Search Results (Searched for: )

- unknown

- unknown

03 Apr 2025 23:02

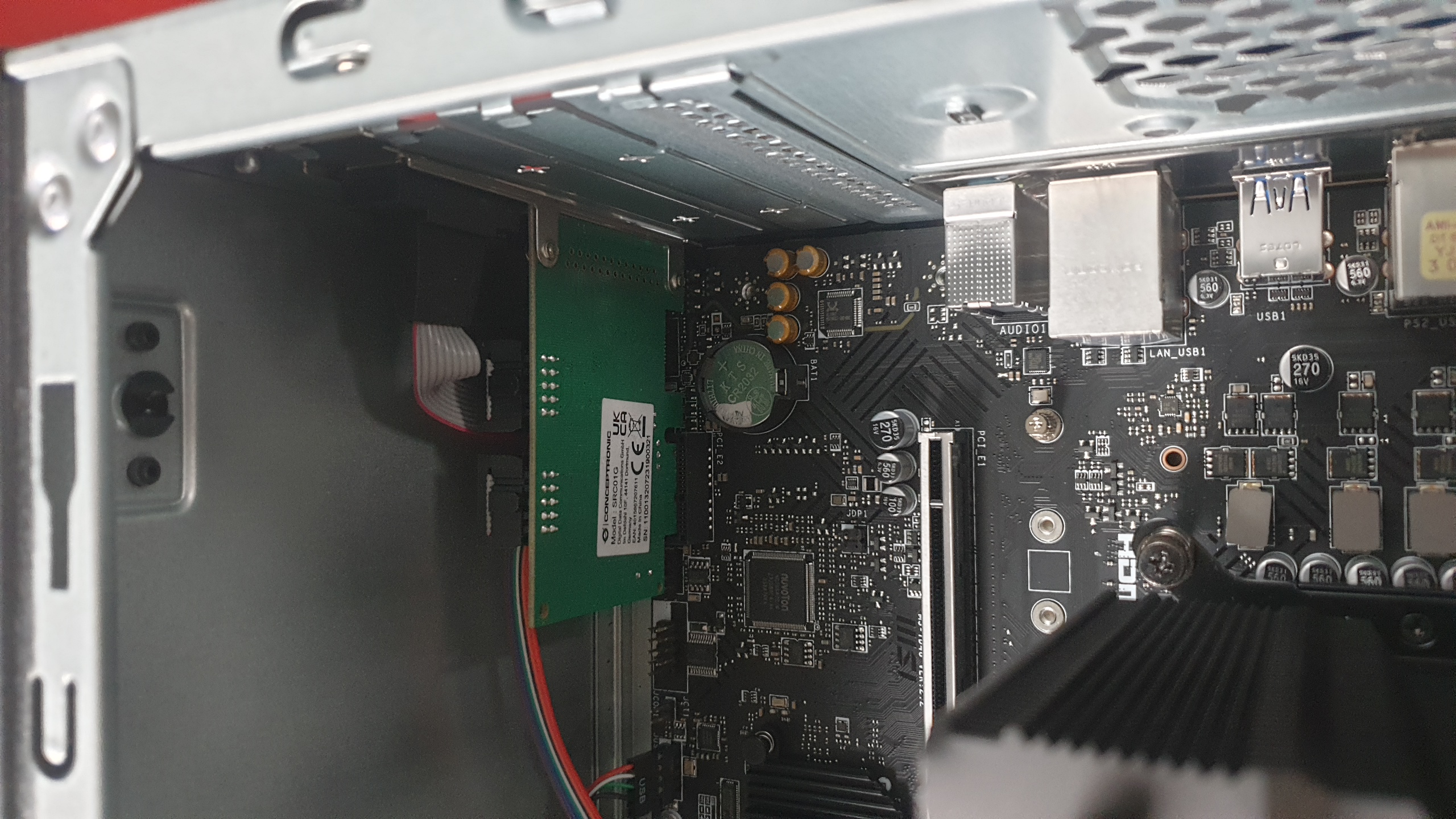

Replied by unknown on topic PCIe to ParPort - chipset PCI 60806A works?

PCIe to ParPort - chipset PCI 60806A works?

Category: Computers and Hardware

- Cherna

- Cherna

03 Apr 2025 21:52 - 03 Apr 2025 21:55

Replied by Cherna on topic PCIe to ParPort - chipset PCI 60806A works?

PCIe to ParPort - chipset PCI 60806A works?

Category: Computers and Hardware

- unknown

- unknown

03 Apr 2025 21:44

Replied by unknown on topic PCIe to ParPort - chipset PCI 60806A works?

PCIe to ParPort - chipset PCI 60806A works?

Category: Computers and Hardware

- unknown

- unknown

03 Apr 2025 21:37

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- unknown

- unknown

03 Apr 2025 21:35

- Masiwood123

03 Apr 2025 21:16

Replied by Masiwood123 on topic bandit controller retrofit

bandit controller retrofit

Category: General LinuxCNC Questions

- irwinger

- irwinger

03 Apr 2025 20:40

Spindle control not showing in Axis window... was created by irwinger

Spindle control not showing in Axis window...

Category: Basic Configuration

- atrex77

03 Apr 2025 20:11

Replied by atrex77 on topic Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Category: General LinuxCNC Questions

- COFHAL

- COFHAL

03 Apr 2025 19:06

- tommylight

03 Apr 2025 18:56

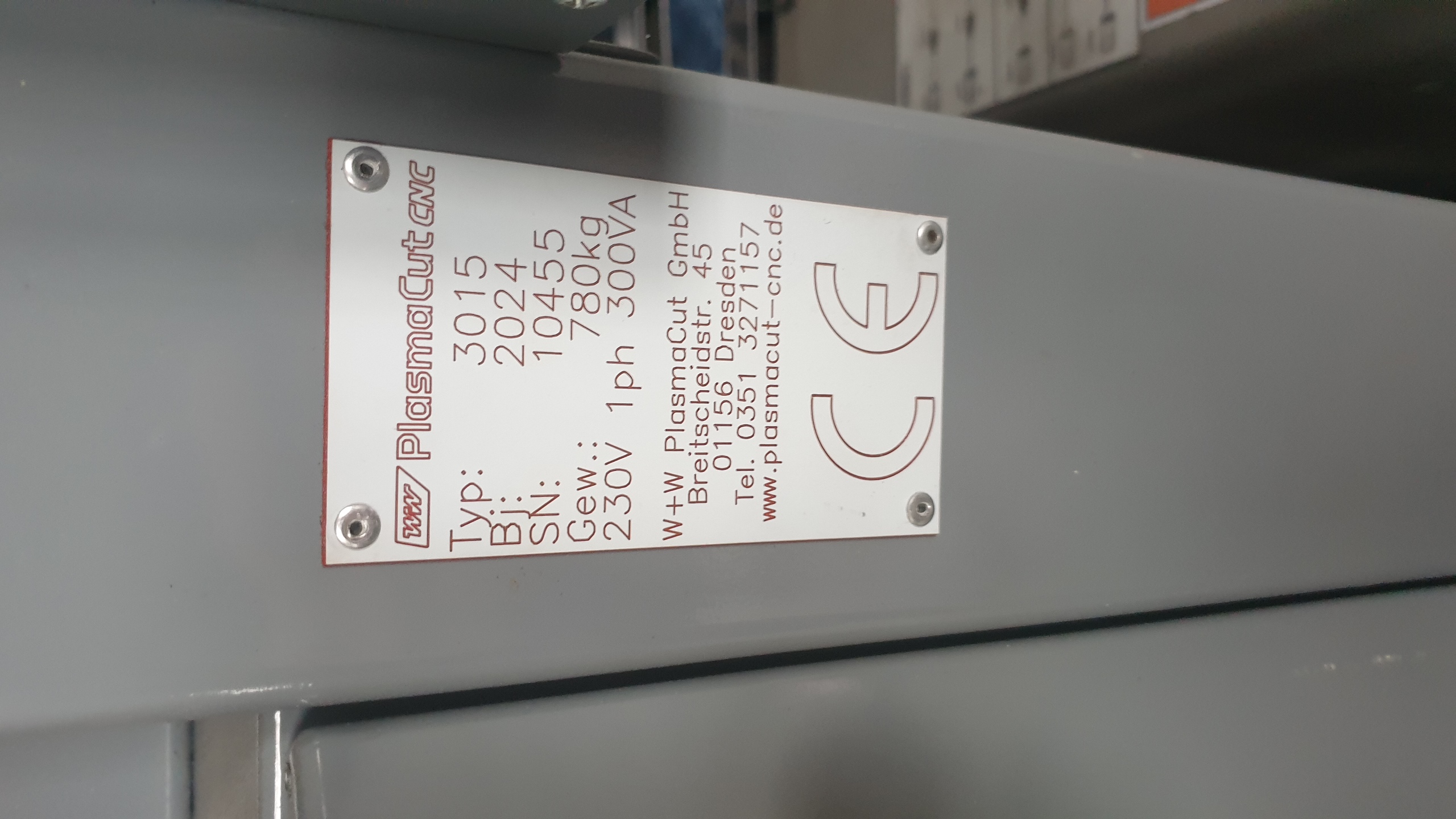

New CNC machine with RS232 (plain serial) connection to PC!!! was created by tommylight

New CNC machine with RS232 (plain serial) connection to PC!!!

Category: Show Your Stuff

- COFHAL

- COFHAL

03 Apr 2025 18:50

- tommylight

03 Apr 2025 18:00

Replied by tommylight on topic Hurco Hawk 5M Retrofit w/ existing motors

Hurco Hawk 5M Retrofit w/ existing motors

Category: General LinuxCNC Questions

- tommylight

03 Apr 2025 17:54

- tommylight

03 Apr 2025 17:53

Replied by tommylight on topic bandit controller retrofit

bandit controller retrofit

Category: General LinuxCNC Questions

- Beovoxo

- Beovoxo

03 Apr 2025 17:30

Time to create page: 0.976 seconds