Search Results (Searched for: )

- tommylight

03 Jan 2025 11:05

Replied by tommylight on topic Estop all the axes that scroll at low speed, a few hundredths per second

Estop all the axes that scroll at low speed, a few hundredths per second

Category: General LinuxCNC Questions

- my1987toyota

03 Jan 2025 11:00

Replied by my1987toyota on topic Some 3D printing advice to start this section

Some 3D printing advice to start this section

Category: Additive Manufacturing

- Guytou

- Guytou

03 Jan 2025 10:41

encoder to change PWM value to VFD was created by Guytou

encoder to change PWM value to VFD

Category: Computers and Hardware

- Edi_48

- Edi_48

03 Jan 2025 10:39

- Odiug

- Odiug

03 Jan 2025 10:37

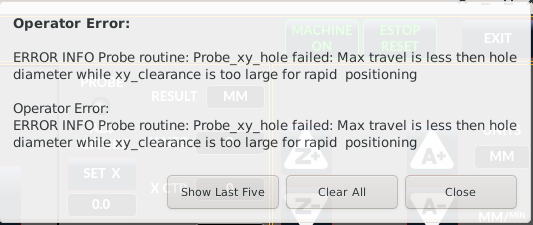

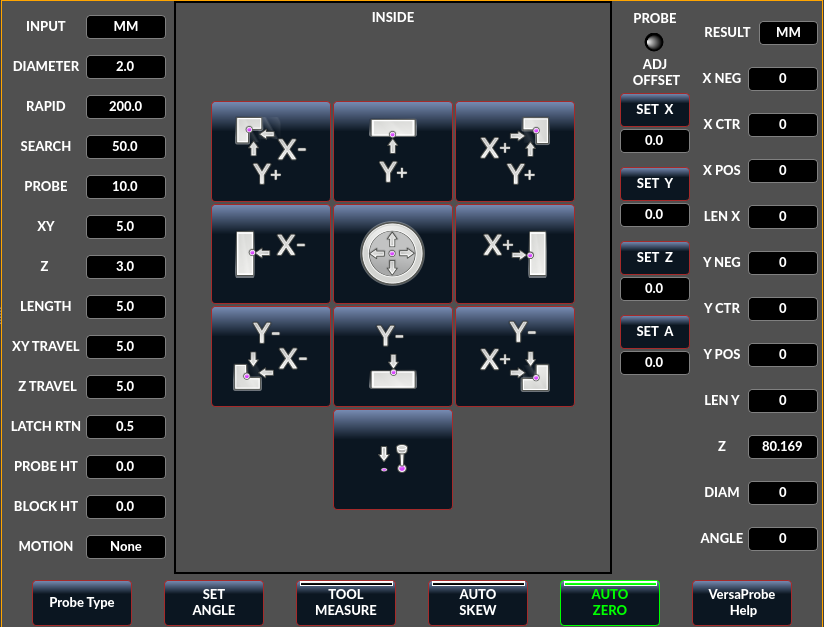

QtDragon PROBE: understanding popup error message was created by Odiug

QtDragon PROBE: understanding popup error message

Category: Qtvcp

- Cant do this anymore bye all

03 Jan 2025 09:09

Replied by Cant do this anymore bye all on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Cant do this anymore bye all

03 Jan 2025 09:01

Replied by Cant do this anymore bye all on topic Arduino IO Expansion

Arduino IO Expansion

Category: Show Your Stuff

- Ginou

- Ginou

03 Jan 2025 08:43

- Ehsan_R

- Ehsan_R

03 Jan 2025 08:36

- AnkerFly

- AnkerFly

03 Jan 2025 07:44 - 03 Jan 2025 07:45

Probe basiс and Cyrillic characters was created by AnkerFly

Probe basiс and Cyrillic characters

Category: QtPyVCP

- RV3Dtech

- RV3Dtech

03 Jan 2025 07:30

Replied by RV3Dtech on topic qtDragon LED Probe und Spindeldrehzahl anzeigen

qtDragon LED Probe und Spindeldrehzahl anzeigen

Category: Deutsch

- phillc54

03 Jan 2025 06:57

Replied by phillc54 on topic Cut Recovery Not Consistently Triggering

Cut Recovery Not Consistently Triggering

Category: Plasmac

- TomAlborough

03 Jan 2025 06:20

Replied by TomAlborough on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- stirra

- stirra

03 Jan 2025 04:19

Replied by stirra on topic Missing link in homing LC10E

Missing link in homing LC10E

Category: EtherCAT

- yoshimitsuspeed

- yoshimitsuspeed

03 Jan 2025 04:09

Replied by yoshimitsuspeed on topic Questions in trying to get my home built machine dialed in with a 7i76E

Questions in trying to get my home built machine dialed in with a 7i76E

Category: General LinuxCNC Questions

Time to create page: 0.638 seconds