Search Results (Searched for: )

- Reddiamonduk

- Reddiamonduk

09 Feb 2025 18:18 - 09 Feb 2025 18:35

Replied by Reddiamonduk on topic Error starting gmoccapy with spindle speed display.

Error starting gmoccapy with spindle speed display.

Category: pyVCP

- timo

- timo

09 Feb 2025 18:11

Replied by timo on topic need help! mesa 7i95 connection problem

need help! mesa 7i95 connection problem

Category: Driver Boards

- Lcvette

09 Feb 2025 18:08

Replied by Lcvette on topic Launch Probe basic not in fullscreen

Launch Probe basic not in fullscreen

Category: QtPyVCP

- jhandel

- jhandel

09 Feb 2025 18:07

Replied by jhandel on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Lcvette

09 Feb 2025 18:04

Replied by Lcvette on topic Losing some values after PB restart

Losing some values after PB restart

Category: QtPyVCP

- andypugh

09 Feb 2025 18:02

Replied by andypugh on topic Fusion360 postprocessor for linuxcnc lathe with tailstock axis in Z Direction

Fusion360 postprocessor for linuxcnc lathe with tailstock axis in Z Direction

Category: Fusion 360

- bkt

09 Feb 2025 18:02

Replied by bkt on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- Lcvette

09 Feb 2025 18:00

Replied by Lcvette on topic ProbeBasic and sidemount, retractable 3D Probe

ProbeBasic and sidemount, retractable 3D Probe

Category: QtPyVCP

- andypugh

09 Feb 2025 17:53

- PCW

09 Feb 2025 17:52

Replied by PCW on topic need help! mesa 7i95 connection problem

need help! mesa 7i95 connection problem

Category: Driver Boards

- andypugh

09 Feb 2025 17:46 - 09 Feb 2025 17:50

Replied by andypugh on topic Carousel component with 2 Towers.

Carousel component with 2 Towers.

Category: Configuration Tools

- andypugh

09 Feb 2025 17:44

Replied by andypugh on topic rotation plane around y axis in g18

rotation plane around y axis in g18

Category: G&M Codes

- tommylight

09 Feb 2025 17:40

Replied by tommylight on topic Serious dependency trouble while installing linuxcnc

Serious dependency trouble while installing linuxcnc

Category: General LinuxCNC Questions

- sin-do-re

- sin-do-re

09 Feb 2025 17:01

Serious dependency trouble while installing linuxcnc was created by sin-do-re

Serious dependency trouble while installing linuxcnc

Category: General LinuxCNC Questions

- beauxnez

- beauxnez

09 Feb 2025 16:27 - 09 Feb 2025 17:47

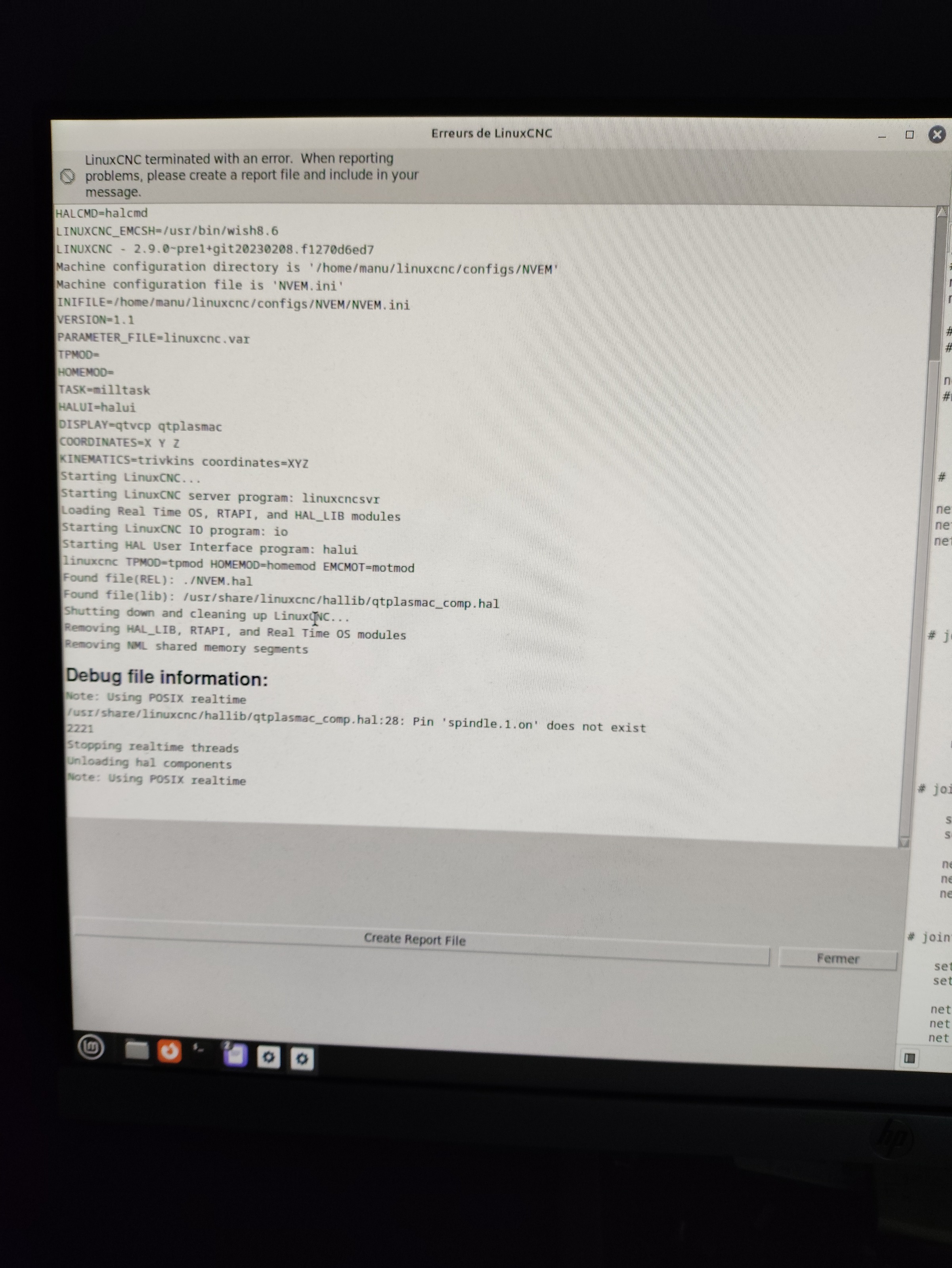

Replied by beauxnez on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Time to create page: 0.899 seconds