Search Results (Searched for: )

- rodw

09 Feb 2025 20:42

Replied by rodw on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- tommylight

09 Feb 2025 20:32

Replied by tommylight on topic THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

THC with Beckhoff EL5101 and THCAD2 => encoder signal loss

Category: Plasmac

- IB_CnC

- IB_CnC

09 Feb 2025 20:11

Replied by IB_CnC on topic Losing some values after PB restart

Losing some values after PB restart

Category: QtPyVCP

- rodw

09 Feb 2025 20:04

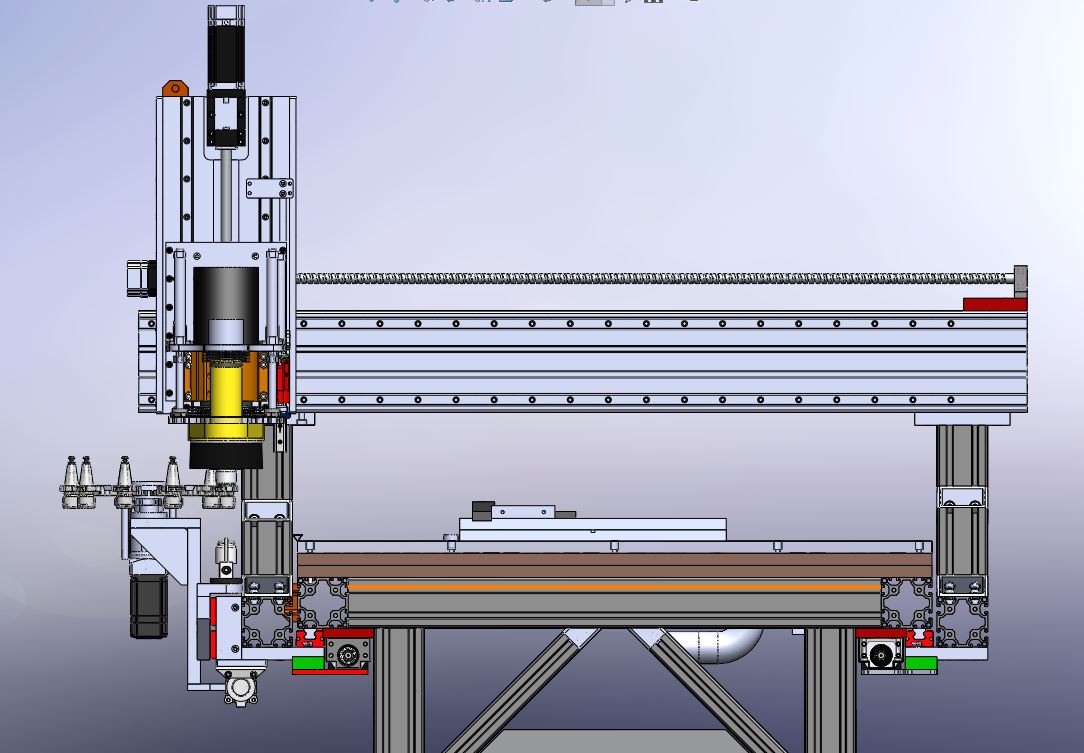

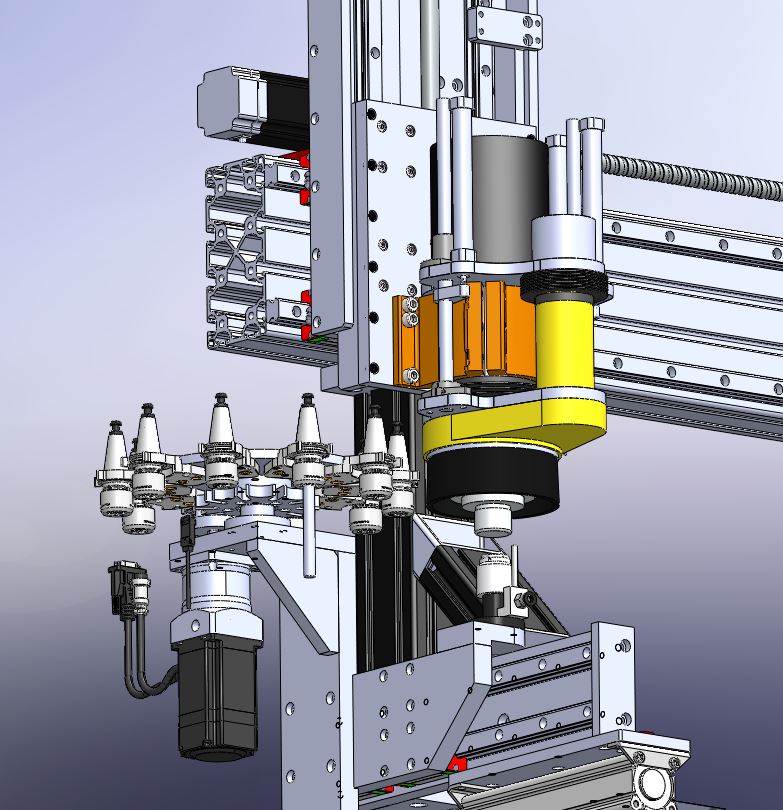

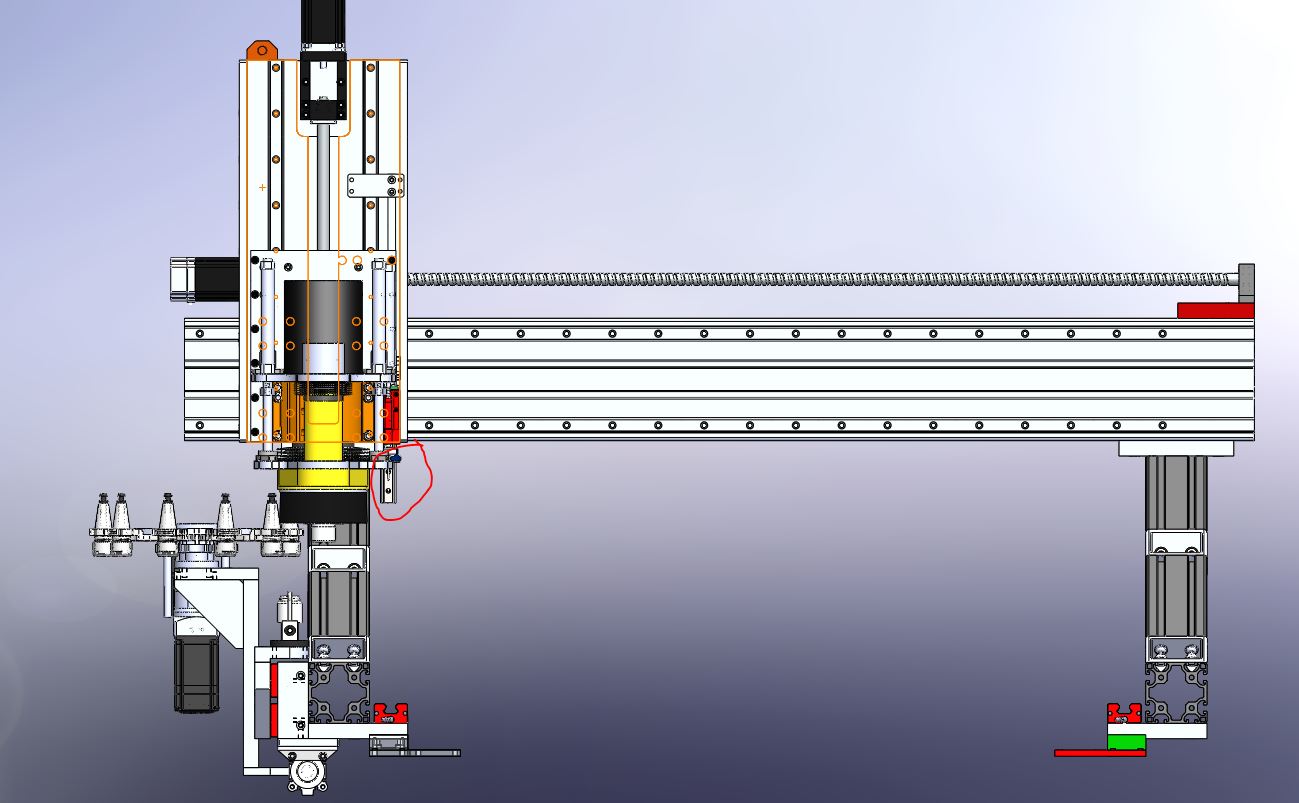

Replied by rodw on topic New ethercat / probe basic control for minimonster

New ethercat / probe basic control for minimonster

Category: CNC Machines

- IB_CnC

- IB_CnC

09 Feb 2025 19:56

Replied by IB_CnC on topic ProbeBasic and sidemount, retractable 3D Probe

ProbeBasic and sidemount, retractable 3D Probe

Category: QtPyVCP

- andypugh

09 Feb 2025 19:45

Replied by andypugh on topic From Grbl to linuxcnc

From Grbl to linuxcnc

Category: General LinuxCNC Questions

- Guytou

- Guytou

09 Feb 2025 19:44

Replied by Guytou on topic M-code to toggle macrobutton not working on QtDragon

M-code to toggle macrobutton not working on QtDragon

Category: General LinuxCNC Questions

- NT4Boy

- NT4Boy

09 Feb 2025 19:44

Replied by NT4Boy on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- ihavenofish

- ihavenofish

09 Feb 2025 19:43

Replied by ihavenofish on topic New ethercat / probe basic control for minimonster

New ethercat / probe basic control for minimonster

Category: CNC Machines

- andypugh

09 Feb 2025 19:43

Replied by andypugh on topic From Grbl to linuxcnc

From Grbl to linuxcnc

Category: General LinuxCNC Questions

- andypugh

09 Feb 2025 19:37

Replied by andypugh on topic Starting a new (first) project

Starting a new (first) project

Category: General LinuxCNC Questions

- andypugh

09 Feb 2025 19:20

Replied by andypugh on topic QtPlasmaC Error: "E word with no G70,G76,M66,M67 or M68 to use it"

QtPlasmaC Error: "E word with no G70,G76,M66,M67 or M68 to use it"

Category: Plasmac

- Lcvette

09 Feb 2025 19:18

- Lcvette

09 Feb 2025 19:17

Replied by Lcvette on topic Losing some values after PB restart

Losing some values after PB restart

Category: QtPyVCP

- Lcvette

09 Feb 2025 19:16

Replied by Lcvette on topic Losing some values after PB restart

Losing some values after PB restart

Category: QtPyVCP

Time to create page: 0.507 seconds