Search Results (Searched for: )

- SPH

20 Nov 2025 07:16

- SPH

20 Nov 2025 06:38

- aDm1N

20 Nov 2025 05:50

- Jensner

- Jensner

20 Nov 2025 05:48 - 20 Nov 2025 05:48

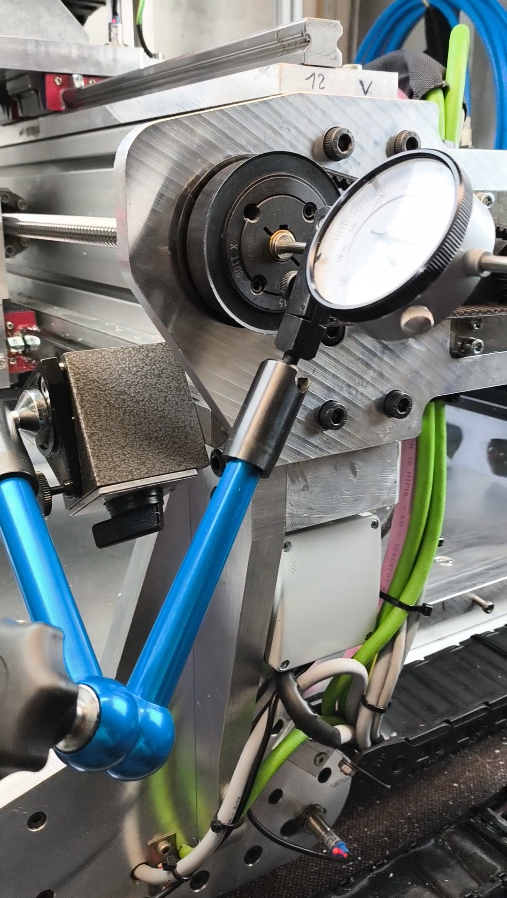

Replied by Jensner on topic Aufschaukeln mit JMC iHSS60-36-30-21-38 in Verbindung mit Linear Encodern

Aufschaukeln mit JMC iHSS60-36-30-21-38 in Verbindung mit Linear Encodern

Category: Deutsch

- SPH

20 Nov 2025 04:48

- Muftijaja

- Muftijaja

20 Nov 2025 02:39 - 21 Nov 2025 21:24

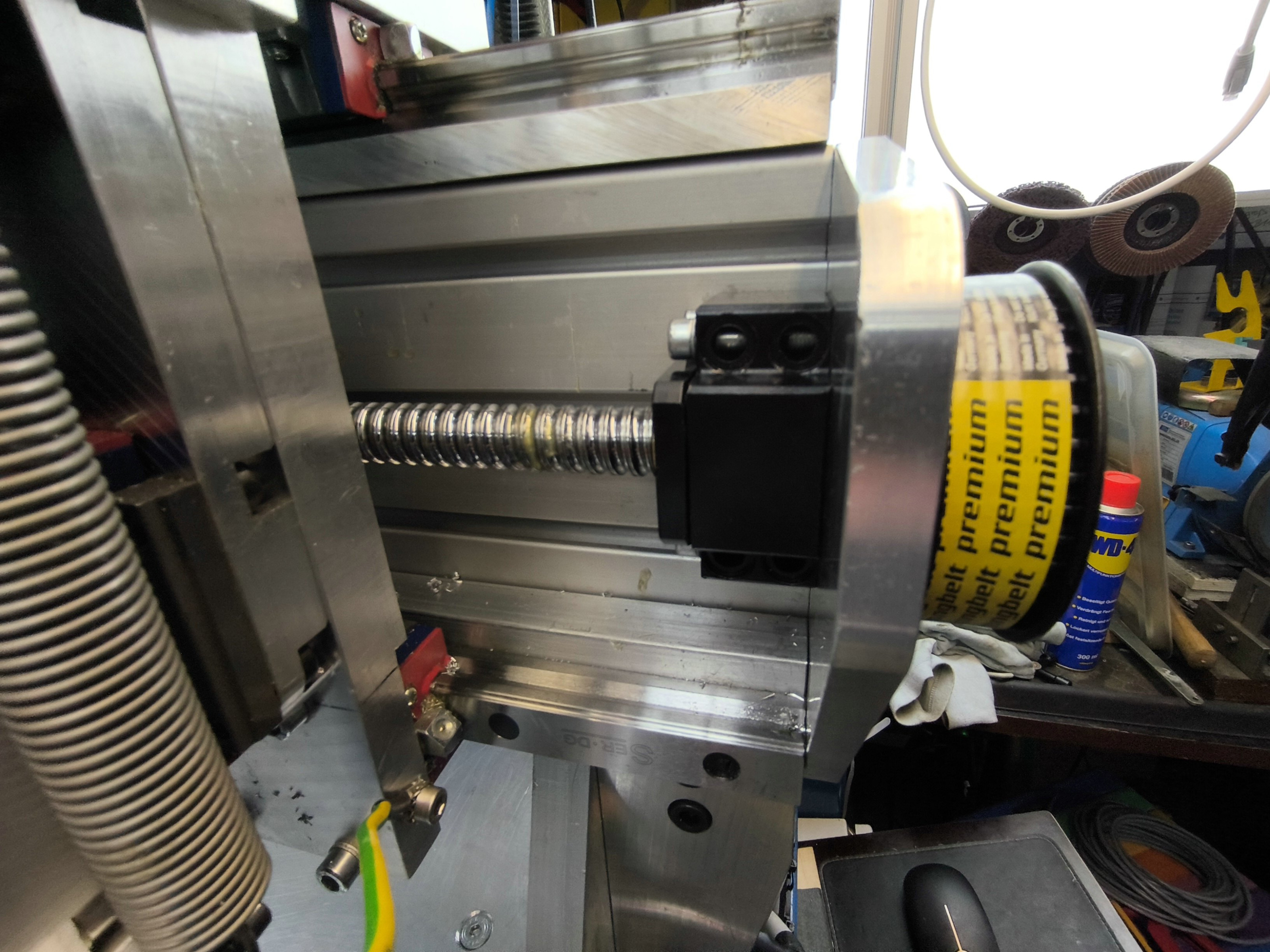

Replied by Muftijaja on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Category: QtPyVCP

- Muftijaja

- Muftijaja

20 Nov 2025 02:25 - 20 Nov 2025 02:26

Replied by Muftijaja on topic problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

problems with Y-Axis, elliptic deviations after several changes -Probe Basic V.5

Category: QtPyVCP

- kn612

- kn612

20 Nov 2025 01:46

Replied by kn612 on topic Servo Driver Plasma Retrofit

Servo Driver Plasma Retrofit

Category: Plasmac

- DemonClaW

- DemonClaW

19 Nov 2025 22:55 - 19 Nov 2025 22:56

Replied by DemonClaW on topic Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Beckhoff Problem with Communication (TwinCAT, LinuxCNC)

Category: EtherCAT

- Hakan

- Hakan

19 Nov 2025 22:31

Replied by Hakan on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- kor

- kor

19 Nov 2025 22:24

Replied by kor on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- tommylight

19 Nov 2025 22:06

Replied by tommylight on topic Aufschaukeln mit JMC iHSS60-36-30-21-38 in Verbindung mit Linear Encodern

Aufschaukeln mit JMC iHSS60-36-30-21-38 in Verbindung mit Linear Encodern

Category: Deutsch

- tommylight

19 Nov 2025 21:49

Replied by tommylight on topic Aufschaukeln mit JMC iHSS60-36-30-21-38 in Verbindung mit Linear Encodern

Aufschaukeln mit JMC iHSS60-36-30-21-38 in Verbindung mit Linear Encodern

Category: Deutsch

- tommylight

19 Nov 2025 21:43

Replied by tommylight on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- PCW

19 Nov 2025 21:29

Replied by PCW on topic Setting up a Mesa 7i95T

Setting up a Mesa 7i95T

Category: Configuration Tools

Time to create page: 0.225 seconds