Search Results (Searched for: )

- rodw

Today 10:19

Replied by rodw on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Muecke

Today 10:02

- Hakan

- Hakan

Today 09:55

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- papagno-source

- papagno-source

Today 09:48

Replied by papagno-source on topic update running in place linuxcnc

update running in place linuxcnc

Category: General LinuxCNC Questions

- rodw

Today 09:36

Replied by rodw on topic update running in place linuxcnc

update running in place linuxcnc

Category: General LinuxCNC Questions

- papagno-source

- papagno-source

Today 08:59

update running in place linuxcnc was created by papagno-source

update running in place linuxcnc

Category: General LinuxCNC Questions

- Giovanni

- Giovanni

Today 08:49

- rodw

Today 08:17

Replied by rodw on topic Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Category: Installing LinuxCNC

- rodw

Today 08:08

Replied by rodw on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hakan

- Hakan

Today 07:15

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- rodw

Yesterday 02:40

Replied by rodw on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- hmnijp

- hmnijp

Yesterday 01:32 - Yesterday 01:37

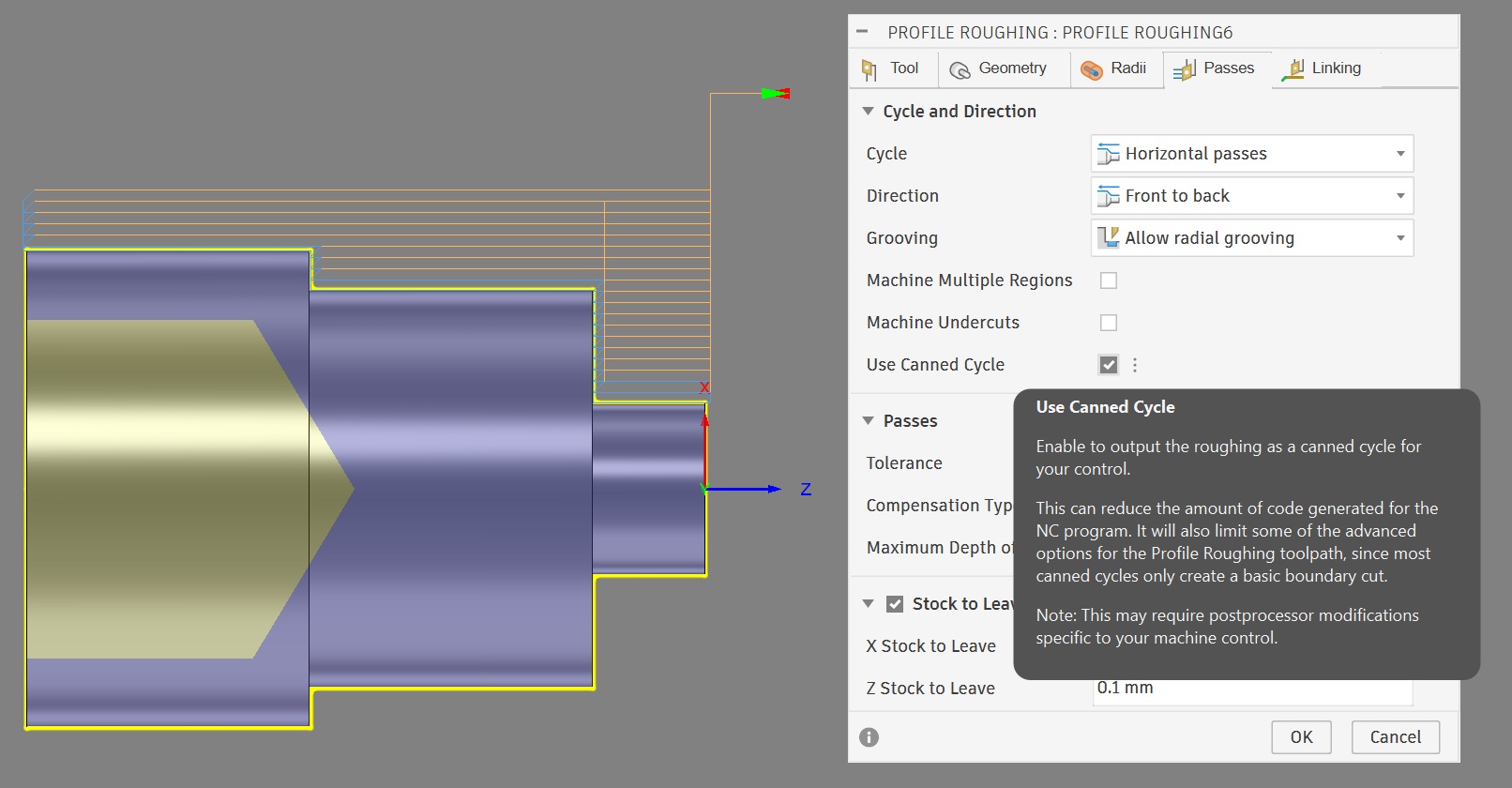

Replied by hmnijp on topic Post process Fusion 360 lathe

Post process Fusion 360 lathe

Category: Fusion 360

- saquzi

- saquzi

Yesterday 22:31

Replied by saquzi on topic 7i97+8i20 error function not found

7i97+8i20 error function not found

Category: PnCConf Wizard

- TAKUYA

- TAKUYA

Yesterday 20:33

- Finngineering

- Finngineering

Yesterday 19:47

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

Time to create page: 0.369 seconds