Search Results (Searched for: )

- meister

- meister

03 Jul 2024 13:42 - 03 Jul 2024 13:44

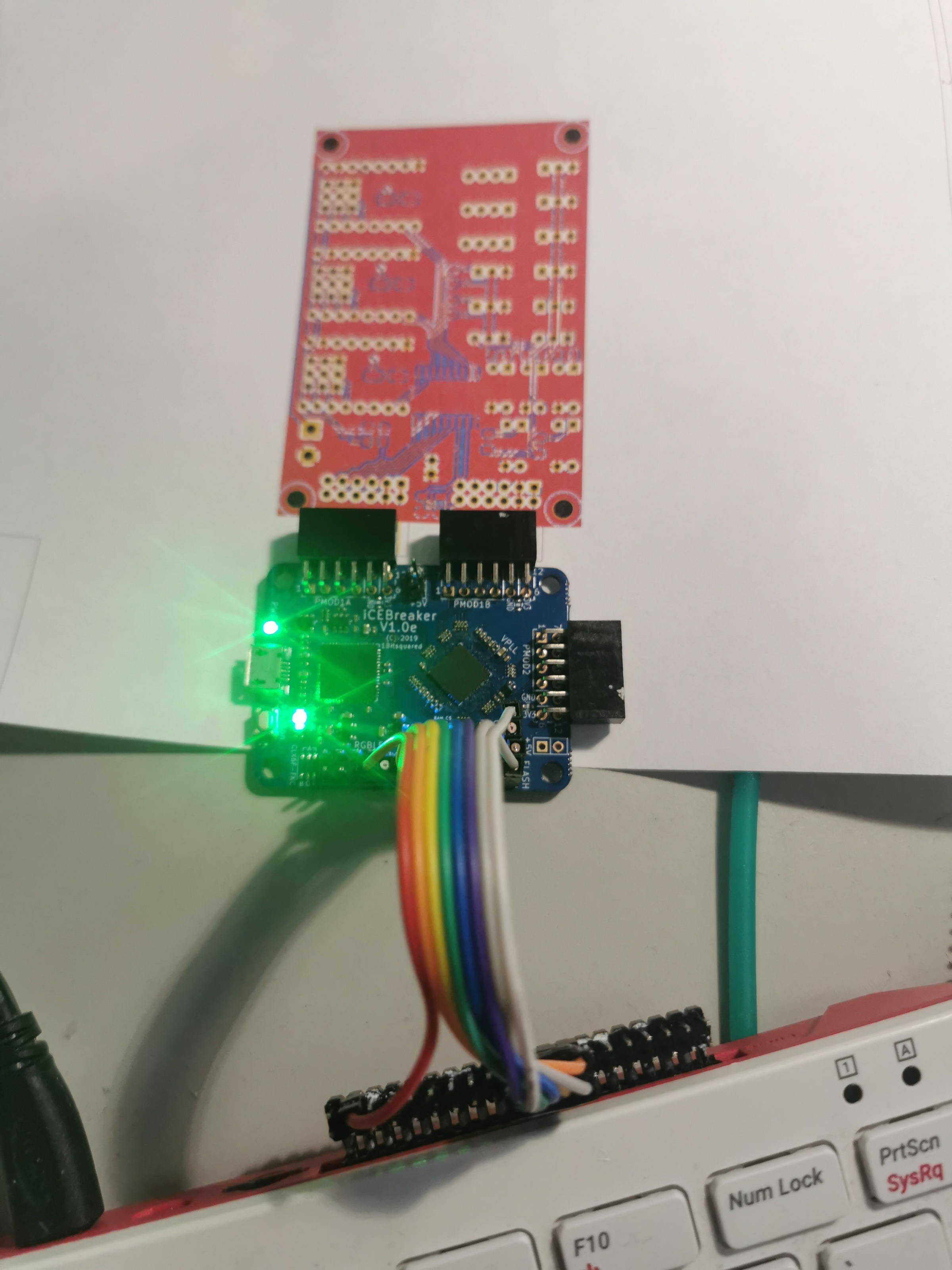

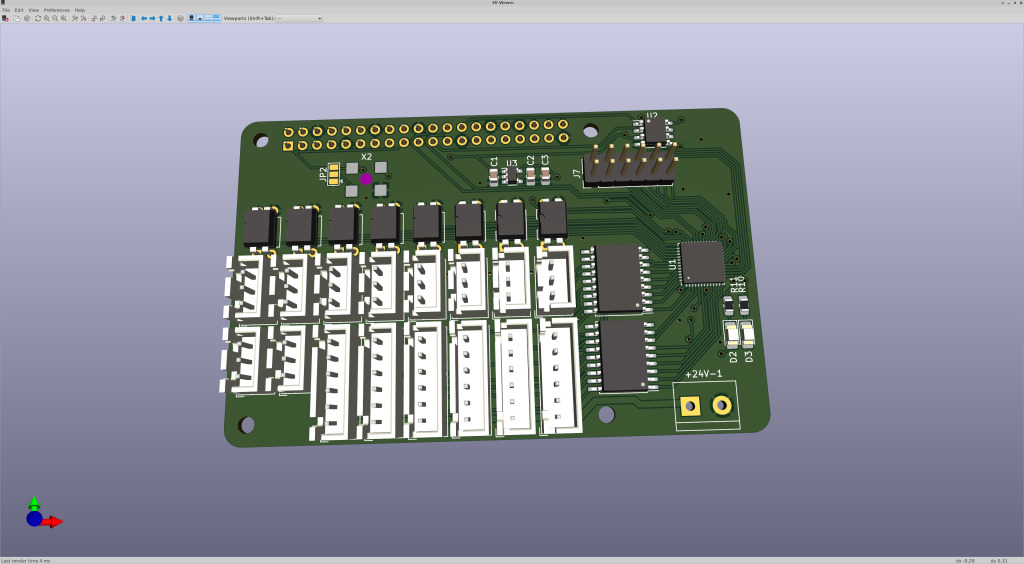

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- hpmax

- hpmax

03 Jul 2024 13:23 - 03 Jul 2024 13:24

- andypugh

03 Jul 2024 13:19

Replied by andypugh on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- andypugh

03 Jul 2024 12:46

Replied by andypugh on topic Machine ways warpage compensation with probekins

Machine ways warpage compensation with probekins

Category: Advanced Configuration

- Donb9261

03 Jul 2024 11:57

- Aciera

03 Jul 2024 11:24

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Donb9261

03 Jul 2024 11:08

- byunchov

03 Jul 2024 11:07

Replied by byunchov on topic MS300 EtherCAT not going into OP state with CMM-02 (rev 131328)

MS300 EtherCAT not going into OP state with CMM-02 (rev 131328)

Category: EtherCAT

- Donb9261

03 Jul 2024 10:57

- Grotius

03 Jul 2024 10:53

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Donb9261

03 Jul 2024 10:48

- zmrdko

03 Jul 2024 10:44

- Donb9261

03 Jul 2024 10:20

- Cant do this anymore bye all

03 Jul 2024 09:04

Replied by Cant do this anymore bye all on topic Mesa 7i96 Ethernet Socket Problems - LC2.9.2 on Raspberry Pi 4B

Mesa 7i96 Ethernet Socket Problems - LC2.9.2 on Raspberry Pi 4B

Category: Driver Boards

- tommylight

03 Jul 2024 08:50 - 03 Jul 2024 08:50

Replied by tommylight on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

Time to create page: 0.638 seconds