Search Results (Searched for: )

- ihavenofish

- ihavenofish

11 Dec 2024 06:31 - 11 Dec 2024 06:32

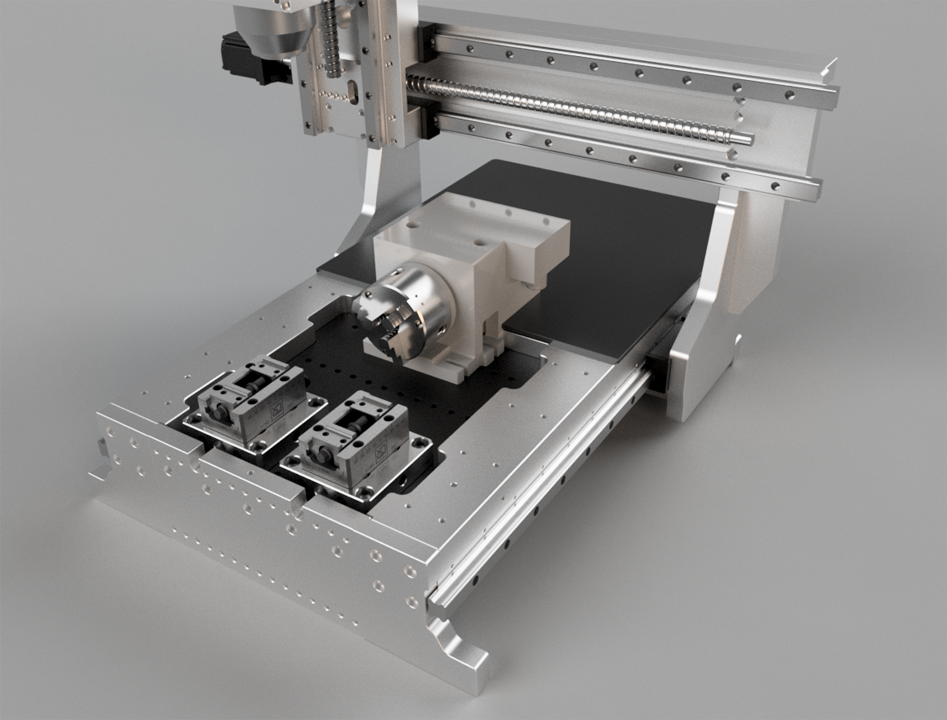

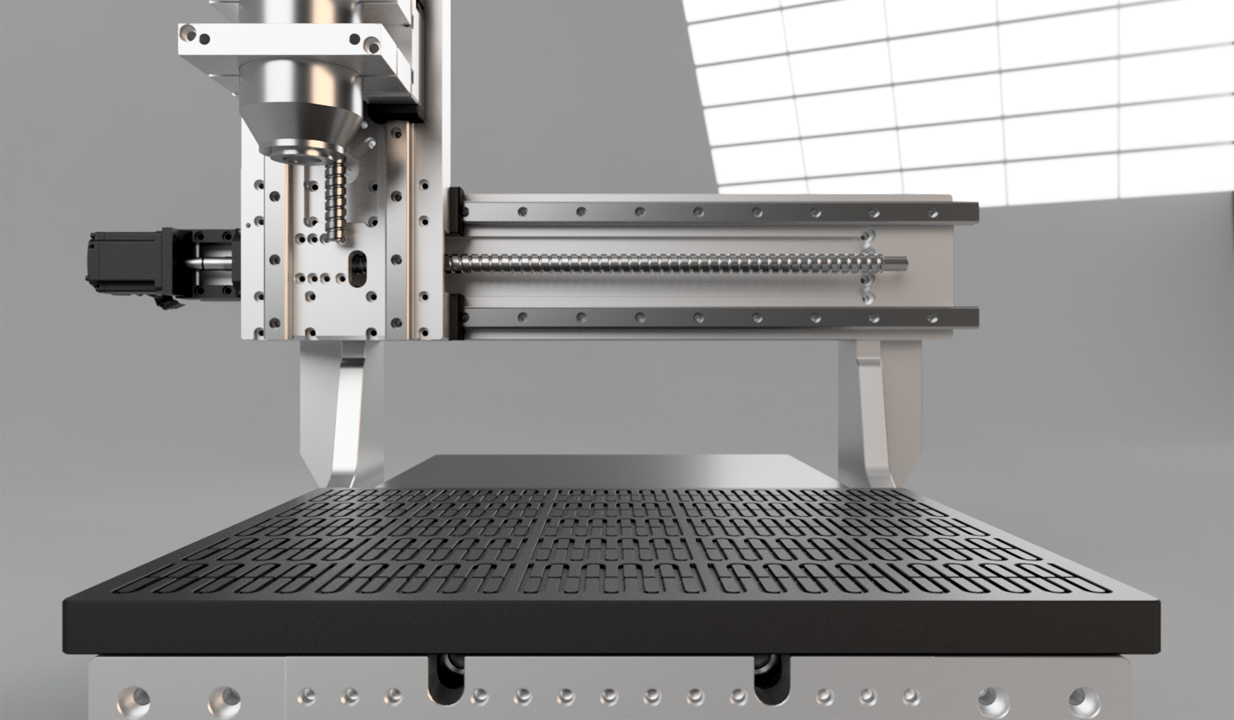

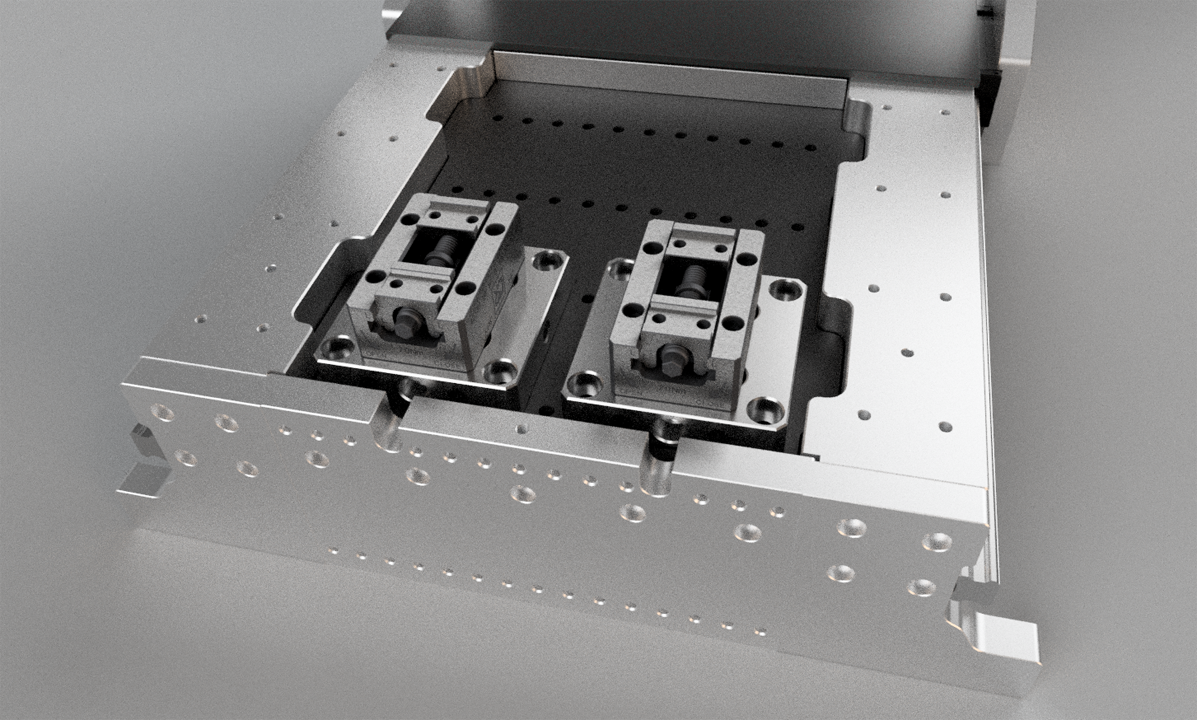

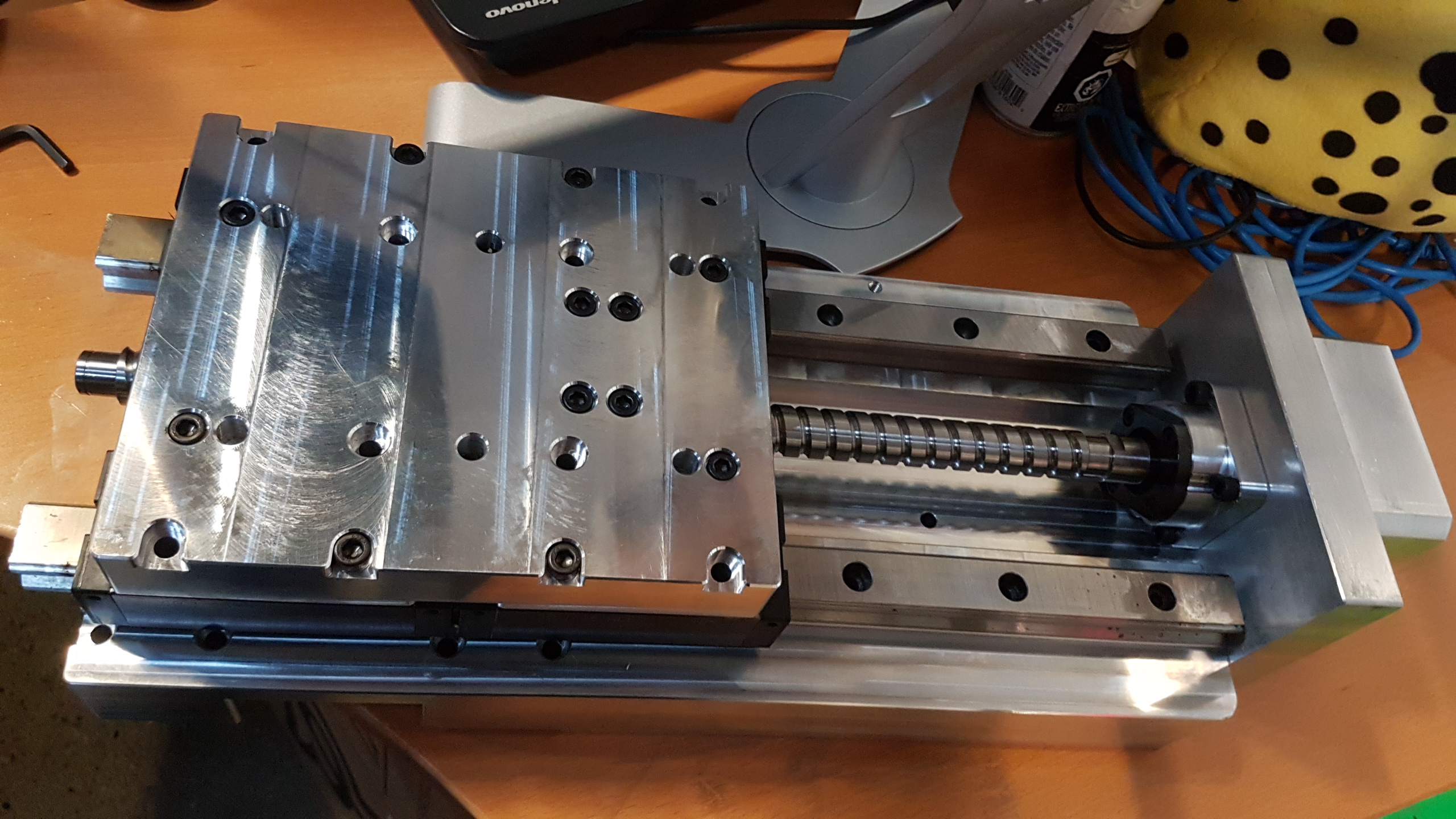

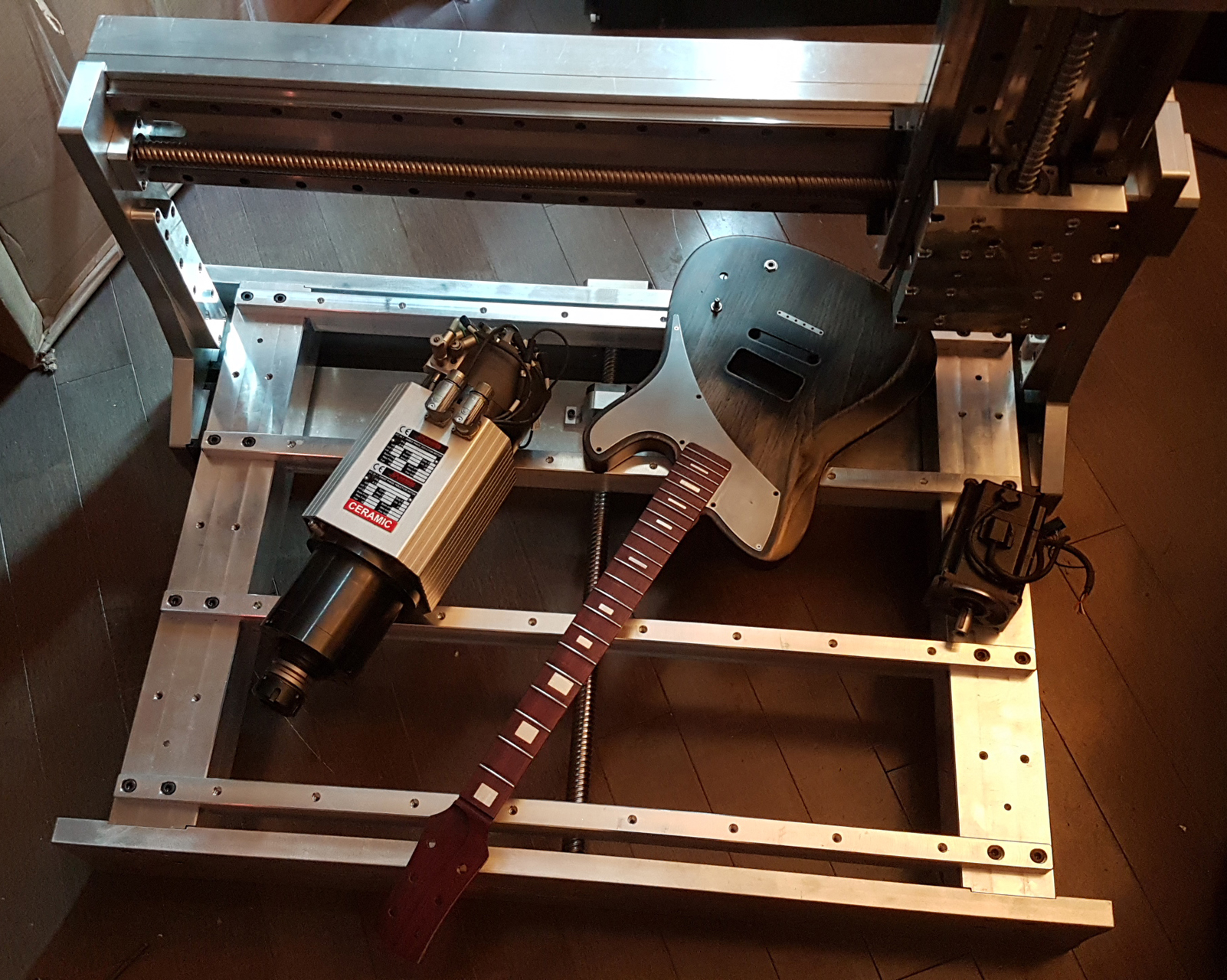

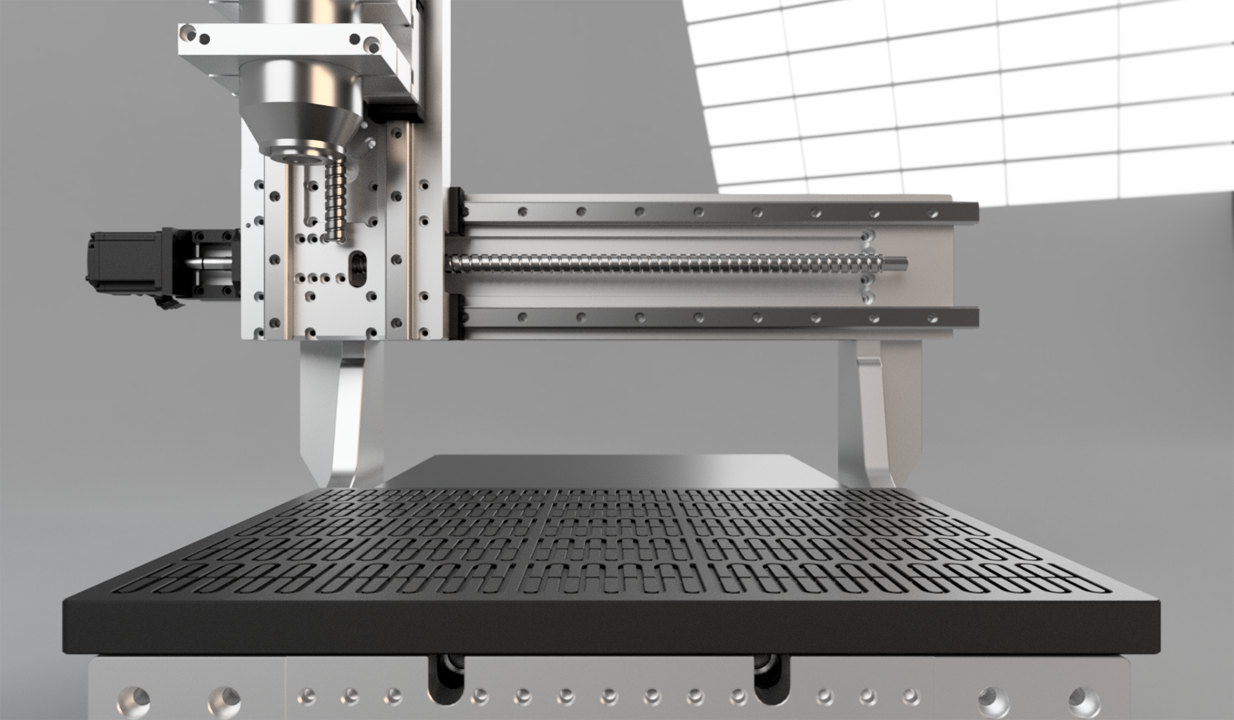

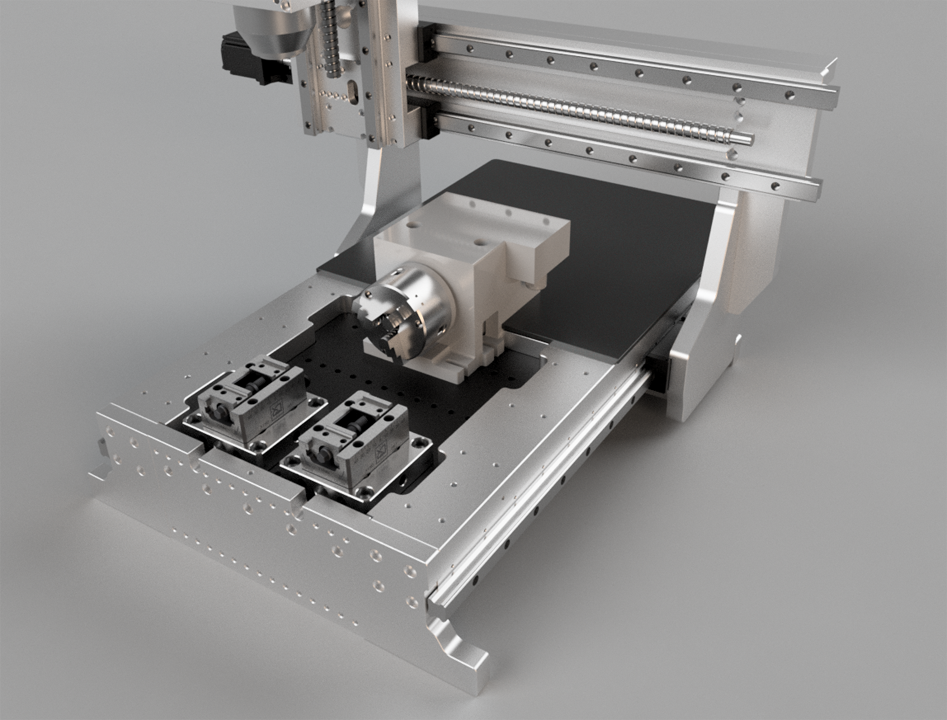

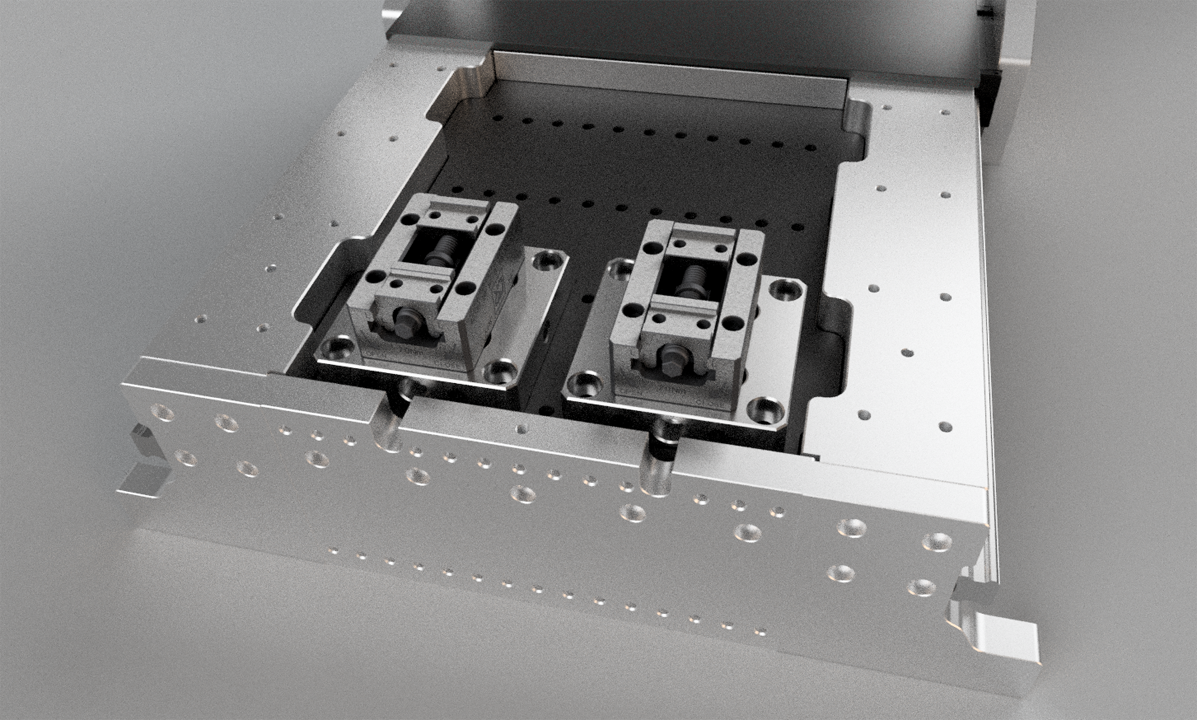

Replied by ihavenofish on topic Mini wannabe datron build

Mini wannabe datron build

Category: CNC Machines

- Unlogic

- Unlogic

11 Dec 2024 06:19 - 11 Dec 2024 10:19

Replied by Unlogic on topic Optimum Optimill MH50V CNC conversion

Optimum Optimill MH50V CNC conversion

Category: Milling Machines

- timo

- timo

11 Dec 2024 06:05 - 11 Dec 2024 06:07

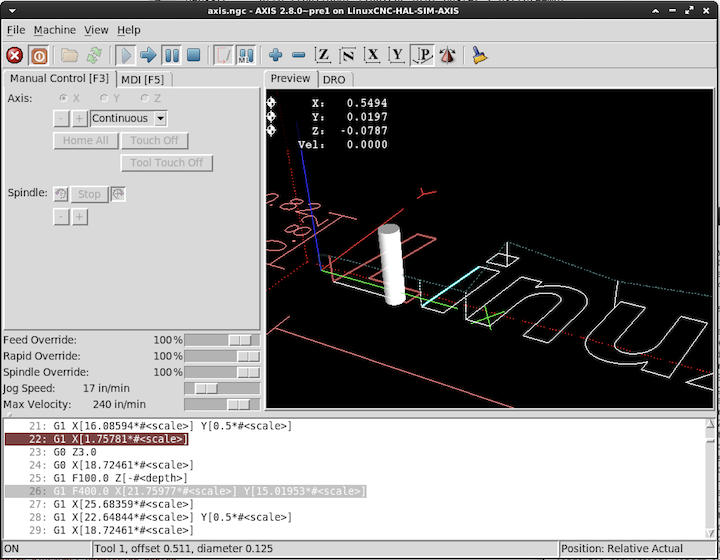

Replied by timo on topic How to build a spaceship with Linuxcnc and a Mesa 7i76e

How to build a spaceship with Linuxcnc and a Mesa 7i76e

Category: Basic Configuration

- meister

- meister

11 Dec 2024 05:57

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- timo

- timo

11 Dec 2024 05:44 - 11 Dec 2024 05:53

- dbtayl

- dbtayl

11 Dec 2024 04:06

Replied by dbtayl on topic FreeCAD 1.0 Who's using it?

FreeCAD 1.0 Who's using it?

Category: CAD CAM

- tcbmetalworks

- tcbmetalworks

11 Dec 2024 03:28

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- P.J.B.C

- P.J.B.C

11 Dec 2024 02:10

Same settings, different result was created by P.J.B.C

Same settings, different result

Category: Basic Configuration

- ihavenofish

- ihavenofish

11 Dec 2024 01:22

Replied by ihavenofish on topic Rotating coordinate space via probing

Rotating coordinate space via probing

Category: General LinuxCNC Questions

- D Jensen

- D Jensen

11 Dec 2024 01:14

Replied by D Jensen on topic Retrofitting a 1986 Maho 400E

Retrofitting a 1986 Maho 400E

Category: Milling Machines

- ihavenofish

- ihavenofish

11 Dec 2024 01:09

Replied by ihavenofish on topic Rotating coordinate space via probing

Rotating coordinate space via probing

Category: General LinuxCNC Questions

- tommylight

11 Dec 2024 01:03

Replied by tommylight on topic Rotating coordinate space via probing

Rotating coordinate space via probing

Category: General LinuxCNC Questions

- ihavenofish

- ihavenofish

11 Dec 2024 00:52

Rotating coordinate space via probing was created by ihavenofish

Rotating coordinate space via probing

Category: General LinuxCNC Questions

- tommylight

11 Dec 2024 00:51

- CORBETT

11 Dec 2024 00:34 - 11 Dec 2024 01:18

Replied by CORBETT on topic Ethercat build from source instructions - Updated for 2024

Ethercat build from source instructions - Updated for 2024

Category: EtherCAT

Time to create page: 0.703 seconds