Search Results (Searched for: stepper spindle)

- aDm1N

20 Nov 2025 05:50

Replied by aDm1N on topic EtherCAT + CiA402 Servo: OP state reached, but axis won’t move (only Following E

EtherCAT + CiA402 Servo: OP state reached, but axis won’t move (only Following E

Category: General LinuxCNC Questions

The reference to the forum post was helpful. I now have the basic framework up and running. The servo, which is supposed to act as a spindle, is working to the point that it can be controlled with M commands, and the stepper driver (one driver for two closed-loop steppers) is also working. I've attached the files. More to come.

de.aliexpress.com/item/1005008271228331....gatewayAdapt=glo2deu

de.aliexpress.com/item/1005010098887410....gatewayAdapt=glo2deu

de.aliexpress.com/item/1005008271228331....gatewayAdapt=glo2deu

de.aliexpress.com/item/1005010098887410....gatewayAdapt=glo2deu

- dgdodo

- dgdodo

19 Nov 2025 01:18

Replied by dgdodo on topic [SOLVED] Backlash issues on Y-AXIS

[SOLVED] Backlash issues on Y-AXIS

Category: Advanced Configuration

Thanks for all info so far.

I decided to change the Y-axis also with a M4-(screw) spindle drive (not M3 as I said before), as I did on the X-axis.

Had the (almost) same stepper-motor around, although after testing it needed 2 times more Volt to be powerful enough.

Now it all looks much better!

The old gear setup was too much worn out, I believe. And 2 (plastic) gears before driving the arm had 1.3 mm backlash is also kinda 'too much'.

PS. I thought I tried the write action at last position in the .hal file (base-thread), but was forgotten to change the .ini file accordingly.

It does run fine now and I am not (willing) able to build back the old situation to test this again, sorry for that.

And yes, I will cleanup my configuration files after this change, the X- and Y-axis are now the same.

Regards, DG.

I decided to change the Y-axis also with a M4-(screw) spindle drive (not M3 as I said before), as I did on the X-axis.

Had the (almost) same stepper-motor around, although after testing it needed 2 times more Volt to be powerful enough.

Now it all looks much better!

The old gear setup was too much worn out, I believe. And 2 (plastic) gears before driving the arm had 1.3 mm backlash is also kinda 'too much'.

PS. I thought I tried the write action at last position in the .hal file (base-thread), but was forgotten to change the .ini file accordingly.

It does run fine now and I am not (willing) able to build back the old situation to test this again, sorry for that.

And yes, I will cleanup my configuration files after this change, the X- and Y-axis are now the same.

Regards, DG.

- Muftijaja

- Muftijaja

18 Nov 2025 21:48

problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5 was created by Muftijaja

problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Category: QtPyVCP

Hello community!

I have a Mesa 7i76e running, the wiring is correct except for the alarm loop. Using a Lenovo ThinkCentre M910q with i7 4-core, 256/GB NVMe SSD, i7 16GB RAM WLAN Intel Core i7-6700T 4x 2.80 - 3.60GHz with Linuxcnc 2.9.4, Probe Basic V.5 on Debian 12. No latency problems.

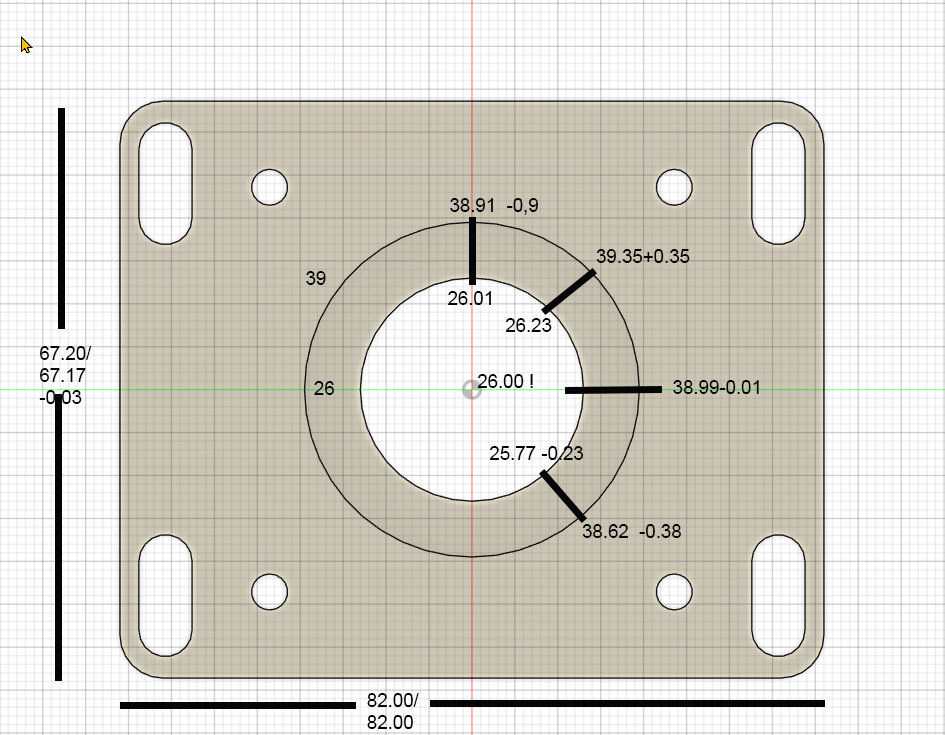

Once again, I'm here with a big problem. My DIY milling machine (1000x500x220 with aluminum profile frame, 20mm HGR, 1605 ball screws, 3 axes, 2x OMC Stpperonline 400W integrated servo, 1x JMC CL Stepper 3.5Nm, set 2000 steps/rev) is now mechanically finally assembled. I also got a lot of help from this forum in setting up LinuxCNC, eliminating latency problems and spindle control problems, but now I have a milling problem that I can't solve.

I have milled several test parts with drill holes, 2 circular pockets, and a rectangular outer contour, and have noticed that my circular pockets are becoming elliptical. The deviations in Y are approximately +0.35 mm at 45° and approximately -0.38 mm at 135°. The X values for the rectangular contour are perfect to within 0.01 mm in X and 0.09 mm in Y, X I consider to be acceptable, but Y is over tolerance. However, the circular movements contain deviations I cannot tolerate. I will show you a photo of the last test piece. After each individual test part, I made changes to rule out certain things.

The first change was to replace a simple Chinese C7 ball screw with a ground C5 spindle with double nuts. This reduced the originally even higher values by almost half. However, the deviations described above remained. After the next test part, I replaced the 400 W servo with a 3.5 Nm JMC CL stepper motor. The results remained almost the same. As a final attempt, a few days ago I replaced the spindle's fixed bearing with a new one, with 7002AC angular contact bearings in an O-arrangement with a 1 mm spacer ring between the outer rings. I inspected the previous fixed bearing and found no faults. There was a 1mm spacer also and the O arrangement was the same. I had also taken measurements at the spindle end earlier and actually and found no backlash.

Yesterday, moving away from mechanical faults, I noticed a difference in the motor definitions for the X and Y axes in the .ini file. The Ferror and min_Ferror points differed by one decimal place. X was set to 0.1 and 0.01, while the Y axis was set to 1.0 and 0.1. After I corrected this difference, the motor on the Y axis went into alarm mode after a few position changes.

What could be the reason for this? How can it be that one motor runs perfectly with much lower tolerance values, while the other quickly goes into alarm mode with less load? The motor in question has the same power supply and is certainly less demanding in terms of starting currents than the servo on the X-axis. With the higher tolerance values, the Y motor runs without alarm, but has these deviations. Are these tolerance values in the .ini file responsible for these deviations?

The mechanics of the Y and Z axes are flawless, as checked with a dial gauge, and the repeat accuracy is also very good, less than one hundredth.

Do you have any ideas about this? Where can I look further?

Thanks for your time and hints

I have a Mesa 7i76e running, the wiring is correct except for the alarm loop. Using a Lenovo ThinkCentre M910q with i7 4-core, 256/GB NVMe SSD, i7 16GB RAM WLAN Intel Core i7-6700T 4x 2.80 - 3.60GHz with Linuxcnc 2.9.4, Probe Basic V.5 on Debian 12. No latency problems.

Once again, I'm here with a big problem. My DIY milling machine (1000x500x220 with aluminum profile frame, 20mm HGR, 1605 ball screws, 3 axes, 2x OMC Stpperonline 400W integrated servo, 1x JMC CL Stepper 3.5Nm, set 2000 steps/rev) is now mechanically finally assembled. I also got a lot of help from this forum in setting up LinuxCNC, eliminating latency problems and spindle control problems, but now I have a milling problem that I can't solve.

I have milled several test parts with drill holes, 2 circular pockets, and a rectangular outer contour, and have noticed that my circular pockets are becoming elliptical. The deviations in Y are approximately +0.35 mm at 45° and approximately -0.38 mm at 135°. The X values for the rectangular contour are perfect to within 0.01 mm in X and 0.09 mm in Y, X I consider to be acceptable, but Y is over tolerance. However, the circular movements contain deviations I cannot tolerate. I will show you a photo of the last test piece. After each individual test part, I made changes to rule out certain things.

The first change was to replace a simple Chinese C7 ball screw with a ground C5 spindle with double nuts. This reduced the originally even higher values by almost half. However, the deviations described above remained. After the next test part, I replaced the 400 W servo with a 3.5 Nm JMC CL stepper motor. The results remained almost the same. As a final attempt, a few days ago I replaced the spindle's fixed bearing with a new one, with 7002AC angular contact bearings in an O-arrangement with a 1 mm spacer ring between the outer rings. I inspected the previous fixed bearing and found no faults. There was a 1mm spacer also and the O arrangement was the same. I had also taken measurements at the spindle end earlier and actually and found no backlash.

Yesterday, moving away from mechanical faults, I noticed a difference in the motor definitions for the X and Y axes in the .ini file. The Ferror and min_Ferror points differed by one decimal place. X was set to 0.1 and 0.01, while the Y axis was set to 1.0 and 0.1. After I corrected this difference, the motor on the Y axis went into alarm mode after a few position changes.

What could be the reason for this? How can it be that one motor runs perfectly with much lower tolerance values, while the other quickly goes into alarm mode with less load? The motor in question has the same power supply and is certainly less demanding in terms of starting currents than the servo on the X-axis. With the higher tolerance values, the Y motor runs without alarm, but has these deviations. Are these tolerance values in the .ini file responsible for these deviations?

The mechanics of the Y and Z axes are flawless, as checked with a dial gauge, and the repeat accuracy is also very good, less than one hundredth.

Do you have any ideas about this? Where can I look further?

Thanks for your time and hints

- Ferra

- Ferra

18 Nov 2025 08:28

Replied by Ferra on topic Mesa 7i95t with pwm firmware

Mesa 7i95t with pwm firmware

Category: Driver Boards

Hi, thanks for helping, here are the files!

Hal file

# This file was created with the Mesa Configuration Tool on nov 15 2025 15:24:04

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS](KINEMATICS)

# motion controller

loadrt [EMCMOT](EMCMOT) servo_period_nsec=[EMCMOT](SERVO_PERIOD) num_joints=[KINS](JOINTS)

# hostmot2 driver

loadrt hostmot2

loadrt [HM2](DRIVER) board_ip=[HM2](ADDRESS) config="num_encoders=6 num_pwmgens=1 num_stepgens=6 sserial_port_0=00000000"

setp hm2_[MESA](BOARD).0.watchdog.timeout_ns 10000000

loadrt pid names=pid.x,pid.y,pid.z

# PID Information for Stepper Boards

# Mesa hardware step generators at every servo thread invocation, the step

# generator hardware is given a new velocity. Without feedback from the PID

# controller the hardware position would slowly drift because of clock speed and

# timing differences between LinuxCNC and the step generator hardware.

# The PID controller gets feedback from the actual (fractional) step position and

# corrects for these small differences.

# THREADS

addf hm2_[MESA](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf hm2_[MESA](BOARD).0.write servo-thread

# DPLL TIMER

setp hm2_[MESA](BOARD).0.dpll.01.timer-us -200

setp hm2_[MESA](BOARD).0.stepgen.timer-number 1

# amp enable

net motion-enable <= motion.motion-enabled

# Board: 7i95

# Axis: X Joint: 0 Output: 0

# PID Setup

setp pid.x.Pgain [JOINT_0](P)

setp pid.x.Igain [JOINT_0](I)

setp pid.x.Dgain [JOINT_0](D)

setp pid.x.bias [JOINT_0](BIAS)

setp pid.x.FF0 [JOINT_0](FF0)

setp pid.x.FF1 [JOINT_0](FF1)

setp pid.x.FF2 [JOINT_0](FF2)

setp pid.x.deadband [JOINT_0](DEADBAND)

setp pid.x.maxoutput [JOINT_0](MAX_OUTPUT)

setp pid.x.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.x.maxerror [JOINT_0](MAX_ERROR)

# joint-0 enable chain

net joint-0-index-enable <=> pid.x.index-enable

net joint-0-index-enable <=> joint.0.index-enable

net joint-0-enable <= joint.0.amp-enable-out

net joint-0-enable => pid.x.enable

net joint-0-enable => hm2_[MESA](BOARD).0.stepgen.00.enable

# Joint 0 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.00.dirsetup [JOINT_0](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.00.dirhold [JOINT_0](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.00.steplen [JOINT_0](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.00.stepspace [JOINT_0](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.00.position-scale [JOINT_0](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.00.maxvel [JOINT_0](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.00.maxaccel [JOINT_0](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.00.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.00.control-type 1

# position command and feedback

net joint-0-pos-cmd <= joint.0.motor-pos-cmd

net joint-0-pos-cmd => pid.x.command

net joint-0-pos-fb <= hm2_[MESA](BOARD).0.stepgen.00.position-fb

net joint-0-pos-fb => joint.0.motor-pos-fb

net joint-0-pos-fb => pid.x.feedback

# PID Output

net joint.0.output <= pid.x.output

net joint.0.output => hm2_[MESA](BOARD).0.stepgen.00.velocity-cmd

# Axis: Y Joint: 1 Output: 1

# PID Setup

setp pid.y.Pgain [JOINT_1](P)

setp pid.y.Igain [JOINT_1](I)

setp pid.y.Dgain [JOINT_1](D)

setp pid.y.bias [JOINT_1](BIAS)

setp pid.y.FF0 [JOINT_1](FF0)

setp pid.y.FF1 [JOINT_1](FF1)

setp pid.y.FF2 [JOINT_1](FF2)

setp pid.y.deadband [JOINT_1](DEADBAND)

setp pid.y.maxoutput [JOINT_1](MAX_OUTPUT)

setp pid.y.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.y.maxerror [JOINT_1](MAX_ERROR)

# joint-1 enable chain

net joint-1-index-enable <=> pid.y.index-enable

net joint-1-index-enable <=> joint.1.index-enable

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.y.enable

net joint-1-enable => hm2_[MESA](BOARD).0.stepgen.01.enable

# Joint 1 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.01.dirsetup [JOINT_1](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.01.dirhold [JOINT_1](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.01.steplen [JOINT_1](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.01.stepspace [JOINT_1](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.01.position-scale [JOINT_1](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.01.maxvel [JOINT_1](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.01.maxaccel [JOINT_1](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.01.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.01.control-type 1

# position command and feedback

net joint-1-pos-cmd <= joint.1.motor-pos-cmd

net joint-1-pos-cmd => pid.y.command

net joint-1-pos-fb <= hm2_[MESA](BOARD).0.stepgen.01.position-fb

net joint-1-pos-fb => joint.1.motor-pos-fb

net joint-1-pos-fb => pid.y.feedback

# PID Output

net joint.1.output <= pid.y.output

net joint.1.output => hm2_[MESA](BOARD).0.stepgen.01.velocity-cmd

# Axis: Z Joint: 2 Output: 2

# PID Setup

setp pid.z.Pgain [JOINT_2](P)

setp pid.z.Igain [JOINT_2](I)

setp pid.z.Dgain [JOINT_2](D)

setp pid.z.bias [JOINT_2](BIAS)

setp pid.z.FF0 [JOINT_2](FF0)

setp pid.z.FF1 [JOINT_2](FF1)

setp pid.z.FF2 [JOINT_2](FF2)

setp pid.z.deadband [JOINT_2](DEADBAND)

setp pid.z.maxoutput [JOINT_2](MAX_OUTPUT)

setp pid.z.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.z.maxerror [JOINT_2](MAX_ERROR)

# joint-2 enable chain

net joint-2-index-enable <=> pid.z.index-enable

net joint-2-index-enable <=> joint.2.index-enable

net joint-2-enable <= joint.2.amp-enable-out

net joint-2-enable => pid.z.enable

net joint-2-enable => hm2_[MESA](BOARD).0.stepgen.02.enable

# Joint 2 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.02.dirsetup [JOINT_2](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.02.dirhold [JOINT_2](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.02.steplen [JOINT_2](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.02.stepspace [JOINT_2](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.02.position-scale [JOINT_2](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.02.maxvel [JOINT_2](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.02.maxaccel [JOINT_2](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.02.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.02.control-type 1

# position command and feedback

net joint-2-pos-cmd <= joint.2.motor-pos-cmd

net joint-2-pos-cmd => pid.z.command

net joint-2-pos-fb <= hm2_[MESA](BOARD).0.stepgen.02.position-fb

net joint-2-pos-fb => joint.2.motor-pos-fb

net joint-2-pos-fb => pid.z.feedback

# PID Output

net joint.2.output <= pid.z.output

net joint.2.output => hm2_[MESA](BOARD).0.stepgen.02.velocity-cmd

# Manual Tool Change Dialog

loadusr -W hal_manualtoolchange

net tool-number hal_manualtoolchange.number <= iocontrol.0.tool-prep-number

net tool-change-request hal_manualtoolchange.change <= iocontrol.0.tool-change

net tool-change-confirmed iocontrol.0.tool-changed => hal_manualtoolchange.changed

# tool prep loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

#######################################################

# SPINDLE PWM - MESA 7i95T pwmgen.00

#######################################################

# Imposto la frequenza PWM hardware (valore tipico 10 kHz)

# Usa il parametro dall'INI [SPINDLE_0](PWM_FREQUENCY)

setp hm2_[MESA](BOARD).0.pwmgen.pwm_frequency [SPINDLE_0](PWM_FREQUENCY)

# pwmgen.00: PWM su Out0, direzione su Out1 (che puoi anche non usare)

setp hm2_[MESA](BOARD).0.pwmgen.00.output-type 1

# Scala: valore in ingresso = RPM, duty = RPM / SCALE

# Esempio: SCALE = 24000 => 24000 rpm = 100% duty

setp hm2_[MESA](BOARD).0.pwmgen.00.scale [SPINDLE_0](SCALE)

# --- Collegamento con il motion ---

# Abilitazione PWM: attivo quando lo spindle è "on" (M3/M4)

net spindle-enable motion.spindle-on => hm2_[MESA](BOARD).0.pwmgen.00.enable

# Comando velocità in RPM dal planner

net spindle-speed-cmd-rpm motion.spindle-speed-out => hm2_[MESA](BOARD).0.pwmgen.00.value

ini file

# This file was updated with the Mesa Configuration Tool on nov 15 2025 15:24:04

# Changes to most things are ok and will be read by the Configuration Tool

[MESA]

VERSION = 2.1.8

BOARD = 7i95

BOARD_NAME = 7i95t

FIRMWARE = 7i95t_1pwmd.bin

CARD_0 = None

CARD_1 = None

[EMC]

VERSION = 1.1

MACHINE = Mesa_7i95t

DEBUG = 0x00000000

[HM2]

DRIVER = hm2_eth

ADDRESS = 192.168.1.121

[DISPLAY]

DISPLAY = qtvcp qtdragon_hd

EDITOR = geany

PROGRAM_PREFIX = /home/linuxcnc/linuxcnc/nc_files

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = COMMANDED

MAX_FEED_OVERRIDE = 1.5

MIN_LINEAR_VELOCITY = 0.0

DEFAULT_LINEAR_VELOCITY = 1.5

MAX_LINEAR_VELOCITY = 80.0

INCREMENTS = 10mm , 5mm , 1mm , 0.5mm , 0.1mm , 0.05mm , 0.01mm

CYCLE_TIME = 0.1

INTRO_GRAPHIC = emc2.gif

INTRO_TIME = 0

OPEN_FILE = ""

[KINS]

KINEMATICS = trivkins coordinates=XYZ

JOINTS = 3

[EMCIO]

EMCIO = iov2

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[RS274NGC]

PARAMETER_FILE = parameters.var

SUBROUTINE_PATH = /home/linuxcnc/linuxcnc/subroutines

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 2000000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

MAX_LINEAR_VELOCITY = 80.0

NO_FORCE_HOMING = 1

SPINDLES = 1

[HAL]

HALFILE = main.hal

HALFILE = io.hal

[AXIS_X]

MIN_LIMIT = 0

MAX_LIMIT = 295

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

[JOINT_0]

CARD = 0

TAB = 0

AXIS = X

MIN_LIMIT = 0

MAX_LIMIT = 295

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

TYPE = LINEAR

SCALE = 200

DRIVE = Custom

STEP_INVERT = False

DIR_INVERT = False

STEPGEN_MAX_VEL = 96.00

STEPGEN_MAX_ACC = 600.00

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 2000

ENCODER_SCALE =

FERROR = 0.01

MIN_FERROR = 0.005

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = 0

HOME_SEARCH_VEL = 30

HOME_LATCH_VEL = 3

HOME_FINAL_VEL = 6

HOME_SEQUENCE = 2

[AXIS_Y]

MIN_LIMIT = 0

MAX_LIMIT = 195

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

[JOINT_1]

CARD = 0

TAB = 1

AXIS = Y

MIN_LIMIT = 0

MAX_LIMIT = 195

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

TYPE = LINEAR

SCALE = 200

DRIVE = Custom

STEP_INVERT = False

DIR_INVERT = False

STEPGEN_MAX_VEL = 96.00

STEPGEN_MAX_ACC = 600.00

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 2000

ENCODER_SCALE =

FERROR = 0.01

MIN_FERROR = 0.005

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = 195

HOME_SEARCH_VEL = 30

HOME_LATCH_VEL = 3

HOME_FINAL_VEL = 6

HOME_SEQUENCE = 1

[AXIS_Z]

MIN_LIMIT = -135

MAX_LIMIT = 0

MAX_VELOCITY = 40

MAX_ACCELERATION = 500

[JOINT_2]

CARD = 0

TAB = 2

AXIS = Z

MIN_LIMIT = -135

MAX_LIMIT = 0

MAX_VELOCITY = 40

MAX_ACCELERATION = 500

TYPE = LINEAR

SCALE = 200

DRIVE = Custom

STEP_INVERT = False

DIR_INVERT = False

STEPGEN_MAX_VEL = 48.00

STEPGEN_MAX_ACC = 600.00

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 2000

ENCODER_SCALE =

FERROR = 0.01

MIN_FERROR = 0.005

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = 0

HOME_SEARCH_VEL = 30

HOME_LATCH_VEL = 3

HOME_FINAL_VEL = 6

HOME_SEQUENCE = 0

[INPUTS]

# DO NOT change the inputs they are used by the configuration tool

INPUT_0_0 = Joint 0 Home

INPUT_INVERT_0_0 = False

INPUT_SLOW_0_0 = False

INPUT_0_1 = Joint 1 Home

INPUT_INVERT_0_1 = False

INPUT_SLOW_0_1 = False

INPUT_0_2 = Joint 2 Home

INPUT_INVERT_0_2 = False

INPUT_SLOW_0_2 = False

INPUT_0_3 = E Stop 0

INPUT_INVERT_0_3 = False

INPUT_SLOW_0_3 = False

INPUT_0_4 = Probe Input

INPUT_INVERT_0_4 = False

INPUT_SLOW_0_4 = False

[OUTPUTS]

# DO NOT change the outputs they are used by the configuration tool

OUTPUT_0_1 = Spindle CW

OUTPUT_INVERT_0_1 = False

OUTPUT_0_2 = Coolant Flood

OUTPUT_INVERT_0_2 = False

OUTPUT_0_3 = E-Stop Out

OUTPUT_INVERT_0_3 = False

[OPTIONS]

# DO NOT change the options they are used by the configuration tool

LOAD_CONFIG = False

INTRO_GRAPHIC = emc2.gif

INTRO_GRAPHIC_TIME = 0

MANUAL_TOOL_CHANGE = True

CUSTOM_HAL = False

POST_GUI_HAL = False

SHUTDOWN_HAL = False

HALUI = False

PYVCP = False

GLADEVCP = False

LADDER = False

BACKUP = True

[SPINDLE_0]

# RPM corrispondenti al 100% di duty-cycle

SCALE = 24000

# Massimo RPM ammesso per G-code / GUI

MAX_RPM = 24000

MIN_RPM = 1000

# Frequenza del PWM hardware (Hz)

PWM_FREQUENCY = 2000

Hal file

# This file was created with the Mesa Configuration Tool on nov 15 2025 15:24:04

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS](KINEMATICS)

# motion controller

loadrt [EMCMOT](EMCMOT) servo_period_nsec=[EMCMOT](SERVO_PERIOD) num_joints=[KINS](JOINTS)

# hostmot2 driver

loadrt hostmot2

loadrt [HM2](DRIVER) board_ip=[HM2](ADDRESS) config="num_encoders=6 num_pwmgens=1 num_stepgens=6 sserial_port_0=00000000"

setp hm2_[MESA](BOARD).0.watchdog.timeout_ns 10000000

loadrt pid names=pid.x,pid.y,pid.z

# PID Information for Stepper Boards

# Mesa hardware step generators at every servo thread invocation, the step

# generator hardware is given a new velocity. Without feedback from the PID

# controller the hardware position would slowly drift because of clock speed and

# timing differences between LinuxCNC and the step generator hardware.

# The PID controller gets feedback from the actual (fractional) step position and

# corrects for these small differences.

# THREADS

addf hm2_[MESA](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf hm2_[MESA](BOARD).0.write servo-thread

# DPLL TIMER

setp hm2_[MESA](BOARD).0.dpll.01.timer-us -200

setp hm2_[MESA](BOARD).0.stepgen.timer-number 1

# amp enable

net motion-enable <= motion.motion-enabled

# Board: 7i95

# Axis: X Joint: 0 Output: 0

# PID Setup

setp pid.x.Pgain [JOINT_0](P)

setp pid.x.Igain [JOINT_0](I)

setp pid.x.Dgain [JOINT_0](D)

setp pid.x.bias [JOINT_0](BIAS)

setp pid.x.FF0 [JOINT_0](FF0)

setp pid.x.FF1 [JOINT_0](FF1)

setp pid.x.FF2 [JOINT_0](FF2)

setp pid.x.deadband [JOINT_0](DEADBAND)

setp pid.x.maxoutput [JOINT_0](MAX_OUTPUT)

setp pid.x.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.x.maxerror [JOINT_0](MAX_ERROR)

# joint-0 enable chain

net joint-0-index-enable <=> pid.x.index-enable

net joint-0-index-enable <=> joint.0.index-enable

net joint-0-enable <= joint.0.amp-enable-out

net joint-0-enable => pid.x.enable

net joint-0-enable => hm2_[MESA](BOARD).0.stepgen.00.enable

# Joint 0 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.00.dirsetup [JOINT_0](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.00.dirhold [JOINT_0](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.00.steplen [JOINT_0](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.00.stepspace [JOINT_0](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.00.position-scale [JOINT_0](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.00.maxvel [JOINT_0](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.00.maxaccel [JOINT_0](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.00.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.00.control-type 1

# position command and feedback

net joint-0-pos-cmd <= joint.0.motor-pos-cmd

net joint-0-pos-cmd => pid.x.command

net joint-0-pos-fb <= hm2_[MESA](BOARD).0.stepgen.00.position-fb

net joint-0-pos-fb => joint.0.motor-pos-fb

net joint-0-pos-fb => pid.x.feedback

# PID Output

net joint.0.output <= pid.x.output

net joint.0.output => hm2_[MESA](BOARD).0.stepgen.00.velocity-cmd

# Axis: Y Joint: 1 Output: 1

# PID Setup

setp pid.y.Pgain [JOINT_1](P)

setp pid.y.Igain [JOINT_1](I)

setp pid.y.Dgain [JOINT_1](D)

setp pid.y.bias [JOINT_1](BIAS)

setp pid.y.FF0 [JOINT_1](FF0)

setp pid.y.FF1 [JOINT_1](FF1)

setp pid.y.FF2 [JOINT_1](FF2)

setp pid.y.deadband [JOINT_1](DEADBAND)

setp pid.y.maxoutput [JOINT_1](MAX_OUTPUT)

setp pid.y.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.y.maxerror [JOINT_1](MAX_ERROR)

# joint-1 enable chain

net joint-1-index-enable <=> pid.y.index-enable

net joint-1-index-enable <=> joint.1.index-enable

net joint-1-enable <= joint.1.amp-enable-out

net joint-1-enable => pid.y.enable

net joint-1-enable => hm2_[MESA](BOARD).0.stepgen.01.enable

# Joint 1 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.01.dirsetup [JOINT_1](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.01.dirhold [JOINT_1](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.01.steplen [JOINT_1](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.01.stepspace [JOINT_1](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.01.position-scale [JOINT_1](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.01.maxvel [JOINT_1](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.01.maxaccel [JOINT_1](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.01.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.01.control-type 1

# position command and feedback

net joint-1-pos-cmd <= joint.1.motor-pos-cmd

net joint-1-pos-cmd => pid.y.command

net joint-1-pos-fb <= hm2_[MESA](BOARD).0.stepgen.01.position-fb

net joint-1-pos-fb => joint.1.motor-pos-fb

net joint-1-pos-fb => pid.y.feedback

# PID Output

net joint.1.output <= pid.y.output

net joint.1.output => hm2_[MESA](BOARD).0.stepgen.01.velocity-cmd

# Axis: Z Joint: 2 Output: 2

# PID Setup

setp pid.z.Pgain [JOINT_2](P)

setp pid.z.Igain [JOINT_2](I)

setp pid.z.Dgain [JOINT_2](D)

setp pid.z.bias [JOINT_2](BIAS)

setp pid.z.FF0 [JOINT_2](FF0)

setp pid.z.FF1 [JOINT_2](FF1)

setp pid.z.FF2 [JOINT_2](FF2)

setp pid.z.deadband [JOINT_2](DEADBAND)

setp pid.z.maxoutput [JOINT_2](MAX_OUTPUT)

setp pid.z.error-previous-target True

# limit stepgen velocity corrections caused by position feedback jitter

setp pid.z.maxerror [JOINT_2](MAX_ERROR)

# joint-2 enable chain

net joint-2-index-enable <=> pid.z.index-enable

net joint-2-index-enable <=> joint.2.index-enable

net joint-2-enable <= joint.2.amp-enable-out

net joint-2-enable => pid.z.enable

net joint-2-enable => hm2_[MESA](BOARD).0.stepgen.02.enable

# Joint 2 Step Generator Settings

setp hm2_[MESA](BOARD).0.stepgen.02.dirsetup [JOINT_2](DIRSETUP)

setp hm2_[MESA](BOARD).0.stepgen.02.dirhold [JOINT_2](DIRHOLD)

setp hm2_[MESA](BOARD).0.stepgen.02.steplen [JOINT_2](STEPLEN)

setp hm2_[MESA](BOARD).0.stepgen.02.stepspace [JOINT_2](STEPSPACE)

setp hm2_[MESA](BOARD).0.stepgen.02.position-scale [JOINT_2](SCALE)

setp hm2_[MESA](BOARD).0.stepgen.02.maxvel [JOINT_2](STEPGEN_MAX_VEL)

setp hm2_[MESA](BOARD).0.stepgen.02.maxaccel [JOINT_2](STEPGEN_MAX_ACC)

setp hm2_[MESA](BOARD).0.stepgen.02.step_type 0

setp hm2_[MESA](BOARD).0.stepgen.02.control-type 1

# position command and feedback

net joint-2-pos-cmd <= joint.2.motor-pos-cmd

net joint-2-pos-cmd => pid.z.command

net joint-2-pos-fb <= hm2_[MESA](BOARD).0.stepgen.02.position-fb

net joint-2-pos-fb => joint.2.motor-pos-fb

net joint-2-pos-fb => pid.z.feedback

# PID Output

net joint.2.output <= pid.z.output

net joint.2.output => hm2_[MESA](BOARD).0.stepgen.02.velocity-cmd

# Manual Tool Change Dialog

loadusr -W hal_manualtoolchange

net tool-number hal_manualtoolchange.number <= iocontrol.0.tool-prep-number

net tool-change-request hal_manualtoolchange.change <= iocontrol.0.tool-change

net tool-change-confirmed iocontrol.0.tool-changed => hal_manualtoolchange.changed

# tool prep loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

#######################################################

# SPINDLE PWM - MESA 7i95T pwmgen.00

#######################################################

# Imposto la frequenza PWM hardware (valore tipico 10 kHz)

# Usa il parametro dall'INI [SPINDLE_0](PWM_FREQUENCY)

setp hm2_[MESA](BOARD).0.pwmgen.pwm_frequency [SPINDLE_0](PWM_FREQUENCY)

# pwmgen.00: PWM su Out0, direzione su Out1 (che puoi anche non usare)

setp hm2_[MESA](BOARD).0.pwmgen.00.output-type 1

# Scala: valore in ingresso = RPM, duty = RPM / SCALE

# Esempio: SCALE = 24000 => 24000 rpm = 100% duty

setp hm2_[MESA](BOARD).0.pwmgen.00.scale [SPINDLE_0](SCALE)

# --- Collegamento con il motion ---

# Abilitazione PWM: attivo quando lo spindle è "on" (M3/M4)

net spindle-enable motion.spindle-on => hm2_[MESA](BOARD).0.pwmgen.00.enable

# Comando velocità in RPM dal planner

net spindle-speed-cmd-rpm motion.spindle-speed-out => hm2_[MESA](BOARD).0.pwmgen.00.value

ini file

# This file was updated with the Mesa Configuration Tool on nov 15 2025 15:24:04

# Changes to most things are ok and will be read by the Configuration Tool

[MESA]

VERSION = 2.1.8

BOARD = 7i95

BOARD_NAME = 7i95t

FIRMWARE = 7i95t_1pwmd.bin

CARD_0 = None

CARD_1 = None

[EMC]

VERSION = 1.1

MACHINE = Mesa_7i95t

DEBUG = 0x00000000

[HM2]

DRIVER = hm2_eth

ADDRESS = 192.168.1.121

[DISPLAY]

DISPLAY = qtvcp qtdragon_hd

EDITOR = geany

PROGRAM_PREFIX = /home/linuxcnc/linuxcnc/nc_files

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = COMMANDED

MAX_FEED_OVERRIDE = 1.5

MIN_LINEAR_VELOCITY = 0.0

DEFAULT_LINEAR_VELOCITY = 1.5

MAX_LINEAR_VELOCITY = 80.0

INCREMENTS = 10mm , 5mm , 1mm , 0.5mm , 0.1mm , 0.05mm , 0.01mm

CYCLE_TIME = 0.1

INTRO_GRAPHIC = emc2.gif

INTRO_TIME = 0

OPEN_FILE = ""

[KINS]

KINEMATICS = trivkins coordinates=XYZ

JOINTS = 3

[EMCIO]

EMCIO = iov2

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[RS274NGC]

PARAMETER_FILE = parameters.var

SUBROUTINE_PATH = /home/linuxcnc/linuxcnc/subroutines

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 2000000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

MAX_LINEAR_VELOCITY = 80.0

NO_FORCE_HOMING = 1

SPINDLES = 1

[HAL]

HALFILE = main.hal

HALFILE = io.hal

[AXIS_X]

MIN_LIMIT = 0

MAX_LIMIT = 295

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

[JOINT_0]

CARD = 0

TAB = 0

AXIS = X

MIN_LIMIT = 0

MAX_LIMIT = 295

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

TYPE = LINEAR

SCALE = 200

DRIVE = Custom

STEP_INVERT = False

DIR_INVERT = False

STEPGEN_MAX_VEL = 96.00

STEPGEN_MAX_ACC = 600.00

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 2000

ENCODER_SCALE =

FERROR = 0.01

MIN_FERROR = 0.005

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = 0

HOME_SEARCH_VEL = 30

HOME_LATCH_VEL = 3

HOME_FINAL_VEL = 6

HOME_SEQUENCE = 2

[AXIS_Y]

MIN_LIMIT = 0

MAX_LIMIT = 195

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

[JOINT_1]

CARD = 0

TAB = 1

AXIS = Y

MIN_LIMIT = 0

MAX_LIMIT = 195

MAX_VELOCITY = 80

MAX_ACCELERATION = 500

TYPE = LINEAR

SCALE = 200

DRIVE = Custom

STEP_INVERT = False

DIR_INVERT = False

STEPGEN_MAX_VEL = 96.00

STEPGEN_MAX_ACC = 600.00

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 2000

ENCODER_SCALE =

FERROR = 0.01

MIN_FERROR = 0.005

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = 195

HOME_SEARCH_VEL = 30

HOME_LATCH_VEL = 3

HOME_FINAL_VEL = 6

HOME_SEQUENCE = 1

[AXIS_Z]

MIN_LIMIT = -135

MAX_LIMIT = 0

MAX_VELOCITY = 40

MAX_ACCELERATION = 500

[JOINT_2]

CARD = 0

TAB = 2

AXIS = Z

MIN_LIMIT = -135

MAX_LIMIT = 0

MAX_VELOCITY = 40

MAX_ACCELERATION = 500

TYPE = LINEAR

SCALE = 200

DRIVE = Custom

STEP_INVERT = False

DIR_INVERT = False

STEPGEN_MAX_VEL = 48.00

STEPGEN_MAX_ACC = 600.00

DIRSETUP = 3000

DIRHOLD = 3000

STEPLEN = 2000

STEPSPACE = 2000

ENCODER_SCALE =

FERROR = 0.01

MIN_FERROR = 0.005

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = 0

HOME_SEARCH_VEL = 30

HOME_LATCH_VEL = 3

HOME_FINAL_VEL = 6

HOME_SEQUENCE = 0

[INPUTS]

# DO NOT change the inputs they are used by the configuration tool

INPUT_0_0 = Joint 0 Home

INPUT_INVERT_0_0 = False

INPUT_SLOW_0_0 = False

INPUT_0_1 = Joint 1 Home

INPUT_INVERT_0_1 = False

INPUT_SLOW_0_1 = False

INPUT_0_2 = Joint 2 Home

INPUT_INVERT_0_2 = False

INPUT_SLOW_0_2 = False

INPUT_0_3 = E Stop 0

INPUT_INVERT_0_3 = False

INPUT_SLOW_0_3 = False

INPUT_0_4 = Probe Input

INPUT_INVERT_0_4 = False

INPUT_SLOW_0_4 = False

[OUTPUTS]

# DO NOT change the outputs they are used by the configuration tool

OUTPUT_0_1 = Spindle CW

OUTPUT_INVERT_0_1 = False

OUTPUT_0_2 = Coolant Flood

OUTPUT_INVERT_0_2 = False

OUTPUT_0_3 = E-Stop Out

OUTPUT_INVERT_0_3 = False

[OPTIONS]

# DO NOT change the options they are used by the configuration tool

LOAD_CONFIG = False

INTRO_GRAPHIC = emc2.gif

INTRO_GRAPHIC_TIME = 0

MANUAL_TOOL_CHANGE = True

CUSTOM_HAL = False

POST_GUI_HAL = False

SHUTDOWN_HAL = False

HALUI = False

PYVCP = False

GLADEVCP = False

LADDER = False

BACKUP = True

[SPINDLE_0]

# RPM corrispondenti al 100% di duty-cycle

SCALE = 24000

# Massimo RPM ammesso per G-code / GUI

MAX_RPM = 24000

MIN_RPM = 1000

# Frequenza del PWM hardware (Hz)

PWM_FREQUENCY = 2000

- Ferra

- Ferra

18 Nov 2025 00:47

Mesa 7i95t with pwm firmware was created by Ferra

Mesa 7i95t with pwm firmware

Category: Driver Boards

Hi everyone,

this is my first time using LinuxCNC and a Mesa board. I received my 7i95T a few days ago and have been running several tests since then.

I installed LinuxCNC 2.9.4 on an old desktop PC and everything runs smoothly. After that, I updated the system and installed the Mesa Configuration Tool, since I read that the 7i95T cannot be configured with the standard PNCconf wizard.I successfully connected to the board using the default IP address 192.168.1.121, and the PC communicates with it correctly.

Because I need a PWM output for my 0–10 V analog converter (my VFD does not support RS-485 unfortunately), I downloaded the appropriate firmware, flashed it to the board, and the update went fine.

After completing the basic configuration, I switched the GUI to qtDragon_hd for a better interface. LinuxCNC loads without errors, and I was able to test one axis (stepper + proximity sensor) without issues.Where I’m stuck: PWM generationReading the HMIDs, I can see that the last stepgen has been replaced by a PWM generator, but I’m not understanding how to properly use this PWM output.Here’s what I tried:

Also, I would also like to use my MPG wheel.

My idea is:

Thanks a lot to everyone in advance!

this is my first time using LinuxCNC and a Mesa board. I received my 7i95T a few days ago and have been running several tests since then.

I installed LinuxCNC 2.9.4 on an old desktop PC and everything runs smoothly. After that, I updated the system and installed the Mesa Configuration Tool, since I read that the 7i95T cannot be configured with the standard PNCconf wizard.I successfully connected to the board using the default IP address 192.168.1.121, and the PC communicates with it correctly.

Because I need a PWM output for my 0–10 V analog converter (my VFD does not support RS-485 unfortunately), I downloaded the appropriate firmware, flashed it to the board, and the update went fine.

After completing the basic configuration, I switched the GUI to qtDragon_hd for a better interface. LinuxCNC loads without errors, and I was able to test one axis (stepper + proximity sensor) without issues.Where I’m stuck: PWM generationReading the HMIDs, I can see that the last stepgen has been replaced by a PWM generator, but I’m not understanding how to properly use this PWM output.Here’s what I tried:

- I connected the PWM signal to pin 9 on the 7i95T header.

- I left the DIR pin disconnected for now because I only need the spindle to run clockwise.

- I connected my 0–10 V PWM-to-analog converter, but no voltage output appears.

- I also tried checking the signal using an oscilloscope, but I get no PWM activity at all.

- I misconfigured the PWM generator in LinuxCNC/HAL,

- I am misunderstanding how the PWM output on the 7i95T is supposed to work.

Also, I would also like to use my MPG wheel.

My idea is:

- connect the MPG encoder to the left-side encoder input (ENC0),

- connect the MPG pushbuttons and the selector to the input pins on the right side, according to the Mesa Config Tool assignments.

Thanks a lot to everyone in advance!

- ihavenofish

- ihavenofish

14 Nov 2025 19:09

Replied by ihavenofish on topic lemontart - a call for help with s curve, ui's, and all the cool toys

lemontart - a call for help with s curve, ui's, and all the cool toys

Category: General LinuxCNC Questions

yeah. i perhaps worded this badly.

There's 2 components. getting the basic UI all done up, and then what I guess is a really a wizard, with some preset options for recommended hardware such as jss (stepperonline) drives, delta ms300 spindle, etc

Basically I was a more full features wizard that covers modbus and ethercat. haha.

Thanks

There's 2 components. getting the basic UI all done up, and then what I guess is a really a wizard, with some preset options for recommended hardware such as jss (stepperonline) drives, delta ms300 spindle, etc

Basically I was a more full features wizard that covers modbus and ethercat. haha.

Thanks

- Hakan

- Hakan

13 Nov 2025 17:27

Replied by Hakan on topic AX58100

AX58100

Category: EtherCAT

I would start looking at

- encoders. With the current stm32f407 the quadrature counters are tied to certain pins, and max 4 such hardware counters. Code is in E3000, would copy that.

- EtherCAT chip, would base it on LAN9252 (which most of the cards use) due to Ax58100 limit of 2x16 pdos. Don't know of a limit for LAN9252, it's not less than 2x16.

- Opto-couplers, would revisit.

If you are thinking of stepper generator with encoder inputs, say for four of them, would base it on E3000 for the user code and extend to four encoders, code is already there. soes library from E7000. Hardware will be based on E3000 around stm32, around E7000 for EtherCAT.

One can think of one card supporting 1 drive. Or 2 stepper drives. And use multiple cards

In linuxcnc 2.10 there is 64-bit integers, so no risk for encoders overflowing. 32-bit isn't quite enough at least for spindles.

Is it just an idea, or are you going to do it?

.

- encoders. With the current stm32f407 the quadrature counters are tied to certain pins, and max 4 such hardware counters. Code is in E3000, would copy that.

- EtherCAT chip, would base it on LAN9252 (which most of the cards use) due to Ax58100 limit of 2x16 pdos. Don't know of a limit for LAN9252, it's not less than 2x16.

- Opto-couplers, would revisit.

If you are thinking of stepper generator with encoder inputs, say for four of them, would base it on E3000 for the user code and extend to four encoders, code is already there. soes library from E7000. Hardware will be based on E3000 around stm32, around E7000 for EtherCAT.

One can think of one card supporting 1 drive. Or 2 stepper drives. And use multiple cards

In linuxcnc 2.10 there is 64-bit integers, so no risk for encoders overflowing. 32-bit isn't quite enough at least for spindles.

Is it just an idea, or are you going to do it?

.

- TurboStreetCar

- TurboStreetCar

11 Nov 2025 14:48

Determining Rate Of Accelleration was created by TurboStreetCar

Determining Rate Of Accelleration

Category: General LinuxCNC Questions

Hello, i have a project im working on (Not a CNC machine, but i believe a Mesa card is good capable hardware for this application) where im trying to determine the rate of acceleration of an externally driven spindle using an encoder.

There doesn't seem to be any built in components for this that i can find.

The use case, is to feed the rate of acceleration into a PID loop to control the output of a stepper/servo that regulates the spindles speed.

Is there a relatively easy way to measure/determine rate of acceleration accurately?

There doesn't seem to be any built in components for this that i can find.

The use case, is to feed the rate of acceleration into a PID loop to control the output of a stepper/servo that regulates the spindles speed.

Is there a relatively easy way to measure/determine rate of acceleration accurately?

- Hakan

- Hakan

31 Oct 2025 11:06

Replied by Hakan on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

Sounds good. Let's hope it keeps that way.

I ran the RPi4 for some time and it was ok, so the Rpi5 should be ok too?

Latency isn't so much of an issue now with the "-" sign.

That "should" keep it on track (sync).

You can check if it isn't doing so great with the value of the pin lcec.0.pll-reset-count

If that is way above 1 there may be a problem.

First thing to do then is to increase lcec.0.pll-step to 10000 which is max, or something in between say 5000,

setp lcec.0.pll-step 10000

If pll-reset-count then keeps increasing you need to work on the latency.

The main reason I switched to Intel-based is that the gui became more and more

sophisticated and needed more and more processing power to function smoothly.

I am hesitant to recommend a setup, there are many that works fine.

For ethercat I would definitely look for an Intel network adapter,

the rest is more form factor, power draw, cpu performance.

I have had good luck with the N100/N150 mini pcs. Intel network adapter though.

I ran the RPi4 for some time and it was ok, so the Rpi5 should be ok too?

Latency isn't so much of an issue now with the "-" sign.

That "should" keep it on track (sync).

You can check if it isn't doing so great with the value of the pin lcec.0.pll-reset-count

If that is way above 1 there may be a problem.

First thing to do then is to increase lcec.0.pll-step to 10000 which is max, or something in between say 5000,

setp lcec.0.pll-step 10000

If pll-reset-count then keeps increasing you need to work on the latency.

The main reason I switched to Intel-based is that the gui became more and more

sophisticated and needed more and more processing power to function smoothly.

I am hesitant to recommend a setup, there are many that works fine.

For ethercat I would definitely look for an Intel network adapter,

the rest is more form factor, power draw, cpu performance.

I have had good luck with the N100/N150 mini pcs. Intel network adapter though.

- Will_cnc

- Will_cnc

31 Oct 2025 10:05

Replied by Will_cnc on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

Having tested the machine this morning , the Juddering on the servo drives appears too of stopped for the time being?

Could it be due to the pi not being powerful enough and having bad latency? Yesterday I had a few windows open running whilst running linux .

If this is the issue is it worth upgrading from the pi5 to something with more powerful ? .

Any suggestions on reasonable priced upgrade options

Could it be due to the pi not being powerful enough and having bad latency? Yesterday I had a few windows open running whilst running linux .

If this is the issue is it worth upgrading from the pi5 to something with more powerful ? .

Any suggestions on reasonable priced upgrade options

- Hakan

- Hakan

31 Oct 2025 09:19

Replied by Hakan on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

Looks fine so far.

Can you start linuxcnc to see if any useful message comes out to explain jerkiness.

You can also try to temporarily remove/comment out the dcconf line for the spindle driver only in the ethercat.conf.

Can you start linuxcnc to see if any useful message comes out to explain jerkiness.

You can also try to temporarily remove/comment out the dcconf line for the spindle driver only in the ethercat.conf.

- Will_cnc

- Will_cnc

31 Oct 2025 09:14

Replied by Will_cnc on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

here is the result of running sudo dmesg

[ 4.057274] Bluetooth: HCI UART protocol Broadcom registered

[ 4.083683] brcmfmac: F1 signature read @0x18000000=0x15264345

[ 4.087327] brcmfmac: brcmf_fw_alloc_request: using brcm/brcmfmac43455-sdio for chip BCM4345/6

[ 4.087734] usbcore: registered new interface driver brcmfmac

[ 4.291603] brcmfmac: brcmf_c_process_txcap_blob: no txcap_blob available (err=-2)

[ 4.291861] brcmfmac: brcmf_c_preinit_dcmds: Firmware: BCM4345/6 wl0: Apr 15 2021 03:03:20 version 7.45.234 (4ca95bb CY) FWID 01-996384e2

[ 4.393502] Bluetooth: hci0: BCM: chip id 107

[ 4.393719] Bluetooth: hci0: BCM: features 0x2f

[ 4.394870] Bluetooth: hci0: BCM4345C0

[ 4.394873] Bluetooth: hci0: BCM4345C0 (003.001.025) build 0000

[ 4.426812] Bluetooth: hci0: BCM4345C0 'brcm/BCM4345C0.hcd' Patch

[ 4.462459] macb 1f00100000.ethernet eth0: PHY [1f00100000.ethernet-ffffffff:01] driver [Broadcom BCM54213PE] (irq=POLL)

[ 4.462471] macb 1f00100000.ethernet eth0: configuring for phy/rgmii-id link mode

[ 4.469213] pps pps0: new PPS source ptp0

[ 4.469263] macb 1f00100000.ethernet: gem-ptp-timer ptp clock registered.

[ 4.470153] warning: `iwconfig' uses wireless extensions which will stop working for Wi-Fi 7 hardware; use nl80211

[ 4.470300] ec_master: loading out-of-tree module taints kernel.

[ 4.470306] ec_master: module verification failed: signature and/or required key missing - tainting kernel

[ 4.475936] EtherCAT: Master driver 1.6.8 1.6.8.g2543cc5-1+27.1

[ 4.476617] EtherCAT: 1 master waiting for devices.

[ 4.490862] zram: Added device: zram0

[ 4.628070] ec_generic: EtherCAT master generic Ethernet device module 1.6.8 1.6.8.g2543cc5-1+27.1

[ 4.628086] EtherCAT: Accepting 2C:CF:67:24:E6:CD as main device for master 0.

[ 4.628096] ec_generic: Binding socket to interface 2 (eth0).

[ 4.645137] EtherCAT 0: Starting EtherCAT-IDLE thread.

[ 4.747291] Bluetooth: BNEP (Ethernet Emulation) ver 1.3

[ 4.747296] Bluetooth: BNEP filters: protocol multicast

[ 4.747300] Bluetooth: BNEP socket layer initialized

[ 4.752789] brcmfmac: brcmf_cfg80211_set_power_mgmt: power save enabled

[ 5.129671] Bluetooth: hci0: BCM: features 0x2f

[ 5.131033] Bluetooth: hci0: BCM43455 37.4MHz Raspberry Pi 3+

[ 5.131037] Bluetooth: hci0: BCM4345C0 (003.001.025) build 0342

[ 5.131328] Bluetooth: hci0: BCM: Using default device address (43:45:c0:00:1f:ac)

[ 5.150144] Bluetooth: MGMT ver 1.23

[ 5.155700] NET: Registered PF_ALG protocol family

[ 6.530993] macb 1f00100000.ethernet eth0: Link is Up - 100Mbps/Full - flow control off

[ 6.537016] EtherCAT 0: Link state of ecm0 changed to UP.

[ 6.545022] EtherCAT 0: 4 slave(s) responding on main device. Re-scanning on next possibility.

[ 6.545024] EtherCAT 0: Slave states on main device: PREOP.

[ 6.545025] EtherCAT 0: Re-scanning now.

[ 6.545194] EtherCAT 0: Scanning bus.

[ 7.356283] EtherCAT 0: Bus scanning completed in 808 ms.

[ 7.356289] EtherCAT 0: Using slave 0 as DC reference clock.

[ 4.057274] Bluetooth: HCI UART protocol Broadcom registered

[ 4.083683] brcmfmac: F1 signature read @0x18000000=0x15264345

[ 4.087327] brcmfmac: brcmf_fw_alloc_request: using brcm/brcmfmac43455-sdio for chip BCM4345/6

[ 4.087734] usbcore: registered new interface driver brcmfmac

[ 4.291603] brcmfmac: brcmf_c_process_txcap_blob: no txcap_blob available (err=-2)

[ 4.291861] brcmfmac: brcmf_c_preinit_dcmds: Firmware: BCM4345/6 wl0: Apr 15 2021 03:03:20 version 7.45.234 (4ca95bb CY) FWID 01-996384e2

[ 4.393502] Bluetooth: hci0: BCM: chip id 107

[ 4.393719] Bluetooth: hci0: BCM: features 0x2f

[ 4.394870] Bluetooth: hci0: BCM4345C0

[ 4.394873] Bluetooth: hci0: BCM4345C0 (003.001.025) build 0000

[ 4.426812] Bluetooth: hci0: BCM4345C0 'brcm/BCM4345C0.hcd' Patch

[ 4.462459] macb 1f00100000.ethernet eth0: PHY [1f00100000.ethernet-ffffffff:01] driver [Broadcom BCM54213PE] (irq=POLL)

[ 4.462471] macb 1f00100000.ethernet eth0: configuring for phy/rgmii-id link mode

[ 4.469213] pps pps0: new PPS source ptp0

[ 4.469263] macb 1f00100000.ethernet: gem-ptp-timer ptp clock registered.

[ 4.470153] warning: `iwconfig' uses wireless extensions which will stop working for Wi-Fi 7 hardware; use nl80211

[ 4.470300] ec_master: loading out-of-tree module taints kernel.

[ 4.470306] ec_master: module verification failed: signature and/or required key missing - tainting kernel

[ 4.475936] EtherCAT: Master driver 1.6.8 1.6.8.g2543cc5-1+27.1

[ 4.476617] EtherCAT: 1 master waiting for devices.

[ 4.490862] zram: Added device: zram0

[ 4.628070] ec_generic: EtherCAT master generic Ethernet device module 1.6.8 1.6.8.g2543cc5-1+27.1

[ 4.628086] EtherCAT: Accepting 2C:CF:67:24:E6:CD as main device for master 0.

[ 4.628096] ec_generic: Binding socket to interface 2 (eth0).

[ 4.645137] EtherCAT 0: Starting EtherCAT-IDLE thread.

[ 4.747291] Bluetooth: BNEP (Ethernet Emulation) ver 1.3

[ 4.747296] Bluetooth: BNEP filters: protocol multicast

[ 4.747300] Bluetooth: BNEP socket layer initialized

[ 4.752789] brcmfmac: brcmf_cfg80211_set_power_mgmt: power save enabled

[ 5.129671] Bluetooth: hci0: BCM: features 0x2f

[ 5.131033] Bluetooth: hci0: BCM43455 37.4MHz Raspberry Pi 3+

[ 5.131037] Bluetooth: hci0: BCM4345C0 (003.001.025) build 0342

[ 5.131328] Bluetooth: hci0: BCM: Using default device address (43:45:c0:00:1f:ac)

[ 5.150144] Bluetooth: MGMT ver 1.23

[ 5.155700] NET: Registered PF_ALG protocol family

[ 6.530993] macb 1f00100000.ethernet eth0: Link is Up - 100Mbps/Full - flow control off

[ 6.537016] EtherCAT 0: Link state of ecm0 changed to UP.

[ 6.545022] EtherCAT 0: 4 slave(s) responding on main device. Re-scanning on next possibility.

[ 6.545024] EtherCAT 0: Slave states on main device: PREOP.

[ 6.545025] EtherCAT 0: Re-scanning now.

[ 6.545194] EtherCAT 0: Scanning bus.

[ 7.356283] EtherCAT 0: Bus scanning completed in 808 ms.

[ 7.356289] EtherCAT 0: Using slave 0 as DC reference clock.

- Hakan

- Hakan

31 Oct 2025 05:37

Replied by Hakan on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

Here it looks fine. Saw it in the first ethercat-conf.xml you attached.

There is no reason the PV mode should cause problems with other drives.

Check the output of "sudo dmesg" the last say 20 lines are of interest.

There is no reason the PV mode should cause problems with other drives.

Check the output of "sudo dmesg" the last say 20 lines are of interest.

- Will_cnc

- Will_cnc

30 Oct 2025 21:46

Replied by Will_cnc on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

would you be able to point to where the issue is in the .xml file ?

<masters>

<master idx="0" appTimePeriod="1000000" refClockSyncCycles="-5">

<!-- X axis EL8 Servo Drive -->

<slave idx="0" type="generic" vid="00004321" pid="0000d0" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1601">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="16" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

<!-- Y0 axis EL8 Servo Drive -->

<slave idx="1" type="generic" vid="00004321" pid="0000d0" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1601">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="16" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

<!-- Z axis EL8 Servo Drive -->

<slave idx="2" type="generic" vid="00004321" pid="000010c2" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1601">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="16" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

<!-- Spindle Servo Drive -->

<slave idx="3" name="Spindle" type="generic" vid="00400000" pid="00000715" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1600">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="60FF" subIdx="00" bitLen="32" halPin="target-velocity" halType="s32"/>

<pdoEntry idx="6083" subIdx="00" bitLen="32" halPin="acceleration" halType="s32"/>

<pdoEntry idx="6084" subIdx="00" bitLen="32" halPin="deceleration" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="32" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

</master>

</masters>

<masters>

<master idx="0" appTimePeriod="1000000" refClockSyncCycles="-5">

<!-- X axis EL8 Servo Drive -->

<slave idx="0" type="generic" vid="00004321" pid="0000d0" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1601">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="16" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

<!-- Y0 axis EL8 Servo Drive -->

<slave idx="1" type="generic" vid="00004321" pid="0000d0" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1601">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="16" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

<!-- Z axis EL8 Servo Drive -->

<slave idx="2" type="generic" vid="00004321" pid="000010c2" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1601">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="607A" subIdx="00" bitLen="32" halPin="target-position" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="16" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

<!-- Spindle Servo Drive -->

<slave idx="3" name="Spindle" type="generic" vid="00400000" pid="00000715" configPdos="true">

<dcConf assignActivate="300" sync0Cycle="*1" sync0Shift="0"/>

<syncManager idx="2" dir="out">

<pdo idx="1600">

<pdoEntry idx="6040" subIdx="00" bitLen="16" halPin="cia-controlword" halType="u32"/>

<pdoEntry idx="6060" subIdx="00" bitLen="8" halPin="opmode" halType="s32"/>

<pdoEntry idx="60FF" subIdx="00" bitLen="32" halPin="target-velocity" halType="s32"/>

<pdoEntry idx="6083" subIdx="00" bitLen="32" halPin="acceleration" halType="s32"/>

<pdoEntry idx="6084" subIdx="00" bitLen="32" halPin="deceleration" halType="s32"/>

</pdo>

</syncManager>

<syncManager idx="3" dir="in">

<pdo idx="1a00">

<pdoEntry idx="6041" subIdx="00" bitLen="16" halPin="cia-statusword" halType="u32"/>

<pdoEntry idx="6061" subIdx="00" bitLen="8" halPin="opmode-display" halType="s32"/>

<pdoEntry idx="6064" subIdx="00" bitLen="32" halPin="actual-position" halType="s32"/>

<pdoEntry idx="606C" subIdx="00" bitLen="32" halPin="actual-velocity" halType="s32"/>

<pdoEntry idx="6077" subIdx="00" bitLen="32" halPin="actual-torque" halType="s32"/>

</pdo>

</syncManager>

</slave>

</master>

</masters>

- Hakan

- Hakan

30 Oct 2025 21:26

Replied by Hakan on topic Stepper online A6 Servo motor as Spindle motor

Stepper online A6 Servo motor as Spindle motor

Category: General LinuxCNC Questions

And btw there may be an error in your ethercat-conf.xml file. Two slave lines for idx=3.

Time to create page: 0.536 seconds