Search Results (Searched for: )

- rodw

25 Nov 2025 06:23

Replied by rodw on topic LinuxCNC homing twice in Axis SImulation

LinuxCNC homing twice in Axis SImulation

Category: AXIS

- meister

- meister

25 Nov 2025 05:47 - 25 Nov 2025 05:57

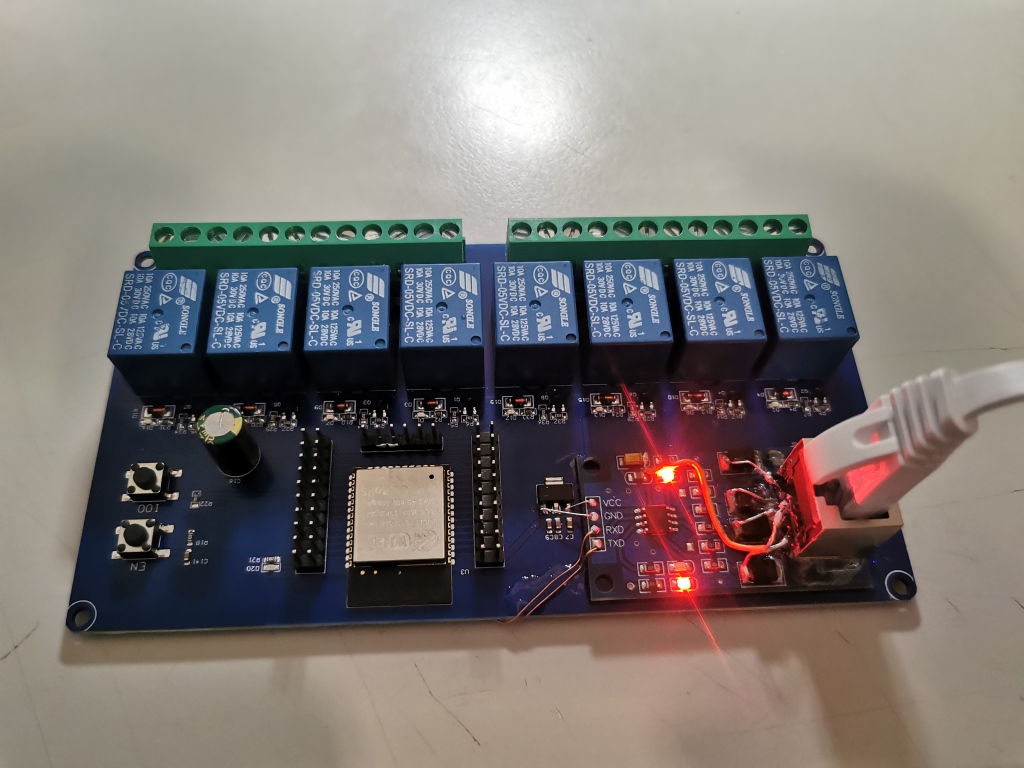

SmartSerial on cheap ESP32-8ch-Relais Card was created by meister

SmartSerial on cheap ESP32-8ch-Relais Card

Category: Driver Boards

- emresensoy

- emresensoy

25 Nov 2025 02:59

Replied by emresensoy on topic LinuxCNC Hardware Survey

LinuxCNC Hardware Survey

Category: Driver Boards

- EW_CNC

25 Nov 2025 02:46

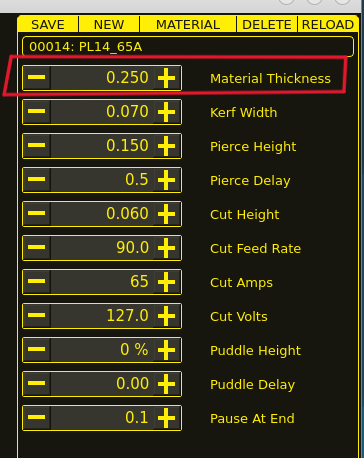

Replied by EW_CNC on topic Ohmic Probe + Material Height Feature Request

Ohmic Probe + Material Height Feature Request

Category: Plasmac

- Lcvette

- johnbump

- johnbump

25 Nov 2025 02:30

Replied by johnbump on topic calling subroutine from G54, G55, G56, but it acts weird

calling subroutine from G54, G55, G56, but it acts weird

Category: O Codes (subroutines) and NGCGUI

- PCW

24 Nov 2025 22:23

Replied by PCW on topic Chinese Mesa 7I92 from aliexpress NEW

Chinese Mesa 7I92 from aliexpress NEW

Category: Driver Boards

- AgentWD40

24 Nov 2025 21:02

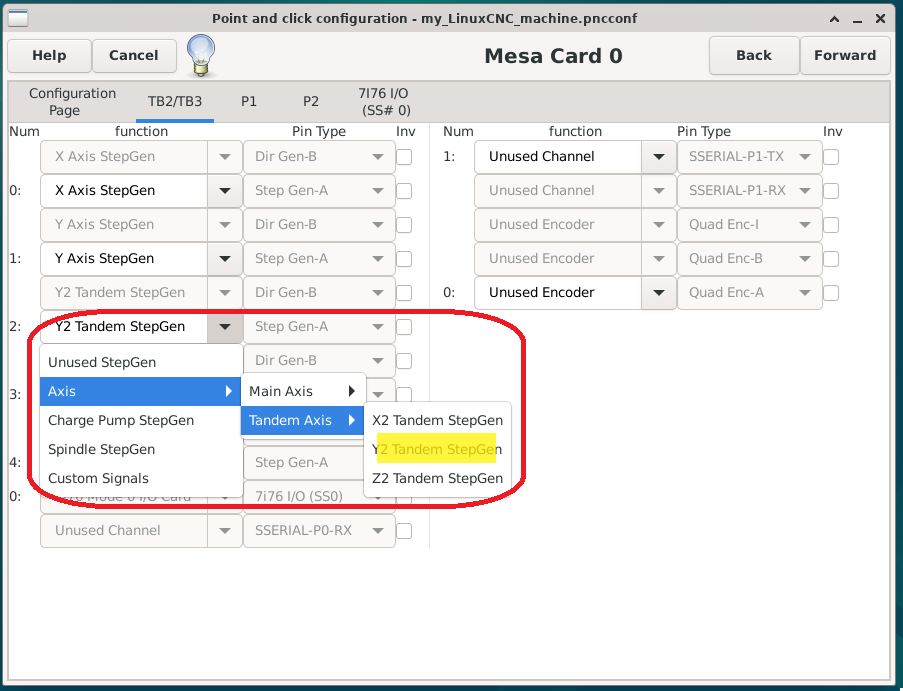

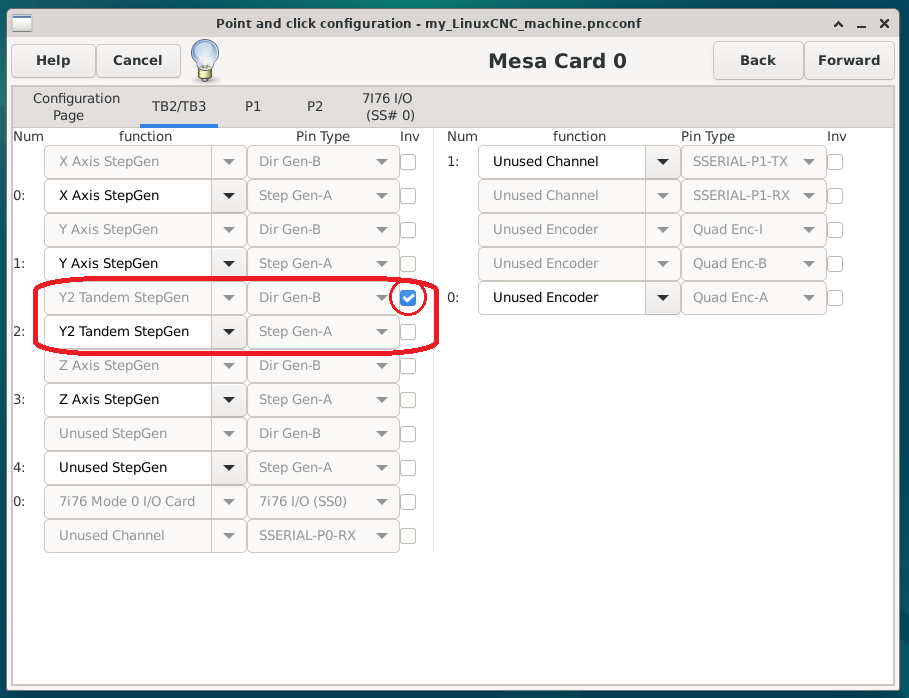

Replied by AgentWD40 on topic Configuring dual Y Axis drivers

Configuring dual Y Axis drivers

Category: Advanced Configuration

- melayate

- melayate

24 Nov 2025 20:03 - 24 Nov 2025 21:00

Replied by melayate on topic QtDragon M6 Remap Tool Measurement - Inconsistent/Wrong Offsets with VersaProbe

QtDragon M6 Remap Tool Measurement - Inconsistent/Wrong Offsets with VersaProbe

Category: Qtvcp

- Aciera

24 Nov 2025 19:55

Replied by Aciera on topic CNC AXIS IN PARKING MODE

CNC AXIS IN PARKING MODE

Category: Advanced Configuration

- gardenweazel

24 Nov 2025 19:52

Replied by gardenweazel on topic qt_auto_probe_tool.ngc Oddity(Again)

qt_auto_probe_tool.ngc Oddity(Again)

Category: Qtvcp

- melayate

- melayate

24 Nov 2025 19:15

Replied by melayate on topic QtDragon M6 Remap Tool Measurement - Inconsistent/Wrong Offsets with VersaProbe

QtDragon M6 Remap Tool Measurement - Inconsistent/Wrong Offsets with VersaProbe

Category: Qtvcp

- tommylight

24 Nov 2025 18:42

Replied by tommylight on topic LinuxCNC homing twice in Axis SImulation

LinuxCNC homing twice in Axis SImulation

Category: AXIS

Time to create page: 0.261 seconds