Search Results (Searched for: )

- Altenthaler1988

- Altenthaler1988

06 Jul 2024 12:52

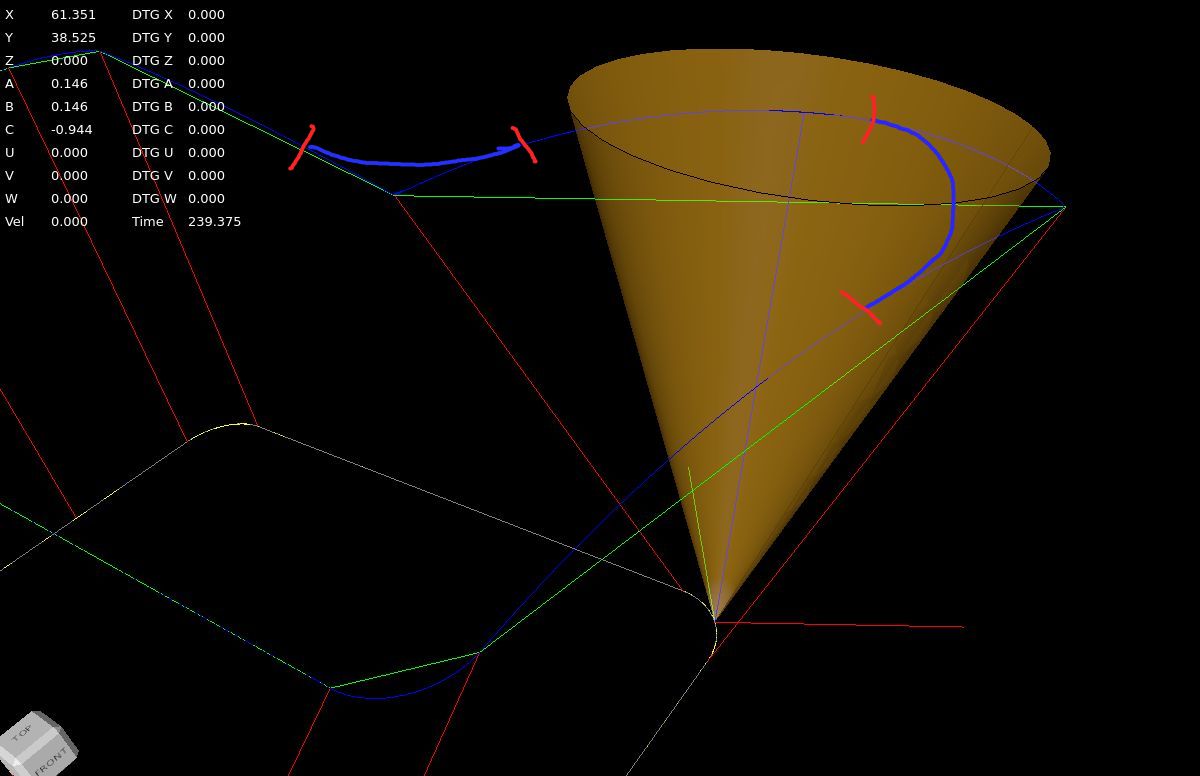

Replied by Altenthaler1988 on topic qtplasmac "torch not showing"

qtplasmac "torch not showing"

Category: Plasmac

- garthnoakes

- garthnoakes

06 Jul 2024 12:51

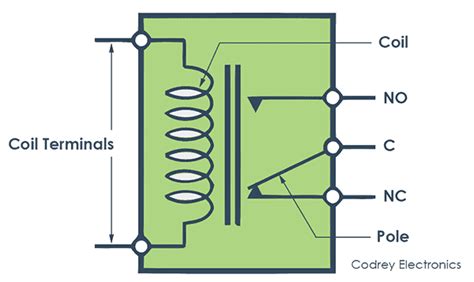

Replied by garthnoakes on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- Grotius

06 Jul 2024 12:50

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Cant do this anymore bye all

06 Jul 2024 12:34 - 06 Jul 2024 12:37

Replied by Cant do this anymore bye all on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- Grotius

06 Jul 2024 12:33

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Robbbbbb

- Robbbbbb

06 Jul 2024 12:16

- garthnoakes

- garthnoakes

06 Jul 2024 12:16

Replied by garthnoakes on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- tjtr33

06 Jul 2024 11:50

Replied by tjtr33 on topic Build 2.9 RIP in Debian 12 without Documents

Build 2.9 RIP in Debian 12 without Documents

Category: General LinuxCNC Questions

- garthnoakes

- garthnoakes

06 Jul 2024 11:41

Replied by garthnoakes on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- Walkahz

- Walkahz

06 Jul 2024 10:49

Replied by Walkahz on topic Deckel FP4 Gearbox Comp

Deckel FP4 Gearbox Comp

Category: Advanced Configuration

- Cant do this anymore bye all

06 Jul 2024 10:28

Replied by Cant do this anymore bye all on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- Aciera

06 Jul 2024 10:26

Replied by Aciera on topic Driving relay using NO, COM and or NC

Driving relay using NO, COM and or NC

Category: Driver Boards

- rodw

06 Jul 2024 09:50 - 06 Jul 2024 09:51

- garthnoakes

- garthnoakes

06 Jul 2024 09:22

Driving relay using NO, COM and or NC was created by garthnoakes

Driving relay using NO, COM and or NC

Category: Driver Boards

- phillc54

06 Jul 2024 09:00

Replied by phillc54 on topic qtplasmac "torch not showing"

qtplasmac "torch not showing"

Category: Plasmac

Time to create page: 0.743 seconds