisolated Analog ?

For speak about positive things the 7i83 seem to be very good with correct power supply : without any PID the actual speed are really close to the commanded speed and are really helpfull for easy 0v at 0rpm without any offset component ! (including watchdog !!)

The 7i96 are really cool regarding to the input/output i have now only one pull-up resistor for probe !

I do not speak about step generation because they are already know for quality !

old 24v kill switch + 24v PWM + Ena + 24V + 5v + Gnd + free wire + encoder in the same shielded harness (isolated by DAC and Opto inside spindle box)

now 5v Kill switch + Analog signal + Ena + Com (+unused 15v) + 5v + Gnd + encoder in the same shielded harness

both have shield to Gnd

It is possible EMI from unisolated Analog ?

For speak about positive things the 7i83 seem to be very good with correct power supply : without any PID the actual speed are really close to the commanded speed and are really helpfull for easy 0v at 0rpm without any offset component ! (including watchdog !!)

The 7i96 are really cool regarding to the input/output i have now only one pull-up resistor for probe !

I do not speak about step generation because they are already know for quality !

Last edit: 10 Mar 2020 23:48 by alkabal.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17695

- Thank you received: 5174

10 Mar 2020 23:52 - 10 Mar 2020 23:54 #159716

by PCW

Replied by PCW on topic 7i76e and opto ancoder TCST2103

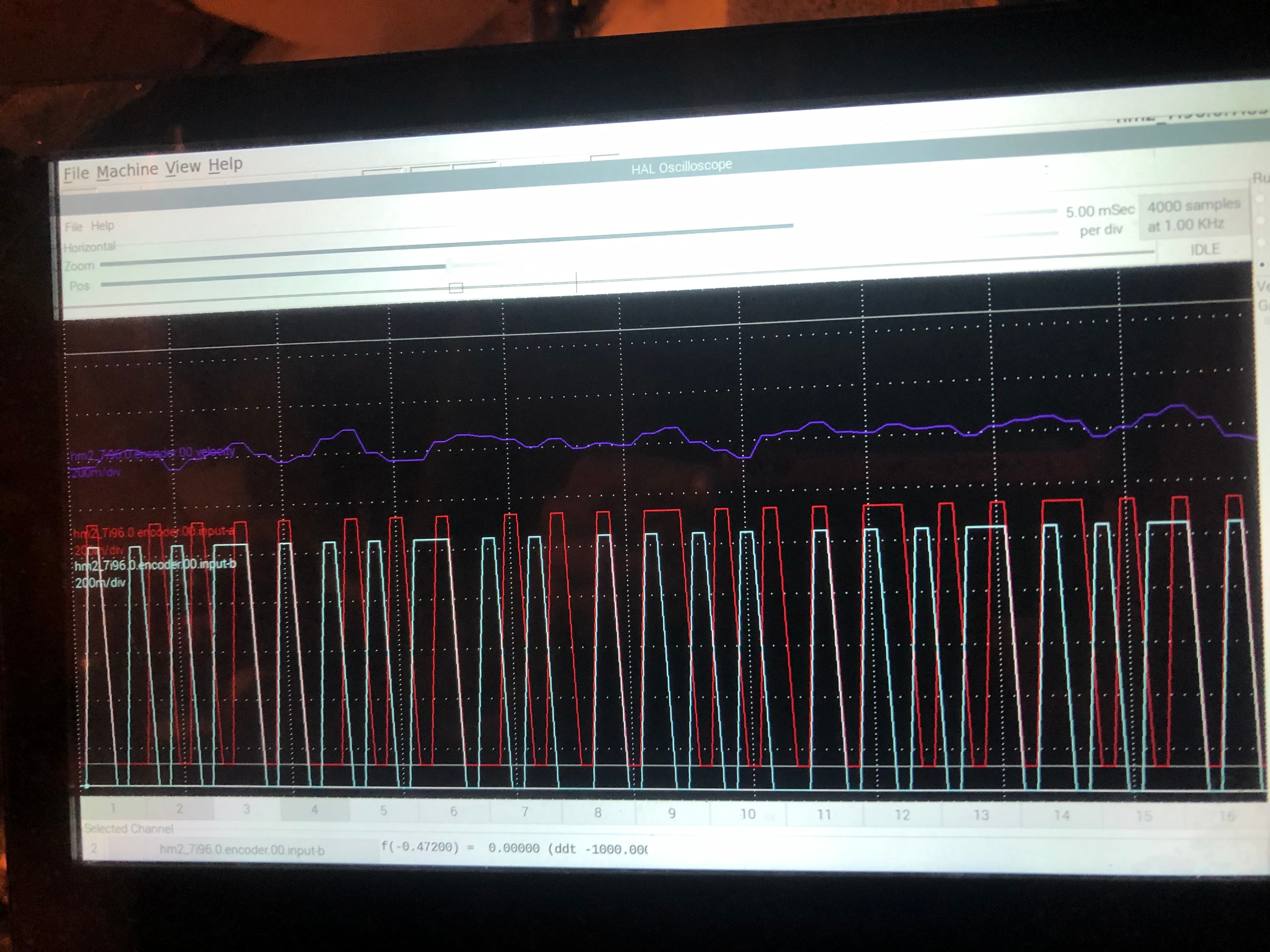

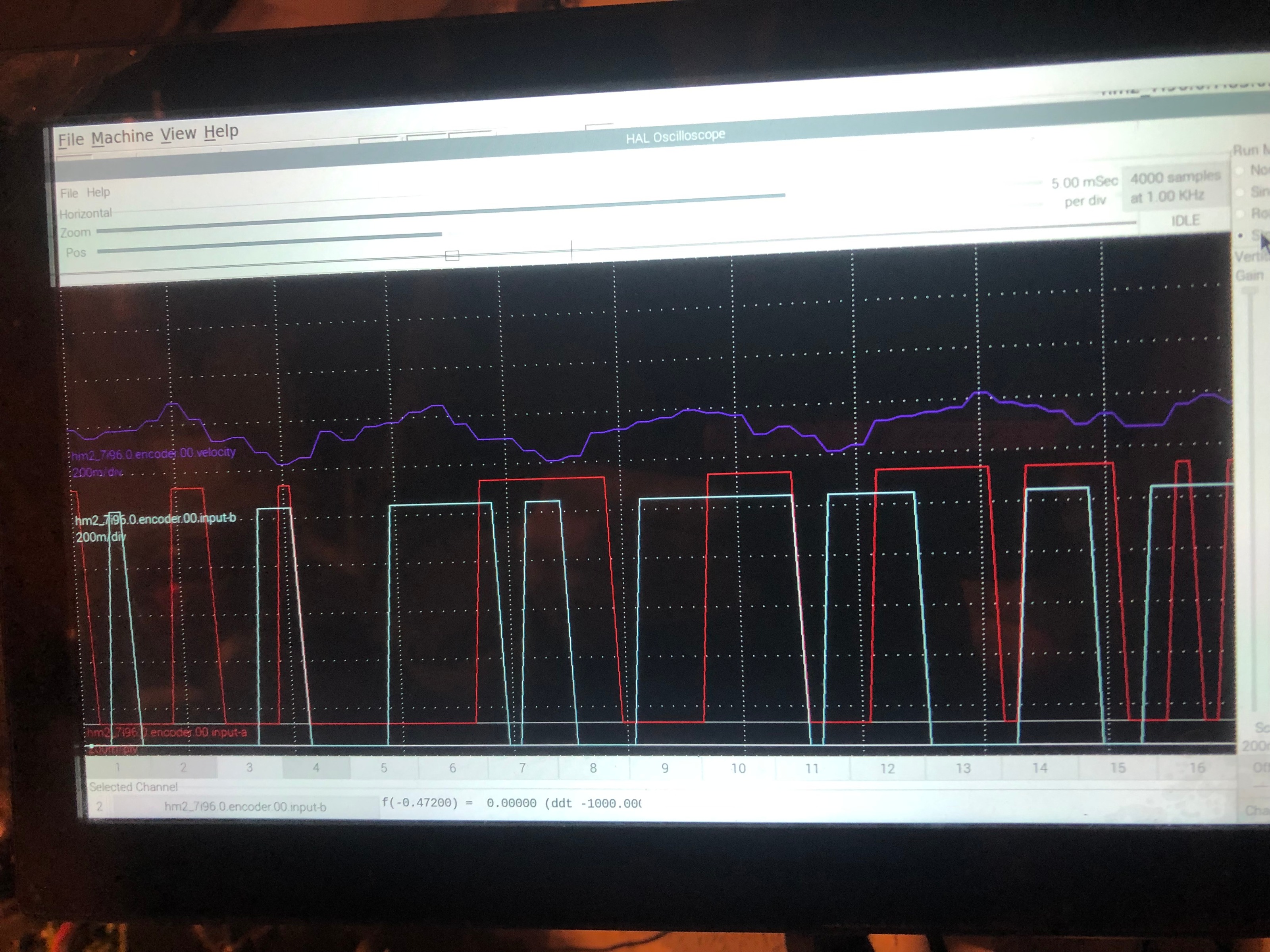

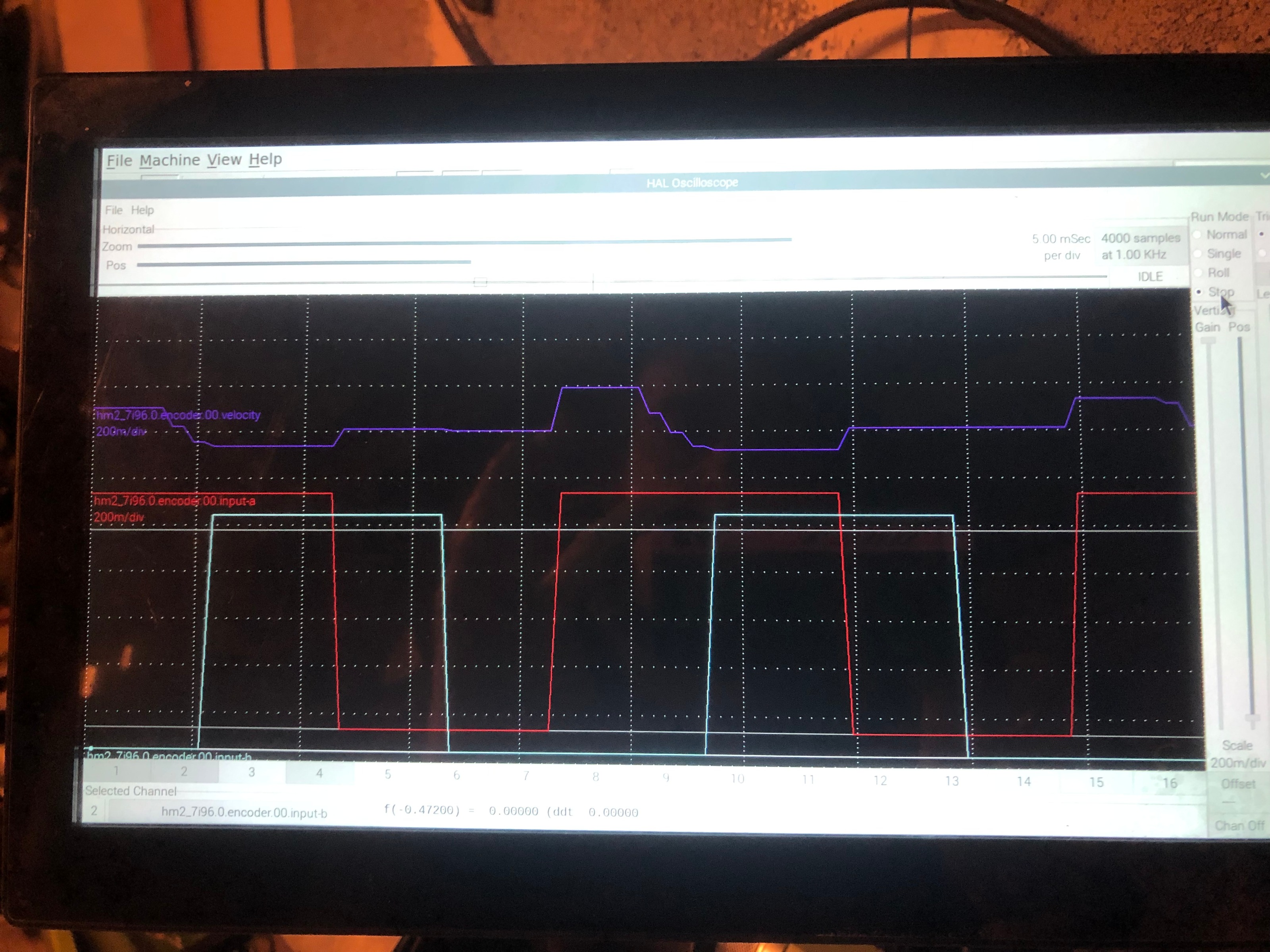

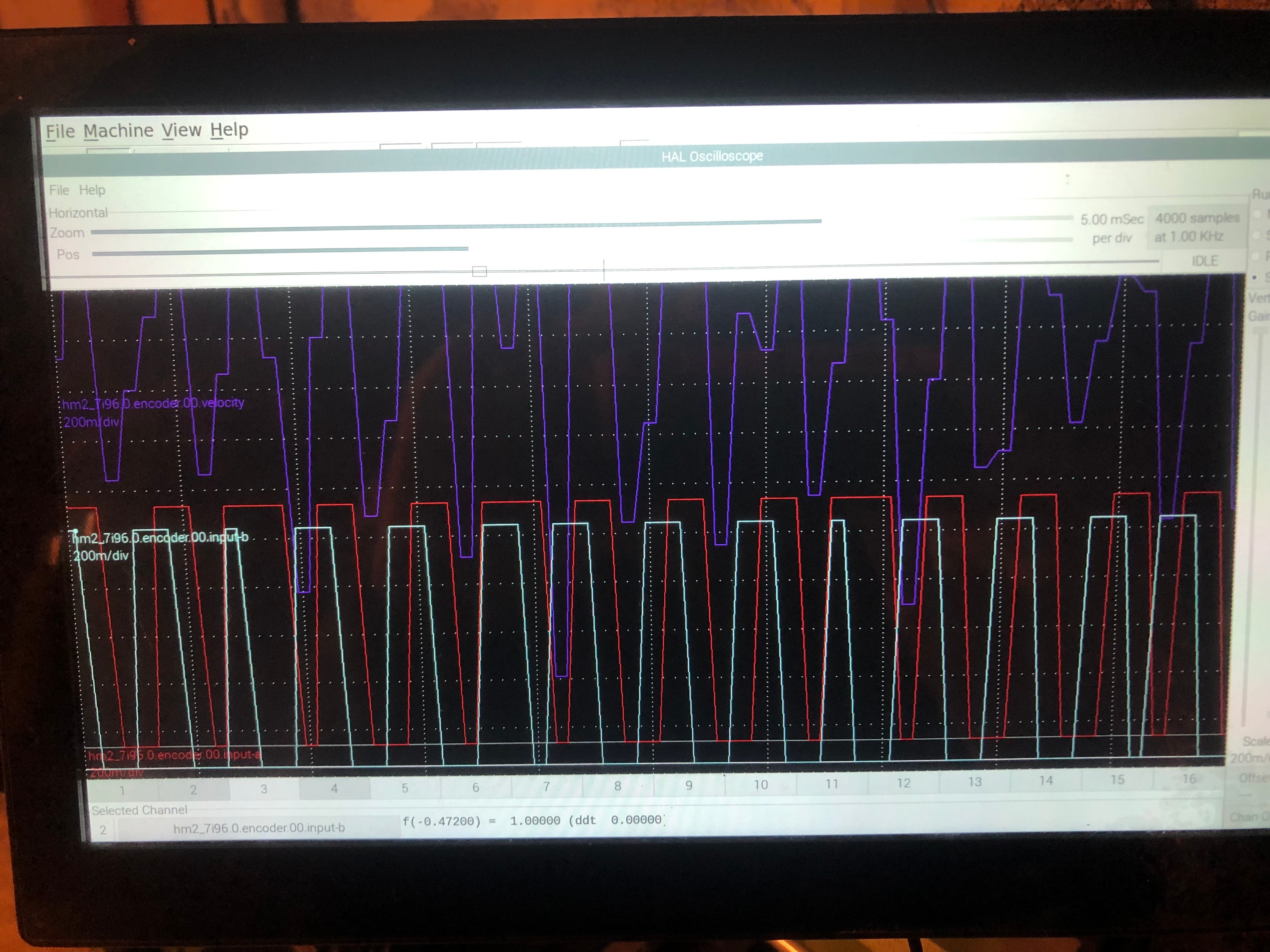

That last plot doesn't look like quadrature (no 90 degree between phases)

It really doesn't look so much like EMI but rather bad signals from the encoder

The earlier plot (in count mode I think) might be about as good

as you can get if the signal is as bad as it looks it (its a bit hard to

tell without going slower so the 1 ms quantization is less of an issue)

That is if you have a 20% variation in edge position in the cycle,

at low speeds this can result in a 40% velocity estimate error

(because if one cycle is late by 20% and the next is early by 20%

the time between edges will be off by 40%. This should get better at

higher speeds where you have multiple edges per servo thread so

the velocity estimate has more than 1 edge-edge cycle to time

for the velocity calculation

It really doesn't look so much like EMI but rather bad signals from the encoder

The earlier plot (in count mode I think) might be about as good

as you can get if the signal is as bad as it looks it (its a bit hard to

tell without going slower so the 1 ms quantization is less of an issue)

That is if you have a 20% variation in edge position in the cycle,

at low speeds this can result in a 40% velocity estimate error

(because if one cycle is late by 20% and the next is early by 20%

the time between edges will be off by 40%. This should get better at

higher speeds where you have multiple edges per servo thread so

the velocity estimate has more than 1 edge-edge cycle to time

for the velocity calculation

Last edit: 10 Mar 2020 23:54 by PCW.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

11 Mar 2020 00:12 #159725

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Well

Ok i will continue to search the correct positioning, but before changing a few hours ago this (original) encoder work fine with older hardwar.

Changing optocoupler can be a good idea ? (if possible to found for better signal)

Changing the whole encoder for some chinese manufactured holow shaft encoder ?

Ok i will continue to search the correct positioning, but before changing a few hours ago this (original) encoder work fine with older hardwar.

Changing optocoupler can be a good idea ? (if possible to found for better signal)

Changing the whole encoder for some chinese manufactured holow shaft encoder ?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17695

- Thank you received: 5174

11 Mar 2020 01:18 #159731

by PCW

Replied by PCW on topic 7i76e and opto ancoder TCST2103

Not sure why the difference,maybe the optical thresholds changed do to the

differing load resistance or similar

if you want to verify the encoder velocity estimation you can

loop a free stepgen back to the encoder (either just A in counter mode

or A,B with encoder and stepgen in quadrature mode)

differing load resistance or similar

if you want to verify the encoder velocity estimation you can

loop a free stepgen back to the encoder (either just A in counter mode

or A,B with encoder and stepgen in quadrature mode)

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

11 Mar 2020 01:33 #159733

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Oh yes, soon i can rewire my tailstock unused encoder to the mesa encoder and remove the belt

if i understand the goal is turn the stepper motor with fixed velocity and check encoder accuracy

Thanks a lot

if i understand the goal is turn the stepper motor with fixed velocity and check encoder accuracy

Thanks a lot

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

11 Mar 2020 21:06 - 11 Mar 2020 21:24 #159806

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

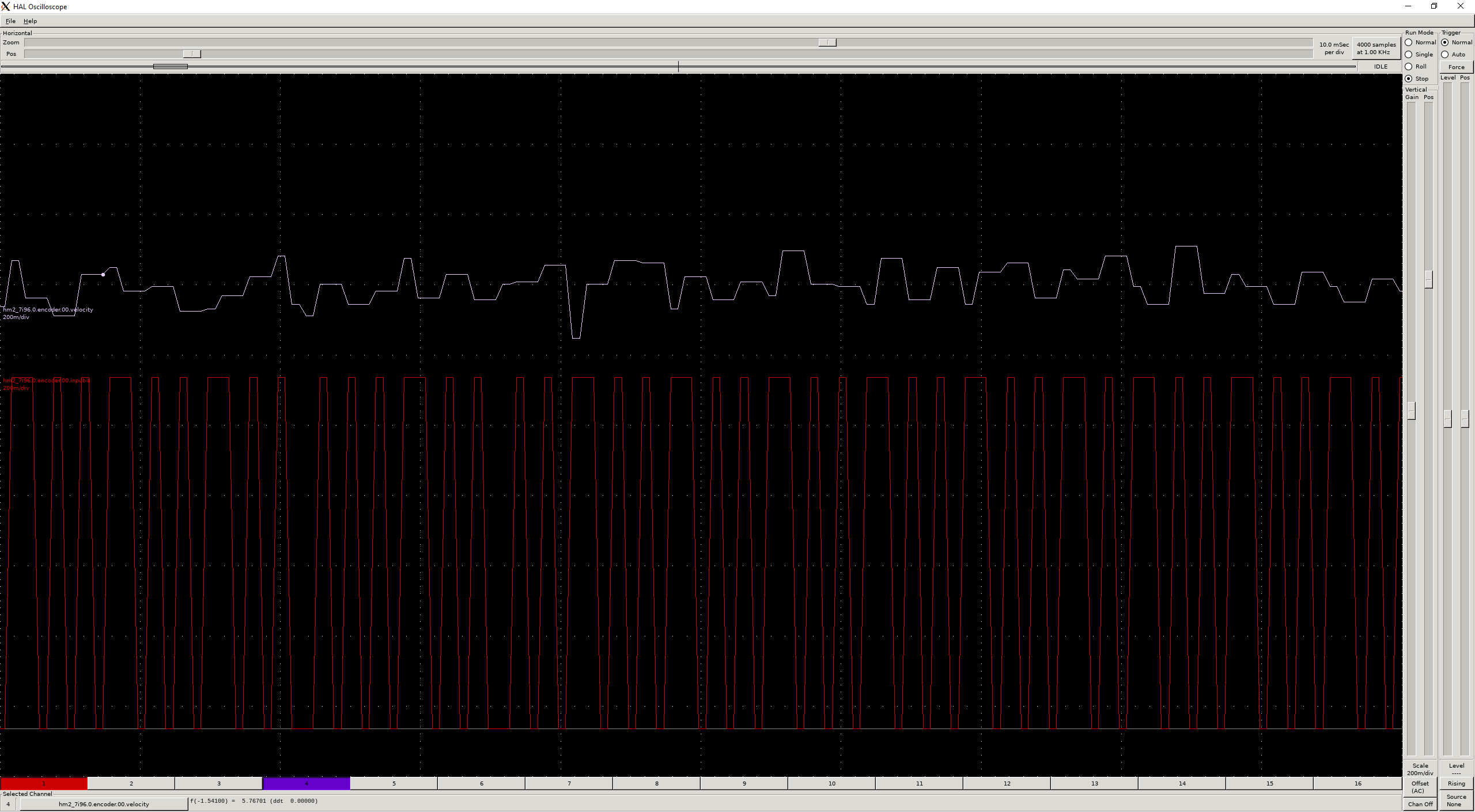

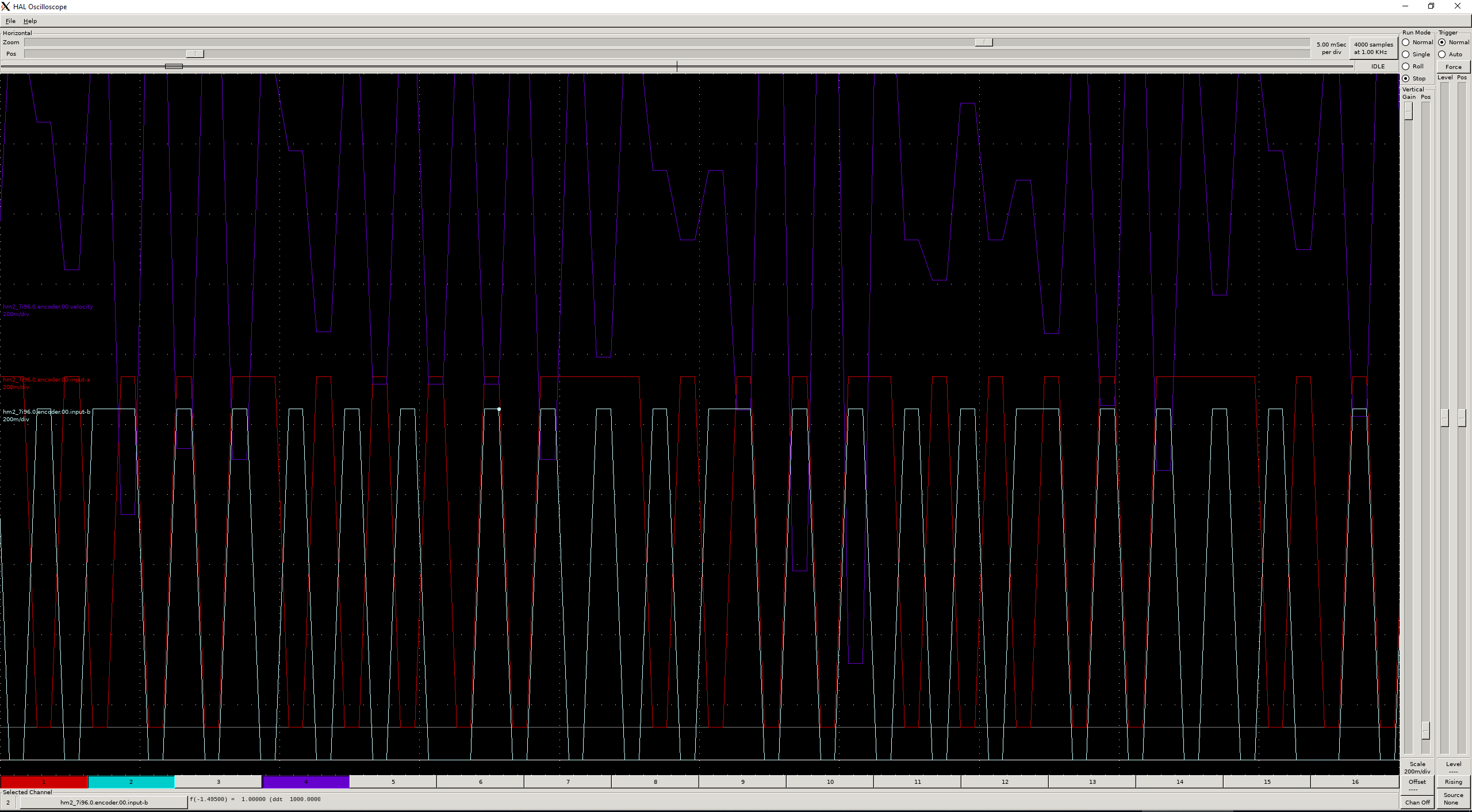

Well

It seems to be not really better with nema23 1000ppr encoder , scale set ENCODER_SCALE = 4000, quadrature mode

Wire are short, i have unconected all the input/output and other stepper

attached my modified hal file

velocity set to 0.5 rps :

velocity set to 15 rps :

At the end displayed RPM seem to be in a tiny range but encoder signal is for my eyes not really better

It seems to be not really better with nema23 1000ppr encoder , scale set ENCODER_SCALE = 4000, quadrature mode

Wire are short, i have unconected all the input/output and other stepper

attached my modified hal file

velocity set to 0.5 rps :

velocity set to 15 rps :

At the end displayed RPM seem to be in a tiny range but encoder signal is for my eyes not really better

Last edit: 11 Mar 2020 21:24 by alkabal.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17695

- Thank you received: 5174

11 Mar 2020 21:25 - 11 Mar 2020 21:28 #159811

by PCW

Replied by PCW on topic 7i76e and opto ancoder TCST2103

The encoder signals will not look good because they are not representative

of the actual signals (A and B are 15 KHz signals at 15 RPS so you

will just get aliased signals when you sample them at 1 KHz)

Even at 1/2 RPS you get 500 Hz square waves (1 ms high 1 ms low if perfect)

the1 ms sampling of linuxcnc/halscope will cause massive distortion of these waveforms

You would need a real oscilloscope to see the encoder signal at this speed

at 15 RPS you should get a quite accurate RPM reading

of the actual signals (A and B are 15 KHz signals at 15 RPS so you

will just get aliased signals when you sample them at 1 KHz)

Even at 1/2 RPS you get 500 Hz square waves (1 ms high 1 ms low if perfect)

the1 ms sampling of linuxcnc/halscope will cause massive distortion of these waveforms

You would need a real oscilloscope to see the encoder signal at this speed

at 15 RPS you should get a quite accurate RPM reading

Last edit: 11 Mar 2020 21:28 by PCW.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

11 Mar 2020 21:26 - 13 Mar 2020 15:07 #159812

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Attachments:

Last edit: 13 Mar 2020 15:07 by alkabal.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.194 seconds