7i76e and opto ancoder TCST2103

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

11 Mar 2020 21:29 - 11 Mar 2020 23:23 #159813

by alkabal

Unfortunatly i no have real oscilloscope.

Yes you are right with NEMA encoder at 15 RPS display is very accurate !

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

The encoder signals will not look good because they are not representative

of the actual signals (A and B are 15 KHz signals at 15 RPS so you

will just get aliased signals when you sample them at 1 KHz)

You would need a real oscilloscope to see the encoder signal at this speed

at 15 RPS you should get a quite accurate RPM reading

Unfortunatly i no have real oscilloscope.

Yes you are right with NEMA encoder at 15 RPS display is very accurate !

Last edit: 11 Mar 2020 23:23 by alkabal.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

11 Mar 2020 22:24 - 11 Mar 2020 22:30 #159817

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Can i ask what is for you the best option ?

Or is there any other opto sensor know to work ?

PS : i can think about ordering some professional encoder but the (unretroffited for now) mill have the same TCST2103 encoder...

Or is there any other opto sensor know to work ?

PS : i can think about ordering some professional encoder but the (unretroffited for now) mill have the same TCST2103 encoder...

Last edit: 11 Mar 2020 22:30 by alkabal.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17697

- Thank you received: 5174

11 Mar 2020 23:32 - 11 Mar 2020 23:33 #159827

by PCW

Replied by PCW on topic 7i76e and opto ancoder TCST2103

My guess is that you have some kind of signal fidelity issue maybe

related to the change in load resistor values. Unfortunately, without an

oscilloscope you are working blind...

related to the change in load resistor values. Unfortunately, without an

oscilloscope you are working blind...

Last edit: 11 Mar 2020 23:33 by PCW.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

12 Mar 2020 16:43 - 12 Mar 2020 17:11 #159885

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Hello

I dont' know how to thanks enough.

At the end i have found some acceptable adjustement for opto position, not perfect but fluctuating range is less than 80tr min, i think the original encoder position is not a quadrature that make difficult to adjust (because one sensor is originaly connected to spindle controler and the second is connected to motion controler)

ASAP i plan to wire the encoder from the mill to the lathe card for check halscope maybee it can be better (it seem to be a "original quadrature" fixture plate but i'm not really sure)

Before doing this i need to investigate the index-enable and index pin, i think does not work fine for now.

-voltmeter checking is ok and same result for A/B (5v outside of sensor position, 0v aligned to sensor position)

-setp [HMOT](CARD0).encoder.00.index-invert 1

Never see the position reseted or the index-enable reverted to false after set to true and rotating spindle.

From Halscope i show nothing that change.

edit : maybee i have miss something and the reset index need to use some synchronised motion and is not reseted by hand rotation or simple velocity

Br

I dont' know how to thanks enough.

At the end i have found some acceptable adjustement for opto position, not perfect but fluctuating range is less than 80tr min, i think the original encoder position is not a quadrature that make difficult to adjust (because one sensor is originaly connected to spindle controler and the second is connected to motion controler)

ASAP i plan to wire the encoder from the mill to the lathe card for check halscope maybee it can be better (it seem to be a "original quadrature" fixture plate but i'm not really sure)

Before doing this i need to investigate the index-enable and index pin, i think does not work fine for now.

-voltmeter checking is ok and same result for A/B (5v outside of sensor position, 0v aligned to sensor position)

-setp [HMOT](CARD0).encoder.00.index-invert 1

Never see the position reseted or the index-enable reverted to false after set to true and rotating spindle.

From Halscope i show nothing that change.

edit : maybee i have miss something and the reset index need to use some synchronised motion and is not reseted by hand rotation or simple velocity

Br

# setup mesa encoder

setp [HMOT](CARD0).encoder.sample-frequency [SPINDLE_0]SAMPLE-FREQUENCY

setp [HMOT](CARD0).encoder.00.scale [SPINDLE_0]ENCODER_SCALE

setp [HMOT](CARD0).encoder.00.counter-mode 0

setp [HMOT](CARD0).encoder.00.filter 1

setp [HMOT](CARD0).encoder.00.index-invert 1

# encoder connections index

net spindle-index-enable <=> [HMOT](CARD0).encoder.00.index-enable

net spindle-index-enable <= spindle.0.index-enable # particular case in+out, this replace old pin motion.spindle-index-enable

net spindle-index-enable => pid.spindle.index-enable

Last edit: 12 Mar 2020 17:11 by alkabal.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

13 Mar 2020 00:31 - 13 Mar 2020 02:09 #159965

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Hi

Today i have wired the mill encoder to the 7i96 and the result is something similar (brand new tcst2103, shielded harness, 150 ohm resistor for led)

I see in the TCST2103 datasheet other version with more tiny gap what did you think about that ?

And i have also do some test with some synchronised motion but the move does not start because the index-enable is never changed.

Test with multimeter www.mouser.in/datasheet/2/698/fn7529-1301979.pdf

regarding to position A

B1 = 0 or 5v A1 = 1.6v or 1.6v RO1 = 3.3v or 0.5v

regarding to position I

B2 = 0 or 5v A2 = 1.6v or 1.6v RO2 = 0.5v or 0.5v

Unfortunately i think the IC is damaged (i hope nothing other) but i don't know the reason, only one seller in china have this in stock i found nothing over the traditional shop.

Today i have wired the mill encoder to the 7i96 and the result is something similar (brand new tcst2103, shielded harness, 150 ohm resistor for led)

I see in the TCST2103 datasheet other version with more tiny gap what did you think about that ?

And i have also do some test with some synchronised motion but the move does not start because the index-enable is never changed.

Test with multimeter www.mouser.in/datasheet/2/698/fn7529-1301979.pdf

regarding to position A

B1 = 0 or 5v A1 = 1.6v or 1.6v RO1 = 3.3v or 0.5v

regarding to position I

B2 = 0 or 5v A2 = 1.6v or 1.6v RO2 = 0.5v or 0.5v

Unfortunately i think the IC is damaged (i hope nothing other) but i don't know the reason, only one seller in china have this in stock i found nothing over the traditional shop.

Last edit: 13 Mar 2020 02:09 by alkabal.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

13 Mar 2020 12:29 #160004

by andypugh

Replied by andypugh on topic 7i76e and opto ancoder TCST2103

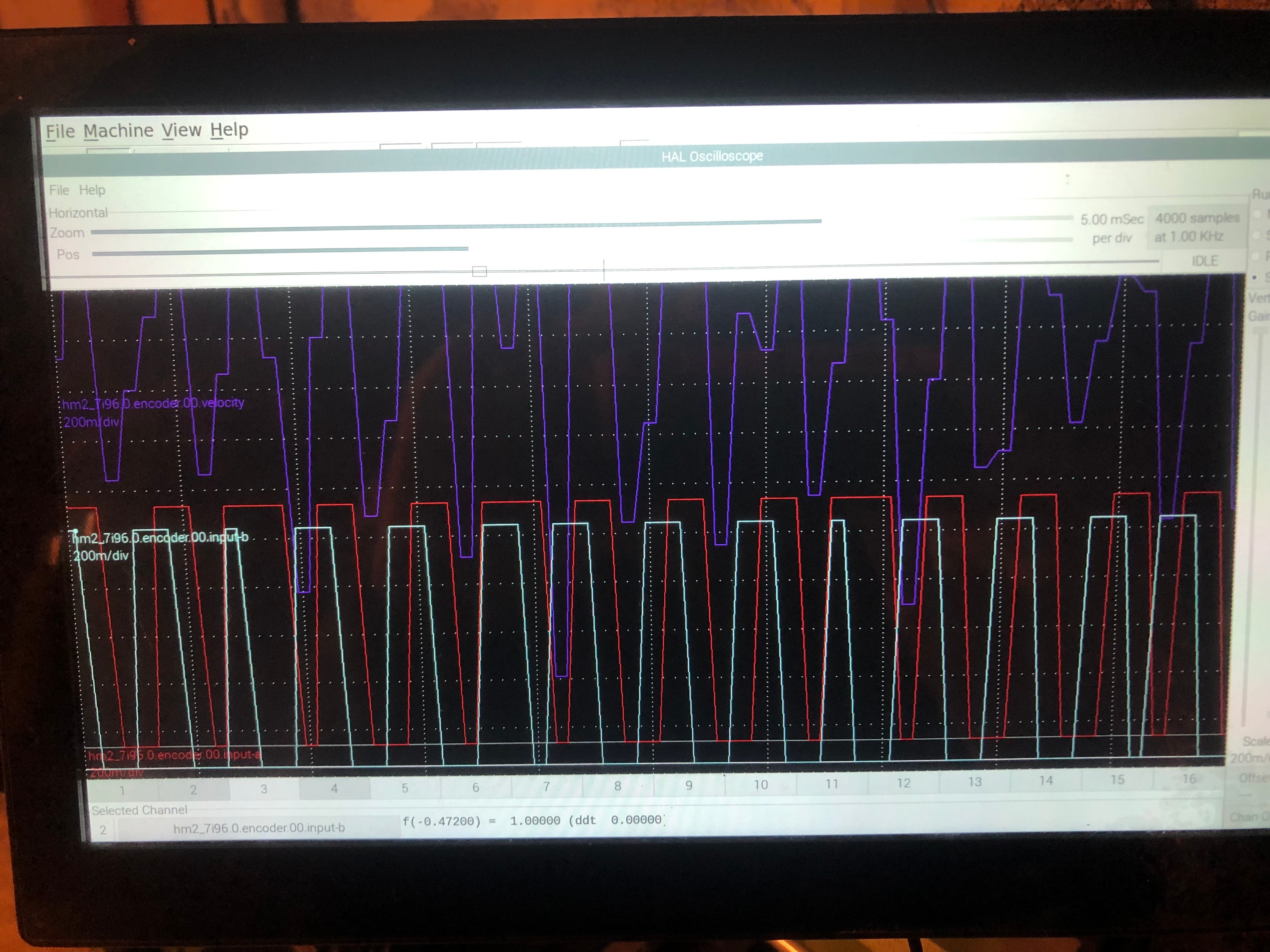

Your velocity scale is set to 200m/div and we see 7 divisions, so +/- 0.7rps noise.

What is the test speed?

Bear in mind that a lot of the bad data you see is due to low-frequency sampling in Halscope. And at low speeds the effect of quadrature variability on measured velocity is larger.

What do you plan on using the velocity output for? Can you just low-pass filter it?

What is the test speed?

Bear in mind that a lot of the bad data you see is due to low-frequency sampling in Halscope. And at low speeds the effect of quadrature variability on measured velocity is larger.

What do you plan on using the velocity output for? Can you just low-pass filter it?

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

13 Mar 2020 13:20 - 13 Mar 2020 13:22 #160012

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

Last edit: 13 Mar 2020 13:22 by alkabal.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

13 Mar 2020 15:07 #160022

by andypugh

PID will naturally smooth out the variation,

Synchronised motion uses position not velocity.

Do not low-pass those inputs, but you might want to low-pass any on-screen display that you add for your own viewing.

Replied by andypugh on topic 7i76e and opto ancoder TCST2103

Velocity output is for => spindle.0.speed-in => pid.spindle.feedback

I'm afraid about this for synchronised motion.

PID will naturally smooth out the variation,

Synchronised motion uses position not velocity.

Do not low-pass those inputs, but you might want to low-pass any on-screen display that you add for your own viewing.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

13 Mar 2020 15:44 #160030

by alkabal

Replied by alkabal on topic 7i76e and opto ancoder TCST2103

My own viewing is not really important.

For the test i have bypassed PID

you says do not filtre spindle.0.speed-in => pid.spindle.feedback

If you think this is enough with some noisy signal like i have = job done and go to PID tuning ?

Br

For the test i have bypassed PID

you says do not filtre spindle.0.speed-in => pid.spindle.feedback

If you think this is enough with some noisy signal like i have = job done and go to PID tuning ?

Br

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

13 Mar 2020 15:50 #160033

by andypugh

Replied by andypugh on topic 7i76e and opto ancoder TCST2103

I think so, yes.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.132 seconds