Search Results (Searched for: )

- slowpoke

- slowpoke

20 Nov 2025 10:29

Replied by slowpoke on topic Used Laptops tested with LinuxCNC and Mesa Ethernet boards

Used Laptops tested with LinuxCNC and Mesa Ethernet boards

Category: Computers and Hardware

- vre

- vre

20 Nov 2025 10:11

- timo

- timo

20 Nov 2025 09:57 - 20 Nov 2025 10:06

Replied by timo on topic Need your opinion on Axes placement.

Need your opinion on Axes placement.

Category: CNC Machines

- Hakan

- Hakan

20 Nov 2025 09:43

Replied by Hakan on topic Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Category: EtherCAT

- Hakan

- Hakan

20 Nov 2025 09:40

Replied by Hakan on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- kor

- kor

20 Nov 2025 09:37 - 20 Nov 2025 09:37

Replied by kor on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- TimP

- TimP

20 Nov 2025 09:35

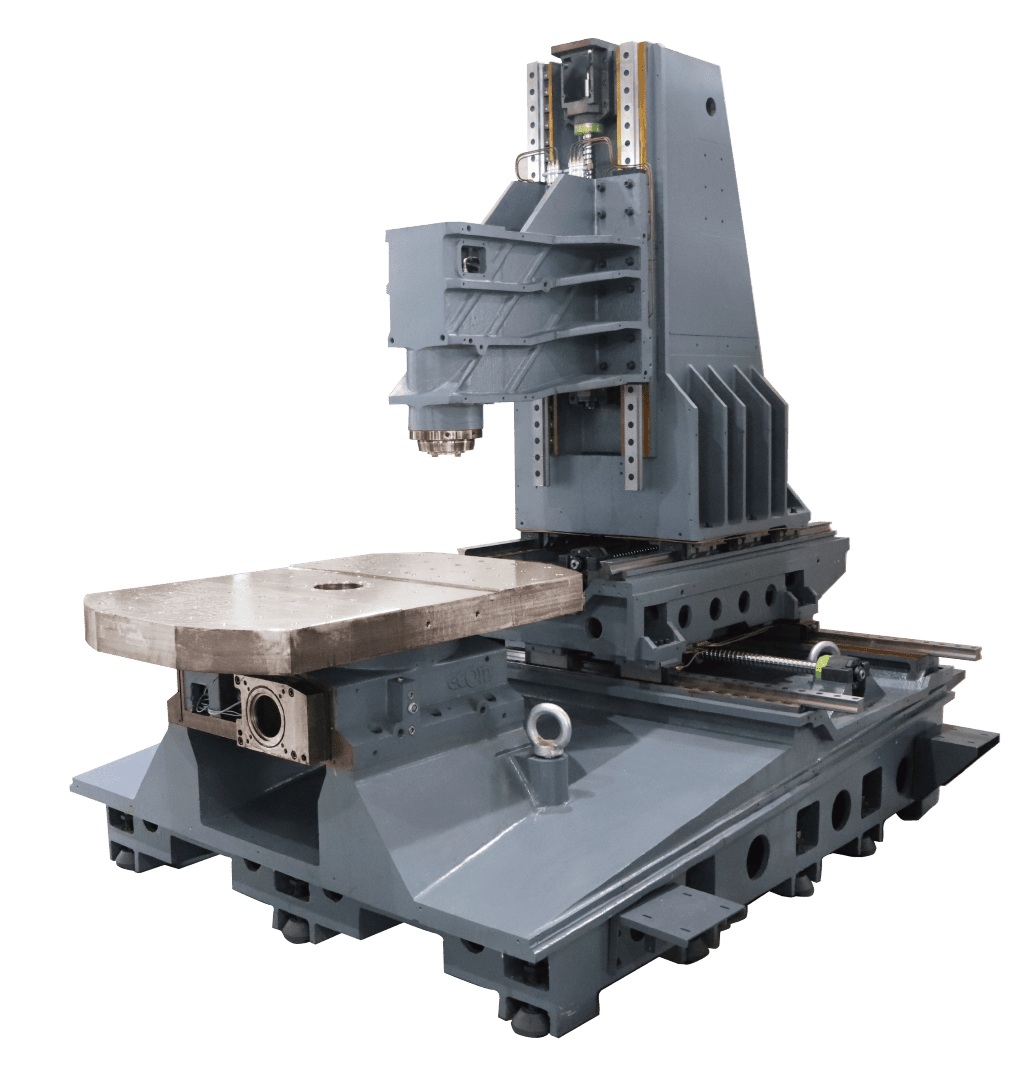

Need your opinion on Axes placement. was created by TimP

Need your opinion on Axes placement.

Category: CNC Machines

- DemonClaW

- DemonClaW

20 Nov 2025 09:34 - 20 Nov 2025 09:37

Replied by DemonClaW on topic Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Category: EtherCAT

- Hakan

- Hakan

20 Nov 2025 09:07

- SPH

20 Nov 2025 08:47

- Hakan

- Hakan

20 Nov 2025 08:24

Replied by Hakan on topic Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Category: EtherCAT

- Hakan

- Hakan

20 Nov 2025 08:17

- T_D

- T_D

20 Nov 2025 07:55

- SPH

20 Nov 2025 07:16

- SPH

20 Nov 2025 06:38

Time to create page: 0.191 seconds