Search Results (Searched for: )

- Tinine

- Tinine

21 Aug 2024 14:16

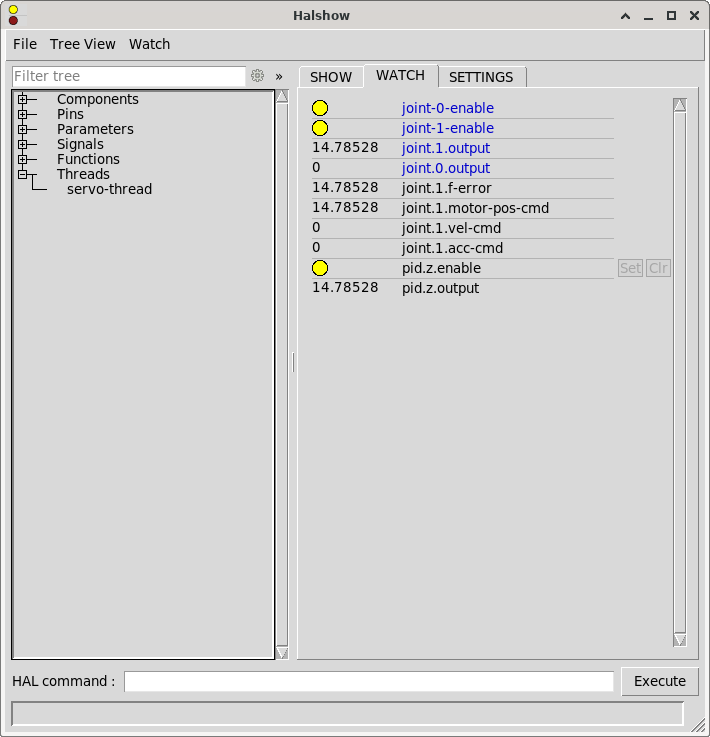

Replied by Tinine on topic PID Servo Loop rates

PID Servo Loop rates

Category: General LinuxCNC Questions

- Todd Zuercher

21 Aug 2024 14:10 - 21 Aug 2024 14:23

Replied by Todd Zuercher on topic What's the Oddest Machine You Have Powered with LinuxCNC

What's the Oddest Machine You Have Powered with LinuxCNC

Category: Off Topic and Test Posts

- PCW

21 Aug 2024 14:07

- Todd Zuercher

21 Aug 2024 13:57

Replied by Todd Zuercher on topic PID Servo Loop rates

PID Servo Loop rates

Category: General LinuxCNC Questions

- Tinine

- Tinine

21 Aug 2024 13:39

PID Servo Loop rates was created by Tinine

PID Servo Loop rates

Category: General LinuxCNC Questions

- mooser

- mooser

21 Aug 2024 13:37

Replied by mooser on topic Fuse for toroid transformer... sanity check

Fuse for toroid transformer... sanity check

Category: CNC Machines

- my1987toyota

21 Aug 2024 13:23

What's the Oddest Machine You Have Powered with LinuxCNC was created by my1987toyota

What's the Oddest Machine You Have Powered with LinuxCNC

Category: Off Topic and Test Posts

- slowpoke

- slowpoke

21 Aug 2024 13:07

- pawel77

- pawel77

21 Aug 2024 13:07

- Pickle

- Pickle

21 Aug 2024 12:02

Replied by Pickle on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

[ Vfdmod ] An easy VFD control over MODBUS RTU

Category: HAL

- Aciera

21 Aug 2024 11:00

Replied by Aciera on topic Post GUI HAL not loading and "Bad character '[' used" error on E-Stop

Post GUI HAL not loading and "Bad character '[' used" error on E-Stop

Category: QtPyVCP

- TheRoslyak

21 Aug 2024 10:34 - 21 Aug 2024 10:35

- zmrdko

21 Aug 2024 09:44 - 21 Aug 2024 09:44

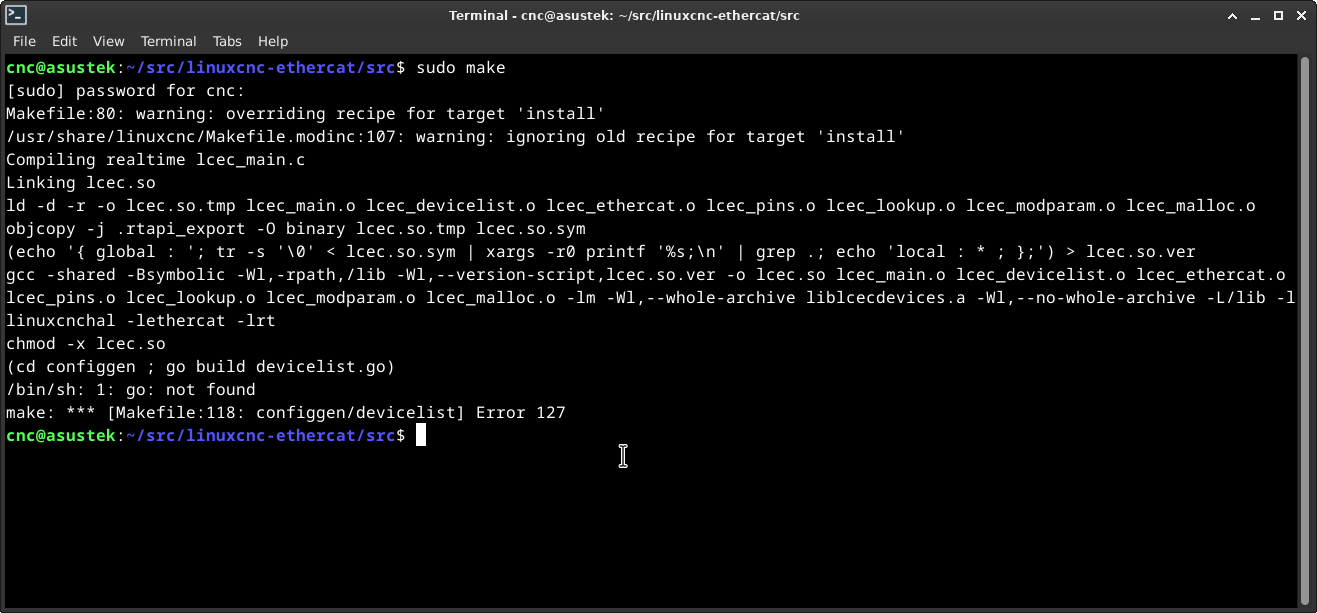

Replied by zmrdko on topic New LinuxCNC-Ethercat git tree

New LinuxCNC-Ethercat git tree

Category: EtherCAT

- greg23_78

- greg23_78

21 Aug 2024 09:34 - 21 Aug 2024 10:06

- avive

- avive

21 Aug 2024 09:15

Replied by avive on topic Message: "Ignoring task mode change while jogging"

Message: "Ignoring task mode change while jogging"

Category: GladeVCP

Time to create page: 0.496 seconds