Elumatec SBZ 130/01 retrofit

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

30 Jan 2017 22:56 #87014

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Andy, thank you for pointing me in the right direction.

Got it working......but have to fix the pocket numbering as it is fuzzy right now.

Tuned the long X axis and set it at 9000mm/minute for now. I have all axes set at a mild speed since it is going to be used by inexperienced personel there, till they get a grip on things.

Back on the subject of two X axis.

Todd, i understand your idea of using sum, but i doubt it will do as is without added logic to it, namely short X should be always at 0 for the long X to move to the start of job, clamp pneumatic brake and motor brake, then have the short X do the job inside it's dimensions, when finished start over again from the new long X position.

That is my idea, but i feel a bit like cayotee in the road runner cartoon, i have a great idea but actual implementation is ......well cartoonish!

The machine is going to be used for drilling and taping and sloting, so i have to figure out what to use for CAM, ideas are welcome, always.

Got it working......but have to fix the pocket numbering as it is fuzzy right now.

Tuned the long X axis and set it at 9000mm/minute for now. I have all axes set at a mild speed since it is going to be used by inexperienced personel there, till they get a grip on things.

Back on the subject of two X axis.

Todd, i understand your idea of using sum, but i doubt it will do as is without added logic to it, namely short X should be always at 0 for the long X to move to the start of job, clamp pneumatic brake and motor brake, then have the short X do the job inside it's dimensions, when finished start over again from the new long X position.

That is my idea, but i feel a bit like cayotee in the road runner cartoon, i have a great idea but actual implementation is ......well cartoonish!

The machine is going to be used for drilling and taping and sloting, so i have to figure out what to use for CAM, ideas are welcome, always.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

30 Jan 2017 23:51 #87018

by andypugh

Replied by andypugh on topic Elumatec SBZ 130/01 retrofit

If you add long to short (either with sum2, or inside the kinematics) then the behaviour ought to be that the when you move the long-X then the short-X holds station above the same spot in the workpiece. Which sounds about right.

I am curious why you wouldn't just use long-X for everything?

I am curious why you wouldn't just use long-X for everything?

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

31 Jan 2017 01:32 #87024

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

That would be to easy. I do not like easy!

I realy enjoy running my brain till it starts melting, several times on this thread i have used the phrase "more fun", that is very true.

Yeasterday i was there working from 11AM till 1:45 AM so again nearly 15 hours, although till 4:30 PM not very productive as there are workers there making to much noise and smoke, so i have to do tasks like testing things that are already set up, or just have a coffee.

Thanks for everything.

I realy enjoy running my brain till it starts melting, several times on this thread i have used the phrase "more fun", that is very true.

Yeasterday i was there working from 11AM till 1:45 AM so again nearly 15 hours, although till 4:30 PM not very productive as there are workers there making to much noise and smoke, so i have to do tasks like testing things that are already set up, or just have a coffee.

Thanks for everything.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

01 Feb 2017 00:09 #87102

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Here i go again on my own.........as Whitesnake said a long time ago.

Had to change the tool chnager routine as it was giving incosistent changes, checked the hal configuration and it would send diferent values as a request for the same tool after several changes, something with the AD conversion was not right, and it would not know where it was located as it uses 4 pins and that makes for 16 slots og gray code. The main problem was that i tired of hunting up and down several files and remaps and modal changes etc etc etc, so i had a look at every config for carousel on the site and forum till i bumped on an Emco comp made by ArcEye a while back using paraport. Modified the inputs and outputs, it has options for sequence of each input pin ( thank you ArcEye, much apreciated ), some smal modifications, a quick compile and install, and it works perfectly.

Aslo regarding independent brakes, gave the joint.N.active a go, no good it activates all brakes at once even when in e-stop. Joint.N.unlock does not work ( something else has to be set somewhere else for radial axis etc ), and so on.

Gues i will have to try abs from analogout through a comp, that should do it.

Still thinking about the long/short X axis (geting boring, but i do not bore easily).

Have to wait for them to fix some more air pipes, do a full clean up and lube, change oils etc, told them two weeks ago to do that, still not done, so i will have to give them a nudge tomorrow.

Got some more logic to add to air clamps, some alarms for low pressure and low oil, and move on to the next project.

I did not upload pictures yet waiting for it to be cleaned, will do as soon as possible.

Regards,

Tom

Had to change the tool chnager routine as it was giving incosistent changes, checked the hal configuration and it would send diferent values as a request for the same tool after several changes, something with the AD conversion was not right, and it would not know where it was located as it uses 4 pins and that makes for 16 slots og gray code. The main problem was that i tired of hunting up and down several files and remaps and modal changes etc etc etc, so i had a look at every config for carousel on the site and forum till i bumped on an Emco comp made by ArcEye a while back using paraport. Modified the inputs and outputs, it has options for sequence of each input pin ( thank you ArcEye, much apreciated ), some smal modifications, a quick compile and install, and it works perfectly.

Aslo regarding independent brakes, gave the joint.N.active a go, no good it activates all brakes at once even when in e-stop. Joint.N.unlock does not work ( something else has to be set somewhere else for radial axis etc ), and so on.

Gues i will have to try abs from analogout through a comp, that should do it.

Still thinking about the long/short X axis (geting boring, but i do not bore easily).

Have to wait for them to fix some more air pipes, do a full clean up and lube, change oils etc, told them two weeks ago to do that, still not done, so i will have to give them a nudge tomorrow.

Got some more logic to add to air clamps, some alarms for low pressure and low oil, and move on to the next project.

I did not upload pictures yet waiting for it to be cleaned, will do as soon as possible.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

03 Feb 2017 06:42 #87194

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Found a solution for the brakes, as that is a must on the long X axis.

Used joint.N.vel.cmd to an ABS and the abs.N.is-positive and abs.N.is-negative outputs to an OR2 inputs, the output of OR2 does exactly what it should, namely releasing the brake whenever a command to move the axis is issued. I have not test it on the machine yet, will test tomorrow, i need to check if the smal fluctuations will triger it, while the motor is at stand still.

Also made some modifications to pyvcp panel to add signals for individual brakes, air pressure, tool in position, clamps locked, low oil, etc.

Will have to add a DDT for the spindle velocity, since using absolute encoders does not privide that.

I would like to say that this would conclude this project, but i am sure i will find something else to do with it.

And then i have to do some training to someone ( still no candidate awailable ).

Regards,

Tom

Used joint.N.vel.cmd to an ABS and the abs.N.is-positive and abs.N.is-negative outputs to an OR2 inputs, the output of OR2 does exactly what it should, namely releasing the brake whenever a command to move the axis is issued. I have not test it on the machine yet, will test tomorrow, i need to check if the smal fluctuations will triger it, while the motor is at stand still.

Also made some modifications to pyvcp panel to add signals for individual brakes, air pressure, tool in position, clamps locked, low oil, etc.

Will have to add a DDT for the spindle velocity, since using absolute encoders does not privide that.

I would like to say that this would conclude this project, but i am sure i will find something else to do with it.

And then i have to do some training to someone ( still no candidate awailable ).

Regards,

Tom

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

03 Feb 2017 14:03 #87209

by andypugh

You should be able to use just the "near" component.

Replied by andypugh on topic Elumatec SBZ 130/01 retrofit

Found a solution for the brakes, as that is a must on the long X axis.

Used joint.N.vel.cmd to an ABS and the abs.N.is-positive and abs.N.is-negative outputs to an OR2 inputs, the output of OR2 does exactly what it should

You should be able to use just the "near" component.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

03 Feb 2017 14:15 #87211

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Thank you, Andy.

I read a lot of the functions there but i somehow missed that, will have a look in about 15 minutes while i eat breakfast at 3PM.

So far on the bench (well coffe table in the living room, to cold in the workshop and keeping the heating on all night was not an option, over 80 square meters at 4 meters high), it looks perfectly, it has a smal treshhold for activation on both directions so that should keep it from oscilating while stationary due to deadband on the servo.

Food...........

I read a lot of the functions there but i somehow missed that, will have a look in about 15 minutes while i eat breakfast at 3PM.

So far on the bench (well coffe table in the living room, to cold in the workshop and keeping the heating on all night was not an option, over 80 square meters at 4 meters high), it looks perfectly, it has a smal treshhold for activation on both directions so that should keep it from oscilating while stationary due to deadband on the servo.

Food...........

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

07 Feb 2017 06:44 #87436

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

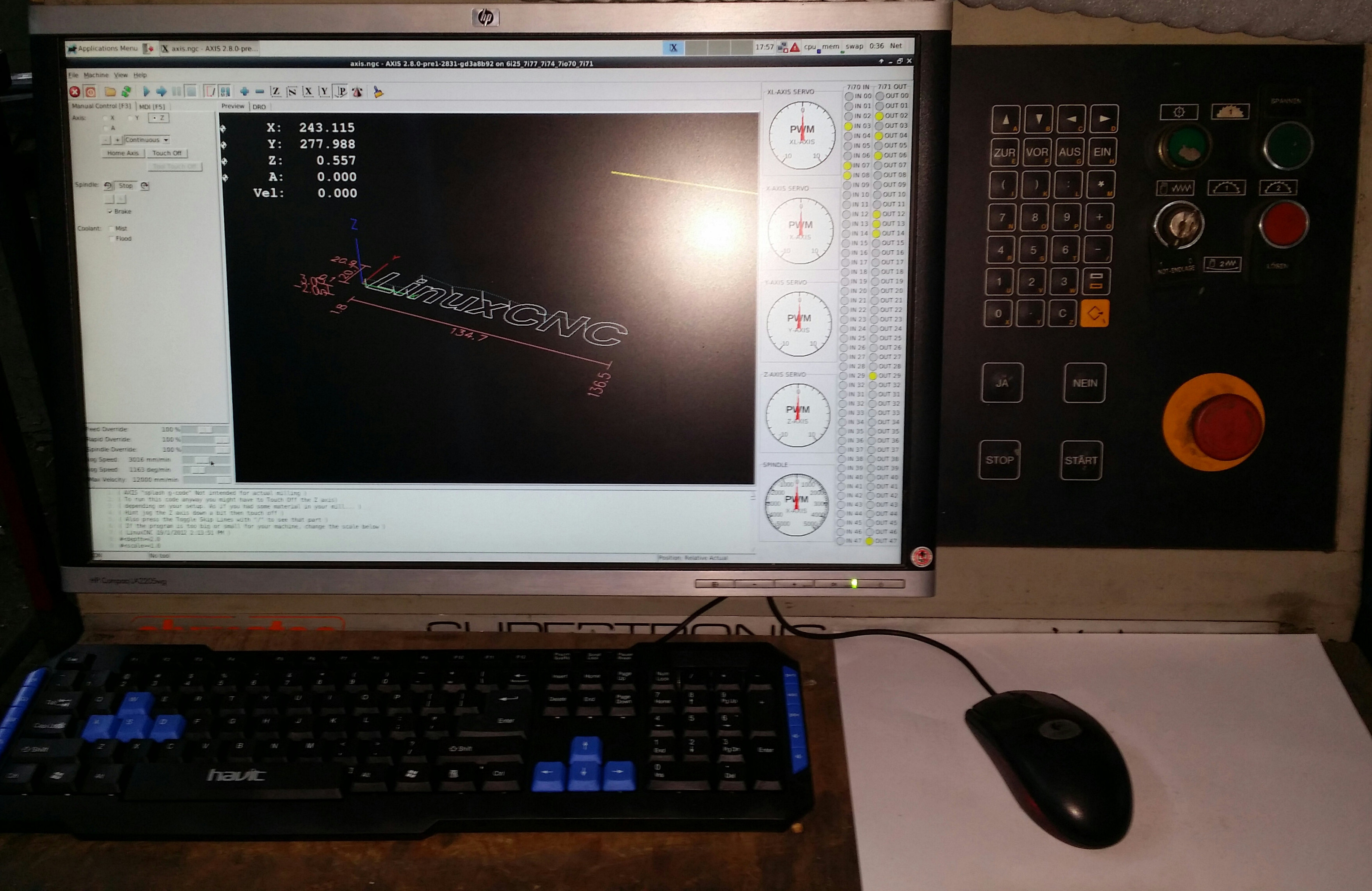

Finaly got some time to mount the monitor and close the cabinet, checked everything and all is in good working order. Camera on the tablet kept freezing but got some short videos of a test run and tool changes.

All in all, it was a nice job, took over 2 weeks to finish, and we are pleased with the result. Air pipes are not changed yet, so stay tuned for more videos.

All in all, it was a nice job, took over 2 weeks to finish, and we are pleased with the result. Air pipes are not changed yet, so stay tuned for more videos.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

07 Feb 2017 06:55 #87437

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21169

- Thank you received: 7232

22 Feb 2017 23:21 #88523

by tommylight

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Please Log in or Create an account to join the conversation.

Time to create page: 0.202 seconds