epoxy granite cnc lathe

- andypugh

-

- Away

- Moderator

-

- Posts: 19782

- Thank you received: 4604

The second link should have been goo.gl/photos/2dwiVYxDTyD9ibti6this looks great! and it's great say for the headstock in my case, because I didn't make it the best, but I'll see in practice.. (unfortunately, I can't open this second link).

Typically I design the part, then make a copy 2% bigger to allow for shrinkage, then add on the casting draft (and any core prints) That becomes the main pattern. Then core boxes and "odd sides" and other similar things are made by subtracting the main pattern from solids.Do you draw a 3d model in Cad (positive or negative) and they do it, or do you draw a mold for them? Is it in UK or ? Tom and I are far from you, although I think there is a foundry near me, so I could ask..

It's a fun exercise, designing patterns, but the simplest pattern is just a slightly over-sized and plus-matarial version of the part you want.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21183

- Thank you received: 7235

Set the font to something smaller, it should fit ok.only for some reason the sliders cover the spindle dro, maybe I should try a different monitor resolution?

Tomo, when I return the ini to display -axis..it starts the normal axis configuration, regardless of the fact that the files are overwritten, so that's great too.

Nice, i am glad it does work with both Axis!

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 412

- Thank you received: 93

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 412

- Thank you received: 93

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 412

- Thank you received: 93

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21183

- Thank you received: 7235

I am disapointed!

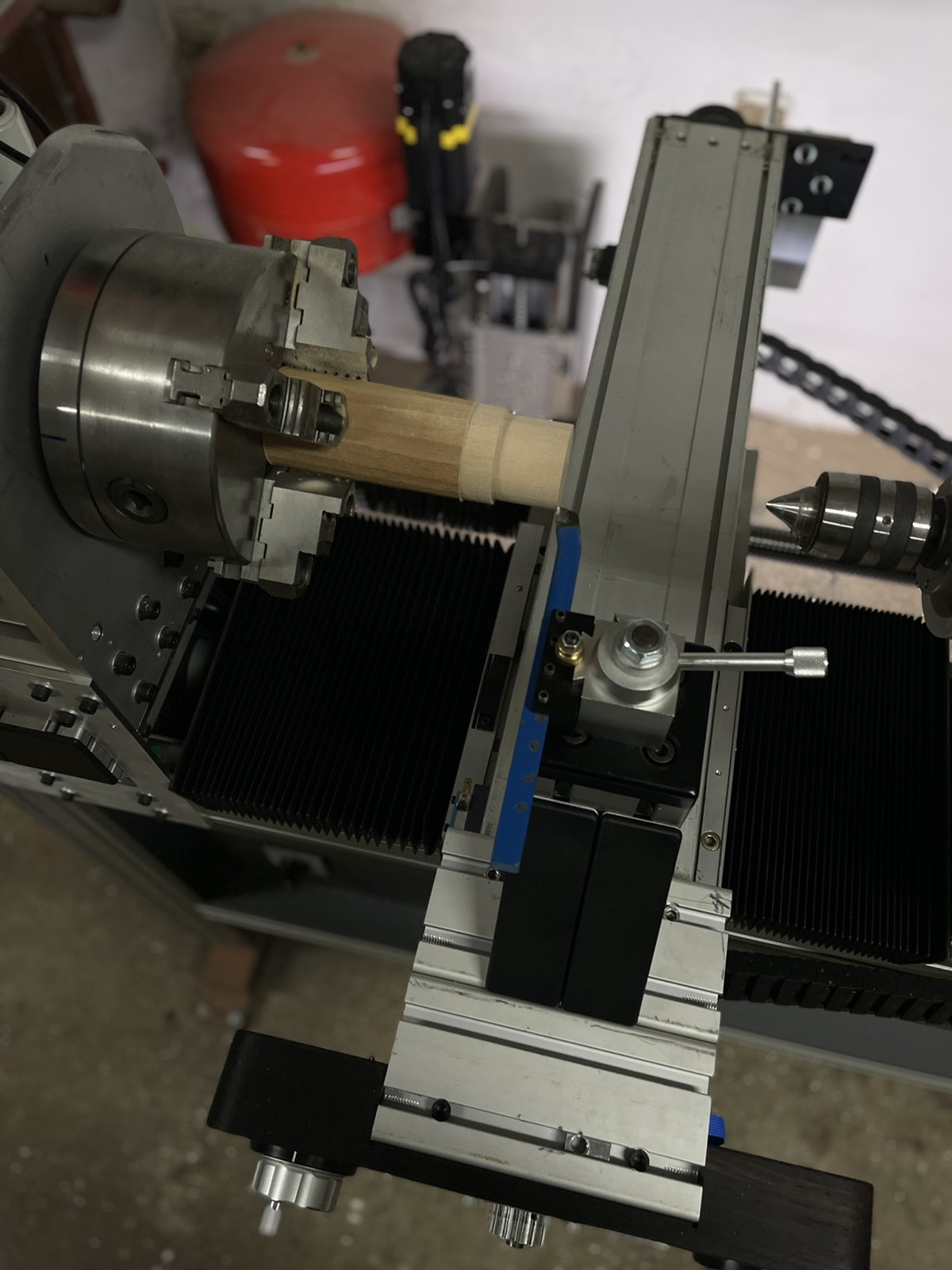

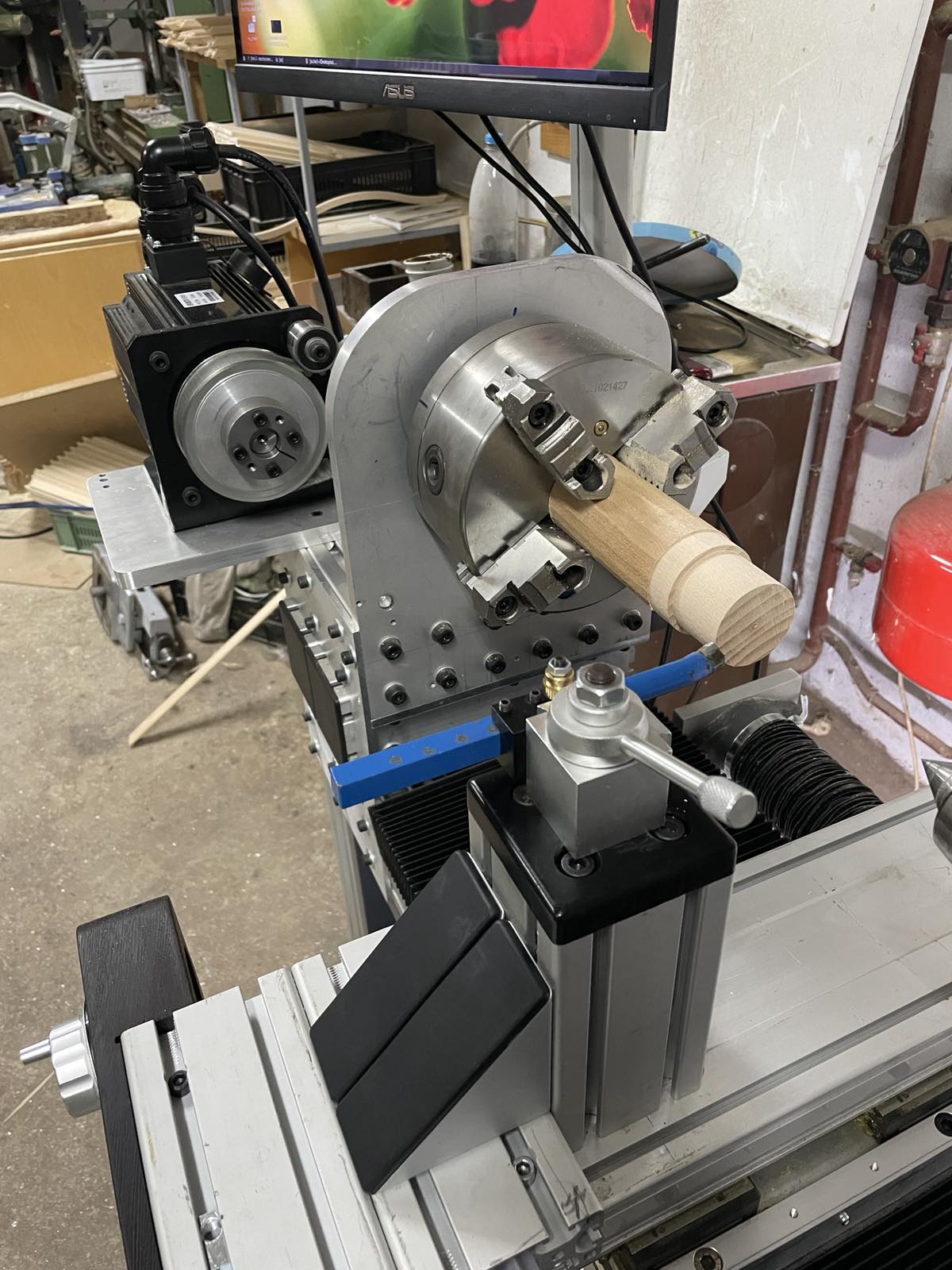

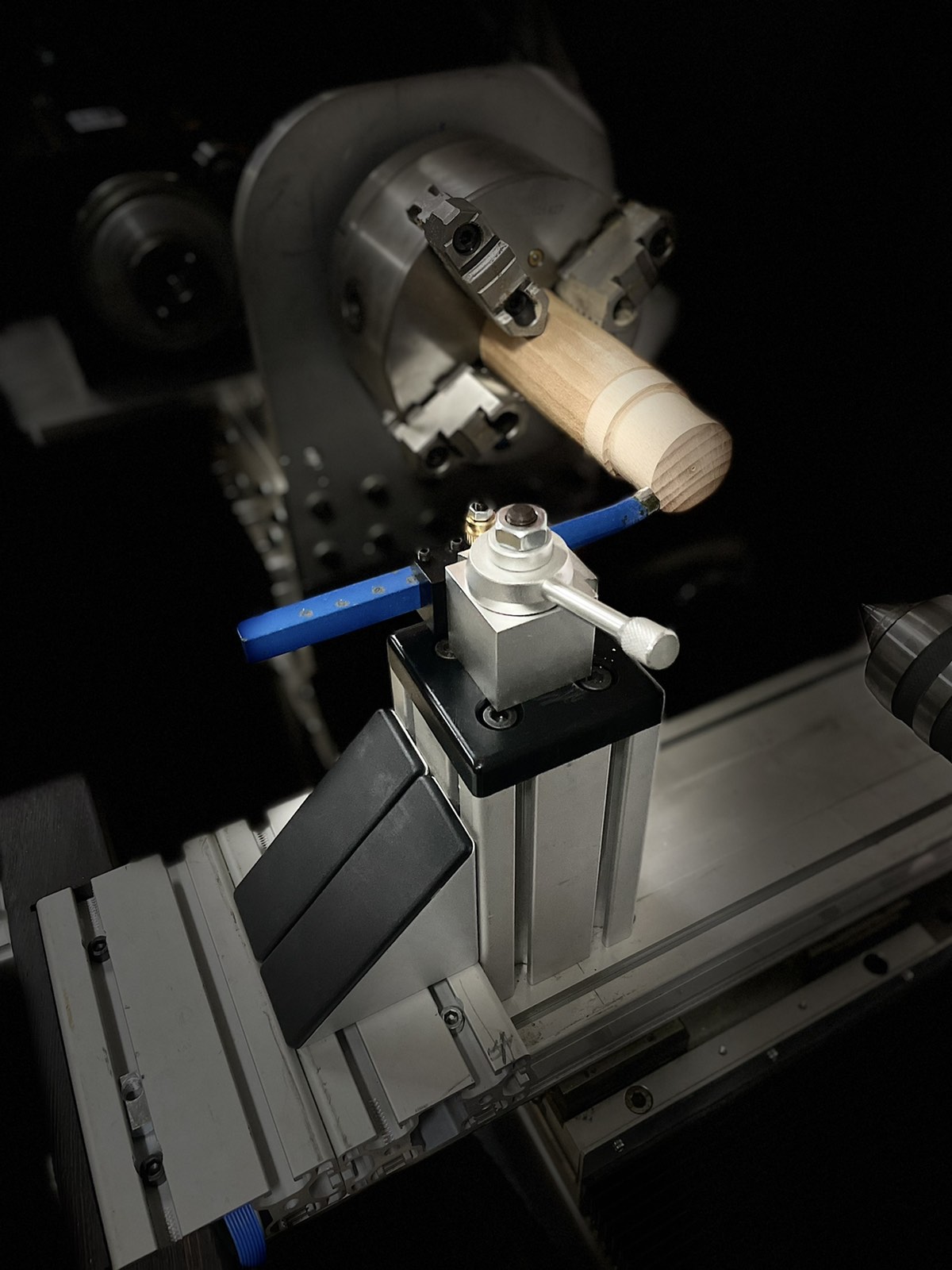

Cuts look clean, so no vibration as far as i can see on the pictures, nice.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 412

- Thank you received: 93

I will quickly draw a chess figure and document it, since everything is around the knife holder

all a bit weak'' even the holder accepts only 12x12 mm, i am satisfied with the processing ,and that by hand.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 412

- Thank you received: 93

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

- Posts: 21183

- Thank you received: 7235

What did i do now?out of the title, Tomo,

Yes, the bigger ones have a Z axis, small ones do not, they use a small 3 phase servo motor to put pressure of about 1KG to 2KG on the spinning bit.does the stone engraving machine you are making have a z axis? is that the construction is not so strong, but the quality is top (less wind turns the ballscrew:)

Big ones do about 2KG to 4KG.

Please Log in or Create an account to join the conversation.

- Masiwood123

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 412

- Thank you received: 93

Please Log in or Create an account to join the conversation.