Search Results (Searched for: )

- Finngineering

- Finngineering

26 Feb 2026 10:13

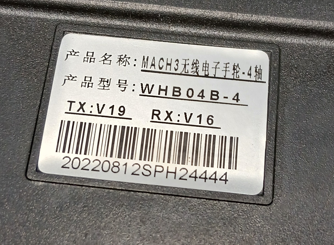

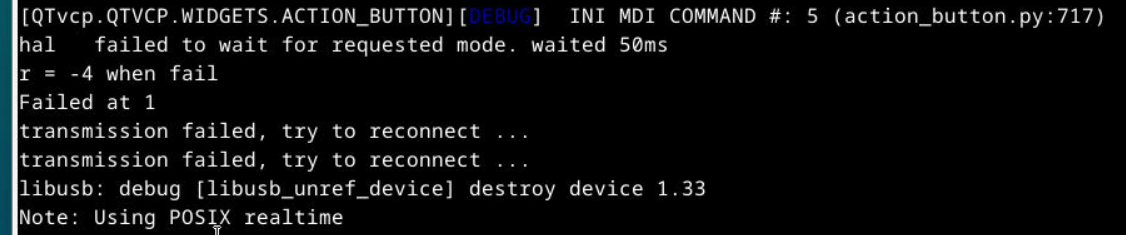

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- DerKlotz

- DerKlotz

26 Feb 2026 10:03

Replied by DerKlotz on topic Add Buttons in Probe Basic

Add Buttons in Probe Basic

Category: QtPyVCP

- Hakan

- Hakan

26 Feb 2026 08:44

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hakan

- Hakan

26 Feb 2026 08:36 - 26 Feb 2026 08:41

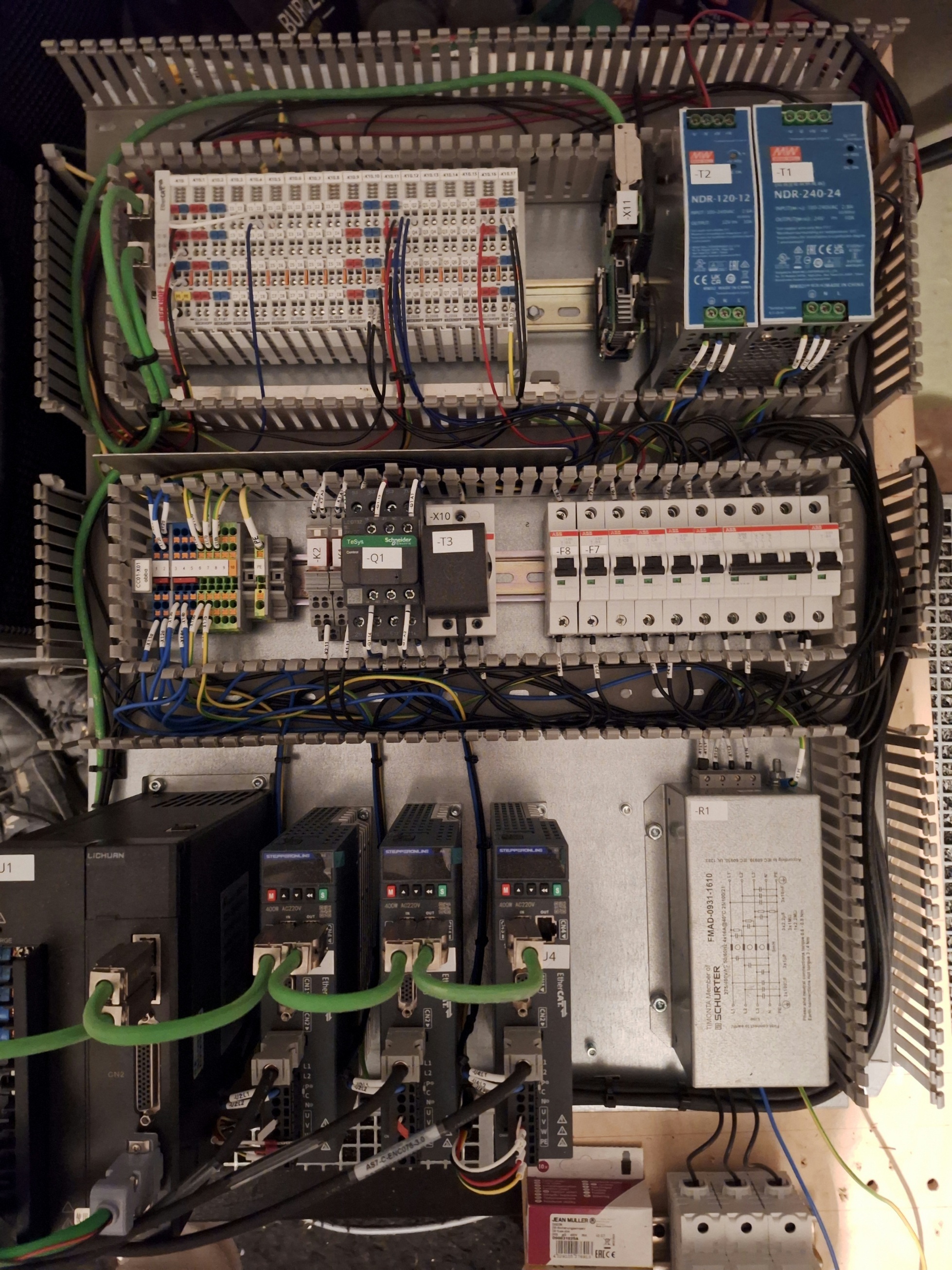

Replied by Hakan on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- Finngineering

- Finngineering

26 Feb 2026 08:29

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Hakan

- Hakan

26 Feb 2026 08:10

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Jensner

- Jensner

26 Feb 2026 07:55 - 26 Feb 2026 07:57

- nichtAlex

- nichtAlex

26 Feb 2026 05:17

Replied by nichtAlex on topic Umstieg von LinuxCNC + Mesa auf EtherCAT (Leadshine EL8 / Beckhoff) – Erfahrunge

Umstieg von LinuxCNC + Mesa auf EtherCAT (Leadshine EL8 / Beckhoff) – Erfahrunge

Category: Deutsch

- Marcos DC

26 Feb 2026 04:49

Replied by Marcos DC on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- tar_san

- tar_san

26 Feb 2026 04:30 - 26 Feb 2026 04:36

Replied by tar_san on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- NWE

26 Feb 2026 03:38

- tommylight

25 Feb 2026 23:24

Replied by tommylight on topic [AUTOMATIC] [XML] [HAL] [INI] [GENERATORS] [ETHERCAT] [LICHUAN]

[AUTOMATIC] [XML] [HAL] [INI] [GENERATORS] [ETHERCAT] [LICHUAN]

Category: EtherCAT

- tommylight

25 Feb 2026 23:21

Replied by tommylight on topic Simple G7x Profile editor for Linuxcnc/Axis

Simple G7x Profile editor for Linuxcnc/Axis

Category: AXIS

- tommylight

25 Feb 2026 23:19

Replied by tommylight on topic Ethercat A6 Servo Homing problem

Ethercat A6 Servo Homing problem

Category: EtherCAT

Time to create page: 0.407 seconds