Work with probe

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

10 Jun 2023 18:35 #273283

by andypugh

Replied by andypugh on topic Work with probe

This problem sounds like something is wring with the wiring of hal_manualtoolchange in the HAL file.

Do you want/need the dialog box popup?

Do you want/need the dialog box popup?

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 8

27 Jun 2023 01:48 - 27 Jun 2023 03:28 #274291

by jcdammeyer

Replied by jcdammeyer on topic Work with probe

I've not finished the code yet. Haven't used the mill for anything since I started playing with that and it was a few months ago. Hopefully I documented enough of what I did in the MillMockup.pdf I've attached.

Clearly more than a year later as I start to use this again my documentation was not sufficient. I've forgotten everything I've done and am once again confused. I should have had more information in that PDF. At the moment I'm not getting the tool length properly calculated and therefore changing a tool does not correctly change the parameters so the tip of the tool matches where the previous tip was.

I'm sure I'll figure it out and then write up a more detailed step by step. I'm using the rev 2 of the Probe screen since I don't like the rev 3 version layout. At the moment I can't even remember why there's the Remap M6 and Auto Zero check box.

I know if the Remap M6 Enable is checked that then a tool change causes the move to the tool-setter and causes the tool length to be measured and the value put into the tool table. The G43 should then also offset the Z position so the Z=0 point moves.

Not sure what the Auto Zero check box is for.

More when I figure it out again.

Last edit: 27 Jun 2023 03:28 by jcdammeyer. Reason: Make old message different from new.

Please Log in or Create an account to join the conversation.

- verser

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 69

27 Jun 2023 04:26 - 27 Jun 2023 05:03 #274293

by verser

Replied by verser on topic Work with probe

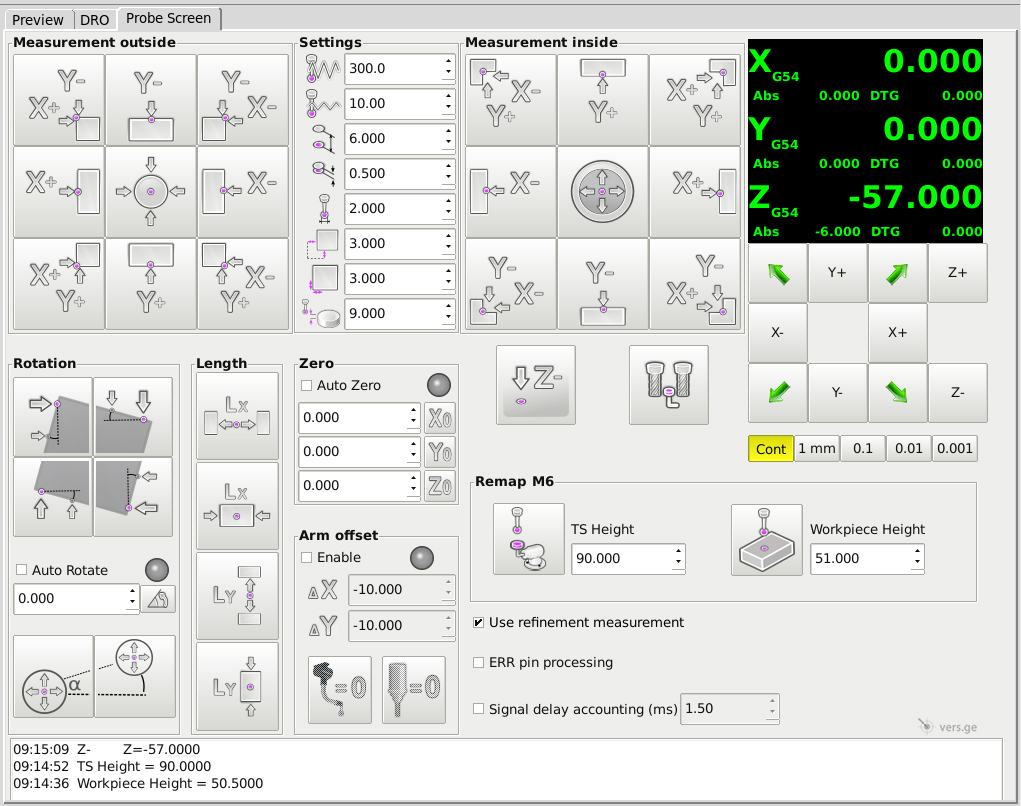

Probe Screen v2.8 update - all commonly used probe macros on one stylish screen, intuitive look, minimal steps to set up.

Сhanges:

►Designed for LinuxCNC v 2.8

►Included some additions from the PSNG development team

►First attempt to support metric and imperial

►Support for Axis and Gmoccapy interfaces, screens from 1280x1024

►Added diagonal movements

►Added rotation of coordinates by two holes

►Added probe arm support

►You can turn off the refinement measurement

►Accounting for signal delay from the probe

►Repeat measurement if an error signal is caught (for wireless)

►Tool diameter measuring with reverse rotation

Open source

Сhanges:

►Designed for LinuxCNC v 2.8

►Included some additions from the PSNG development team

►First attempt to support metric and imperial

►Support for Axis and Gmoccapy interfaces, screens from 1280x1024

►Added diagonal movements

►Added rotation of coordinates by two holes

►Added probe arm support

►You can turn off the refinement measurement

►Accounting for signal delay from the probe

►Repeat measurement if an error signal is caught (for wireless)

►Tool diameter measuring with reverse rotation

Open source

Attachments:

Last edit: 27 Jun 2023 05:03 by verser.

The following user(s) said Thank You: Roguish, GuiHue, jcdammeyer, itsme, Maik

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 8

27 Jun 2023 05:20 #274295

by jcdammeyer

Replied by jcdammeyer on topic Work with probe

Make sense to use this then. I'll install it and check it out tomorrow. I do want to change some things.

If the Z value in the tool table is 0 then measure it and replace it. If the value in the tool table is -1 then measure the tool and use it but don't change the tool table. If there is a positive value in the tool table just use it.

This takes care of a chuck with various drill bits, an R8 mounted tool but leaves alone pre-measured TTS tool holders.

If the Z value in the tool table is 0 then measure it and replace it. If the value in the tool table is -1 then measure the tool and use it but don't change the tool table. If there is a positive value in the tool table just use it.

This takes care of a chuck with various drill bits, an R8 mounted tool but leaves alone pre-measured TTS tool holders.

Please Log in or Create an account to join the conversation.

- itsme

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 21

27 Jun 2023 08:51 #274300

by itsme

Replied by itsme on topic Work with probe

Yes, this would be a good add on!Make sense to use this then. I'll install it and check it out tomorrow. I do want to change some things.

If the Z value in the tool table is 0 then measure it and replace it. If the value in the tool table is -1 then measure the tool and use it but don't change the tool table. If there is a positive value in the tool table just use it.

This takes care of a chuck with various drill bits, an R8 mounted tool but leaves alone pre-measured TTS tool holders.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

27 Jun 2023 13:41 #274305

by andypugh

github.com/andypugh/probe-screen-ng/comm...5cf18d2ae14cafb47766

Replied by andypugh on topic Work with probe

I don't now if you included this, but I made a patch to PSNG to switch to machine base units before probing.Probe Screen v2.8 update - all commonly used probe macros on one stylish screen, intuitive look, minimal steps to set up.

github.com/andypugh/probe-screen-ng/comm...5cf18d2ae14cafb47766

The following user(s) said Thank You: verser

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 8

27 Jun 2023 22:47 #274340

by jcdammeyer

Replied by jcdammeyer on topic Work with probe

I don't understand why the check box for M6 Enable has been removed. Once the tools installed in TTS holders have been measured and their lengths installed in the tool table there isn't a need to go over to the tool setter and measure them again.

If you are going to add a checkbox or method of changing between metric and imperial then the correct way, from a human factors engineering perspective, is to change all the values to the correct values. For example if you have metric checked and a box has 25.40 then when you uncheck metric or check imperial then the value in the box should change to 1.000

Similarly if metric is checked and you type in 1.000" and hit enter or leave the box the value should change automatically to 25.40. If however you type in 1.000 without the " then it redisplays as 1.00.

The system also doesn't appear to work with more than 3 decimal places and for imperial it should be 4.

If you are going to add a checkbox or method of changing between metric and imperial then the correct way, from a human factors engineering perspective, is to change all the values to the correct values. For example if you have metric checked and a box has 25.40 then when you uncheck metric or check imperial then the value in the box should change to 1.000

Similarly if metric is checked and you type in 1.000" and hit enter or leave the box the value should change automatically to 25.40. If however you type in 1.000 without the " then it redisplays as 1.00.

The system also doesn't appear to work with more than 3 decimal places and for imperial it should be 4.

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 8

27 Jun 2023 23:01 - 27 Jun 2023 23:04 #274342

by jcdammeyer

Replied by jcdammeyer on topic Work with probe

Andy,

He's modified the screen and removed the checkbox for enabling M6. He's also combined a number of the python files into one larger one.

So you changes aren't in his code below.

He's modified the screen and removed the checkbox for enabling M6. He's also combined a number of the python files into one larger one.

So you changes aren't in his code below.

# -------------------------- #

# Generic Probe Movement Methods #

# --------------------------

def z_clearance_down(self, data=None):

# move Z - z_clearance

s = """G91

G1 Z-%f

G90""" % (

self.halcomp["ps_z_clearance"]

)

if self.gcode(s) == -1:

return -1

return 0

Doesn't have your self.setunits feature.

And in addition, if a probe distance is 25.4mm and the machine is running metric a change to imperial would make it try to move 25.4" not 1"

Last edit: 27 Jun 2023 23:04 by jcdammeyer.

Please Log in or Create an account to join the conversation.

- verser

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 78

- Thank you received: 69

28 Jun 2023 03:37 - 28 Jun 2023 03:41 #274355

by verser

Replied by verser on topic Work with probe

Thank you for this work. I will study it and try to add.I don't now if you included this, but I made a patch to PSNG to switch to machine base units before probing.

github.com/andypugh/probe-screen-ng/comm...5cf18d2ae14cafb47766

Last edit: 28 Jun 2023 03:41 by verser.

The following user(s) said Thank You: Roguish

Please Log in or Create an account to join the conversation.

- jcdammeyer

-

- Offline

- Senior Member

-

Less

More

- Posts: 73

- Thank you received: 8

28 Jun 2023 05:34 #274359

by jcdammeyer

Replied by jcdammeyer on topic Work with probe

When I developed dual metric/imperial features for my Electronic Lead Screw I made the decision to keep all the units as one type. In the case of the ELS this was Imperial units because initially I didn't intend to make it dual. I then added a user settable flag for Metric units. So the lead screw pitch might be 10 TPI and it would be stored as 0.100. Each menu entry had a conversion routine so for pitch it didn't convert. For the TPI display menu it would call an invert function and show 10 TPI. And for the metric menu entry it called the convert to metric function and displayed 2.54.

If a user entered in 5mm as the lead screw metric pitch internally although the display remained as 5.00 the data stored was converted by the convert to imperial function and that value was saved to EEROM.

To make the the probe screen work with metric or imperial and respondent to the G20 G21 G-codes the same sort of operation must occur. If the MDI command is G20 is issued then the entire probe screen needs to be rewritten to display unit in imperial converted from the internally stored metric values. And ideally the data field should be parsed to measurement values.

The CAD software I use, AlibreCAD, allows this. If the drawing is configured as metric then entering a value in with the " symbol automatically converts it to metric. Add mm to a number in an imperial drawing and it's interpreted as metric. And if no units are specified it uses the drawing default.

If I go to the main menu and change the drawing units to be imperial then the drawing =11.0ptdimensions are all converted to imperial. Unfortunately the add on program AlibreCAM created by MECSOFT as a version of their VisualCAM was not as intelligent. A tool entered as 0.25" is not automatically configured to be 6.35mm. So if you load an imperial drawing and your tools are metric it thinks that mill is actually 6.35" in diameter. Very dumb.

Anyway, IMHO, I believe high end applications should work like this.

If a user entered in 5mm as the lead screw metric pitch internally although the display remained as 5.00 the data stored was converted by the convert to imperial function and that value was saved to EEROM.

To make the the probe screen work with metric or imperial and respondent to the G20 G21 G-codes the same sort of operation must occur. If the MDI command is G20 is issued then the entire probe screen needs to be rewritten to display unit in imperial converted from the internally stored metric values. And ideally the data field should be parsed to measurement values.

The CAD software I use, AlibreCAD, allows this. If the drawing is configured as metric then entering a value in with the " symbol automatically converts it to metric. Add mm to a number in an imperial drawing and it's interpreted as metric. And if no units are specified it uses the drawing default.

If I go to the main menu and change the drawing units to be imperial then the drawing =11.0ptdimensions are all converted to imperial. Unfortunately the add on program AlibreCAM created by MECSOFT as a version of their VisualCAM was not as intelligent. A tool entered as 0.25" is not automatically configured to be 6.35mm. So if you load an imperial drawing and your tools are metric it thinks that mill is actually 6.35" in diameter. Very dumb.

Anyway, IMHO, I believe high end applications should work like this.

The following user(s) said Thank You: verser

Please Log in or Create an account to join the conversation.

Time to create page: 0.348 seconds