Work with probe

- lrak

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 22

I am looking to do some probing with a redesigned probe based on Andy's work:

lrak.net/uploads/simplescreenrecorder-2023-07-14_12.48.24.mkv

I saw the probescreen in several places on github - but found probe bits linuxcnc-userspace itself.. not sure if this is the same thing? Anyway, where would I find the current probe install instructions?

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 8

forum.linuxcnc.org/49-basic-configuratio...obe?start=550#232195

Please Log in or Create an account to join the conversation.

- lrak

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 22

Most of the forks on github don't seem to have active changes - The one you pointed me at:

github.com/andypugh/probe-screen-ng 2 months

github.com/alkabal/PSNG_V3 6-months

github.com/linuxcnc-probe-screen/probe-screen-ng 2years

github.com/verser-git/probe_screen_v2 4 years

qtDragon screens

Which one should I try for linuxcnc_userspace 2.9 ? (I'm thinking the one Andy is working on?).

Please Log in or Create an account to join the conversation.

- JPL

- Offline

- Platinum Member

-

- Posts: 337

- Thank you received: 118

Updated 2 weeks ago (not counting the readme)

See ref here: forum.linuxcnc.org/49-basic-configuratio...obe?start=590#274688

But I agree, there is way too many version of the damn thing

Please Log in or Create an account to join the conversation.

- JPL

- Offline

- Platinum Member

-

- Posts: 337

- Thank you received: 118

Then NONE of the current verser version will work for you because of python incompatibility.OK - I just upgraded to 2.9.0

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11653

- Thank you received: 3924

Just to add to the confusion probing by versby and basic probe are already included in QT_DRAGON in V2.9 . This is probably where changes need find their way to as that's where most probing activity can be expected once 2.9 is released.I'm trying to figure out which fork people are using.

Most of the forks on github don't seem to have active changes - The one you pointed me at

Which one should I try for linuxcnc_userspace 2.9 ? (I'm thinking the one Andy is working on?).

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 8

Part of the problem is I believe the design philosophy was to place the tool setter on top of the work (perhaps a sheet of MDF on a CNC router) and be able to probe various configuration edges etc. The PSNG screen is an amazing bit of work but it keeps changing appearance on each iteration and likely the code keeps changing too.

So for now I'm staying with 2.8 and I've now got several processes in place.

1. Probe the tool setter to determine the length of the tool tip to the quill and put that into the tool table.

2. For tools like R8 collets that hold various cutters with different shanks the length in the tool table for that tool # is 0.

3. Same with Drill Chucks unless you have several for one project and the drill bits stay in them for the entire project in which case measure them.

4. On a tool change if there is a valid length then use that to set the new work space Z zero position.

5. If there isn't a length go probe the tool setter.

6. Finally , normally, the M06 macro does not perform a tool change if the requested tool is the same as the currently mounted tool. What I've done is forced a re-probe at the tool setter if the length in the tool table is 0. This avoids doing a T00 M06 G9 and then a T5 M06 G43. Instead a T5 M06 G43 will result in a tool measurement after I put a new drill bit in the drill chuck (TTS Tool #5).

I still need to do more testing before I post the modified code.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11653

- Thank you received: 3924

Then install QTDRAGON_HD on V 2.9 and use it's version inspired by verser.

OK - I just upgraded to 2.9.0

Then NONE of the current verser version will work for you because of python incompatibility.

Please Log in or Create an account to join the conversation.

- verser

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Posts: 78

- Thank you received: 69

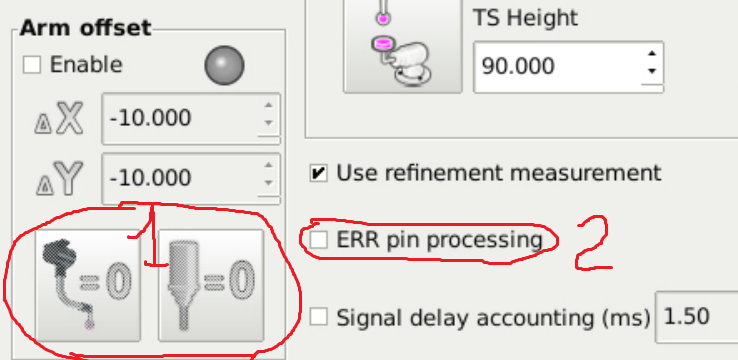

First question. These buttons only set to 0 the current coordinate system for arm or spindle, but do not physically move the axes.Serg452 wrote:

What is the value of the buttons (1) if the enable measurement is still pressed with an offset?

What does the ERR check mean (2)?

Second question. I made edits to the 'ERR pin proccessing' code yesterday ( Probe Screen v2.8.3 ) and am preparing the information for the User Guide. This checkbox will be useful for users of wireless probes, such as Vers WLR v7, in which radio signal delay is critical. The ERR pin is physically connected to the CNC controller and signals an abnormal delay in radio. Probe Screen will repeat the measurement if an ERR signal occurs.

Probe Screen can also handle any delay. Not only from wireless probes. For example, Connection Module Vers CM in anti-vibration mode generates a fixed delay of 5 ms, which must be taken into account.

This is an important question. And it looks like simple advice is not enough. I'll try to make an appropriate update.Serg452 wrote:

Another question. The remap enable button has disappeared. I use a tool in a cone BT40 and every time there is no need to measure. What should I do?

Please Log in or Create an account to join the conversation.

- lrak

-

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 22

I've written in a bunch of languages, but not python - (I'm thinking I'm too old to learn yet another language.. )

Perhaps something else changed in the latest version of LinuxCNC?

Please Log in or Create an account to join the conversation.