Search Results (Searched for: )

- Aciera

14 Apr 2025 06:48

Replied by Aciera on topic CNC doesn't work with new update

CNC doesn't work with new update

Category: General LinuxCNC Questions

- Aciera

14 Apr 2025 06:45

Replied by Aciera on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Category: Advanced Configuration

- sameedansar

- sameedansar

14 Apr 2025 06:33

Replied by sameedansar on topic Steppers motor start moving without any commads being given

Steppers motor start moving without any commads being given

Category: General LinuxCNC Questions

- theslawek

- theslawek

14 Apr 2025 06:16

Replied by theslawek on topic Need help making rotary axis behave like second spindle

Need help making rotary axis behave like second spindle

Category: Advanced Configuration

- tcbmetalworks

- tcbmetalworks

14 Apr 2025 05:43

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- unknown

- unknown

14 Apr 2025 04:41

- notJamesLee

- notJamesLee

14 Apr 2025 03:44

Determining Angular Scale - Help w/ Microsteps was created by notJamesLee

Determining Angular Scale - Help w/ Microsteps

Category: Configuration Tools

- PCW

14 Apr 2025 03:03

- unknown

- unknown

14 Apr 2025 00:53

Replied by unknown on topic RPi 4, LinuxCNC upgrade doesn't upgrade kernel

RPi 4, LinuxCNC upgrade doesn't upgrade kernel

Category: Installing LinuxCNC

- tcbmetalworks

- tcbmetalworks

14 Apr 2025 00:08

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- vre

- vre

13 Apr 2025 23:23

- foam man

- foam man

13 Apr 2025 22:54

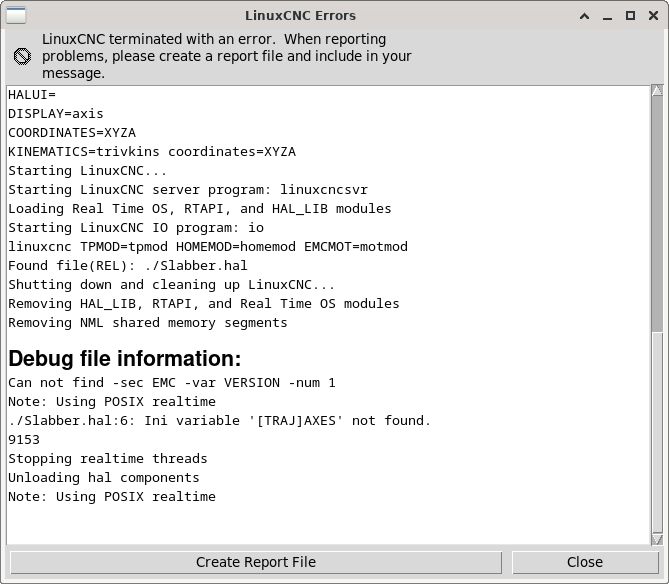

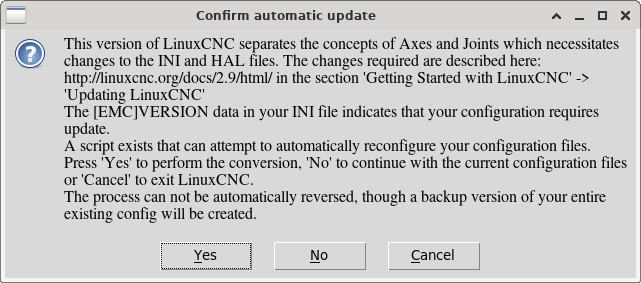

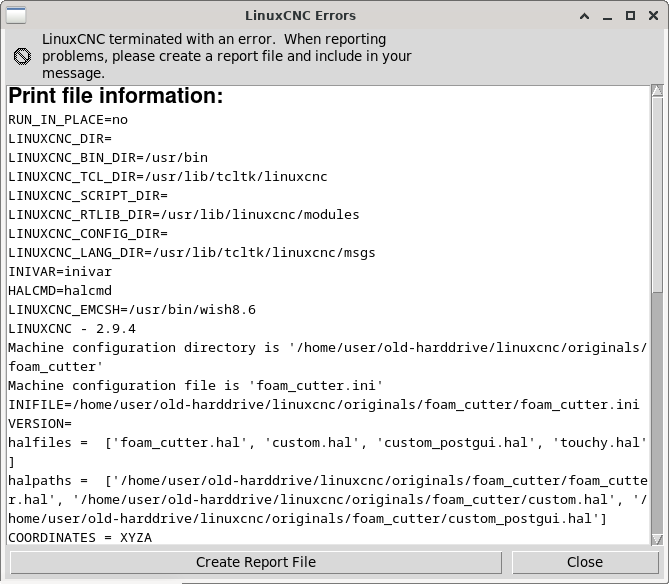

Replied by foam man on topic CNC doesn't work with new update

CNC doesn't work with new update

Category: General LinuxCNC Questions

- foam man

- foam man

13 Apr 2025 22:50

CNC doesn't work with new update was created by foam man

CNC doesn't work with new update

Category: General LinuxCNC Questions

- rodw

13 Apr 2025 22:03

Replied by rodw on topic How to pass parameters .comp file

How to pass parameters .comp file

Category: HAL

- jochen91

- jochen91

13 Apr 2025 21:49 - 13 Apr 2025 23:03

Replied by jochen91 on topic Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Planning to Retrofit a Mazak Integrex200Y Mill-Turn Machine

Category: Advanced Configuration

Time to create page: 0.465 seconds