Search Results (Searched for: )

- andreabonuc

- andreabonuc

07 Feb 2025 18:56

Replied by andreabonuc on topic 7i73 input 0-7 i cant'use

7i73 input 0-7 i cant'use

Category: Basic Configuration

- jairobbo

- jairobbo

07 Feb 2025 18:42 - 07 Feb 2025 18:43

Replied by jairobbo on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- PCW

07 Feb 2025 18:26

Replied by PCW on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- PCW

07 Feb 2025 18:23 - 07 Feb 2025 18:24

Replied by PCW on topic 7i73 input 0-7 i cant'use

7i73 input 0-7 i cant'use

Category: Basic Configuration

- KrisJ

- KrisJ

07 Feb 2025 17:57

Replied by KrisJ on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- NT4Boy

- NT4Boy

07 Feb 2025 17:48

Replied by NT4Boy on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- andreabonuc

- andreabonuc

07 Feb 2025 17:26

7i73 input 0-7 i cant'use was created by andreabonuc

7i73 input 0-7 i cant'use

Category: Basic Configuration

- Aciera

07 Feb 2025 17:16 - 07 Feb 2025 17:17

Replied by Aciera on topic Coordinate system and touch off

Coordinate system and touch off

Category: General LinuxCNC Questions

- zz912

07 Feb 2025 17:16

- ihavenofish

- ihavenofish

07 Feb 2025 17:05

Replied by ihavenofish on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- PCW

07 Feb 2025 16:48

Replied by PCW on topic 7i96s Replacement Needed

7i96s Replacement Needed

Category: General LinuxCNC Questions

- PCW

07 Feb 2025 16:43

- IronManDylan

- IronManDylan

07 Feb 2025 16:32

Replied by IronManDylan on topic 7i96s Replacement Needed

7i96s Replacement Needed

Category: General LinuxCNC Questions

- Murphy

- Murphy

07 Feb 2025 16:06

Replied by Murphy on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- PCW

07 Feb 2025 16:01

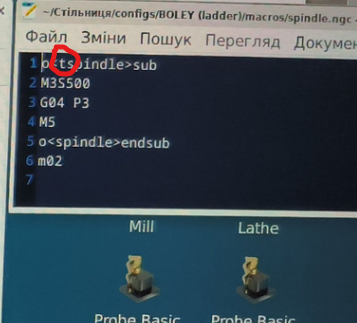

Replied by PCW on topic 7i95T + 7i78 spindle configuration

7i95T + 7i78 spindle configuration

Category: Basic Configuration

Time to create page: 0.439 seconds