Search Results (Searched for: )

- spumco

- spumco

17 Jan 2025 18:01

Replied by spumco on topic Carousel with step motor

Carousel with step motor

Category: Advanced Configuration

- richcolvin

17 Jan 2025 17:56

Problems configuring 7i92TH with pncconf was created by richcolvin

Problems configuring 7i92TH with pncconf

Category: PnCConf Wizard

- hmnijp

- hmnijp

17 Jan 2025 17:54 - 17 Jan 2025 17:57

Replied by hmnijp on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- PCW

17 Jan 2025 17:46

Replied by PCW on topic Operating computers in the cold

Operating computers in the cold

Category: Computers and Hardware

- gekonko

17 Jan 2025 17:17

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- Krulli_Fräser

- Krulli_Fräser

17 Jan 2025 17:01

Replied by Krulli_Fräser on topic Operating computers in the cold

Operating computers in the cold

Category: Computers and Hardware

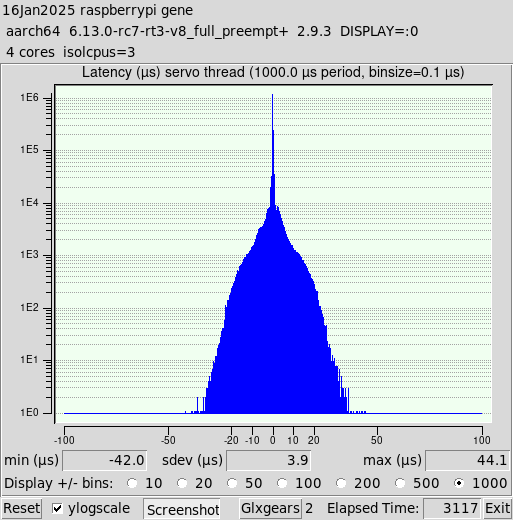

- gene_weber

17 Jan 2025 17:00

Replied by gene_weber on topic Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Category: Installing LinuxCNC

- gekonko

17 Jan 2025 16:51

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- Grotius

17 Jan 2025 16:44

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- zmrdko

17 Jan 2025 15:52

Replied by zmrdko on topic Missing link in homing LC10E

Missing link in homing LC10E

Category: EtherCAT

- tommylight

17 Jan 2025 15:45

Replied by tommylight on topic Operating computers in the cold

Operating computers in the cold

Category: Computers and Hardware

- Krulli_Fräser

- Krulli_Fräser

17 Jan 2025 15:25

Operating computers in the cold was created by Krulli_Fräser

Operating computers in the cold

Category: Computers and Hardware

- Nserega.90

- Nserega.90

17 Jan 2025 15:17

Replied by Nserega.90 on topic ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

ColorCNC Colorlight 5A-75E/5A-75B as FPGA controller board

Category: Driver Boards

- Cant do this anymore bye all

17 Jan 2025 15:16

Replied by Cant do this anymore bye all on topic help to compensate for changes in the rack

help to compensate for changes in the rack

Category: Advanced Configuration

- Cant do this anymore bye all

17 Jan 2025 15:12

Replied by Cant do this anymore bye all on topic Arduino IO Expansion

Arduino IO Expansion

Category: Show Your Stuff

Time to create page: 0.394 seconds