A Widescreen Blender-Style Interface

- Lcvette

-

- Offline

- Platinum Member

-

- Posts: 1536

- Thank you received: 726

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

- Posts: 1536

- Thank you received: 726

I do find it strange that there is no cutting length variable standard.

thats because this is a controller, it is not a CAM package, Cam is where your tooling is setup to detect collision avoidance and gouge detection. Brenda, I am not here trying to hurt your feelings, I am trying to help you understand why things are the way things are, they are a certain way because of many underlying reasons not just whimsicality. everything depends on something. the only needed measurements for a mill tool for the controller to run properly is the physical tool length in relation to the spindle gauge line in relation to the machine coordinate system and work coordinate offset and its diameter in order for it to process kinematics correctly. the rest is dictated by the cam. for a router using only one tool that never changes this may not be important as z zero is always the tool end, but when you change multiple tools, the machine controller MUST know that the z height changes in relation to the work coordinate offsets or the tool will cut air or plunge into the part after changing out the tool for the next.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

- Posts: 266

- Thank you received: 120

In other words, in your discussion, it appears that you have put the carriage before the horse, the object before the class.

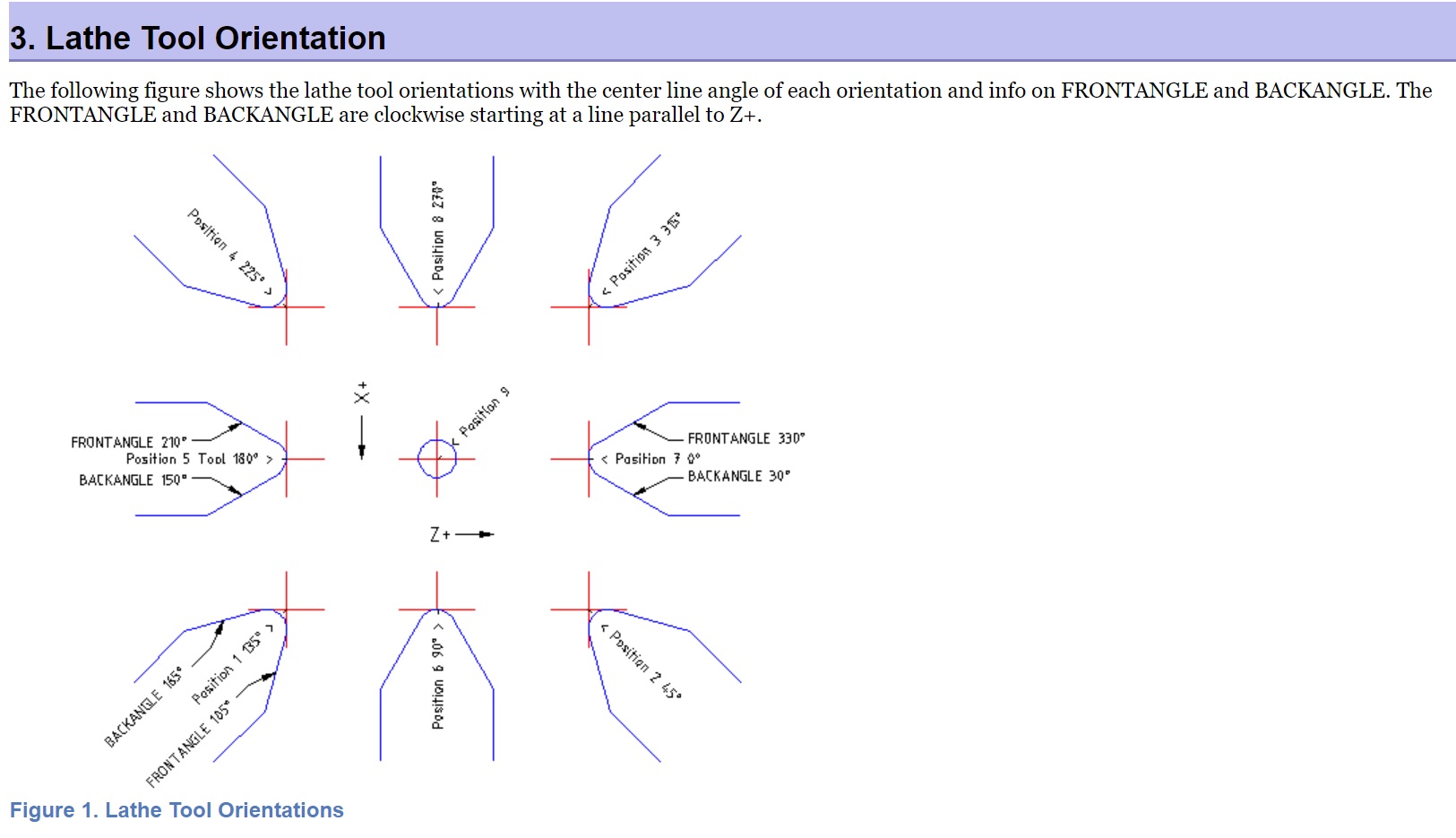

It appears that you wrote of position, when even the manual refers to it as orientation.

Yes, of course there should be some representation of tool Orientation.

I will reiterate that there will not likely be enough programmer to create a new menu for every tool. So, I still think the best option is to have a single picture for each tool type that depicts everything they need to know how to enter it in the tool table--all in one drawing.

(I have discussed my opinions of the manual, its organization, navigation, but not it's presentation, elsewhere on this forum. At this point, I really wouldn't care about the presentation if other ducks were in a row, but in my opinion, they are not.)

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

- Posts: 1536

- Thank you received: 726

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

- Posts: 266

- Thank you received: 120

Please also point out where you objected to anyone here on the forum that Axis is router only.

From the get-go, I wanted to support mills, lathes, and plasma/torches. There is a long preceding thread that where I state so.

I do not agree with your assertion that making it router-inclusive is router-only.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

- Posts: 1536

- Thank you received: 726

I want to be respectful of just how much programming it will or would take get this thing working. And so, the first iteration isn't going to have all the bells and whistles. It's been my experience that the, well products, that succeed well do most things well, and the ones that do one thing exceptionally well may not make it.

The world is changing. The CNC router is becoming a common garage tool. Everyone's doing it. While the needs of the professional should be addressed, yes, but the needs of even the home hobbyist should be addressed too, because one of them is working on this interface, and there will be more where I came from.

I interpret that to read you will leave out the important parts of the control you deem unworthy for parts important to your agenda, if i'm mistaken explain it another way. but as of right now everything i've suggested gets batted away so I don't have a lot of faith you mean anything but what i interpreted.

If i'm going to enlist in helping build something for everyone, it should be for everyone and encompass everything not just one thing, it should be something open for discussion to be made better rather then fall into the ruts of the same bad habits of past guis, otherwise you're simply redressing an existing gui without addressing issues that should be given attention. I don't want to speak for Kurt, but maybe instead of assuming thats where his heads at, ask. lets form a discussion on it. I know you initialized the project but when more people come on to help, sometimes the best option is to reevaluate the scope of the project to see what could be made better along the way to avoid rushing *something* out. by showing flexibility, especially in the front of making something better for the end user more functional and powerful as a tool, it will draw in more help and interest is my guess, which will lighten the load. by being closed off you will have your vision discovered but then its that, your vision, restricted to your experience which i gotta say, seems limited. again not an attack just an observation you should consider. relax your grip on the reigns a little bit and you may be surprised at what a collaboration yields. tighten it and you'll never know.

Please Log in or Create an account to join the conversation.

- BrendaEM

- Offline

- Elite Member

-

- Posts: 266

- Thank you received: 120

A few people have asked me to call this already done, and export the graphics before it was done. While I haven't rushed things out, I likely won't be able to work on the interface at all, in a month or two, so is far as my involvement, my final proposal must be done in a month or two. That's it, and and there's nothing I can do about that--even if I wanted to.

Though, it's been almost two months. I have put hundreds of hours into this project. The filename is bumped up to 199. It needs to be done at some point. I think it's still at 7:11 menus, which means there's about 4 to go.

Keeping things into perspective, the entire graphical layout and a user interface itself would be only a small part of LinuxCNC. We stand on the shoulders of giants.

I can't tell you how to feel. We are all different. Though perhaps you should have some solace that if you offer a counter-proposal after this, it will probably work out for you.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21158

- Thank you received: 7224

Maybe it is just me, but i see no reason for dragging this to the extent that users get bored and move on to using whatever they were using before this. I am one of those users, reading this thread every day, several times a day for nearly 2 months now, just to find some .......well useless ....whatever. Sorry but i do not know how to name most of what is going on here lately.

This would have gone much better if those pictures ( sorry for calling them pictures, but that is all they are right now ) that Brenda spent huge amounts of time designing were already uploaded here and we ( i am looking at you KCJ ) had the chance to start making something with them, do some testing, make it usable and actually see what is working and what needs to be done to make it almost perfect.

Thank you for all the hard work.

P.S.

Admins, if you think any of this is inappropriate, please do delete this post. Thank you.

FYI i have several ( 6 or 7 ) machines that have full HD monitors on them working on 4 more, the smallest is 22", biggest 24". Take this as you will, but it would have been nice to see this on all of them.

Please Log in or Create an account to join the conversation.

- Lcvette

-

- Offline

- Platinum Member

-

- Posts: 1536

- Thank you received: 726

All this talk is doing nothing towards getting those beautiful pictures Brenda made to an actual usable GUI for our dearly beloved Linuxcnc.

Maybe it is just me, but i see no reason for dragging this to the extent that users get bored and move on to using whatever they were using before this. I am one of those users, reading this thread every day, several times a day for nearly 2 months now, just to find some .......well useless ....whatever. Sorry but i do not know how to name most of what is going on here lately.

This would have gone much better if those pictures ( sorry for calling them pictures, but that is all they are right now ) that Brenda spent huge amounts of time designing were already uploaded here and we ( i am looking at you KCJ ) had the chance to start making something with them, do some testing, make it usable and actually see what is working and what needs to be done to make it almost perfect.

Thank you for all the hard work.

P.S.

Admins, if you think any of this is inappropriate, please do delete this post. Thank you.

my bad, apologies to all!

Please Log in or Create an account to join the conversation.

- AnnoyingMutt

-

- Visitor

-

Careful what you say guys, that report button may get used.

Please Log in or Create an account to join the conversation.