epoxy granite cnc lathe

- Bari

-

- Offline

- Platinum Member

-

Less

More

- Posts: 634

- Thank you received: 232

10 Sep 2022 20:48 #251644

by Bari

Replied by Bari on topic epoxy granite cnc lathe

The perfectionist in me is screaming "Beef up the X-axis"!

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

10 Sep 2022 21:33 #251650

by Masiwood123

Replied by Masiwood123 on topic epoxy granite cnc lathe

I agree i should put stronger X but I thought I wouldn't work with metal. The plan is to have two machining motors on the y axis, one with a saw and one with a router bit, on the opposite side there will be a heavy classic knife holder to balance it. on X Axis .Tailstock should be Z axis..I am planning this lathe for making some smaller pieces of wood and primarily the main spindle as the A axis, I have to figure out how to connect it so that it can also work as a spindle (S command to main main motor, instead of A) because the piece needs to be cut at the end with a classic knife.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

17 Sep 2022 09:59 #252155

by Masiwood123

Replied by Masiwood123 on topic epoxy granite cnc lathe

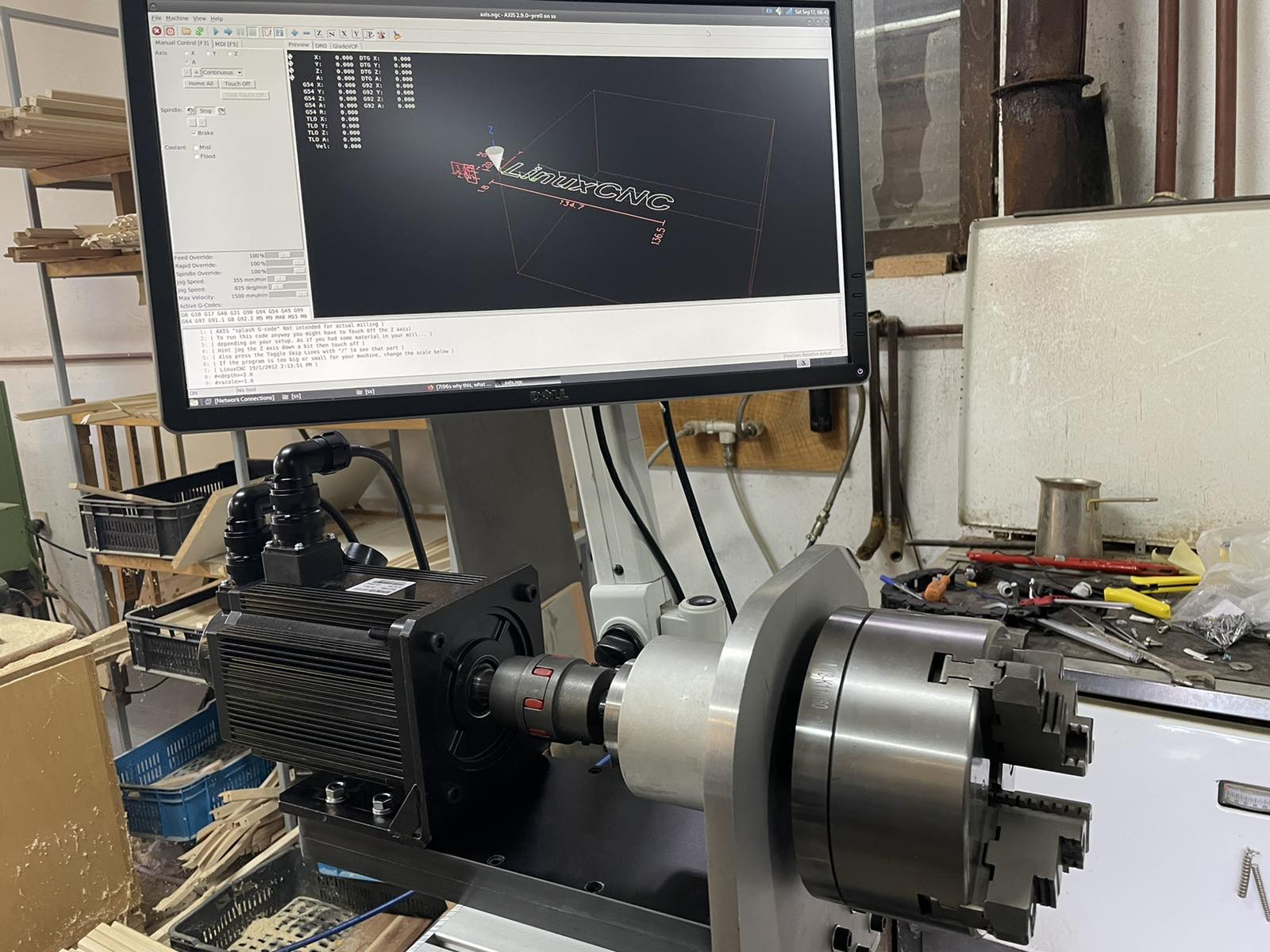

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- pippin88

- Offline

- Elite Member

-

Less

More

- Posts: 262

- Thank you received: 51

17 Sep 2022 14:12 #252170

by pippin88

Replied by pippin88 on topic epoxy granite cnc lathe

Your headstock is going to be the weakest point.

You have a thin plate holding the spindle.

Look at every lathe headstock. There is a reason they are long and beefy and are not just a thin plate with a spindle mounted to it.

You have a thin plate holding the spindle.

Look at every lathe headstock. There is a reason they are long and beefy and are not just a thin plate with a spindle mounted to it.

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

17 Sep 2022 14:25 #252171

by Masiwood123

Replied by Masiwood123 on topic epoxy granite cnc lathe

the spindle is not mounted on that plate, the plate is only held by this aluminum cylinder which is inside with three bearings and an internal fi60mm, the spindle has an MT3 tail with a fi30mm adapter and goes the entire length of about 150mm through the bearings. I agree that the plate should be a little stronger. all in all, I rarely use full rpm, the headstock is primarily an A axis and will be used primarily for woodworking.. and maybe I will additionally strengthen it with some metal diagonal, otherwise the whole assembly seems light, in fact it weighs over 200 kg with epoxy..

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

20 Sep 2022 13:21 - 20 Sep 2022 13:22 #252400

by Masiwood123

Replied by Masiwood123 on topic epoxy granite cnc lathe

New update A axis connected but a mechanical problem appeared..I will try to solve the driver settings first..

youtube.com/shorts/Gqv0OQLVtto

youtube.com/shorts/Gqv0OQLVtto

Last edit: 20 Sep 2022 13:22 by Masiwood123.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

24 Sep 2022 17:49 #252673

by Masiwood123

A and S command works..

Done with output from Mesa 7i96s, to AASD servo driver settings, to change position/speed mode on driver input.

Replied by Masiwood123 on topic epoxy granite cnc lathe

A and S command works..

Done with output from Mesa 7i96s, to AASD servo driver settings, to change position/speed mode on driver input.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21178

- Thank you received: 7235

24 Sep 2022 20:29 #252685

by tommylight

Replied by tommylight on topic epoxy granite cnc lathe

Nice!

You should post the config files, some members of this forum had a hard time setting that up so it might help .

Thank you/Hvala.

You should post the config files, some members of this forum had a hard time setting that up so it might help .

Thank you/Hvala.

The following user(s) said Thank You: Masiwood123

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

24 Sep 2022 20:58 #252686

by Masiwood123

Replied by Masiwood123 on topic epoxy granite cnc lathe

..in this case I didn't use hal, I'm just a beginner, but since I didn't know anything, this is great. As for the configuration in this case, it's all down to the poor Chinese manual for the ASSD driver of the servo motor, the basis is that at the beginning I thought it could only work in 3 modes position/speed/torque.. I listened to your old advice to rest for a day , the next night I read the instructions from beginning to end..every parameter..in the end I realized that the driver has the possibility to change the mode of operation through the input..it is possible to switch from position to speed, but there is one more thing..it inputs in the driver are already factory set to default. they have to be allocated.. (if someone needs parameters I will be happy to help also will attach all hal/ini)... then I connected the output from the Mesa 7i96s to a relay that changes the operating mode on the driver from A (step dir) to S (speed ) .In the gcode, it is only necessary to enter M64 P0 for example and the output activates the input on the driver, change the operating mode and after the m64 command, put M3... follows the S command. Considering that I have no need for accurate indexing, this one has exactly what I wanted for me. Thanks Tom, I'll probably need help in the future with connecting the MPG.. when I get it all done with axis... than Mpg in the end.. beer is always ready if you're up to it Nis get in touch- )/Hvala

)/Hvala

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 412

- Thank you received: 93

29 Sep 2022 12:54 #253028

by Masiwood123

Replied by Masiwood123 on topic epoxy granite cnc lathe

Today I have an idea that I might implement, but I need some advice. the plan is to install an encoder on the knife holder so that with scaling it can read a full 360 degree circle. I would make a reference knife that would be 0 degrees to z or x axis, and in order to manually rotate the holder, a vcp should be made on the screen, that would show the dro encoder reading, referenced to that zero. is it possible to do that, since the spindle encoder input is not needed on the 7i96s would I use it? thanks for the support again with how to configure Hal.

Please Log in or Create an account to join the conversation.

Time to create page: 2.179 seconds