Search Results (Searched for: )

- Catch22

08 May 2025 15:30

Replied by Catch22 on topic Can I have 2 seperate interfaces on the same computer?

Can I have 2 seperate interfaces on the same computer?

Category: General LinuxCNC Questions

- DarkPhoinix

- DarkPhoinix

08 May 2025 15:20

Replied by DarkPhoinix on topic TB6560 jp-1635a driver pin connection to NVEM v5

TB6560 jp-1635a driver pin connection to NVEM v5

Category: Driver Boards

- Spyderbreath

08 May 2025 15:10

Replied by Spyderbreath on topic Moving from Axis to QtDragon?

Moving from Axis to QtDragon?

Category: Qtvcp

- vre

- vre

08 May 2025 14:58 - 08 May 2025 15:04

Replied by vre on topic Run/Step Hold/Resume Buttons

Run/Step Hold/Resume Buttons

Category: HAL Examples

- fery15sty

- fery15sty

08 May 2025 14:51

- bobwolf

- bobwolf

08 May 2025 14:51

- DarkPhoinix

- DarkPhoinix

08 May 2025 14:47

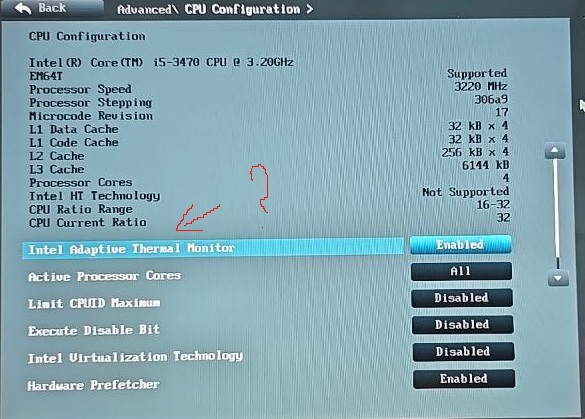

Which kernel version is best for real time? was created by DarkPhoinix

Which kernel version is best for real time?

Category: General LinuxCNC Questions

- Catch22

08 May 2025 14:33

Can I have 2 seperate interfaces on the same computer? was created by Catch22

Can I have 2 seperate interfaces on the same computer?

Category: General LinuxCNC Questions

- Aciera

08 May 2025 14:25

- vre

- vre

08 May 2025 14:17

- PCW

08 May 2025 13:31

- fery15sty

- fery15sty

08 May 2025 12:32

- DarkPhoinix

- DarkPhoinix

08 May 2025 12:18 - 08 May 2025 12:21

Replied by DarkPhoinix on topic [SOLVED]linuxcnc Latency test ambiguous results

[SOLVED]linuxcnc Latency test ambiguous results

Category: General LinuxCNC Questions

- DarkPhoinix

- DarkPhoinix

08 May 2025 11:58 - 08 May 2025 12:00

Replied by DarkPhoinix on topic [SOLVED]linuxcnc Latency test ambiguous results

[SOLVED]linuxcnc Latency test ambiguous results

Category: General LinuxCNC Questions

- RNJFAB

- RNJFAB

08 May 2025 10:29

Replied by RNJFAB on topic Job not showing in position - 2.9.4 - v2.9-238.315

Job not showing in position - 2.9.4 - v2.9-238.315

Category: Plasmac

Time to create page: 0.827 seconds