Search Results (Searched for: 7i77 spindle)

- besriworld

- besriworld

Yesterday 02:56

Replied by besriworld on topic Servo Wiring and Tuning detailed How To example Mesa 7i77.

Servo Wiring and Tuning detailed How To example Mesa 7i77.

Category: Advanced Configuration

- tommylight

02 Jan 2026 21:50

Replied by tommylight on topic Retrofitting Deckel FP4ATC

Retrofitting Deckel FP4ATC

Category: Milling Machines

- Mbrand1901

- Mbrand1901

02 Jan 2026 20:26

Replied by Mbrand1901 on topic Retrofitting Deckel FP4ATC

Retrofitting Deckel FP4ATC

Category: Milling Machines

- jameslc15

- jameslc15

26 Dec 2025 09:14

No speed control on xhc-wb04b-6 pendant on 3 axis router was created by jameslc15

No speed control on xhc-wb04b-6 pendant on 3 axis router

Category: Basic Configuration

- Masiwood123

16 Dec 2025 11:22

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Z3n

- Z3n

01 Dec 2025 04:24

Replied by Z3n on topic Red Init & Done Lights on 7i92M

Red Init & Done Lights on 7i92M

Category: Driver Boards

- Masiwood123

30 Nov 2025 22:11 - 30 Nov 2025 22:14

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- unknown

- unknown

30 Nov 2025 07:30

Replied by unknown on topic Red Init & Done Lights on 7i92M

Red Init & Done Lights on 7i92M

Category: Driver Boards

- Masiwood123

29 Nov 2025 12:59

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Masiwood123

27 Nov 2025 21:27 - 27 Nov 2025 21:28

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- COFHAL

- COFHAL

27 Nov 2025 21:10 - 27 Nov 2025 21:11

Replied by COFHAL on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- PCW

26 Nov 2025 20:27

- Masiwood123

26 Nov 2025 20:02

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Masiwood123

26 Nov 2025 18:35 - 26 Nov 2025 18:37

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Masiwood123

26 Nov 2025 11:06 - 26 Nov 2025 11:11

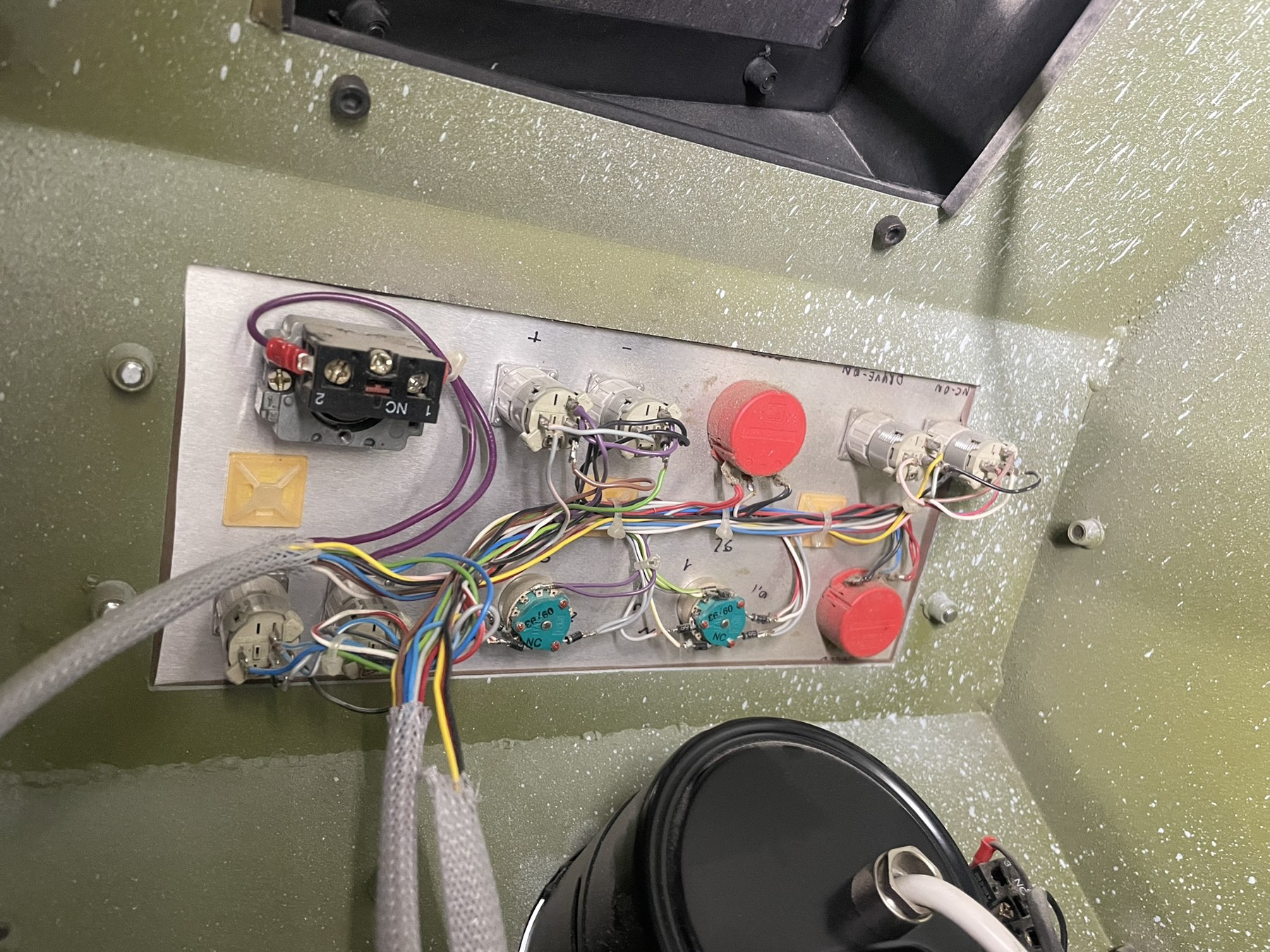

Physical buttons to 7i96s+7i77 was created by Masiwood123

Physical buttons to 7i96s+7i77

Category: HAL

Time to create page: 1.561 seconds