Search Results (Searched for: )

- Grotius

02 Jul 2024 21:12

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

Hi Arciera,

I understand now.

Then my interpolation proposal seems correct :

G1 X1 Y2 Z3 A10 C20

G1 X11 Y2 Z3 A20 C40

Here the xyz moves 10 mm = Line lenght xyz.

Lets assume the spline or fillet lenght from "Q0 to Q1" -> "A10 C20 to A20 C40" = 40mm

Then the interpolation for xyz at 5mm = t0.5 (for interpolation i use time 0 to 1 for a segment)

For Q0 to Q1 is t0.5*40mm = 20mm on the spline or fillet path.

Then we can calculate new vector for A & C. This vector then has a A and a C value for radians.

This whole circus can be done offline in opencascade cad.

So just like you proposed, we do the

1. Run the clothoid fillets algo based on G64 P & Q input values. In one gcode file different fillet sizes can be given.

2. Run a tool orientation algo for a & b axis. I think using A & B is simplest. This then solves smoothing for A & B axis toolpath.

3. Run a check if A & C orientation's can be made in the xyz move time, otherwise xyz velocity must be lowered down.

Did we miss something? Or is it ready to be coded?

I understand now.

Then my interpolation proposal seems correct :

G1 X1 Y2 Z3 A10 C20

G1 X11 Y2 Z3 A20 C40

Here the xyz moves 10 mm = Line lenght xyz.

Lets assume the spline or fillet lenght from "Q0 to Q1" -> "A10 C20 to A20 C40" = 40mm

Then the interpolation for xyz at 5mm = t0.5 (for interpolation i use time 0 to 1 for a segment)

For Q0 to Q1 is t0.5*40mm = 20mm on the spline or fillet path.

Then we can calculate new vector for A & C. This vector then has a A and a C value for radians.

This whole circus can be done offline in opencascade cad.

So just like you proposed, we do the

1. Run the clothoid fillets algo based on G64 P & Q input values. In one gcode file different fillet sizes can be given.

2. Run a tool orientation algo for a & b axis. I think using A & B is simplest. This then solves smoothing for A & B axis toolpath.

3. Run a check if A & C orientation's can be made in the xyz move time, otherwise xyz velocity must be lowered down.

Did we miss something? Or is it ready to be coded?

- hpmax

- hpmax

02 Jul 2024 20:07

Replied by hpmax on topic A Treatsie on the Parallel Port - HP Elitedesk 800 with generic cable

A Treatsie on the Parallel Port - HP Elitedesk 800 with generic cable

Category: Installing LinuxCNC

Yes, the deal is this. I found a guy with a "new" in the box 6040 with 4th axis lathe attachment for $400US, bought a desktop PC to drive it for $40 and the StarTech LPT board for $20.

This wasn't my first choice, it was just an opportunity that presented itself and I thought I'd try out a router because I was thinking of building a PrintNC. A coworker recommended LinuxCNC. I keep wondering why people aren't just running these things off a 3D printer board running Klipper or a slightly modified Klipper... seems like a better option overall than these parallel port controllers.

Obviously everything is a bit questionable, the router is probably underpowered, there are no endstops or position feedback. I can imagine skipping a step really screw you up. But for $500? Meh...

Now if only I could figure out how I screwed up my install and why when I try to reinstall off the USB key it keeps complaining there's an error while trying to create the main ext4 partition.

Thanks for the feedback on the schematic, that was my read as well, I just was unsure what the controls were called on LinuxCNC/stepconf

This wasn't my first choice, it was just an opportunity that presented itself and I thought I'd try out a router because I was thinking of building a PrintNC. A coworker recommended LinuxCNC. I keep wondering why people aren't just running these things off a 3D printer board running Klipper or a slightly modified Klipper... seems like a better option overall than these parallel port controllers.

Obviously everything is a bit questionable, the router is probably underpowered, there are no endstops or position feedback. I can imagine skipping a step really screw you up. But for $500? Meh...

Now if only I could figure out how I screwed up my install and why when I try to reinstall off the USB key it keeps complaining there's an error while trying to create the main ext4 partition.

Thanks for the feedback on the schematic, that was my read as well, I just was unsure what the controls were called on LinuxCNC/stepconf

- zmrdko

02 Jul 2024 19:30

Replied by zmrdko on topic EtherCAT + EL6751 Configuration

EtherCAT + EL6751 Configuration

Category: EtherCAT

I have similar setup, except I have b3 ethercat servos. But I have el6751, since I wanted to use CANOpen vfd. It is possible quite easy to make it work in Twincat. You just make sure you have CANOpen wiring right - you need 120 Ohm resistors on both ends.Hello Herr Columbo,

I am fishing in the same "trüben Teich".

Just started with the liniuxcnc thing ... my last project was a retrofit of an EMCO 3 axis router runing at MACH4.

Now I want retofit an old TOS with 5 Axis and LINUXCNC....

My equipment so far is a Beckhoff EK1100 and EL6751 (SLAVE), Dell Optiplex i7 SFF and some DELTA Servos (B3M).

The Servo motors are with CANopen so thats why the EL6751 should translate to EtherCAT - right?

Right now I am following tu get further...

Maybe you could give me some advice to get out of the struggle?

Thanks a lot in advance!

Jürgen

Could you share

- PCW

02 Jul 2024 19:19 - 02 Jul 2024 19:20

Replied by PCW on topic error finishing read and joint following error.

error finishing read and joint following error.

Category: General LinuxCNC Questions

isolcpus=7

Note that if you have ~10 ms latency this is not likely to be fixed by isolcpus

Did you install the Realtek DKMS driver?

If you did, what are the current results of the ping test?

Note that if you have ~10 ms latency this is not likely to be fixed by isolcpus

Did you install the Realtek DKMS driver?

If you did, what are the current results of the ping test?

- PCW

02 Jul 2024 19:09

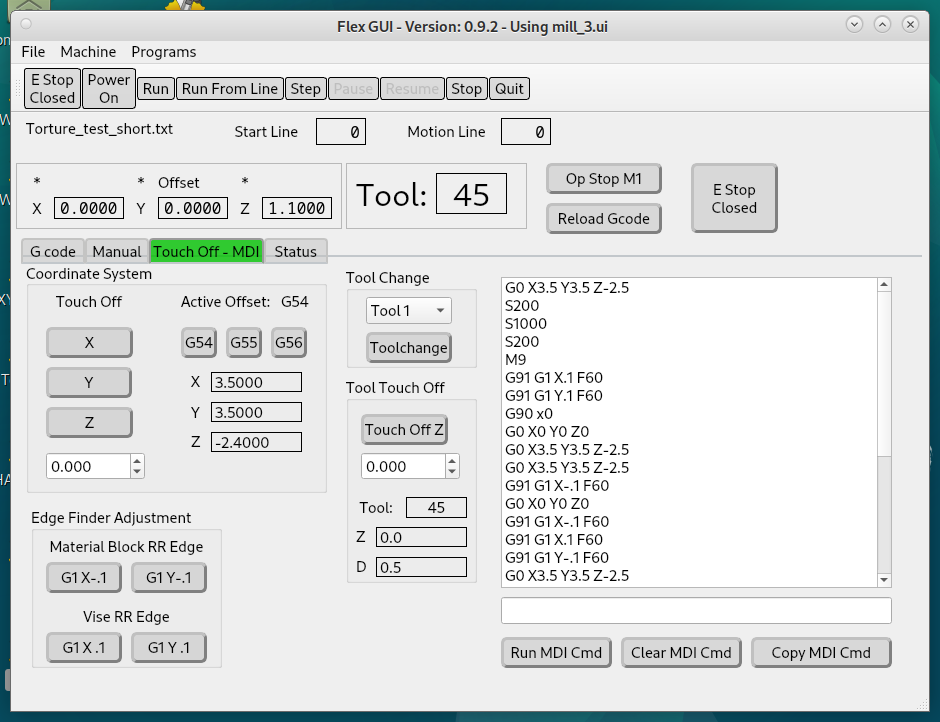

Replied by PCW on topic path pilot on router

path pilot on router

Category: PathPilot

Homing and machine limits are setup in the .ini file:

linuxcnc.org/docs/html/config/ini-homing.html

linuxcnc.org/docs/html/config/ini-config.html

(for machine limits see the "AXIS" section)

linuxcnc.org/docs/html/config/ini-homing.html

linuxcnc.org/docs/html/config/ini-config.html

(for machine limits see the "AXIS" section)

- jg00163206

02 Jul 2024 19:02

Replied by jg00163206 on topic error finishing read and joint following error.

error finishing read and joint following error.

Category: General LinuxCNC Questions

what isolcpus settings do i need for an 8 core ryzen machine?

- Gotdiesel

- Gotdiesel

02 Jul 2024 17:49

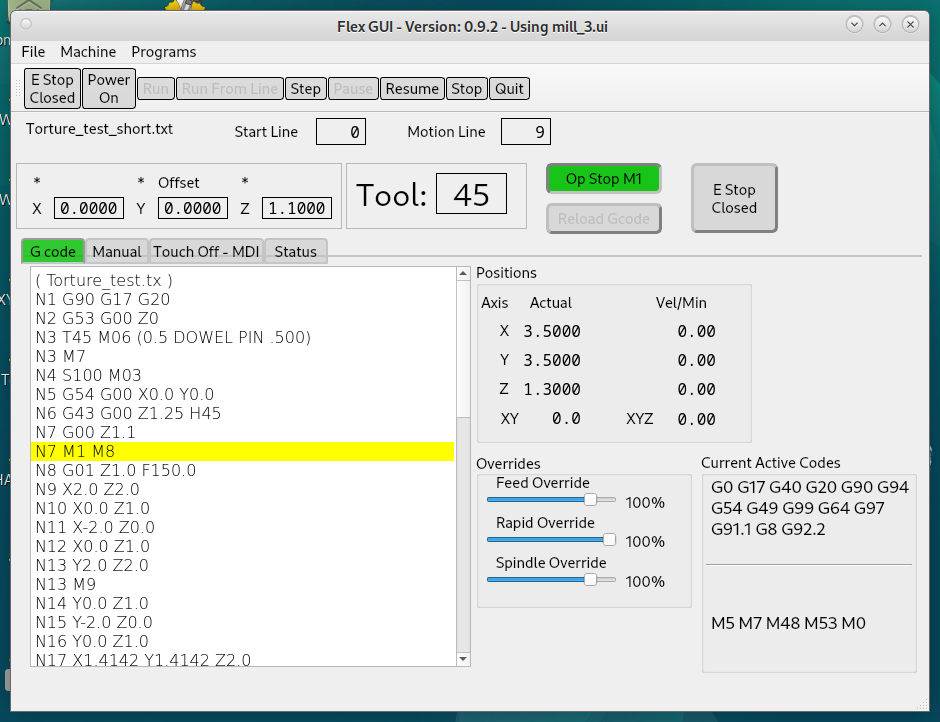

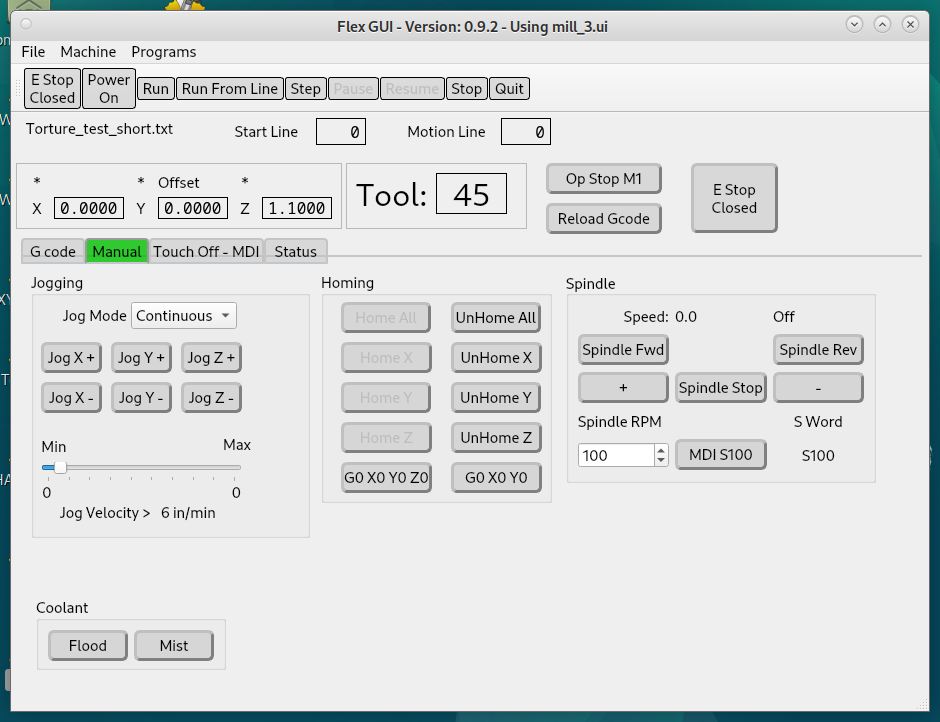

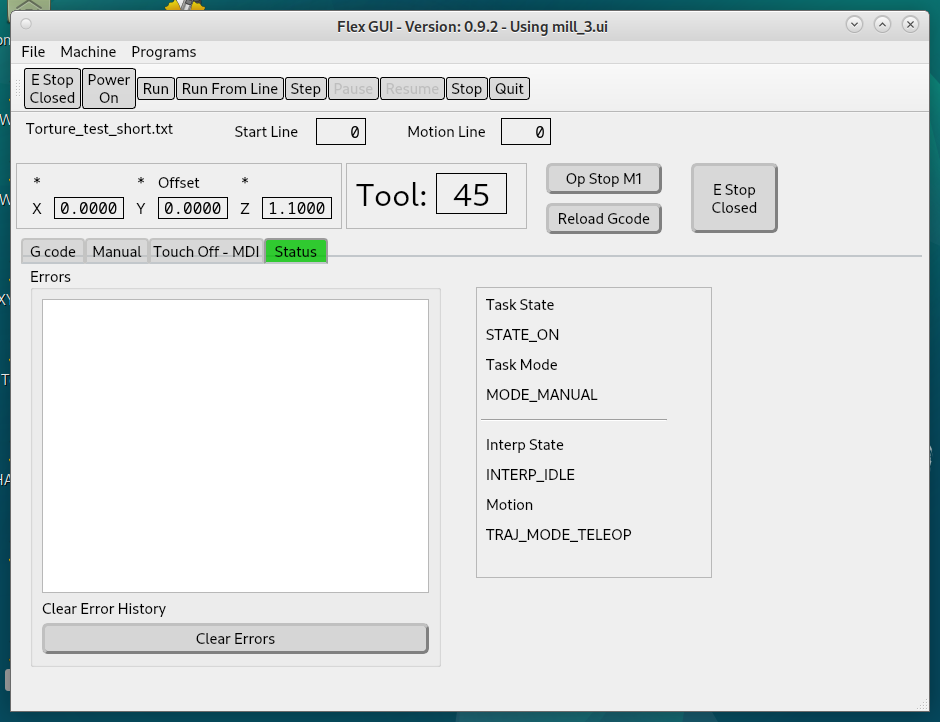

path pilot on router was created by Gotdiesel

path pilot on router

Category: PathPilot

I have a home built router that I set up Path Pilot on. Well, I had an electronics guy set up that understood Linux. How do I set up new “home position” for reference and how to set up the new soft limits? I have limit switches, but Path Pilot only uses one limit switch per axis and assumes other end based on the machine you are using. Is there any way to have home and travel limits match my machine?

- tlightus

- tlightus

02 Jul 2024 17:08

- Aciera

02 Jul 2024 17:04

Replied by Aciera on topic Deckel FP4 Gearbox Comp

Deckel FP4 Gearbox Comp

Category: Advanced Configuration

Ok, I guess these maybe get used in 'FP4_gears.c', but I'm really out of my depth here. Do you have 'FP4_gearbox.comp' installed and all the other .c and .h files in your system? I'm not even sure where you would need to put those, the 'components' folder would be my guess.

/*

LinuxCNC component for controlling the Deckel FP4 gearbox.

Copymitte (C) 2018 Sergey 'Jin' Bostandzhyan <This email address is being protected from spambots. You need JavaScript enabled to view it.>

This program is free software; you can redistribute it and/or

modify it under the terms of the GNU General Public License

as published by the Free Software Foundation; either version 2

of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU General Public License for more details.

You should have received a copy of the GNU General Public License

along with this program; if not, write to the Free Software

Foundation, Inc., 51 Franklin Street, Fifth Floor, Boston, MA 02110-1301, USA.

*/

/* Functions related to gear switching. */

#include "FP4_gears.h"

#include "FP4_twitch.h"

typedef enum

{

SHAFT_STATE_OFF, /* Initial shaft state */

SHAFT_STATE_ON, /* Shift in process (i.e. shaft motor running) */

SHAFT_STATE_RESTART /* Error condition, we missed our target and reached

an end point, we need to go back */

} shaft_state_t;

/* Group all data that is required to operate on one shaft */

typedef struct

{

shaft_state_t state;

pin_group_t status_pins;

hal_bit_t *motor_on;

hal_bit_t *motor_reverse;

hal_bit_t *motor_slow;

unsigned char current_mask; /* auto updated via global variable */

unsigned char target_mask;

} shaft_data_t;

/* Group all data required for gearshifting */

static struct

{

hal_bit_t *start_shift;

hal_bit_t *do_stop_spindle;

hal_bit_t *is_spindle_stopped;

hal_bit_t *trigger_estop;

hal_bit_t *notify_spindle_at_speed;

bool spindle_on_before_shift;

shaft_data_t vorgelege;

shaft_data_t block2;

shaft_data_t block1;

long delay;

statefunc next;

} g_gearbox_data;

/* One time setup function to prepare data structures related to gearbox

* switching*/

FUNCTION(gearbox_setup)

{

/* Populate data structures that will be used be the state functions

* when shifting gears */

g_gearbox_data.vorgelege.state = SHAFT_STATE_OFF;

/* Grabbing the pin pointers in EXTRA_SETUP did not work because the

* component did not seem to be fully initializedt there.

*

* Another issue:

* while output pins are defined as (*__comp_inst->pin_name) by

* halcompile, input pins are turned into (0+*__comp_inst->pin_name)

* which makes it impossible to get the pointers via the defines

* created by halcompile. Accessing the pin variable directly did not

* work due to macro expansion, only workaround I found was to temporarily

* disable the macros.

*/

#pragma push_macro("vorgelege_vorne")

#pragma push_macro("vorgelege_mitte")

#pragma push_macro("vorgelege_hinten")

#pragma push_macro("vorgelege_vorne_hinten")

#undef vorgelege_vorne

#undef vorgelege_mitte

#undef vorgelege_hinten

#undef vorgelege_vorne_hinten

g_gearbox_data.vorgelege.status_pins = (pin_group_t)

{

__comp_inst->vorgelege_vorne,

__comp_inst->vorgelege_mitte,

__comp_inst->vorgelege_hinten,

};

#pragma pop_macro("vorgelege_vorne")

#pragma pop_macro("vorgelege_mitte")

#pragma pop_macro("vorgelege_hinten")

#pragma pop_macro("vorgelege_vorne_hinten")

g_gearbox_data.vorgelege.motor_on = &vorgelege_motor;

g_gearbox_data.vorgelege.motor_reverse = &rueckziehen;

g_gearbox_data.vorgelege.motor_slow = &motor_lowspeed;

g_gearbox_data.vorgelege.current_mask = 0;

g_gearbox_data.vorgelege.target_mask =

FP4_gears[FP4_NEUTRAL_GEAR_INDEX].value; /* neutral */

g_gearbox_data.block2.state = SHAFT_STATE_OFF;

#pragma push_macro("block2_vorne")

#pragma push_macro("block2_mitte")

#pragma push_macro("block2_hinten")

#pragma push_macro("block2_vorne_hinten")

#undef block2_vorne

#undef block2_mitte

#undef block2_hinten

#undef block2_vorne_hinten

g_gearbox_data.block2.status_pins = (pin_group_t)

{

__comp_inst->block2_vorne,

__comp_inst->block2_mitte,

__comp_inst->block2_hinten,

};

#pragma pop_macro("block2_vorne")

#pragma pop_macro("block2_mitte")

#pragma pop_macro("block2_hinten")

#pragma pop_macro("block2_vorne_hinten")

g_gearbox_data.block2.motor_on = &block2_motor;

g_gearbox_data.block2.motor_reverse = &rueckziehen;

g_gearbox_data.block2.motor_slow = &motor_lowspeed;

g_gearbox_data.block2.current_mask = 0;

g_gearbox_data.block2.target_mask = 0; /* don't care for neutral */

g_gearbox_data.block1.state = SHAFT_STATE_OFF;

#pragma push_macro("block1_vorne")

#pragma push_macro("block1_mitte")

#pragma push_macro("block1_hinten")

#pragma push_macro("block1_vorne_hinten")

#undef block1_vorne

#undef block1_mitte

#undef block1_hinten

#undef block1_vorne_hinten

g_gearbox_data.block1.status_pins = (pin_group_t)

{

__comp_inst->block1_vorne,

__comp_inst->block1_mitte,

__comp_inst->block1_hinten,

};

#pragma pop_macro("block1_vorne")

#pragma pop_macro("block1_mitte")

#pragma pop_macro("block1_hinten")

#pragma pop_macro("block1_vorne_hinten")

g_gearbox_data.block1.motor_on = &block1_motor;

g_gearbox_data.block1.motor_reverse = &rueckziehen;

g_gearbox_data.block1.motor_slow = &motor_lowspeed;

g_gearbox_data.block1.current_mask = 0;

g_gearbox_data.block1.target_mask = 0; /* don't care for neutral */

#pragma push_macro("spindle_stopped")

#undef spindle_stopped

#pragma pop_macro("spindle_stopped")

g_gearbox_data.do_stop_spindle = &stop_spindle;

g_gearbox_data.spindle_on_before_shift = false;

g_gearbox_data.trigger_estop = &estop_out;

g_gearbox_data.notify_spindle_at_speed = &spindle_at_speed;

g_gearbox_data.delay = 0;

g_gearbox_data.next = NULL;

}

static void gearshift_stop_spindle(void)

{

g_gearbox_data.spindle_on_before_shift =

!(*g_gearbox_data.is_spindle_stopped);

*g_gearbox_data.do_stop_spindle = true;

}

/* combine values of all pins in a group to a bitmask */

static unsigned char get_bitmask_from_pingroup(pin_group_t *group)

{

unsigned char mask = 0;

int i;

for (i = 0; i < FP4_PINS_IN_GROUP; i++)

{

mask |= *(group->p) << i;

}

return mask;

}

/* Update current mask values for each shaft */

static void update_current_pingroup_masks(void)

{

g_gearbox_data.vorgelege.current_mask =

get_bitmask_from_pingroup(&g_gearbox_data.vorgelege.status_pins);

g_gearbox_data.block2.current_mask =

get_bitmask_from_pingroup(&g_gearbox_data.block2.status_pins);

g_gearbox_data.block1.current_mask =

get_bitmask_from_pingroup(&g_gearbox_data.block1.status_pins);

}

static bool estop_on_spindle_running(void)

{

if (!*g_gearbox_data.is_spindle_stopped)

{

/* This is an invalid condition, spindle must be stopped if we are

* shifting and we tested for it before we started.

*

* We expect that estop_out will be looped back to us so that

* it will trigger our handler. */

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox FATAL ERROR: detected "

"running spindle while shifting, triggering emergency stop!\n");

*g_gearbox_data.trigger_estop = true;

return true;

}

return false;

}

/* Combine masks from each pin group to a value representing the current

* gear setting. A return of NULL means that a corresponding value could

* not be found, which may indicate a gearshift being in progress- */

static pair_t* get_current_gear(tree_node_t *tree)

{

tree_node_t *result;

unsigned combined = (g_gearbox_data.block1.current_mask << 8) |

(g_gearbox_data.block2.current_mask << 4) |

g_gearbox_data.vorgelege.current_mask;

/* special case: ignore all other bits for neutral */

if (g_gearbox_data.vorgelege.current_mask ==

FP4_gears[FP4_NEUTRAL_GEAR_INDEX].value)

{

return &(FP4_gears[FP4_NEUTRAL_GEAR_INDEX]);

}

result = tree_search(tree, combined);

if (result != NULL)

{

return &(FP4_gears[result->value]);

}

return NULL;

}

/* Helper to update delays, returns true if time has not elapsed. */

static bool gearshift_wait_delay(long period)

{

if ((period > 0) && (g_gearbox_data.delay > 0))

{

g_gearbox_data.delay = g_gearbox_data.delay - period;

return true;

}

g_gearbox_data.delay = 0;

return false;

}

/* From:

* forum.linuxcnc.org/12-milling/33035-retr...FP4?start=460#117021

*

* 1. if u need to go to the vorne then turn cw

* 2. if u need to go to the mitte than turn ccw

* 3. if u need to go to the block2 and vorne-hinten is 1 then turn ccw else cw

*

* ┌───┐

* ┘ └──────────────── vorne

* ┌───┐

* ────────┘ └──────── hinten

* ┌───┐

* ────────────────┘ └ mitte

* ┌──────────

* ──────────┘ vorne-hinten

*

*/

static bool gearshift_need_reverse(unsigned char target_mask,

unsigned char current_mask)

{

if (FP4_STAGE_IS_mitte(target_mask)) /* CCW, reverse is on */

{

return true;

}

else if (FP4_STAGE_IS_vorne(target_mask)) /* CW, reverse is off */

{

return false;

}

else if (FP4_STAGE_IS_hinten(target_mask))

{

return false;

}

return true;

}

/* State functions */

/* This is more or less an "overshoot" protection check in case we missed the

* target hinten pos and moved further. We know when we reach an end point

* and we know we can't continue further in this direction, so stop trying and

* go back. Returns true if action needs to be taken. */

static bool gearshift_protect(shaft_data_t *shaft)

{

if (!*shaft->motor_on)

{

return false;

}

if (*shaft->motor_reverse)

{

/* If we move to the vorne/CW and we reached the furthest vorne position

* which does not seem to be our desired target, then we should

* disable the motor and trigger an E-STOP, we should never end up#

* in this situation. */

if ((shaft->current_mask == FP4_STAGE_POS_mitte) &&

(shaft->current_mask != shaft->target_mask))

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox: WARNING: "

"shaft motor at unexpected mitte position!\n");

}

else

{

return false;

}

}

else

{

/* If we move to the vorne/CW and we reached the furthest vorne position

* which does not seem to be our desired target, then we should

* disable the motor and trigger an E-STOP, we should never end up#

* in this situation. */

if ((shaft->current_mask == FP4_STAGE_POS_vorne) &&

(shaft->current_mask != shaft->target_mask))

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox: WARNING: "

"shaft motor at unexpected vorne position!\n");

}

else

{

return false;

}

}

return true;

}

/* Generic function that has the exact same logic, valid for all of the

* three shafts. */

static void gearshift_stage(shaft_data_t *shaft, statefunc me, statefunc next,

long period)

{

if (estop_on_spindle_running())

{

return;

}

if (gearshift_wait_delay(period))

{

g_gearbox_data.next = me;

return;

}

if (shaft->state == SHAFT_STATE_OFF)

{

/* Are the pins already in the desired state? */

if (shaft->current_mask == shaft->target_mask)

{

g_gearbox_data.next = next;

}

else

{

shaft->state = SHAFT_STATE_ON;

if (gearshift_need_reverse(shaft->target_mask,

shaft->current_mask))

{

*shaft->motor_reverse = true;

g_gearbox_data.delay = FP4_REVERSE_MOTOR_INTERVAL;

}

g_gearbox_data.next = me;

}

}

else if (shaft->state == SHAFT_STATE_ON)

{

/* Did we reach the desired position? */

if (shaft->current_mask == shaft->target_mask)

{

if (*shaft->motor_on)

{

/* De-energize the shaft motor */

*shaft->motor_on = false;

}

else

{

/* Second time we enter this state the motor will be off,

* that means that we already did the waiting that may have

* been set in the "if" below. If reverse direction was

* not active originally, then this does nothing */

*shaft->motor_reverse = false;

}

/* If reverse direction has been set, disable it in 100ms */

if (*shaft->motor_reverse)

{

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = me;

return;

}

else

{

*shaft->motor_slow = false;

}

if (*shaft->motor_slow)

{

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = me;

return;

}

/* We are done here, proceed to the next stage */

shaft->state = SHAFT_STATE_OFF;

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = next;

}

else

{

/* Protect furthest lect/CW and mitte/CCW end positions by not

* allowing the motor to continue running if we reached them,

* this should never happen, but it's better to have a safety

* measure to prevent hardware damage. The function will

* immediately stop the motor and trigger an emergency stop if this

* error condition is detected. */

if (gearshift_protect(shaft))

{

*shaft->motor_on = false;

shaft->state = SHAFT_STATE_RESTART;

g_gearbox_data.delay = FP4_REVERSE_MOTOR_INTERVAL;

g_gearbox_data.next = me;

return;

}

/* Going to the hinten requres lowering the motor speed */

if (FP4_STAGE_IS_hinten(shaft->target_mask) &&

!(*shaft->motor_slow))

{

*shaft->motor_slow = true;

}

else if (!(*shaft->motor_on))

{

/* Energize motor if it is not yet running */

*shaft->motor_on = true;

}

g_gearbox_data.delay = FP4_GEAR_STAGE_POLL_INTERVAL;

g_gearbox_data.next = me;

}

}

else if (shaft->state == SHAFT_STATE_RESTART)

{

/* Protection function restarted us, motor is already off and

* we came here after a certain delay. We now need to check what to do

* and re-energize */

if (*shaft->motor_reverse)

{

*shaft->motor_reverse = false;

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = me;

return;

}

if (*shaft->motor_slow)

{

*shaft->motor_slow = false;

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

}

/* Going back to the OFF state will retrigger the shift logic for

* this shaft */

shaft->state = SHAFT_STATE_OFF;

g_gearbox_data.next = me;

}

}

static void gearshift_stop(long period)

{

if (gearshift_wait_delay(period))

{

g_gearbox_data.next = gearshift_stop;

return;

}

twitch_stop(period);

if (!twitch_stop_completed())

{

g_gearbox_data.delay = FP4_TWITCH_KEEP_PIN_OFF;

g_gearbox_data.next = gearshift_stop;

return;

}

if (*g_gearbox_data.start_shift)

{

if (g_gearbox_data.spindle_on_before_shift)

{

*g_gearbox_data.do_stop_spindle = false;

g_gearbox_data.delay = FP4_WAIT_SPINDLE_AT_SPEED;

g_gearbox_data.next = gearshift_stop;

return;

}

}

if (g_gearbox_data.spindle_on_before_shift)

{

*g_gearbox_data.notify_spindle_at_speed = true;

}

/* We are done shifting, reset everything */

g_gearbox_data.next = NULL;

g_gearbox_data.spindle_on_before_shift = false;

}

static void gearshift_vorgelege(long period)

{

gearshift_stage(&(g_gearbox_data.vorgelege), gearshift_vorgelege,

gearshift_stop, period);

}

static void gearshift_block2(long period)

{

gearshift_stage(&(g_gearbox_data.block2), gearshift_block2,

gearshift_vorgelege, period);

}

static void gearshift_block1(long period)

{

gearshift_stage(&(g_gearbox_data.block1), gearshift_block1,

gearshift_block2, period);

}

/* Call this function once per each thread cycle to handle gearshifting,

* implies that gearshift_start() has been called in order to set the

* target gear. */

static void gearshift_handle(long period)

{

twitch_handle(period);

if (g_gearbox_data.next == NULL)

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox FATAL ERROR: "

"gearshift function not set up, triggering E-Stop!\n");

*g_gearbox_data.trigger_estop = true;

return;

}

g_gearbox_data.next(period);

}

/* Start shifting process */

static void gearshift_start(pair_t *target_gear, long period)

{

if (estop_on_spindle_running())

{

return;

}

g_gearbox_data.vorgelege.target_mask = (target_gear->value) & 0x000f;

g_gearbox_data.block2.target_mask = (target_gear->value & 0x00f0) >> 4;

g_gearbox_data.block1.target_mask =

(target_gear->value & 0x0f00) >> 8;

/* Make sure to leave 100ms between setting start_gear_shift to "on"

* and further operations */

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

twitch_start(period);

/* Special case: if we want to go to the neutral position, we

* only care about the vorgelege stage, so we can jump mitte to it */

if (g_gearbox_data.vorgelege.target_mask ==

FP4_gears[FP4_NEUTRAL_GEAR_INDEX].value) {

g_gearbox_data.next = gearshift_vorgelege;

}

else

{

g_gearbox_data.next = gearshift_block1;

}

}

/* Reset pins and state machine if an emergency stop was triggered. */

static void gearbox_handle_estop(void)

{

*g_gearbox_data.block1.motor_on = false;

*g_gearbox_data.block2.motor_on = false;

*g_gearbox_data.vorgelege.motor_on = false;

/* There are no separate pins for revers/slow for each shaft, each

* shaft structure has pointers to the same pins, so its enough to

* reset them only on one shaft. */

*g_gearbox_data.vorgelege.motor_reverse = false;

*g_gearbox_data.vorgelege.motor_slow = false;

gearshift_stop(0); /* Will stop and reset twitching as well */

}

static bool gearshift_in_progress(void)

{

return g_gearbox_data.next != NULL;

}

Warning: Spoiler!

/*

LinuxCNC component for controlling the Deckel FP4 gearbox.

Copymitte (C) 2018 Sergey 'Jin' Bostandzhyan <This email address is being protected from spambots. You need JavaScript enabled to view it.>

This program is free software; you can redistribute it and/or

modify it under the terms of the GNU General Public License

as published by the Free Software Foundation; either version 2

of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU General Public License for more details.

You should have received a copy of the GNU General Public License

along with this program; if not, write to the Free Software

Foundation, Inc., 51 Franklin Street, Fifth Floor, Boston, MA 02110-1301, USA.

*/

/* Functions related to gear switching. */

#include "FP4_gears.h"

#include "FP4_twitch.h"

typedef enum

{

SHAFT_STATE_OFF, /* Initial shaft state */

SHAFT_STATE_ON, /* Shift in process (i.e. shaft motor running) */

SHAFT_STATE_RESTART /* Error condition, we missed our target and reached

an end point, we need to go back */

} shaft_state_t;

/* Group all data that is required to operate on one shaft */

typedef struct

{

shaft_state_t state;

pin_group_t status_pins;

hal_bit_t *motor_on;

hal_bit_t *motor_reverse;

hal_bit_t *motor_slow;

unsigned char current_mask; /* auto updated via global variable */

unsigned char target_mask;

} shaft_data_t;

/* Group all data required for gearshifting */

static struct

{

hal_bit_t *start_shift;

hal_bit_t *do_stop_spindle;

hal_bit_t *is_spindle_stopped;

hal_bit_t *trigger_estop;

hal_bit_t *notify_spindle_at_speed;

bool spindle_on_before_shift;

shaft_data_t vorgelege;

shaft_data_t block2;

shaft_data_t block1;

long delay;

statefunc next;

} g_gearbox_data;

/* One time setup function to prepare data structures related to gearbox

* switching*/

FUNCTION(gearbox_setup)

{

/* Populate data structures that will be used be the state functions

* when shifting gears */

g_gearbox_data.vorgelege.state = SHAFT_STATE_OFF;

/* Grabbing the pin pointers in EXTRA_SETUP did not work because the

* component did not seem to be fully initializedt there.

*

* Another issue:

* while output pins are defined as (*__comp_inst->pin_name) by

* halcompile, input pins are turned into (0+*__comp_inst->pin_name)

* which makes it impossible to get the pointers via the defines

* created by halcompile. Accessing the pin variable directly did not

* work due to macro expansion, only workaround I found was to temporarily

* disable the macros.

*/

#pragma push_macro("vorgelege_vorne")

#pragma push_macro("vorgelege_mitte")

#pragma push_macro("vorgelege_hinten")

#pragma push_macro("vorgelege_vorne_hinten")

#undef vorgelege_vorne

#undef vorgelege_mitte

#undef vorgelege_hinten

#undef vorgelege_vorne_hinten

g_gearbox_data.vorgelege.status_pins = (pin_group_t)

{

__comp_inst->vorgelege_vorne,

__comp_inst->vorgelege_mitte,

__comp_inst->vorgelege_hinten,

};

#pragma pop_macro("vorgelege_vorne")

#pragma pop_macro("vorgelege_mitte")

#pragma pop_macro("vorgelege_hinten")

#pragma pop_macro("vorgelege_vorne_hinten")

g_gearbox_data.vorgelege.motor_on = &vorgelege_motor;

g_gearbox_data.vorgelege.motor_reverse = &rueckziehen;

g_gearbox_data.vorgelege.motor_slow = &motor_lowspeed;

g_gearbox_data.vorgelege.current_mask = 0;

g_gearbox_data.vorgelege.target_mask =

FP4_gears[FP4_NEUTRAL_GEAR_INDEX].value; /* neutral */

g_gearbox_data.block2.state = SHAFT_STATE_OFF;

#pragma push_macro("block2_vorne")

#pragma push_macro("block2_mitte")

#pragma push_macro("block2_hinten")

#pragma push_macro("block2_vorne_hinten")

#undef block2_vorne

#undef block2_mitte

#undef block2_hinten

#undef block2_vorne_hinten

g_gearbox_data.block2.status_pins = (pin_group_t)

{

__comp_inst->block2_vorne,

__comp_inst->block2_mitte,

__comp_inst->block2_hinten,

};

#pragma pop_macro("block2_vorne")

#pragma pop_macro("block2_mitte")

#pragma pop_macro("block2_hinten")

#pragma pop_macro("block2_vorne_hinten")

g_gearbox_data.block2.motor_on = &block2_motor;

g_gearbox_data.block2.motor_reverse = &rueckziehen;

g_gearbox_data.block2.motor_slow = &motor_lowspeed;

g_gearbox_data.block2.current_mask = 0;

g_gearbox_data.block2.target_mask = 0; /* don't care for neutral */

g_gearbox_data.block1.state = SHAFT_STATE_OFF;

#pragma push_macro("block1_vorne")

#pragma push_macro("block1_mitte")

#pragma push_macro("block1_hinten")

#pragma push_macro("block1_vorne_hinten")

#undef block1_vorne

#undef block1_mitte

#undef block1_hinten

#undef block1_vorne_hinten

g_gearbox_data.block1.status_pins = (pin_group_t)

{

__comp_inst->block1_vorne,

__comp_inst->block1_mitte,

__comp_inst->block1_hinten,

};

#pragma pop_macro("block1_vorne")

#pragma pop_macro("block1_mitte")

#pragma pop_macro("block1_hinten")

#pragma pop_macro("block1_vorne_hinten")

g_gearbox_data.block1.motor_on = &block1_motor;

g_gearbox_data.block1.motor_reverse = &rueckziehen;

g_gearbox_data.block1.motor_slow = &motor_lowspeed;

g_gearbox_data.block1.current_mask = 0;

g_gearbox_data.block1.target_mask = 0; /* don't care for neutral */

#pragma push_macro("spindle_stopped")

#undef spindle_stopped

#pragma pop_macro("spindle_stopped")

g_gearbox_data.do_stop_spindle = &stop_spindle;

g_gearbox_data.spindle_on_before_shift = false;

g_gearbox_data.trigger_estop = &estop_out;

g_gearbox_data.notify_spindle_at_speed = &spindle_at_speed;

g_gearbox_data.delay = 0;

g_gearbox_data.next = NULL;

}

static void gearshift_stop_spindle(void)

{

g_gearbox_data.spindle_on_before_shift =

!(*g_gearbox_data.is_spindle_stopped);

*g_gearbox_data.do_stop_spindle = true;

}

/* combine values of all pins in a group to a bitmask */

static unsigned char get_bitmask_from_pingroup(pin_group_t *group)

{

unsigned char mask = 0;

int i;

for (i = 0; i < FP4_PINS_IN_GROUP; i++)

{

mask |= *(group->p) << i;

}

return mask;

}

/* Update current mask values for each shaft */

static void update_current_pingroup_masks(void)

{

g_gearbox_data.vorgelege.current_mask =

get_bitmask_from_pingroup(&g_gearbox_data.vorgelege.status_pins);

g_gearbox_data.block2.current_mask =

get_bitmask_from_pingroup(&g_gearbox_data.block2.status_pins);

g_gearbox_data.block1.current_mask =

get_bitmask_from_pingroup(&g_gearbox_data.block1.status_pins);

}

static bool estop_on_spindle_running(void)

{

if (!*g_gearbox_data.is_spindle_stopped)

{

/* This is an invalid condition, spindle must be stopped if we are

* shifting and we tested for it before we started.

*

* We expect that estop_out will be looped back to us so that

* it will trigger our handler. */

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox FATAL ERROR: detected "

"running spindle while shifting, triggering emergency stop!\n");

*g_gearbox_data.trigger_estop = true;

return true;

}

return false;

}

/* Combine masks from each pin group to a value representing the current

* gear setting. A return of NULL means that a corresponding value could

* not be found, which may indicate a gearshift being in progress- */

static pair_t* get_current_gear(tree_node_t *tree)

{

tree_node_t *result;

unsigned combined = (g_gearbox_data.block1.current_mask << 8) |

(g_gearbox_data.block2.current_mask << 4) |

g_gearbox_data.vorgelege.current_mask;

/* special case: ignore all other bits for neutral */

if (g_gearbox_data.vorgelege.current_mask ==

FP4_gears[FP4_NEUTRAL_GEAR_INDEX].value)

{

return &(FP4_gears[FP4_NEUTRAL_GEAR_INDEX]);

}

result = tree_search(tree, combined);

if (result != NULL)

{

return &(FP4_gears[result->value]);

}

return NULL;

}

/* Helper to update delays, returns true if time has not elapsed. */

static bool gearshift_wait_delay(long period)

{

if ((period > 0) && (g_gearbox_data.delay > 0))

{

g_gearbox_data.delay = g_gearbox_data.delay - period;

return true;

}

g_gearbox_data.delay = 0;

return false;

}

/* From:

* forum.linuxcnc.org/12-milling/33035-retr...FP4?start=460#117021

*

* 1. if u need to go to the vorne then turn cw

* 2. if u need to go to the mitte than turn ccw

* 3. if u need to go to the block2 and vorne-hinten is 1 then turn ccw else cw

*

* ┌───┐

* ┘ └──────────────── vorne

* ┌───┐

* ────────┘ └──────── hinten

* ┌───┐

* ────────────────┘ └ mitte

* ┌──────────

* ──────────┘ vorne-hinten

*

*/

static bool gearshift_need_reverse(unsigned char target_mask,

unsigned char current_mask)

{

if (FP4_STAGE_IS_mitte(target_mask)) /* CCW, reverse is on */

{

return true;

}

else if (FP4_STAGE_IS_vorne(target_mask)) /* CW, reverse is off */

{

return false;

}

else if (FP4_STAGE_IS_hinten(target_mask))

{

return false;

}

return true;

}

/* State functions */

/* This is more or less an "overshoot" protection check in case we missed the

* target hinten pos and moved further. We know when we reach an end point

* and we know we can't continue further in this direction, so stop trying and

* go back. Returns true if action needs to be taken. */

static bool gearshift_protect(shaft_data_t *shaft)

{

if (!*shaft->motor_on)

{

return false;

}

if (*shaft->motor_reverse)

{

/* If we move to the vorne/CW and we reached the furthest vorne position

* which does not seem to be our desired target, then we should

* disable the motor and trigger an E-STOP, we should never end up#

* in this situation. */

if ((shaft->current_mask == FP4_STAGE_POS_mitte) &&

(shaft->current_mask != shaft->target_mask))

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox: WARNING: "

"shaft motor at unexpected mitte position!\n");

}

else

{

return false;

}

}

else

{

/* If we move to the vorne/CW and we reached the furthest vorne position

* which does not seem to be our desired target, then we should

* disable the motor and trigger an E-STOP, we should never end up#

* in this situation. */

if ((shaft->current_mask == FP4_STAGE_POS_vorne) &&

(shaft->current_mask != shaft->target_mask))

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox: WARNING: "

"shaft motor at unexpected vorne position!\n");

}

else

{

return false;

}

}

return true;

}

/* Generic function that has the exact same logic, valid for all of the

* three shafts. */

static void gearshift_stage(shaft_data_t *shaft, statefunc me, statefunc next,

long period)

{

if (estop_on_spindle_running())

{

return;

}

if (gearshift_wait_delay(period))

{

g_gearbox_data.next = me;

return;

}

if (shaft->state == SHAFT_STATE_OFF)

{

/* Are the pins already in the desired state? */

if (shaft->current_mask == shaft->target_mask)

{

g_gearbox_data.next = next;

}

else

{

shaft->state = SHAFT_STATE_ON;

if (gearshift_need_reverse(shaft->target_mask,

shaft->current_mask))

{

*shaft->motor_reverse = true;

g_gearbox_data.delay = FP4_REVERSE_MOTOR_INTERVAL;

}

g_gearbox_data.next = me;

}

}

else if (shaft->state == SHAFT_STATE_ON)

{

/* Did we reach the desired position? */

if (shaft->current_mask == shaft->target_mask)

{

if (*shaft->motor_on)

{

/* De-energize the shaft motor */

*shaft->motor_on = false;

}

else

{

/* Second time we enter this state the motor will be off,

* that means that we already did the waiting that may have

* been set in the "if" below. If reverse direction was

* not active originally, then this does nothing */

*shaft->motor_reverse = false;

}

/* If reverse direction has been set, disable it in 100ms */

if (*shaft->motor_reverse)

{

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = me;

return;

}

else

{

*shaft->motor_slow = false;

}

if (*shaft->motor_slow)

{

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = me;

return;

}

/* We are done here, proceed to the next stage */

shaft->state = SHAFT_STATE_OFF;

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = next;

}

else

{

/* Protect furthest lect/CW and mitte/CCW end positions by not

* allowing the motor to continue running if we reached them,

* this should never happen, but it's better to have a safety

* measure to prevent hardware damage. The function will

* immediately stop the motor and trigger an emergency stop if this

* error condition is detected. */

if (gearshift_protect(shaft))

{

*shaft->motor_on = false;

shaft->state = SHAFT_STATE_RESTART;

g_gearbox_data.delay = FP4_REVERSE_MOTOR_INTERVAL;

g_gearbox_data.next = me;

return;

}

/* Going to the hinten requres lowering the motor speed */

if (FP4_STAGE_IS_hinten(shaft->target_mask) &&

!(*shaft->motor_slow))

{

*shaft->motor_slow = true;

}

else if (!(*shaft->motor_on))

{

/* Energize motor if it is not yet running */

*shaft->motor_on = true;

}

g_gearbox_data.delay = FP4_GEAR_STAGE_POLL_INTERVAL;

g_gearbox_data.next = me;

}

}

else if (shaft->state == SHAFT_STATE_RESTART)

{

/* Protection function restarted us, motor is already off and

* we came here after a certain delay. We now need to check what to do

* and re-energize */

if (*shaft->motor_reverse)

{

*shaft->motor_reverse = false;

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

g_gearbox_data.next = me;

return;

}

if (*shaft->motor_slow)

{

*shaft->motor_slow = false;

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

}

/* Going back to the OFF state will retrigger the shift logic for

* this shaft */

shaft->state = SHAFT_STATE_OFF;

g_gearbox_data.next = me;

}

}

static void gearshift_stop(long period)

{

if (gearshift_wait_delay(period))

{

g_gearbox_data.next = gearshift_stop;

return;

}

twitch_stop(period);

if (!twitch_stop_completed())

{

g_gearbox_data.delay = FP4_TWITCH_KEEP_PIN_OFF;

g_gearbox_data.next = gearshift_stop;

return;

}

if (*g_gearbox_data.start_shift)

{

if (g_gearbox_data.spindle_on_before_shift)

{

*g_gearbox_data.do_stop_spindle = false;

g_gearbox_data.delay = FP4_WAIT_SPINDLE_AT_SPEED;

g_gearbox_data.next = gearshift_stop;

return;

}

}

if (g_gearbox_data.spindle_on_before_shift)

{

*g_gearbox_data.notify_spindle_at_speed = true;

}

/* We are done shifting, reset everything */

g_gearbox_data.next = NULL;

g_gearbox_data.spindle_on_before_shift = false;

}

static void gearshift_vorgelege(long period)

{

gearshift_stage(&(g_gearbox_data.vorgelege), gearshift_vorgelege,

gearshift_stop, period);

}

static void gearshift_block2(long period)

{

gearshift_stage(&(g_gearbox_data.block2), gearshift_block2,

gearshift_vorgelege, period);

}

static void gearshift_block1(long period)

{

gearshift_stage(&(g_gearbox_data.block1), gearshift_block1,

gearshift_block2, period);

}

/* Call this function once per each thread cycle to handle gearshifting,

* implies that gearshift_start() has been called in order to set the

* target gear. */

static void gearshift_handle(long period)

{

twitch_handle(period);

if (g_gearbox_data.next == NULL)

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox FATAL ERROR: "

"gearshift function not set up, triggering E-Stop!\n");

*g_gearbox_data.trigger_estop = true;

return;

}

g_gearbox_data.next(period);

}

/* Start shifting process */

static void gearshift_start(pair_t *target_gear, long period)

{

if (estop_on_spindle_running())

{

return;

}

g_gearbox_data.vorgelege.target_mask = (target_gear->value) & 0x000f;

g_gearbox_data.block2.target_mask = (target_gear->value & 0x00f0) >> 4;

g_gearbox_data.block1.target_mask =

(target_gear->value & 0x0f00) >> 8;

/* Make sure to leave 100ms between setting start_gear_shift to "on"

* and further operations */

g_gearbox_data.delay = FP4_GENERIC_PIN_INTERVAL;

twitch_start(period);

/* Special case: if we want to go to the neutral position, we

* only care about the vorgelege stage, so we can jump mitte to it */

if (g_gearbox_data.vorgelege.target_mask ==

FP4_gears[FP4_NEUTRAL_GEAR_INDEX].value) {

g_gearbox_data.next = gearshift_vorgelege;

}

else

{

g_gearbox_data.next = gearshift_block1;

}

}

/* Reset pins and state machine if an emergency stop was triggered. */

static void gearbox_handle_estop(void)

{

*g_gearbox_data.block1.motor_on = false;

*g_gearbox_data.block2.motor_on = false;

*g_gearbox_data.vorgelege.motor_on = false;

/* There are no separate pins for revers/slow for each shaft, each

* shaft structure has pointers to the same pins, so its enough to

* reset them only on one shaft. */

*g_gearbox_data.vorgelege.motor_reverse = false;

*g_gearbox_data.vorgelege.motor_slow = false;

gearshift_stop(0); /* Will stop and reset twitching as well */

}

static bool gearshift_in_progress(void)

{

return g_gearbox_data.next != NULL;

}

- Aciera

02 Jul 2024 16:55

Replied by Aciera on topic Deckel FP4 Gearbox Comp

Deckel FP4 Gearbox Comp

Category: Advanced Configuration

Well I would have said 'FP4_gearbox.comp' but looking at the component itself has me confused as none of the component pins created seem to be used in the actual function:

Warning: Spoiler!

/*

LinuxCNC component for controlling the Deckel FP4 gearbox.

Copymitte (C) 2018 Sergey 'Jin' Bostandzhyan <This email address is being protected from spambots. You need JavaScript enabled to view it.>

This program is free software; you can redistribute it and/or

modify it under the terms of the GNU General Public License

as published by the Free Software Foundation; either version 2

of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU General Public License for more details.

You should have received a copy of the GNU General Public License

along with this program; if not, write to the Free Software

Foundation, Inc., 51 Franklin Street, Fifth Floor, Boston, MA 02110-1301, USA.

*/

component FP4_gearbox "Component to control the Deckel FP4 gearbox to set the requested speed";

author "Sergey 'Jin' Bostandzhyan midified by Andreas Benz";

license "GPL";

/* to be connected with motion.spindle−speed−out−abs */

pin in float spindle_speed_in_abs = 0 "Desired spindle speed in rotations per minute, always positive regardless of spindle direction.";

/* to be conneced with motion.spindle−speed−in */

pin out float spindle_speed_out = 0 "Actual spindle speed feedback in revolutions per second";

/* gearbox status pins from the MESA 7i96S */

pin in bit vorgelege_vorne "MESA 7i96S INPUT 2: 28X2-11";

pin in bit vorgelege_mitte "MESA 7i96S INPUT 3: 28X2-11";

pin in bit vorgelege_hinten "MESA 7i96S INPUT 4: 28X2-13";

pin in bit block2_vorne "MESA 7i96S INPUT 5: 28X2-15";

pin in bit block2_mitte "MESA 7i96S INPUT 6: 28X2-16";

pin in bit block2_hinten "MESA 7i96S INPUT 7: 28X2-17";

pin in bit block1_vorne "MESA 7i96S INPUT 8: 28X2-19";

pin in bit block1_mitte "MESA 7i96S INPUT 9: 28X2-20";

pin in bit block1_hinten "MESA 7i96S INPUT 10: 28X2-21";

pin in bit spindle_stopped = 0 "MESA 7i84 INPUT 19: TB2-4";

pin out bit stop_spindle = 0 "Start or stop spindle";

pin out bit spindle_at_speed = 0;

/* control pins */

pin out bit motor_lowspeed = 0 "MESA 7i66 OUTPUT ";

pin out bit vorgelege_motor = 0 "MESA 7i66 OUTPUT C3 7i96S.0.7i66.0.0.output-03";

pin out bit block2_motor = 0 "MESA 7i66 OUTPUT C4 7i96S.0.7i66.0.0.output-04";

pin out bit block1_motor = 0 "MESA 7i66 OUTPUT C5 7i96S.0.7i66.0.0.output-05";

pin out bit rueckziehen = 0 "MESA 7i66 OUTPUT C6 7i96S.0.7i66.0.0.output-06";

pin out bit twitch_cw = 0 "MESA 7i66 OUTPUT 6: 28X1-14";

pin out bit twitch_ccw = 0 "MESA 7i66 OUTPUT 7: 28X1-15";

pin out bit estop_out = 0 "This pin will trigger emergency stop in case of an unrecoverably fatal error.";

pin in bit estop_in "This pin notifies us that an emergency stop was triggered outside the component.";

function _;

option singleton yes;

;;

#include <rtapi_math.h>

#include "FP4_common.h"

#include "FP4_util.h"

#include "FP4_gears.h"

static float g_last_spindle_speed = 0;

static tree_node_t *g_tree_rpm = NULL;

static tree_node_t *g_tree_mask = NULL;

static bool g_setup_done = false;

static bool g_last_estop = false;

/* one time setup, called from the main function to initialize whatever we

* need */

FUNCTION(setup)

{

int i;

/* Initialize state data structures */

gearbox_setup(__comp_inst, period);

twitch_setup(__comp_inst, period);

/* we want to have key:value pairs in the binary search tree, where

* the value represents the index of the key in our gears array. So

* we'll put things together the way we need them for the tree generation

*/

pair_t temp[FP4_NUM_GEARS];

for (i = 0; i < FP4_NUM_GEARS; i++)

{

temp.key = FP4_gears.key;

temp.value = i;

}

/* build up binary tree from the gears array to search by rpm, this

* array is already sorted */

g_tree_rpm = tree_from_sorted_array(temp, FP4_NUM_GEARS);

/* build up a key:value list where the bitmask from the m400e_gears

* array is the key and the index of the original position in the

* above array is the value */

for (i = 0; i < FP4_NUM_GEARS; i++)

{

temp.key = FP4_gears.value;

temp.value = i;

}

/* sort the newly created array by key (needed for tree build up) */

sort_array_by_key(temp, FP4_NUM_GEARS);

/* build up binary tree from the gears array to search for bitmask */

g_tree_mask = tree_from_sorted_array(temp, FP4_NUM_GEARS);

g_last_spindle_speed = spindle_speed_in_abs;

g_last_estop = estop_in;

}

/* When e-stop is triggered from the outside everything is already powered

* off, but we want to make sure that our pins are also inactive should

* the power come back. We don't have to care about timings here, because

* everything is already off at this point. */

FUNCTION(handle_external_e_stop)

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox: EMERGENCY STOP condition "

"detected!\n");

/* reset state machine avoiding delays */

gearbox_handle_estop(); /* this function also stops/resets twitching */

spindle_at_speed = false;

stop_spindle = true;

/* reset estop_out pin since we could haave been the ones who triggered

* this e-stop */

estop_out = false;

}

/* main component function */

FUNCTION(_)

{

if (estop_in)

{

if (g_last_estop != estop_in)

{

handle_external_e_stop(__comp_inst, period);

g_last_estop = estop_in;

}

return;

}

g_last_estop = estop_in;

/* perform one time setup */

if (!g_setup_done)

{

setup(__comp_inst, period);

g_setup_done = true;

}

/* read and update global mask variables for each pin group */

update_current_pingroup_masks();

/* Gear shift is in progress */

if (!gearshift_in_progress())

{

if (stop_spindle && !spindle_stopped)

{

stop_spindle = false;

}

/* determine and update current spindle speed information */

pair_t *speed = get_current_gear(g_tree_mask);

if (speed != NULL)

{

spindle_speed_out = (float)speed->key;

}

if (g_last_spindle_speed == spindle_speed_in_abs)

{

/* Nothing to do */

spindle_at_speed = !spindle_stopped;

return;

}

/* We need to quantize the requested speed to see if our current

* gear already matches it */

pair_t *new_gear = select_gear_from_rpm(g_tree_rpm,

spindle_speed_in_abs);

/* Current speed already matches the requested speed, nothing to do */

if (new_gear->key == spindle_speed_out)

{

spindle_at_speed = !spindle_stopped;

return;

}

/* We don't attempt to do anything if the spindle is running. */

/* TODO: check that spindle_stopped triggers only when the spindle

* has come to a full stop and not just a that time it has been

* powered off (might still be moving due to inertia) */

if (!spindle_stopped)

{

gearshift_stop_spindle();

return;

}

/* We need to change to another gear */

g_last_spindle_speed = spindle_speed_in_abs;

spindle_at_speed = false;

/* This call will set the start_gear_shift pin! */

gearshift_start(new_gear, period);

/* Do the rest in the next cycle */

return;

}

/* Do the gear shifting */

gearshift_handle(period);

}

LinuxCNC component for controlling the Deckel FP4 gearbox.

Copymitte (C) 2018 Sergey 'Jin' Bostandzhyan <This email address is being protected from spambots. You need JavaScript enabled to view it.>

This program is free software; you can redistribute it and/or

modify it under the terms of the GNU General Public License

as published by the Free Software Foundation; either version 2

of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful,

but WITHOUT ANY WARRANTY; without even the implied warranty of

MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

GNU General Public License for more details.

You should have received a copy of the GNU General Public License

along with this program; if not, write to the Free Software

Foundation, Inc., 51 Franklin Street, Fifth Floor, Boston, MA 02110-1301, USA.

*/

component FP4_gearbox "Component to control the Deckel FP4 gearbox to set the requested speed";

author "Sergey 'Jin' Bostandzhyan midified by Andreas Benz";

license "GPL";

/* to be connected with motion.spindle−speed−out−abs */

pin in float spindle_speed_in_abs = 0 "Desired spindle speed in rotations per minute, always positive regardless of spindle direction.";

/* to be conneced with motion.spindle−speed−in */

pin out float spindle_speed_out = 0 "Actual spindle speed feedback in revolutions per second";

/* gearbox status pins from the MESA 7i96S */

pin in bit vorgelege_vorne "MESA 7i96S INPUT 2: 28X2-11";

pin in bit vorgelege_mitte "MESA 7i96S INPUT 3: 28X2-11";

pin in bit vorgelege_hinten "MESA 7i96S INPUT 4: 28X2-13";

pin in bit block2_vorne "MESA 7i96S INPUT 5: 28X2-15";

pin in bit block2_mitte "MESA 7i96S INPUT 6: 28X2-16";

pin in bit block2_hinten "MESA 7i96S INPUT 7: 28X2-17";

pin in bit block1_vorne "MESA 7i96S INPUT 8: 28X2-19";

pin in bit block1_mitte "MESA 7i96S INPUT 9: 28X2-20";

pin in bit block1_hinten "MESA 7i96S INPUT 10: 28X2-21";

pin in bit spindle_stopped = 0 "MESA 7i84 INPUT 19: TB2-4";

pin out bit stop_spindle = 0 "Start or stop spindle";

pin out bit spindle_at_speed = 0;

/* control pins */

pin out bit motor_lowspeed = 0 "MESA 7i66 OUTPUT ";

pin out bit vorgelege_motor = 0 "MESA 7i66 OUTPUT C3 7i96S.0.7i66.0.0.output-03";

pin out bit block2_motor = 0 "MESA 7i66 OUTPUT C4 7i96S.0.7i66.0.0.output-04";

pin out bit block1_motor = 0 "MESA 7i66 OUTPUT C5 7i96S.0.7i66.0.0.output-05";

pin out bit rueckziehen = 0 "MESA 7i66 OUTPUT C6 7i96S.0.7i66.0.0.output-06";

pin out bit twitch_cw = 0 "MESA 7i66 OUTPUT 6: 28X1-14";

pin out bit twitch_ccw = 0 "MESA 7i66 OUTPUT 7: 28X1-15";

pin out bit estop_out = 0 "This pin will trigger emergency stop in case of an unrecoverably fatal error.";

pin in bit estop_in "This pin notifies us that an emergency stop was triggered outside the component.";

function _;

option singleton yes;

;;

#include <rtapi_math.h>

#include "FP4_common.h"

#include "FP4_util.h"

#include "FP4_gears.h"

static float g_last_spindle_speed = 0;

static tree_node_t *g_tree_rpm = NULL;

static tree_node_t *g_tree_mask = NULL;

static bool g_setup_done = false;

static bool g_last_estop = false;

/* one time setup, called from the main function to initialize whatever we

* need */

FUNCTION(setup)

{

int i;

/* Initialize state data structures */

gearbox_setup(__comp_inst, period);

twitch_setup(__comp_inst, period);

/* we want to have key:value pairs in the binary search tree, where

* the value represents the index of the key in our gears array. So

* we'll put things together the way we need them for the tree generation

*/

pair_t temp[FP4_NUM_GEARS];

for (i = 0; i < FP4_NUM_GEARS; i++)

{

temp.key = FP4_gears.key;

temp.value = i;

}

/* build up binary tree from the gears array to search by rpm, this

* array is already sorted */

g_tree_rpm = tree_from_sorted_array(temp, FP4_NUM_GEARS);

/* build up a key:value list where the bitmask from the m400e_gears

* array is the key and the index of the original position in the

* above array is the value */

for (i = 0; i < FP4_NUM_GEARS; i++)

{

temp.key = FP4_gears.value;

temp.value = i;

}

/* sort the newly created array by key (needed for tree build up) */

sort_array_by_key(temp, FP4_NUM_GEARS);

/* build up binary tree from the gears array to search for bitmask */

g_tree_mask = tree_from_sorted_array(temp, FP4_NUM_GEARS);

g_last_spindle_speed = spindle_speed_in_abs;

g_last_estop = estop_in;

}

/* When e-stop is triggered from the outside everything is already powered

* off, but we want to make sure that our pins are also inactive should

* the power come back. We don't have to care about timings here, because

* everything is already off at this point. */

FUNCTION(handle_external_e_stop)

{

rtapi_print_msg(RTAPI_MSG_ERR, "FP4_gearbox: EMERGENCY STOP condition "

"detected!\n");

/* reset state machine avoiding delays */

gearbox_handle_estop(); /* this function also stops/resets twitching */

spindle_at_speed = false;

stop_spindle = true;

/* reset estop_out pin since we could haave been the ones who triggered

* this e-stop */

estop_out = false;

}

/* main component function */

FUNCTION(_)

{

if (estop_in)

{

if (g_last_estop != estop_in)

{

handle_external_e_stop(__comp_inst, period);

g_last_estop = estop_in;

}

return;

}

g_last_estop = estop_in;

/* perform one time setup */

if (!g_setup_done)

{

setup(__comp_inst, period);

g_setup_done = true;

}

/* read and update global mask variables for each pin group */

update_current_pingroup_masks();

/* Gear shift is in progress */

if (!gearshift_in_progress())

{

if (stop_spindle && !spindle_stopped)

{

stop_spindle = false;

}

/* determine and update current spindle speed information */

pair_t *speed = get_current_gear(g_tree_mask);

if (speed != NULL)

{

spindle_speed_out = (float)speed->key;

}

if (g_last_spindle_speed == spindle_speed_in_abs)

{

/* Nothing to do */

spindle_at_speed = !spindle_stopped;

return;

}

/* We need to quantize the requested speed to see if our current

* gear already matches it */

pair_t *new_gear = select_gear_from_rpm(g_tree_rpm,

spindle_speed_in_abs);

/* Current speed already matches the requested speed, nothing to do */

if (new_gear->key == spindle_speed_out)

{

spindle_at_speed = !spindle_stopped;

return;

}

/* We don't attempt to do anything if the spindle is running. */

/* TODO: check that spindle_stopped triggers only when the spindle

* has come to a full stop and not just a that time it has been

* powered off (might still be moving due to inertia) */

if (!spindle_stopped)

{

gearshift_stop_spindle();

return;

}

/* We need to change to another gear */

g_last_spindle_speed = spindle_speed_in_abs;

spindle_at_speed = false;

/* This call will set the start_gear_shift pin! */

gearshift_start(new_gear, period);

/* Do the rest in the next cycle */

return;

}

/* Do the gear shifting */

gearshift_handle(period);

}

- Aciera

02 Jul 2024 16:33 - 02 Jul 2024 16:34

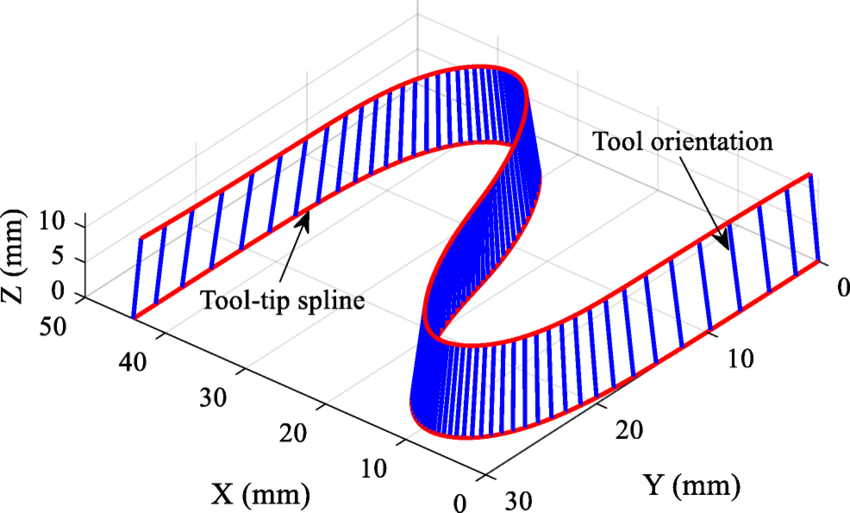

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Aciera

02 Jul 2024 16:29

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- Aciera

02 Jul 2024 16:24 - 02 Jul 2024 16:25

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

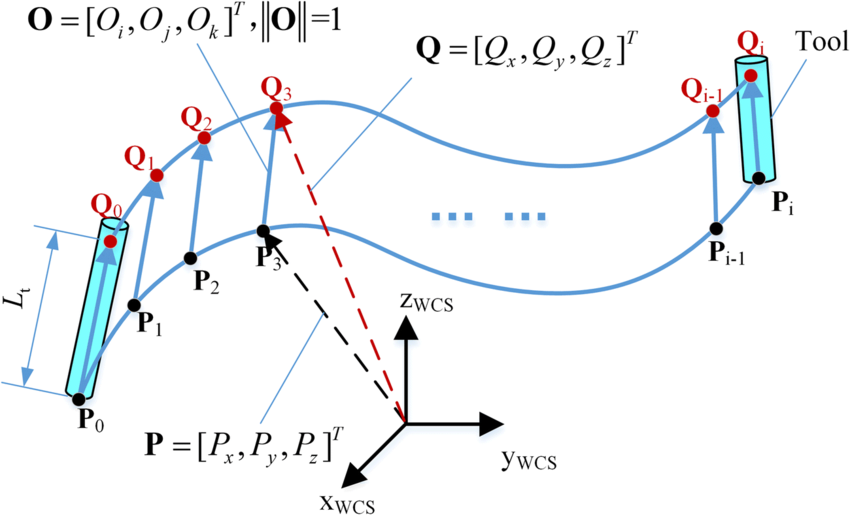

This is another image from the link:

The current tool position XYZ (ie the TCP knot) is at the center of the sphere.

The current tool orientation (black arrow) is defined by angles 'A' and 'C' in red (ie this would be an XYZAC kinematic), the vector points to the corresponding TA knot (green dot, here called 'TO' knot) a certain fixed distance away.

The other two green dots would represent the previous and the next TA/TO knot for the previous and the next TCP knots.

The current tool position XYZ (ie the TCP knot) is at the center of the sphere.

The current tool orientation (black arrow) is defined by angles 'A' and 'C' in red (ie this would be an XYZAC kinematic), the vector points to the corresponding TA knot (green dot, here called 'TO' knot) a certain fixed distance away.

The other two green dots would represent the previous and the next TA/TO knot for the previous and the next TCP knots.

- PCW

02 Jul 2024 16:17 - 02 Jul 2024 16:19

Replied by PCW on topic New project, litehm2: a hostmot2 port to linsn rv901t

New project, litehm2: a hostmot2 port to linsn rv901t

Category: Driver Boards

Yeah, Ethernet cards are different, they have an up to 16

character name stored in EEPROM. On Ethernet cards the

driver uses the card name from the EEPROM rather than

the one in the low level firmware.

character name stored in EEPROM. On Ethernet cards the

driver uses the card name from the EEPROM rather than

the one in the low level firmware.

- Aciera

02 Jul 2024 16:14

G1 X1 Y2 Z3 A10 C20

for the end of each segment we have the toolposition (TCP knot in XYZ coordinates) and the tool orientation vector (using the A and C angles in this example or by whatever angle(s) the kinematic for the particular machine uses eg A, AB, BC ..)

The corresponding TA knot is offset from the TCP knot by a fixed distance (say 10mm) along the tool orientation vector.

Replied by Aciera on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

say we have a gcode line:I'm still a little confused how to solve this 5 axis geometry. Especially caluclating the inbetween TA knots.

G1 X1 Y2 Z3 A10 C20

for the end of each segment we have the toolposition (TCP knot in XYZ coordinates) and the tool orientation vector (using the A and C angles in this example or by whatever angle(s) the kinematic for the particular machine uses eg A, AB, BC ..)

The corresponding TA knot is offset from the TCP knot by a fixed distance (say 10mm) along the tool orientation vector.

Time to create page: 1.290 seconds