A Widescreen Blender-Style Interface

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

08 Jul 2018 21:21 - 08 Jul 2018 21:25 #113841

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

If what I might have done so far will mean anything, then let me finish what I started. I Have to be done with this in a month or two, and I am leaning toward finishing in less than one.

Tommylight, are you not asking one contributor to circumvent another?

If I have an issue, it's not with the level of compliment paid, it is about common respect.

If people go around me, when my proposal is 7:11 done, it may send a message to others, that a LinuxCNC contributor should not ask for the opinions of others, should not be considerate of the needs of the users.

Tommylight, are you not asking one contributor to circumvent another?

If I have an issue, it's not with the level of compliment paid, it is about common respect.

If people go around me, when my proposal is 7:11 done, it may send a message to others, that a LinuxCNC contributor should not ask for the opinions of others, should not be considerate of the needs of the users.

Last edit: 08 Jul 2018 21:25 by BrendaEM.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21158

- Thank you received: 7224

08 Jul 2018 21:22 #113842

by tommylight

I am sorry if it came through like that.

Replied by tommylight on topic A Widescreen Blender-Style Interface

No need for apologies, it was not intended to end the discussion, just to nudge it to the right direction.my bad, apologies to all!

I am sorry if it came through like that.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21158

- Thank you received: 7224

08 Jul 2018 21:28 #113844

by tommylight

Replied by tommylight on topic A Widescreen Blender-Style Interface

NO!Tommylight, are you not asking one contributor to circumvent another?

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

08 Jul 2018 21:43 - 08 Jul 2018 22:04 #113846

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Thank you, Tommy.

My wish is to continue making the the few remaining menus, and submit my proposal to the LinuxCNC community, before forks from the my designs are counter proposed. It is also my wish to lead this design until then. There is a difference between a suggestion and a counter-proposal, and there will be plenty of time for those after I am done. When I am done, I won't even defend this design. In fact, I likely won't be able to work on it.

People comment on how the interface looks, well I've merged a lot of ideas. I've come up with a way of displaying a few controls. One of those has only been improved upon recently.

I feel that the strongest thing I bring here: is just taking the time to come up with an interface as a system, and that has taken time. In the end, the programmers will have to make changes. If I am successful, this will not be the last interface in this series, but I strongly feel that it would be to LinuxCNC's advantage to have a complete outline before writing or in this case programing the book.

I think that the most time-efficient way to do things: is to already know what to do, and if what I will propose what to do is not the right thing to do, then why not let me show you the pitfalls.

My wish is to continue making the the few remaining menus, and submit my proposal to the LinuxCNC community, before forks from the my designs are counter proposed. It is also my wish to lead this design until then. There is a difference between a suggestion and a counter-proposal, and there will be plenty of time for those after I am done. When I am done, I won't even defend this design. In fact, I likely won't be able to work on it.

People comment on how the interface looks, well I've merged a lot of ideas. I've come up with a way of displaying a few controls. One of those has only been improved upon recently.

I feel that the strongest thing I bring here: is just taking the time to come up with an interface as a system, and that has taken time. In the end, the programmers will have to make changes. If I am successful, this will not be the last interface in this series, but I strongly feel that it would be to LinuxCNC's advantage to have a complete outline before writing or in this case programing the book.

I think that the most time-efficient way to do things: is to already know what to do, and if what I will propose what to do is not the right thing to do, then why not let me show you the pitfalls.

Last edit: 08 Jul 2018 22:04 by BrendaEM.

The following user(s) said Thank You: tommylight, emilvv

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

09 Jul 2018 13:58 #113874

by andypugh

This is probably true. I don't have an ATC on my mill, but I am still really glad to have the drawbar that I made . It significanlty lowers the bar to such things as popping the probe back in to make sure of something, or putting a milling cutter in to machine a counterbore by spiral cutting rather than putting something nearly the right size in the already-installed drill chuck.

Replied by andypugh on topic A Widescreen Blender-Style Interface

My guess is within the next few months of real use you will be desperately looking for a solution to your tool changing situation. this isn't to say an ATC, but looking for some way to make it faster and easier than having to get wrenches out.

This is probably true. I don't have an ATC on my mill, but I am still really glad to have the drawbar that I made . It significanlty lowers the bar to such things as popping the probe back in to make sure of something, or putting a milling cutter in to machine a counterbore by spiral cutting rather than putting something nearly the right size in the already-installed drill chuck.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

09 Jul 2018 14:11 #113876

by andypugh

They define offsets in all the available G-code directions. They may not be be used very much, but take this example machine where there is a permanently-mounted probe behind the spindle position. The probe will need both a tool-length and also an X and Y offset (and a diameter) to be useful.

I am not sure that the ABC offsets see much use, but you can imagine that they might be needed if using a 5-axis tool coordinate system and a robot arm. Or the C offset could be used for back-boring where the tool needs to be "fiddled" out (so the actual angular relationship with the spindle is needed)

Replied by andypugh on topic A Widescreen Blender-Style Interface

What are all the extra tool-table dimensions for?

They define offsets in all the available G-code directions. They may not be be used very much, but take this example machine where there is a permanently-mounted probe behind the spindle position. The probe will need both a tool-length and also an X and Y offset (and a diameter) to be useful.

I am not sure that the ABC offsets see much use, but you can imagine that they might be needed if using a 5-axis tool coordinate system and a robot arm. Or the C offset could be used for back-boring where the tool needs to be "fiddled" out (so the actual angular relationship with the spindle is needed)

The following user(s) said Thank You: KCJ, BrendaEM

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

09 Jul 2018 21:48 - 09 Jul 2018 21:51 #113895

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Perhaps, when the drawings are done, there could be two sets of milling diagrams: one for automatic tool changers that reference what need to, and one that references the collet, or what-have-you for use in manual mills.

I am sure that it's just a newbe thought, I wondered if a user could use the extra variables in the table for something.

~

Andy, nice power draw bar setup. Is the tool held in there by a spring, and the air just opens it

I am sure that it's just a newbe thought, I wondered if a user could use the extra variables in the table for something.

~

Andy, nice power draw bar setup. Is the tool held in there by a spring, and the air just opens it

Last edit: 09 Jul 2018 21:51 by BrendaEM.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

09 Jul 2018 22:31 #113904

by andypugh

Yes, a stack of Belleville washers in the usual way.

Replied by andypugh on topic A Widescreen Blender-Style Interface

Andy, nice power draw bar setup. Is the tool held in there by a spring, and the air just opens it

Yes, a stack of Belleville washers in the usual way.

The following user(s) said Thank You: BrendaEM

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

09 Jul 2018 23:12 #113905

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

Oddly, I am familiar with them. There's a few in the fine axis, a few pages pack on this thread.

It's good to see people make something other than landmines from them.

It's good to see people make something other than landmines from them.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

Less

More

- Posts: 266

- Thank you received: 120

09 Jul 2018 23:23 - 10 Jul 2018 05:43 #113906

by BrendaEM

Replied by BrendaEM on topic A Widescreen Blender-Style Interface

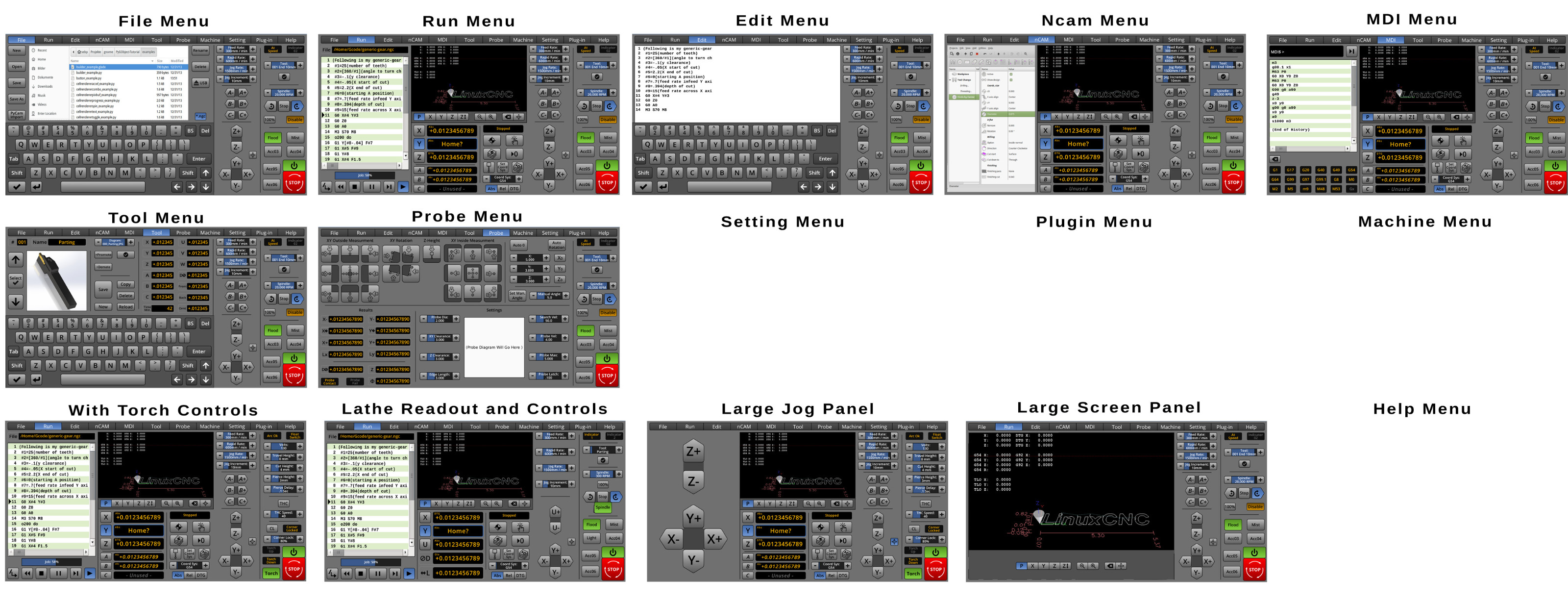

This is a progress report:

Most of the menus are laid out. There are machine controls for Torches and Mills, as well. There are overlay panels for Large Screen, Keyboard, and Large jog.

What's left to design: 2 menus and a few tweaks.

* Setting Menu: Next on the list for most user settings, such as increments, paths, and choosing a plugin. This menu will only be a rough guide as the programmer(s) will be able to include often-used settings here.

* Machine Menu, may have controls for HAL-related things, as Halscope and Halmeter.

* Plug-In, not much to do, this menu will only display whatever the plug-in will do with either 1/3 or 2/3 of the screen, not much to do.

* Help Menu, there not much to do as it will just display a help file.

Some tweaks:

* Remove PyCAM button. Too much will have to be done to Pycam for integration in this version, perhaps the next.

* Add copy/cut and paste buttons, and a few User buttons on MDI. There's room for them, might as well.

* Check Probe and Tool Menu.

Notes:

* For something like NCam, it could either 1/3 or 2/3 or, most of the screen--except the machine-specific controls on the right. The probe menu is also large, and the largest the design supports.

I've read a lot of your feedback, and am trying my best to do the best I can for LinuxCNC. Thank you to Lcvette for making the great looking lathe tool. Thank you for your patience, help, feedback, and support.

(For those with large monitors, the thumbnail image is in 4K. The interface itself was designed for 1920x1080 widescreen, and above.)

Most of the menus are laid out. There are machine controls for Torches and Mills, as well. There are overlay panels for Large Screen, Keyboard, and Large jog.

What's left to design: 2 menus and a few tweaks.

* Setting Menu: Next on the list for most user settings, such as increments, paths, and choosing a plugin. This menu will only be a rough guide as the programmer(s) will be able to include often-used settings here.

* Machine Menu, may have controls for HAL-related things, as Halscope and Halmeter.

* Plug-In, not much to do, this menu will only display whatever the plug-in will do with either 1/3 or 2/3 of the screen, not much to do.

* Help Menu, there not much to do as it will just display a help file.

Some tweaks:

* Remove PyCAM button. Too much will have to be done to Pycam for integration in this version, perhaps the next.

* Add copy/cut and paste buttons, and a few User buttons on MDI. There's room for them, might as well.

* Check Probe and Tool Menu.

Notes:

* For something like NCam, it could either 1/3 or 2/3 or, most of the screen--except the machine-specific controls on the right. The probe menu is also large, and the largest the design supports.

I've read a lot of your feedback, and am trying my best to do the best I can for LinuxCNC. Thank you to Lcvette for making the great looking lathe tool. Thank you for your patience, help, feedback, and support.

(For those with large monitors, the thumbnail image is in 4K. The interface itself was designed for 1920x1080 widescreen, and above.)

Last edit: 10 Jul 2018 05:43 by BrendaEM.

The following user(s) said Thank You: tommylight, Lcvette, KCJ

Please Log in or Create an account to join the conversation.

Time to create page: 0.286 seconds