Work with probe

- mwidlok

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 15

github.com/verser-git/probe_screen_v2.8

It runs on Linuxcnc 2.10, python3 and gtk3. I'm not cnc specialist in any way so treat it as "base" for further work/testing.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11626

- Thank you received: 3913

Here we go again. This isn't ProbeBasic. That is a QTPYVCP GUI.

Seems to give me a running ProbeBasic config on a master RIP installation. However I cannot test actual probing since I do not have a probe.

Please use the git repo name Probe Screen so we know what you are referring to.

Too many similar names is confusing Tommy and a lot of others!

PS, if you have a look at the QTplasmac SIM, it includes a simulated probe in a separate screen. I think qtdragon may also have a probe simulation. But you can probably just use the sim_pin component to turn the probe signal on from a sim in the absence of QT.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Away

- Administrator

-

- Posts: 4632

- Thank you received: 2049

Please Log in or Create an account to join the conversation.

- Roguish

-

- Offline

- Elite Member

-

- Posts: 297

- Thank you received: 31

I use qtdragon on my new small mill, and axis on my old big mill.

With axis, I like 'probe screen' by verser. So, I am interested in both.

Qtdragon is coming along, slowly but it is....

I guess 'probe screen' is good for 2.8, but still needs work for master.

Those working on it should not just post fixes here, but do it officially on github.

Not speaking for verser, but I bet he would appreciate the help.

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 8

The problem isn't fixes as much as a different approach to using the system. I don't want to measure every tool since the TTS allows me to have pre-measured tools in the tool table. And only if the tool table length is zero use the tool height sensor.

And for measuring tools I'd rather see the screen have a measure tool button which then inserts the measured value, not relative to the workpiece, but absolute value, into the tool table.

Each new version of the PSNG also appears to move things around and create a different user interface which I find confusing.

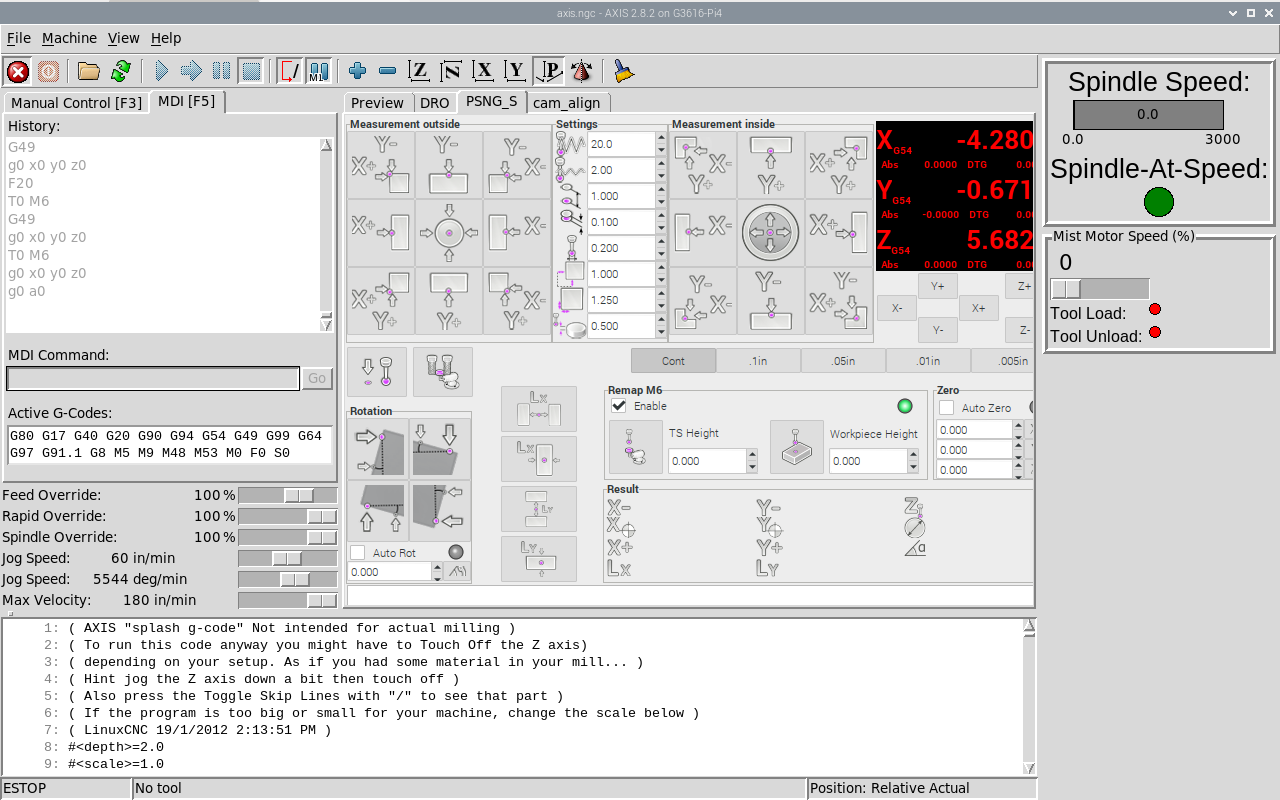

Finally, and at the moment this is a bigger issues as I play with the Pi4 and LinuxCNC is that the new 1200x800 LCD touch screen I just installed doesn't work well with the icons_1024x768 and psng1024x768.glade.

The <object class="GtkHBox" id="hbox4"> doesn't fit in the AXIS tab so none of the messages are visible.

A little bit of the text box shows up if I autohide the menu bar. But it doesn't look like the screen was actually set up for the 1200x800 size screen.

Attachments:

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 8

Loading psng_1024x768.glade results in "The following required catalogs are unavailable: gladevcp"

Click OK and continue and the next error is:

psng_1024x768.glade targets Gtk+2.16 But this version is for GTK+ 3.

Make sure you can run this project with Glade 3.8 with no deprecated wigits first.

Especially because there are 8 objects that can not be built with types: EMC_Action_Reload, Combi_DRO, HAL_LED, ToolEdit

What's the approach to be able to work with this glade file? My first time mucking with glade so have no idea where to start.

Please Log in or Create an account to join the conversation.

- lrak

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 22

I'm getting this error now:

AttributeError: 'Combi_DRO' object has no attribute 'joint_no'

Traceback (most recent call last):

File "/usr/lib/python3/dist-packages/gladevcp/combi_dro.py", line 509, in _homed

self.homed = self.status.homed[self.joint_no]

,.,

The tool change part is not working either. Complains about moving out of the machine range of motion.

,.,.

@mwidlok

As per the Chinese probe, as per quality, what I'm seeing is similar to what happened with Japan in the 1960's - everyone talked about "Jap junk", but that turned into what you bought for the best car just a few years later. China is bigger and the improvements will be spottier - but the disappointing bits I buy from China keep getting better.

I found a cheap Chinese probe tip I used with my printed version of Andy's probe - Messing around I broke it - I was going to thread the end - but it turned out the probe shaft was made of carbide - not junk.

The Chinese ones use the same 6-ball +3 rod design that you see in a Renishaw. Renishaw claims a 1um resolution - the Chinese one I looked listed 10um. Lots of little details make the difference in resolution - centering screws/ thread for the probe / accuracy of the rods/balls - stiffness of the probe - length of the probe - etc etc. The biggest problem I see is most often we are touching off in x-y but the probe is triangular in function. The printed version I made of Andy's probe seems to be around 10um - the carbon-fiber filled nylon is pretty stiff.

The puzzle I was thinking about is why some probes are not based on electrical contact? (Wouldn't work with non conductive materials) - the electrical contact would mostly be limited by surface roughness. I suspect there is a reason that I don't know about?. Another technology I thought about was to mount a probe on a Piezo transducer - These are capable of VERY fine resolution - used in atomic-force microscopes. I'm sure others have thought of the same things. Wonder why they are not on the market? <a few searches later> - yes, others have looked at the same idea.

hackaday.io/project/9193-piezoelectric-cnc-touch-probe

Please Log in or Create an account to join the conversation.

- Roguish

-

- Offline

- Elite Member

-

- Posts: 297

- Thank you received: 31

I too have TTS for my small mill, but large NMTB40 holders.

Not sure what to do for the TTS, but I did just purchase a tool setter from verser, so it's time to address it....

RodW has been working quite a bit with the qtvcp probing, and is dang good at programming and everything. check his post out....

Figure out what you would like to see and contact verser. He's also good and helpful.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11626

- Thank you received: 3913

For my TTS tooling, I bought the little granite plate Tormach have and a digital height gauge. This lets me measure tools on the workbench and enter into the tool library. That way there is no need to use a toll setter. I have not done any work with qtdragon probing,ok, well, there are definitely different approaches to tool length settings. I have not used any of the probing routines for it, yet.

I too have TTS for my small mill, but large NMTB40 holders.

Not sure what to do for the TTS, but I did just purchase a tool setter from verser, so it's time to address it....

RodW has been working quite a bit with the qtvcp probing, and is dang good at programming and everything. check his post out....

Figure out what you would like to see and contact verser. He's also good and helpful.

I've just given Chris some feedback...

Please Log in or Create an account to join the conversation.

- lrak

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 22

That makes sense to me - I suspect it is often the case (like mine) that the knee has no scale input - so you would have to go through convoluted things to match the probe length to the knee height anyway. One could make a swing-out toolsetter table that would always be at the same height - not sure it would be worth it. (I'm trying to figure a way to add tools from FreeCAD without overwriting other tool lengths.. I guess meld would work..)

I think I will make a Piezo probe - (Piezo would make a good tool setter as well).

Please Log in or Create an account to join the conversation.