A Widescreen Blender-Style Interface

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

18 Jul 2018 12:29 - 18 Jul 2018 12:30 #114466

by rodw

Replied by rodw on topic A Widescreen Blender-Style Interface

In the 70's at one of my first engineering lectures, the lecturer did a calculation in horsepower, spread over 2 blackboards, then redid it in kW in a small remaining corner and announced "And thats why we prefer to use SI units!

I did get a laugh a while ago when a friend restoring a Model T Ford called out measurements in inches to his builder stepson during a renovation who announced "I don't do Inches". 21.97 has a nice ring to it after all!

I did get a laugh a while ago when a friend restoring a Model T Ford called out measurements in inches to his builder stepson during a renovation who announced "I don't do Inches". 21.97 has a nice ring to it after all!

Last edit: 18 Jul 2018 12:30 by rodw.

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

- rodw

-

- Online

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

18 Jul 2018 12:29 - 18 Jul 2018 12:30 #114467

by rodw

Replied by rodw on topic A Widescreen Blender-Style Interface

deleted duplicate sorry.

Last edit: 18 Jul 2018 12:30 by rodw.

Please Log in or Create an account to join the conversation.

- AnnoyingMutt

-

- Visitor

-

19 Jul 2018 06:47 #114519

by AnnoyingMutt

Are you sure you're not some kind of Dave Grohl type of the Linuxcnc world ?

(this meant in the very best way)

Replied by AnnoyingMutt on topic A Widescreen Blender-Style Interface

Shame on you Andy! In my world, there is nothing but metric..The exception is the one-off metric job

I was quoting BrendaEM. Personally I am almost entirely metric, it's what we learned at school and I did Physics at college.

But I was brought up by an Imperial engineer, so I _guess_ in Imperial. "Hmm, 1 thou interference sounds good, so for this 22mm shaft I will bore to 21.97mm..."

I also spend a lot of my time making parts for old vehicles ( 1921 Ner-a-Car , 1916 Fire Engine ) but for those I CAD in Imperial but produce drawings in metric. (I use Inventor, you can just type "1 5/8in" in the dimension box and get "41.275"

Are you sure you're not some kind of Dave Grohl type of the Linuxcnc world ?

(this meant in the very best way)

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

21 Jul 2018 05:54 - 21 Jul 2018 07:18 #114627

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

I'm sorry about the lack of updates. My cellphone died, and it's been a lot of work fussing with the new one to get it working for me.

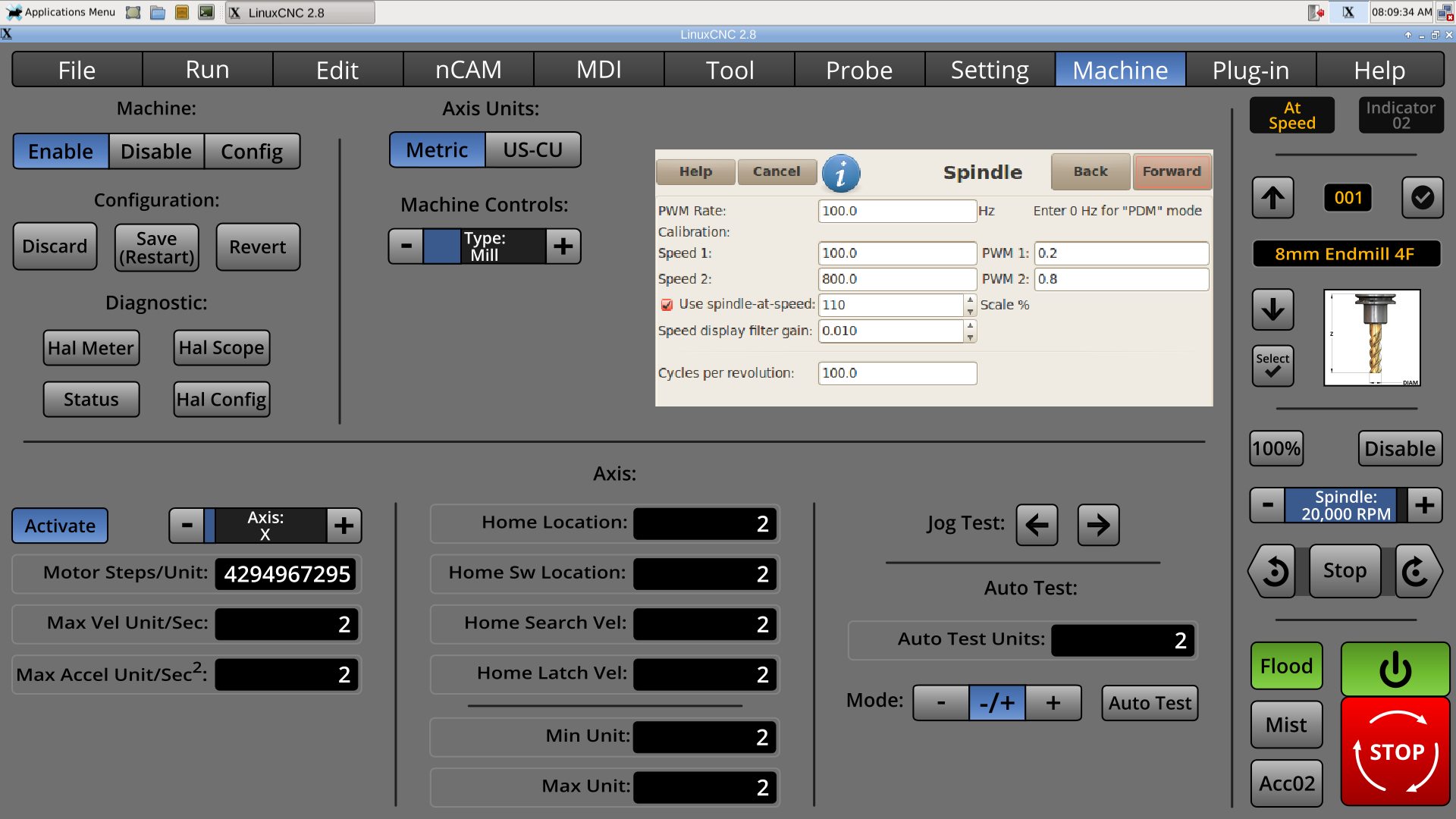

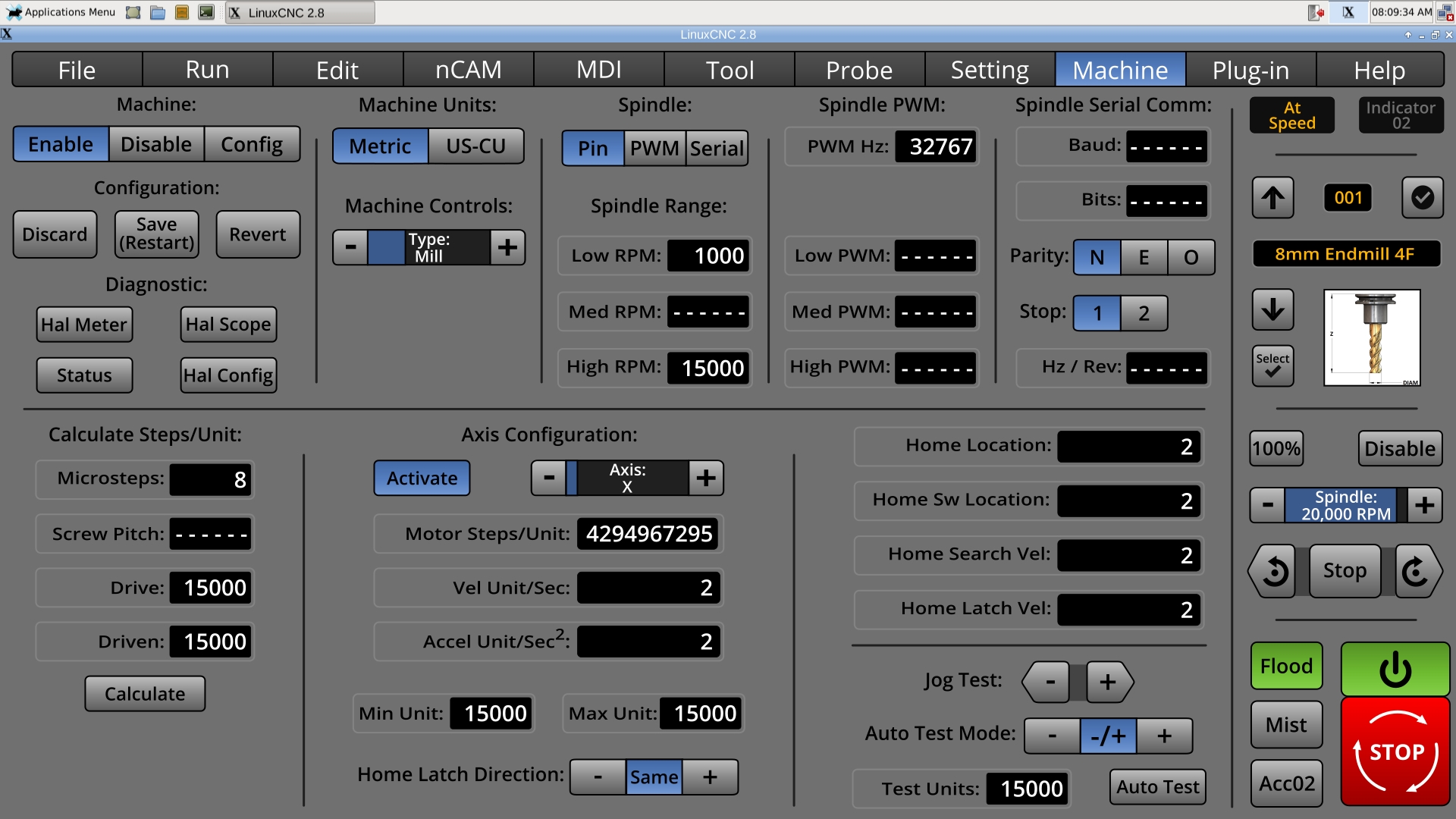

I continue to work on the Machine menu. There are still little changes to be done here and there to the other menus, but I had saved this menu for last. (This plugin menu is control by a plug-in. I may draw out a small example; I may not. The help menu would scroll a document. There's not much for me to do there.)

There's a lot to think consider in the Machine menu.

Firstly: if "Config" is not selected most of this menu would be grayed out. Enabling/Disabling would lock this menu safely out. Disabling the machine would let someone learn the interface, or perhaps Safe it.

Looking at those things which are universal to most machine types, I want to provide controls iterative adjustments and tuning. There will be crossover with StepConf, but there is no promise StepConf promise to support this interface. Additionally, StepConf really didn't support my VFD, anyway, so let's see how this plays out once the controls start get moving around.

There are other things with the UI must have, such as a machine-type selector, for choosing Mill/Lathe/Torch/... because the UI needs to know which machine-dependant controls to use (as seen on the right).

So, for this version, I am am prioritising things that are more universal, things such acceleration and steps, for instance, are universal to lathes, mills, and CNC touches. If there is room left over, who knows.

If I envisioned a second version of this interface, it would have sub-menus, but I feel that would be too high a bar for a first version. Additionally, I feel that sub-menus should be used sparingly because I never want to disorient the user.

[There was a GUI saying that everything should be discoverable by 3 clicks.]

I need to remember to include calibration, as provided in Axis, and look through the .ini for things I have had to adjust more than once.

I continue to work on the Machine menu. There are still little changes to be done here and there to the other menus, but I had saved this menu for last. (This plugin menu is control by a plug-in. I may draw out a small example; I may not. The help menu would scroll a document. There's not much for me to do there.)

There's a lot to think consider in the Machine menu.

Firstly: if "Config" is not selected most of this menu would be grayed out. Enabling/Disabling would lock this menu safely out. Disabling the machine would let someone learn the interface, or perhaps Safe it.

Looking at those things which are universal to most machine types, I want to provide controls iterative adjustments and tuning. There will be crossover with StepConf, but there is no promise StepConf promise to support this interface. Additionally, StepConf really didn't support my VFD, anyway, so let's see how this plays out once the controls start get moving around.

There are other things with the UI must have, such as a machine-type selector, for choosing Mill/Lathe/Torch/... because the UI needs to know which machine-dependant controls to use (as seen on the right).

So, for this version, I am am prioritising things that are more universal, things such acceleration and steps, for instance, are universal to lathes, mills, and CNC touches. If there is room left over, who knows.

If I envisioned a second version of this interface, it would have sub-menus, but I feel that would be too high a bar for a first version. Additionally, I feel that sub-menus should be used sparingly because I never want to disorient the user.

[There was a GUI saying that everything should be discoverable by 3 clicks.]

I need to remember to include calibration, as provided in Axis, and look through the .ini for things I have had to adjust more than once.

Last edit: 21 Jul 2018 07:18 by BrendaEM.

The following user(s) said Thank You: Todd Zuercher, tommylight, emilvv

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

23 Jul 2018 03:25 - 23 Jul 2018 03:29 #114683

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Experimental conflicted Machine menu ponderings....

StepConf didn't really configure my VFD.

I don't know if StepConf will support this GUI.

I want to be be able to adjust software limits on the fly.

I would like to be able to tweak speeds.

My feelings aside, people will come with pitchforks and torches if there is no screw calculator.

We have a whole menu space to configure a machine.

The UI should be non-hardware specific.

So, what I am considering....

* The UI needs to know which type of machine it is using.

* Trying to support four spindle types: On/Off, Low/Med/High, PWM, RS-485/Serial.

* Include a minimal screw calculator.

* Include a tester such as StepConf has, because it would be advantageous to have a way to test the spindle with a software on/off control on the same page.

No, I don't think there is yet enough controls here to set up a machine, but what I want to avoid: two programs fighting over the same settings.

So for the first version of this interface, the user would use StepConf and/or to get the settings close, and then they could be further adjusted with this menu. Or, if the user wanted to limit the range of the machine for a temporary safety reason, it could be done.

This is just an experimental work in progress.

StepConf didn't really configure my VFD.

I don't know if StepConf will support this GUI.

I want to be be able to adjust software limits on the fly.

I would like to be able to tweak speeds.

My feelings aside, people will come with pitchforks and torches if there is no screw calculator.

We have a whole menu space to configure a machine.

The UI should be non-hardware specific.

So, what I am considering....

* The UI needs to know which type of machine it is using.

* Trying to support four spindle types: On/Off, Low/Med/High, PWM, RS-485/Serial.

* Include a minimal screw calculator.

* Include a tester such as StepConf has, because it would be advantageous to have a way to test the spindle with a software on/off control on the same page.

No, I don't think there is yet enough controls here to set up a machine, but what I want to avoid: two programs fighting over the same settings.

So for the first version of this interface, the user would use StepConf and/or to get the settings close, and then they could be further adjusted with this menu. Or, if the user wanted to limit the range of the machine for a temporary safety reason, it could be done.

This is just an experimental work in progress.

Last edit: 23 Jul 2018 03:29 by BrendaEM.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Jul 2018 13:02 #114747

by andypugh

Given that Stepconf is a fair bit of work to keep up o date, and that PnCConf is impossible to make 100% effective I think that even trying to subsume both of them into a GUI would be crazy

Basic machine config should be a one-time process. By all means have over-rides and maybe transient limit changes in the GUI, but I don't think that the GUI should be making persistent config changes. (I actually think that the Axis "Calibrate" menu item would be better as a stand-along tuning-specific GUI that gave a choice of test patterns and monitored the critical "stuff")

Replied by andypugh on topic A Widescreen Blender-Style Interface

So for the first version of this interface, the user would use StepConf and/or to get the settings close, and then they could be further adjusted with this menu

Given that Stepconf is a fair bit of work to keep up o date, and that PnCConf is impossible to make 100% effective I think that even trying to subsume both of them into a GUI would be crazy

Basic machine config should be a one-time process. By all means have over-rides and maybe transient limit changes in the GUI, but I don't think that the GUI should be making persistent config changes. (I actually think that the Axis "Calibrate" menu item would be better as a stand-along tuning-specific GUI that gave a choice of test patterns and monitored the critical "stuff")

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

24 Jul 2018 18:33 - 24 Jul 2018 18:52 #114756

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

I know that my configuration is unusual, but I would still like to try different speeds and accelerations. I've done a lot of hand editing in my .ini on the way of getting it going.

For better or worse, one of the most popular spindle VFDs, is not supported in StepConf in Modbus nor, the High/Middle/Low pin method. To be more pragmatic than diplomatic, if I cannot count on StepConf now, why would I in the future?

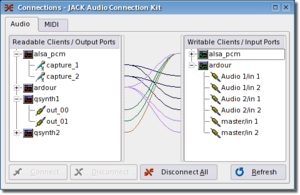

In V1 of a new user interface I am not trying to do what would I feel be ultimately best, but it I were it would be a GUI way to name and connect HAL signals, and save the file, like is routinely done with JACK audio connection kit, like this:

Anyway, back to V1 of this interface....

I am also trying to consider LinuxCNC's presence. Many other CNC programs have setup pages. People will expect that CNC could be set up by someone with some knowledge without problems.

In the previous mockup, there is no parallel-port connection interface. Perhaps USB/Something else will win out in the end, but it would be cool if the settings were modular, such as the machine controls, as if there was a StepConf that the user could choose from a list of possible interchangeable pages.

In a way, looking at the interface, for V1, is there a way that the GUI can support most machines without excluding others?

~

Andypugh, it has been my observation that while you are not the only person helping people on these forums, you are likely one of the most helpful people on the forums. Thank you.

For better or worse, one of the most popular spindle VFDs, is not supported in StepConf in Modbus nor, the High/Middle/Low pin method. To be more pragmatic than diplomatic, if I cannot count on StepConf now, why would I in the future?

In V1 of a new user interface I am not trying to do what would I feel be ultimately best, but it I were it would be a GUI way to name and connect HAL signals, and save the file, like is routinely done with JACK audio connection kit, like this:

Anyway, back to V1 of this interface....

I am also trying to consider LinuxCNC's presence. Many other CNC programs have setup pages. People will expect that CNC could be set up by someone with some knowledge without problems.

In the previous mockup, there is no parallel-port connection interface. Perhaps USB/Something else will win out in the end, but it would be cool if the settings were modular, such as the machine controls, as if there was a StepConf that the user could choose from a list of possible interchangeable pages.

In a way, looking at the interface, for V1, is there a way that the GUI can support most machines without excluding others?

~

Andypugh, it has been my observation that while you are not the only person helping people on these forums, you are likely one of the most helpful people on the forums. Thank you.

Last edit: 24 Jul 2018 18:52 by BrendaEM.

Please Log in or Create an account to join the conversation.

- AnnoyingMutt

-

- Visitor

-

24 Jul 2018 20:49 #114766

by AnnoyingMutt

Replied by AnnoyingMutt on topic A Widescreen Blender-Style Interface

I tend to agree with Andy.

A Thought for Consideration.

Having access to major setup areas in the GUI will tempt people to "play with the big red button" so to say. If you still went along this road there would be the need for a mechanism (say in a job shop environment) to prevent access to this feature. Maybe a startup option or some kind of password ?

Many discussions regarding USB as to why it is not supported for motion control.

A Thought for Consideration.

Having access to major setup areas in the GUI will tempt people to "play with the big red button" so to say. If you still went along this road there would be the need for a mechanism (say in a job shop environment) to prevent access to this feature. Maybe a startup option or some kind of password ?

Many discussions regarding USB as to why it is not supported for motion control.

Please Log in or Create an account to join the conversation.

- grijalvap

-

- Offline

- Elite Member

-

Less

More

- Posts: 197

- Thank you received: 63

26 Jul 2018 01:46 #114850

by grijalvap

Replied by grijalvap on topic A Widescreen Blender-Style Interface

Here is my opinion, I think configuration should be a separate GUI, It is possible to add a very basic configuration or tuning section on the GUI and always it should be password protected.

I understand we all want the best interface, however, I think the project should have a scope.

I mean can be divided into stages, with a defined scope.

please, don't get me wrong, I really like the design, and appreciate the great work.

I understand we all want the best interface, however, I think the project should have a scope.

I mean can be divided into stages, with a defined scope.

please, don't get me wrong, I really like the design, and appreciate the great work.

Please Log in or Create an account to join the conversation.

- Aaroncnc

- Offline

- Elite Member

-

Less

More

- Posts: 204

- Thank you received: 45

26 Jul 2018 15:00 #114891

by Aaroncnc

Replied by Aaroncnc on topic A Widescreen Blender-Style Interface

I have to say this is the nicest interfaces i have seen in a while.

I was wondering when this might enter alpha stage and people could test it out and give feedback?

I was wondering when this might enter alpha stage and people could test it out and give feedback?

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

Time to create page: 0.290 seconds