Search Results (Searched for: )

- besriworld

- besriworld

02 Sep 2024 14:06

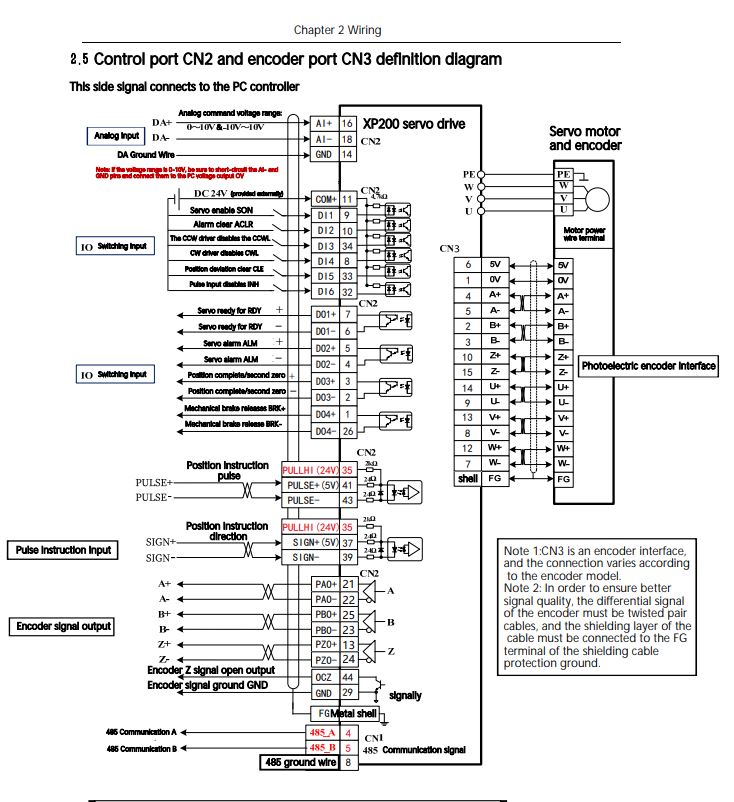

Replied by besriworld on topic Chinese Servo Drive Calibration XP200

Chinese Servo Drive Calibration XP200

Category: Milling Machines

- mighty_mick

02 Sep 2024 12:44

Optimizing Tool Paths or Generated G-code was created by mighty_mick

Optimizing Tool Paths or Generated G-code

Category: Post Processors

- Aciera

02 Sep 2024 12:18

Replied by Aciera on topic Sliders for overrides in gmoccapy

Sliders for overrides in gmoccapy

Category: General LinuxCNC Questions

- Walkahz

- Walkahz

02 Sep 2024 11:40

Chinese Servo Drive Calibration XP200 was created by Walkahz

Chinese Servo Drive Calibration XP200

Category: Milling Machines

- Aciera

02 Sep 2024 11:40

Replied by Aciera on topic Modbus VFD startup delay?

Modbus VFD startup delay?

Category: Basic Configuration

- Aciera

02 Sep 2024 10:59

Replied by Aciera on topic Understanding Source Files and Debugging

Understanding Source Files and Debugging

Category: General LinuxCNC Questions

- zz912

02 Sep 2024 10:31

Replied by zz912 on topic Pendant with 7i73: question with analog inputs

Pendant with 7i73: question with analog inputs

Category: Driver Boards

- Str8jacket

- Str8jacket

02 Sep 2024 10:00

- seyad

- seyad

02 Sep 2024 09:25

Understanding Source Files and Debugging was created by seyad

Understanding Source Files and Debugging

Category: General LinuxCNC Questions

- MennilTossFlykune

- MennilTossFlykune

02 Sep 2024 08:33

Replied by MennilTossFlykune on topic Modbus VFD startup delay?

Modbus VFD startup delay?

Category: Basic Configuration

- Aciera

02 Sep 2024 08:08

Replied by Aciera on topic Modbus VFD startup delay?

Modbus VFD startup delay?

Category: Basic Configuration

- Creative25

- Creative25

02 Sep 2024 07:30 - 07 Sep 2024 11:09

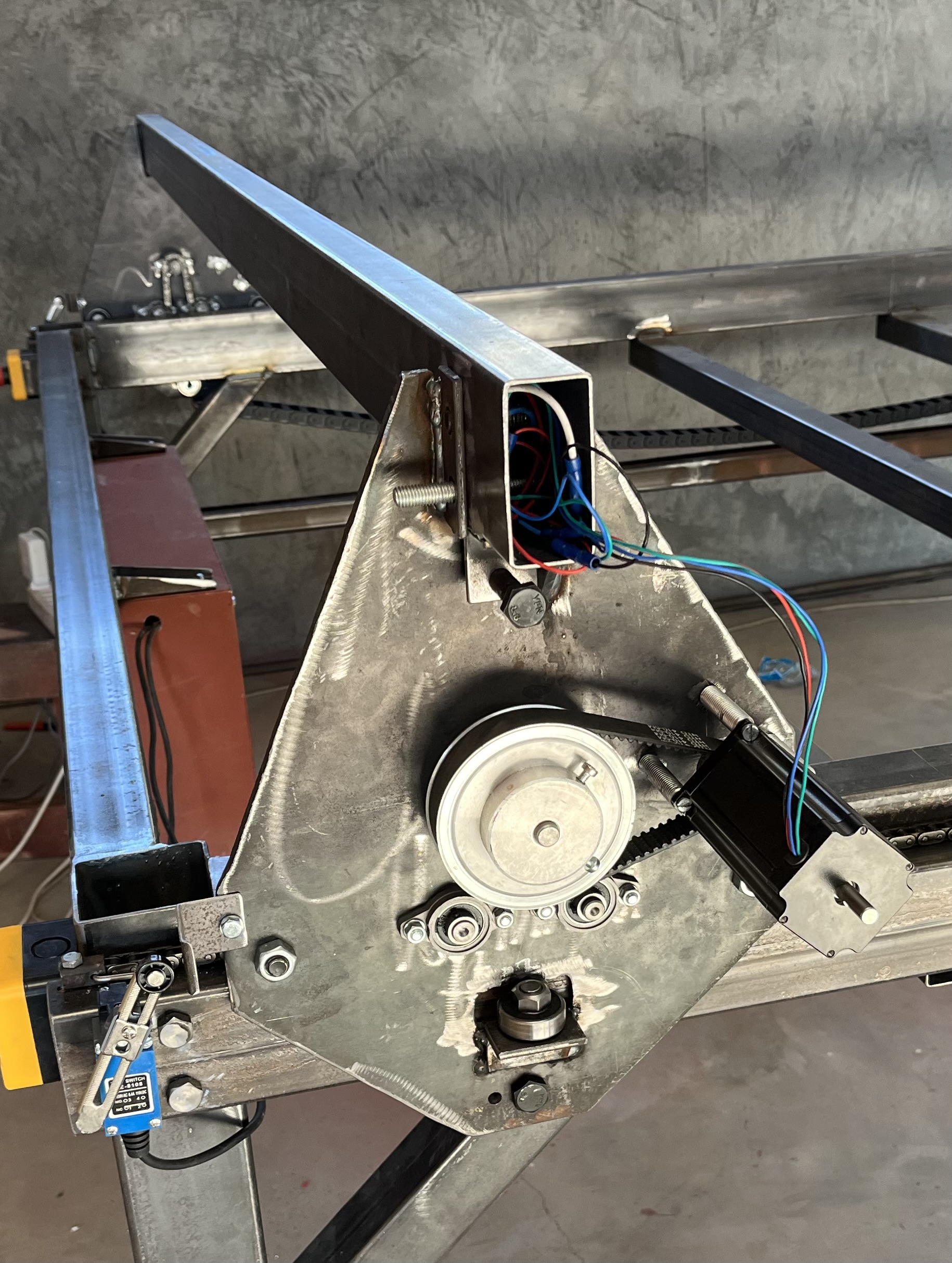

Replied by Creative25 on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- Creative25

- Creative25

02 Sep 2024 07:29

Replied by Creative25 on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- Creative25

- Creative25

02 Sep 2024 07:15

Replied by Creative25 on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- MennilTossFlykune

- MennilTossFlykune

02 Sep 2024 07:09

Replied by MennilTossFlykune on topic Modbus VFD startup delay?

Modbus VFD startup delay?

Category: Basic Configuration

Time to create page: 0.506 seconds