Search Results (Searched for: )

- timo

- timo

22 Feb 2025 09:40

How to integrate manual spindle lock into Axis GUI? was created by timo

How to integrate manual spindle lock into Axis GUI?

Category: General LinuxCNC Questions

- unknown

- unknown

22 Feb 2025 09:33

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- cmorley

- cmorley

22 Feb 2025 09:15

Replied by cmorley on topic development of a qt version of ncam

development of a qt version of ncam

Category: Qtvcp

- MTTI

22 Feb 2025 09:07

- MTTI

22 Feb 2025 08:52 - 22 Feb 2025 08:53

Replied by MTTI on topic Probe function not working after final adjustments

Probe function not working after final adjustments

Category: Plasmac

- azim4411

- azim4411

22 Feb 2025 08:46

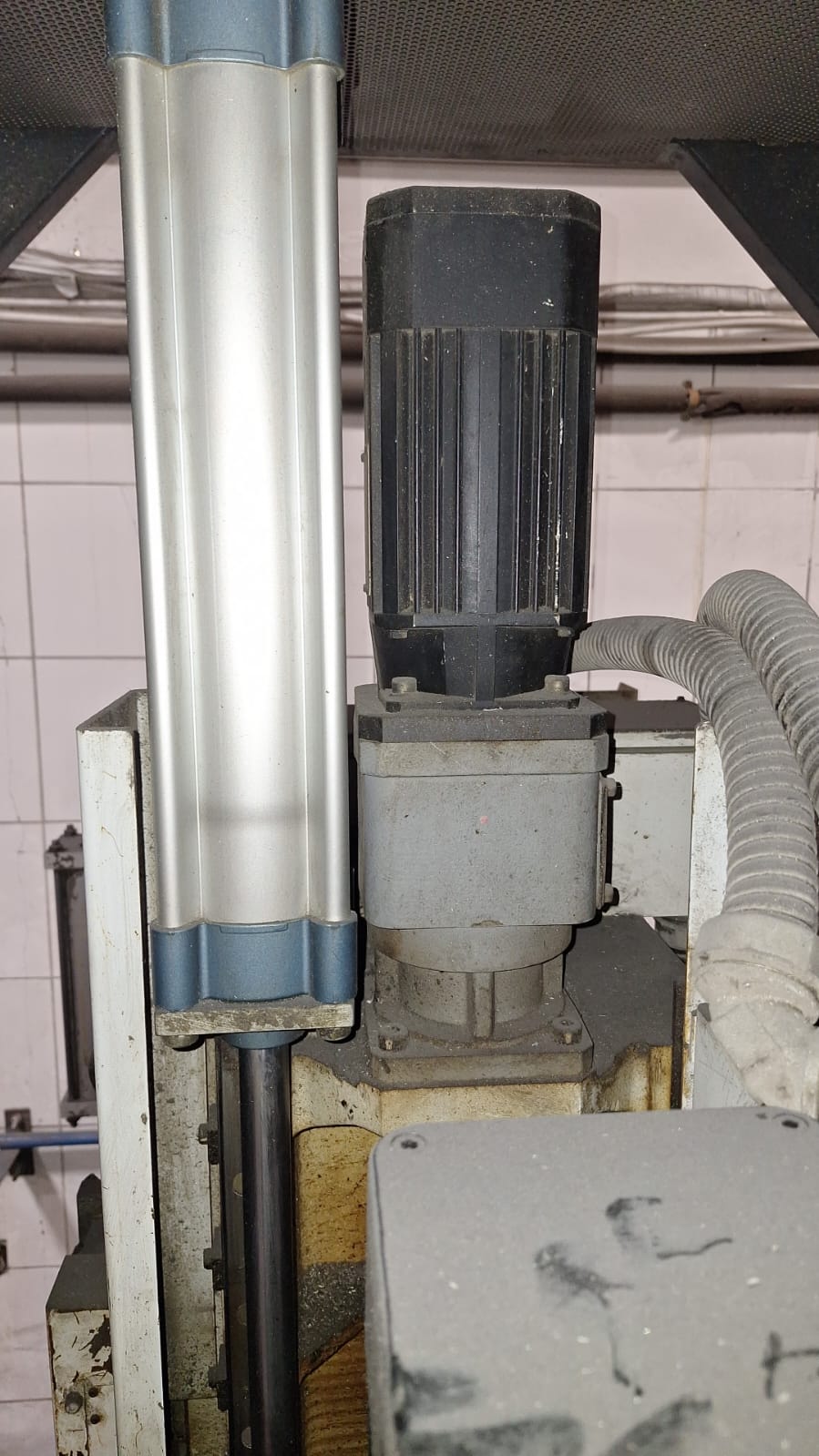

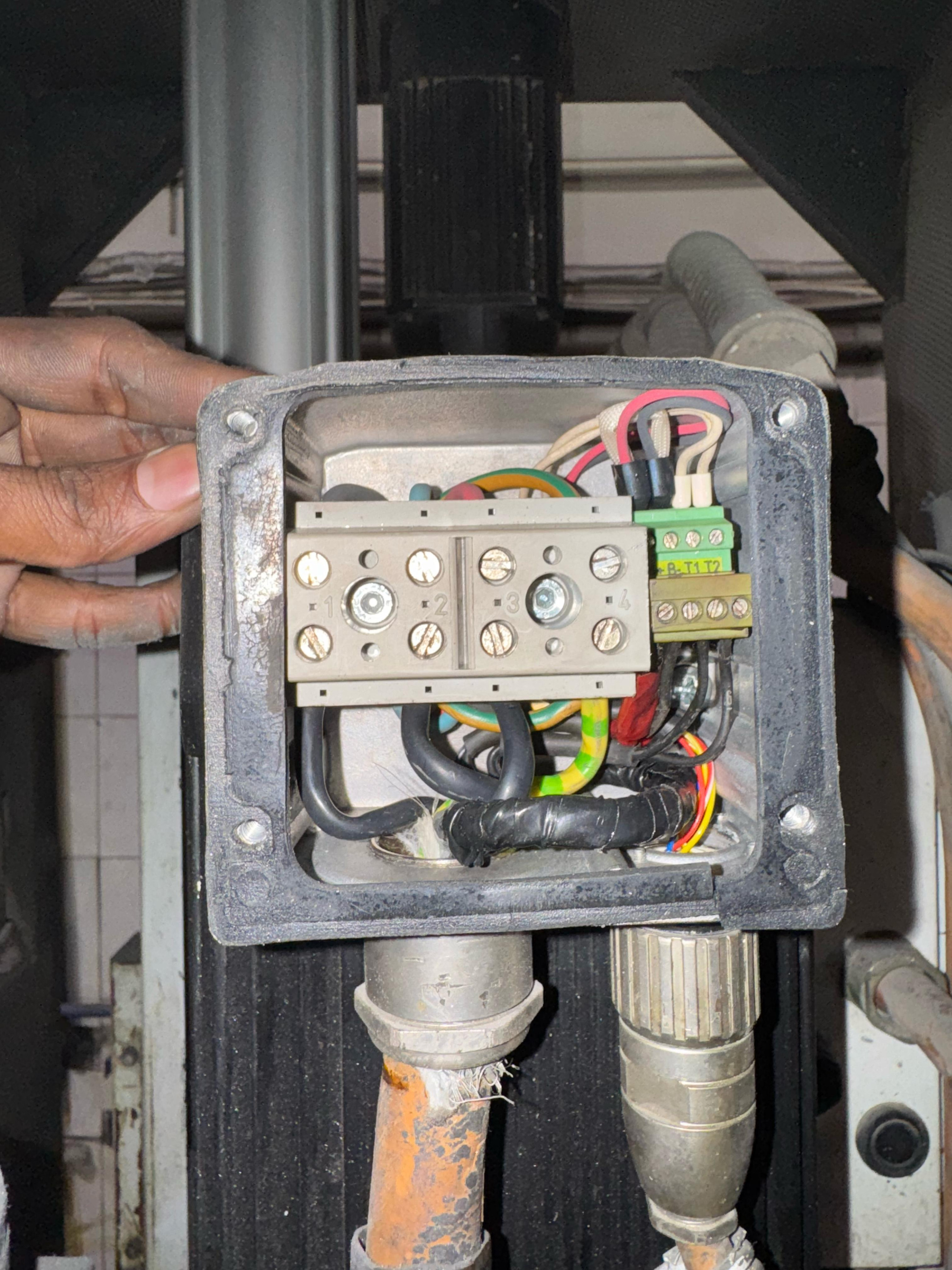

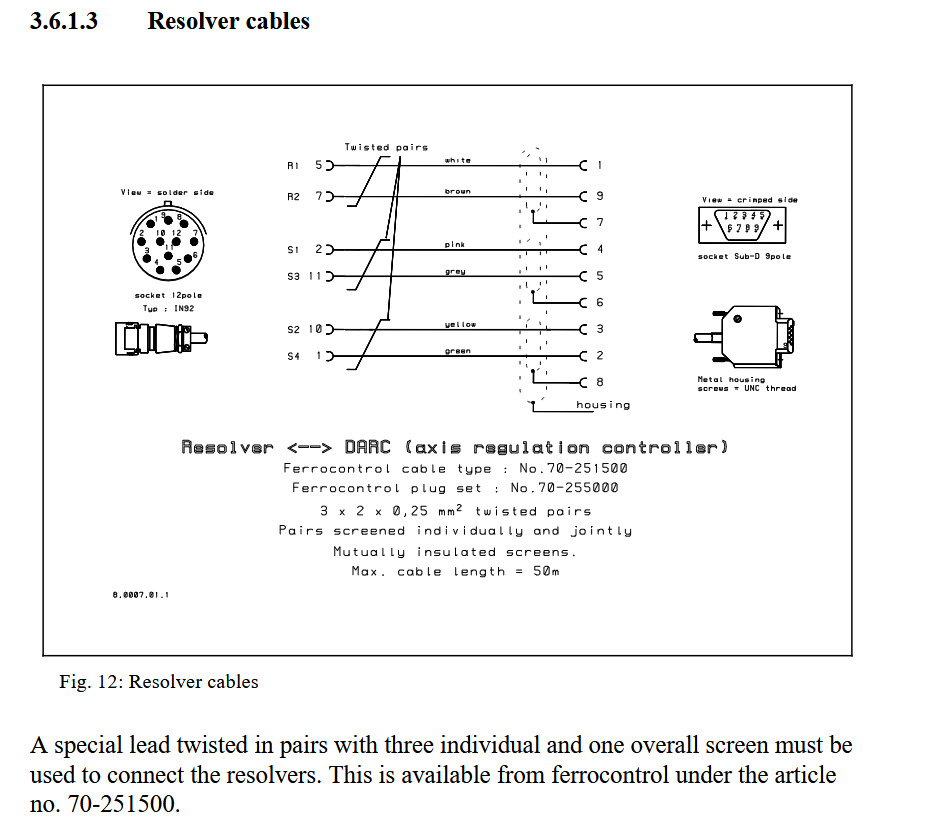

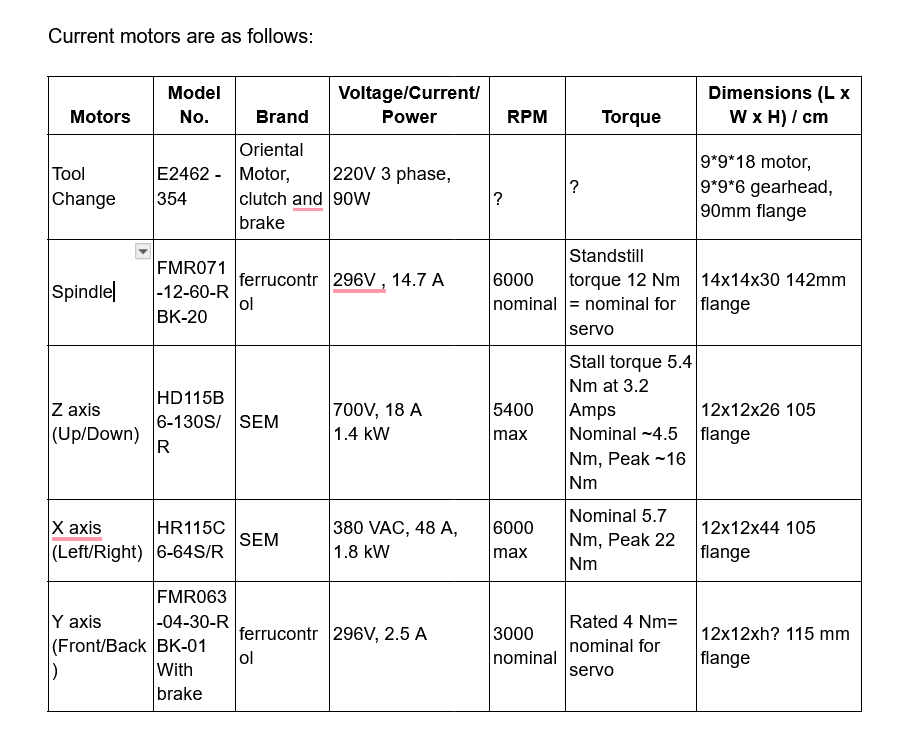

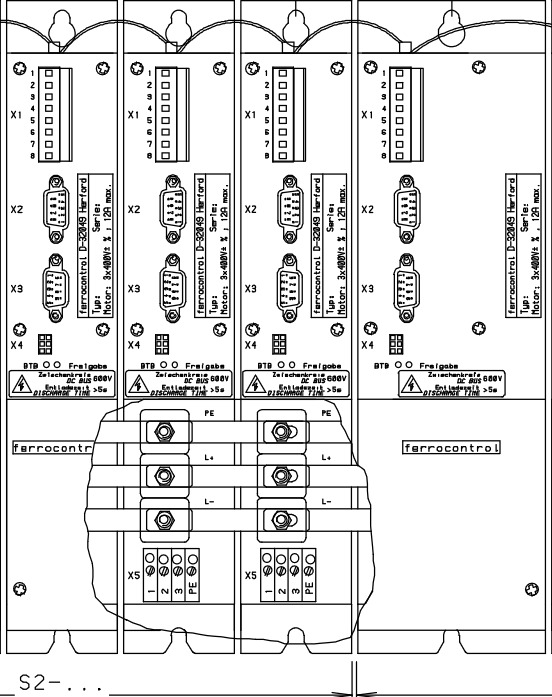

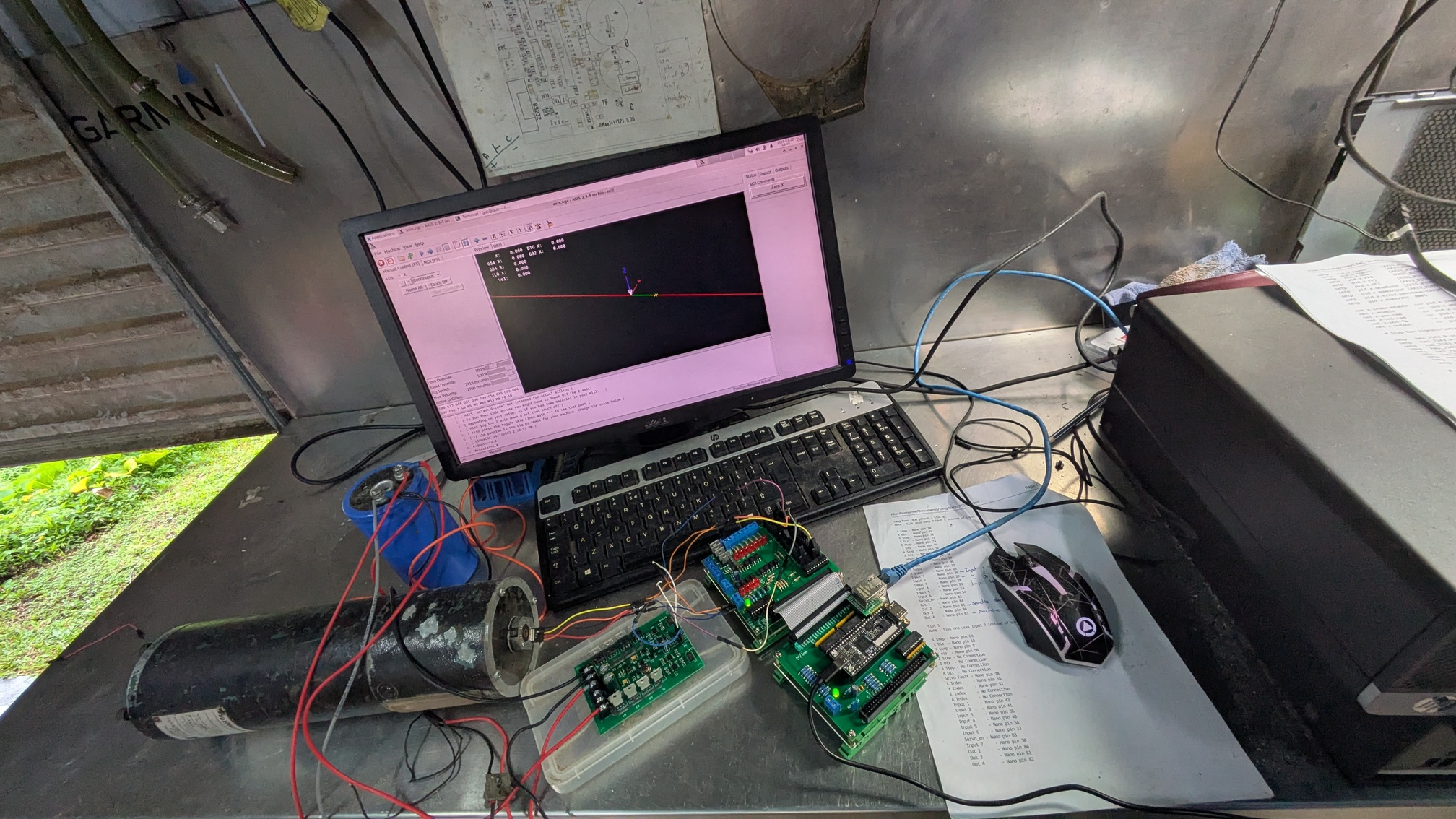

Replied by azim4411 on topic Elumatec SBZ 130/01 retrofit

Elumatec SBZ 130/01 retrofit

Category: CNC Machines

- azim4411

- azim4411

22 Feb 2025 08:42

Replied by azim4411 on topic Elumatec SBZ 130/01 retrofit

Elumatec SBZ 130/01 retrofit

Category: CNC Machines

- rodw

22 Feb 2025 08:01

Replied by rodw on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- Hakan

- Hakan

22 Feb 2025 07:46

Replied by Hakan on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- Str8jacket

- Str8jacket

22 Feb 2025 06:22

- Sziggy_NC

- Sziggy_NC

22 Feb 2025 04:58

Replied by Sziggy_NC on topic +-10v setup 7i97 & .ini

+-10v setup 7i97 & .ini

Category: General LinuxCNC Questions

- unknown

- unknown

22 Feb 2025 04:54

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- PCW

22 Feb 2025 03:56 - 22 Feb 2025 04:13

Replied by PCW on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- epineh

- epineh

22 Feb 2025 01:16

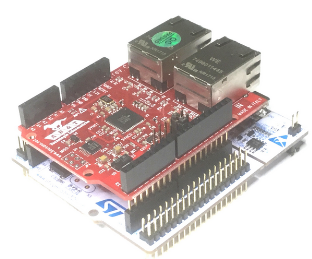

Replied by epineh on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

Time to create page: 0.559 seconds