Search Results (Searched for: )

- JB-Motoring

- JB-Motoring

19 Feb 2025 15:05

Replied by JB-Motoring on topic Mesa 7i97T + 7i84 + 7i78 configuration

Mesa 7i97T + 7i84 + 7i78 configuration

Category: General LinuxCNC Questions

- Aciera

19 Feb 2025 14:45

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Aciera

19 Feb 2025 14:13 - 19 Feb 2025 14:14

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Grotius

19 Feb 2025 13:39 - 19 Feb 2025 13:47

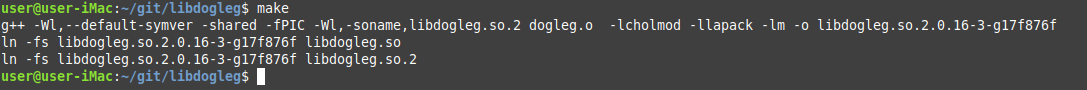

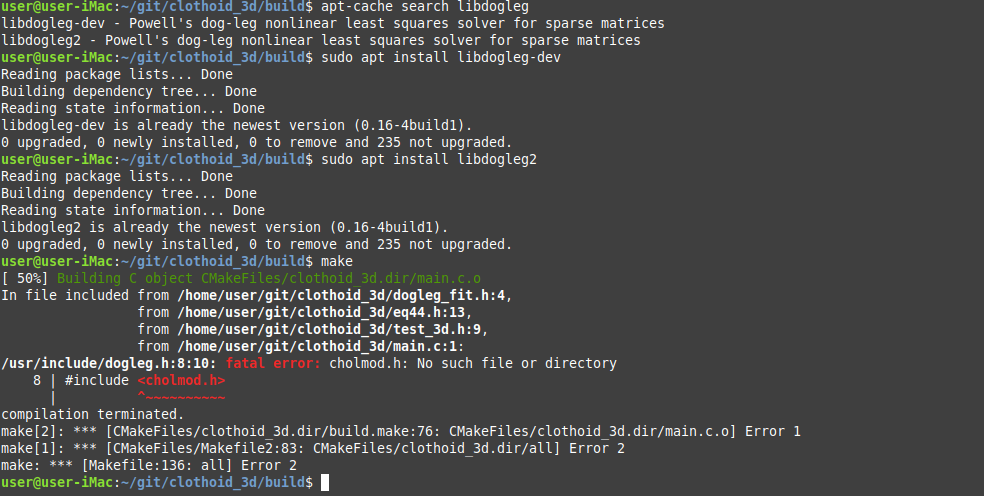

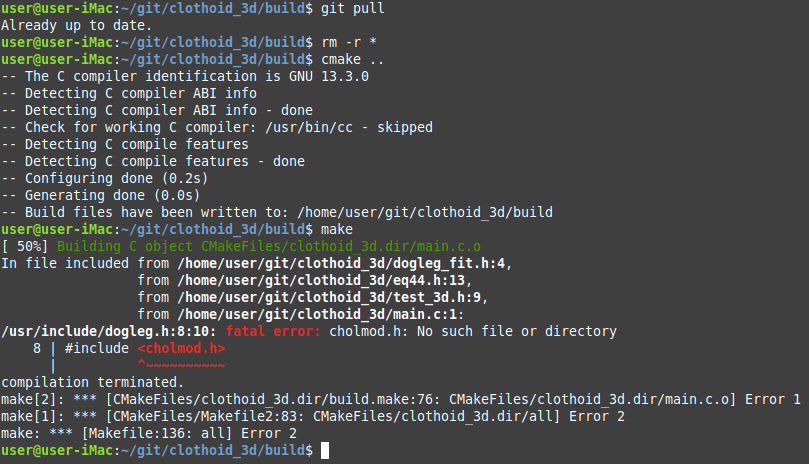

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- meister

- meister

19 Feb 2025 13:29 - 19 Feb 2025 13:40

Replied by meister on topic RPi + Sipeed Tang Nano 20 k: new breakout board for LitexCNC

RPi + Sipeed Tang Nano 20 k: new breakout board for LitexCNC

Category: Driver Boards

- gmouer

- gmouer

19 Feb 2025 13:23

Replied by gmouer on topic development of a qt version of ncam

development of a qt version of ncam

Category: Qtvcp

- Aciera

19 Feb 2025 13:13

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Grotius

19 Feb 2025 13:01

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- Chris54636

- Chris54636

19 Feb 2025 12:40

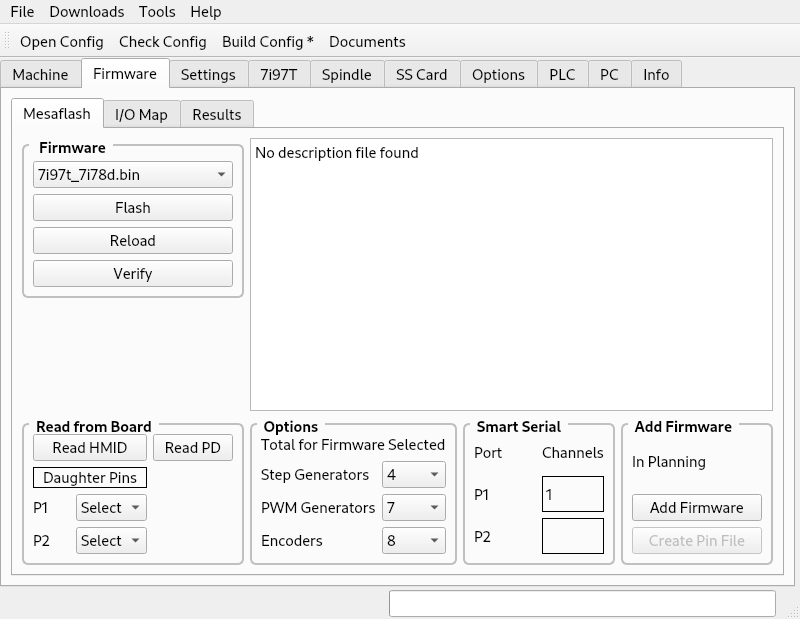

- JT

19 Feb 2025 12:33

Replied by JT on topic Mesa 7i97T + 7i84 + 7i78 configuration

Mesa 7i97T + 7i84 + 7i78 configuration

Category: General LinuxCNC Questions

- Aciera

19 Feb 2025 12:29

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- unknown

- unknown

19 Feb 2025 12:08

Replied by unknown on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- denhen89

19 Feb 2025 11:27

- JT

19 Feb 2025 10:55

Replied by JT on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

- JB-Motoring

- JB-Motoring

19 Feb 2025 10:46

Mesa 7i97T + 7i84 + 7i78 configuration was created by JB-Motoring

Mesa 7i97T + 7i84 + 7i78 configuration

Category: General LinuxCNC Questions

Time to create page: 0.676 seconds