Search Results (Searched for: )

- JT

13 Dec 2024 14:05

- Lcvette

13 Dec 2024 13:47

Replied by Lcvette on topic Feedback control XY not full speed run G1 when curve or Arc

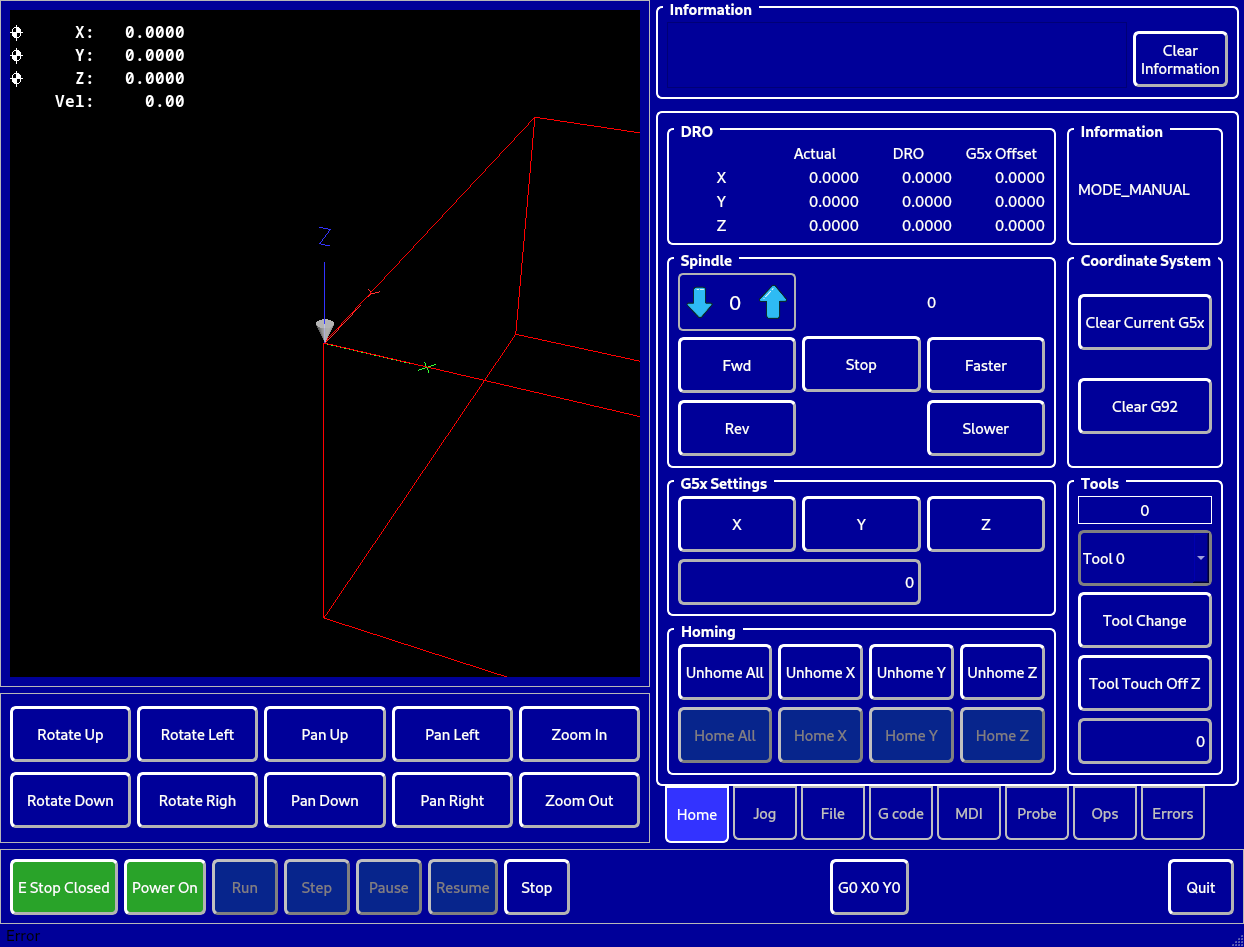

Feedback control XY not full speed run G1 when curve or Arc

Category: General LinuxCNC Questions

- akg1904

- akg1904

13 Dec 2024 13:33

Equivalent of some Fanuc codes was created by akg1904

Equivalent of some Fanuc codes

Category: General LinuxCNC Questions

- greg23_78

- greg23_78

13 Dec 2024 13:00

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- tommylight

13 Dec 2024 12:45

Replied by tommylight on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- StoneB

- StoneB

13 Dec 2024 12:23 - 13 Dec 2024 12:24

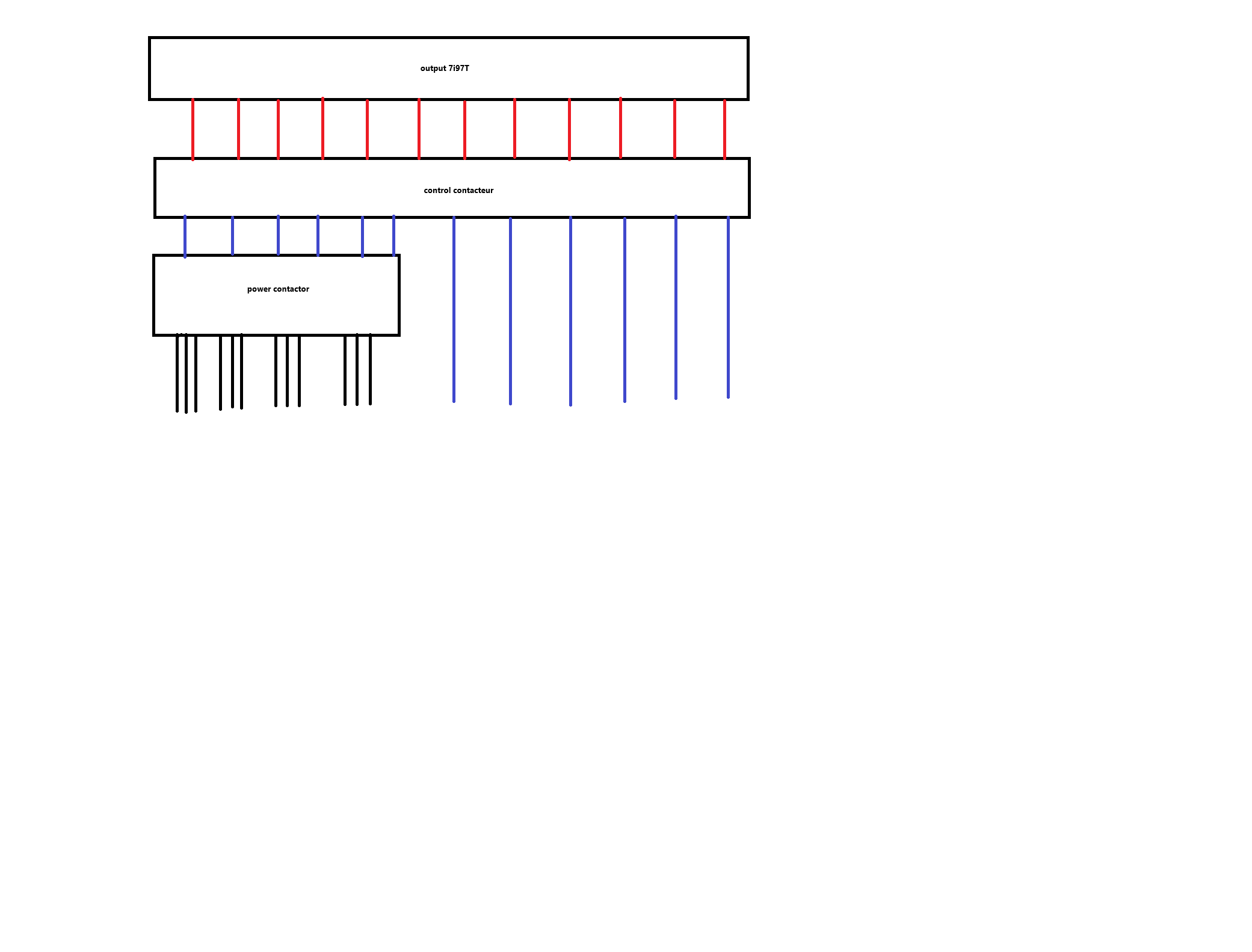

Replied by StoneB on topic Xilinx Setup to edit config for 7i92T

Xilinx Setup to edit config for 7i92T

Category: Driver Boards

- Lcvette

13 Dec 2024 11:57

Replied by Lcvette on topic probe_basic_lathe vtk_backplot.py error

probe_basic_lathe vtk_backplot.py error

Category: QtPyVCP

- Lcvette

13 Dec 2024 11:41

Replied by Lcvette on topic Probe Basic - ATC sim parameter question

Probe Basic - ATC sim parameter question

Category: QtPyVCP

- greg23_78

- greg23_78

13 Dec 2024 11:03

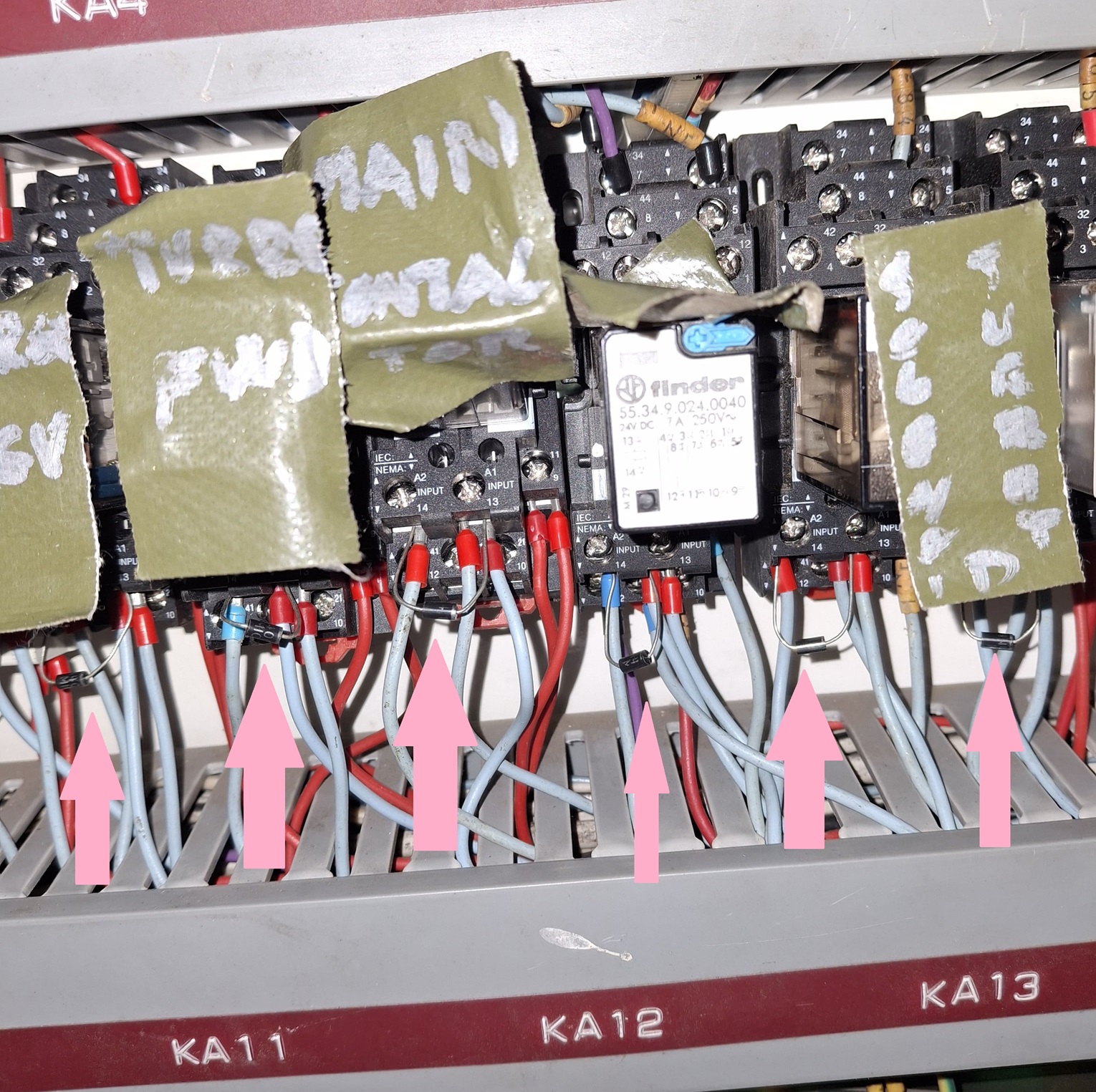

Replied by greg23_78 on topic Solution fo "hm2 error finishing read" with no good PC

Solution fo "hm2 error finishing read" with no good PC

Category: Computers and Hardware

- Lcvette

13 Dec 2024 10:35

- GDTH

13 Dec 2024 10:33

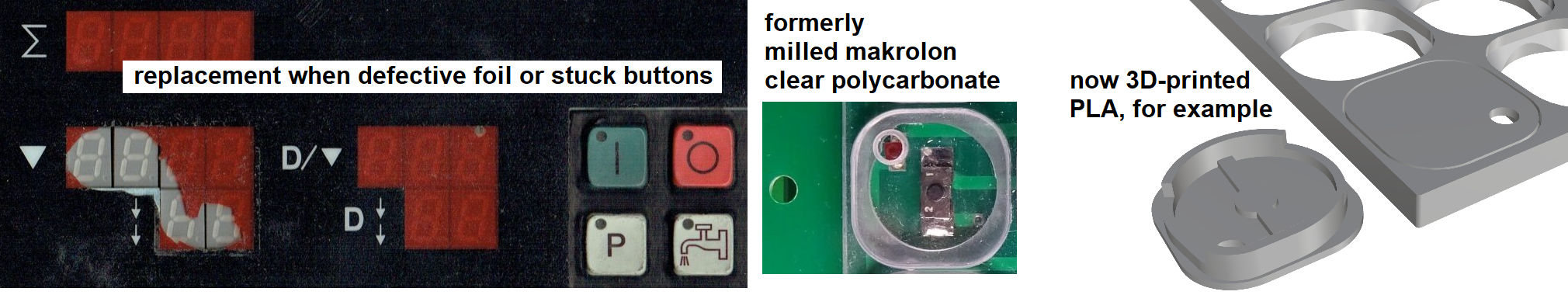

Spindle motor replacement Bridgeport 412 tips was created by GDTH

Spindle motor replacement Bridgeport 412 tips

Category: Computers and Hardware

- partec

- partec

- JPL

- JPL

13 Dec 2024 08:08

7i87 what is the purpose of W1 and W3 ? was created by JPL

7i87 what is the purpose of W1 and W3 ?

Category: Driver Boards

- Aciera

13 Dec 2024 06:39

Replied by Aciera on topic Feedback control XY not full speed run G1 when curve or Arc

Feedback control XY not full speed run G1 when curve or Arc

Category: General LinuxCNC Questions

Time to create page: 0.473 seconds