Search Results (Searched for: )

- JT

25 Jan 2025 12:01

- JT

25 Jan 2025 11:57

- greekart

25 Jan 2025 11:30

Replied by greekart on topic Is this considered good cut?

Is this considered good cut?

Category: Plasma & Laser

- rodw

25 Jan 2025 11:23

- machinedude

25 Jan 2025 10:28

Replied by machinedude on topic Is this considered good cut?

Is this considered good cut?

Category: Plasma & Laser

- NT4Boy

- NT4Boy

25 Jan 2025 10:12

- Red_D85

- Red_D85

25 Jan 2025 09:12

- Tim Bee

- Tim Bee

25 Jan 2025 08:49

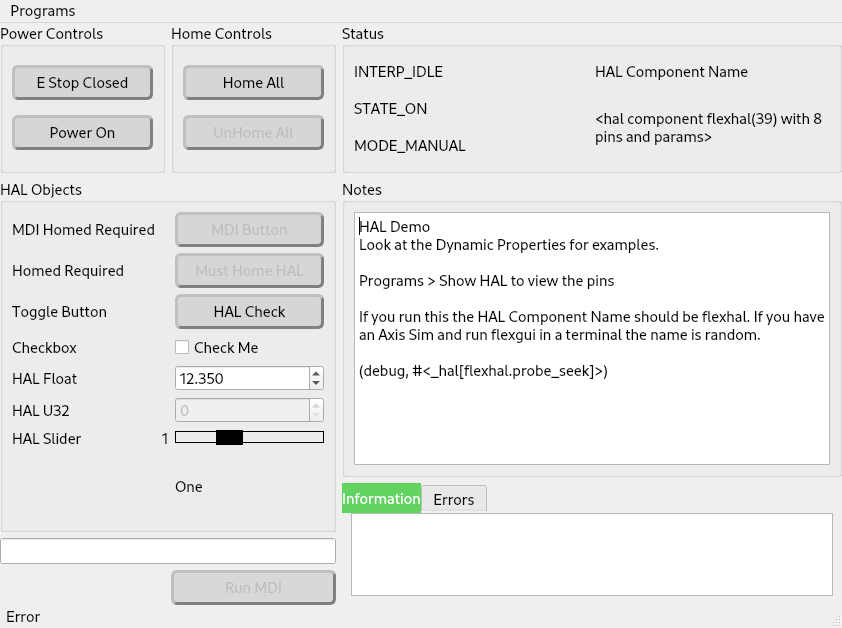

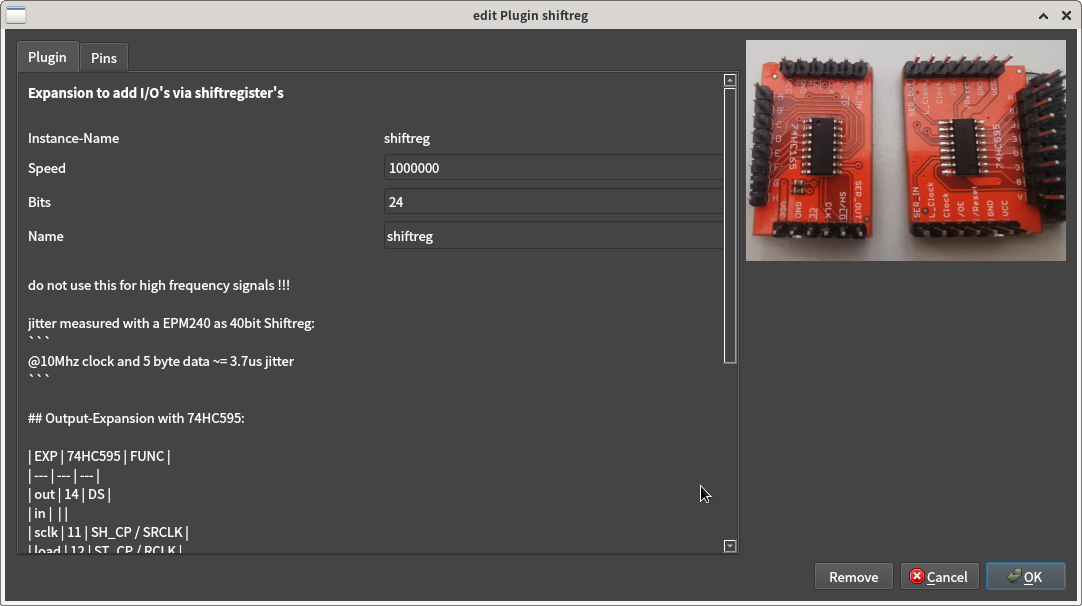

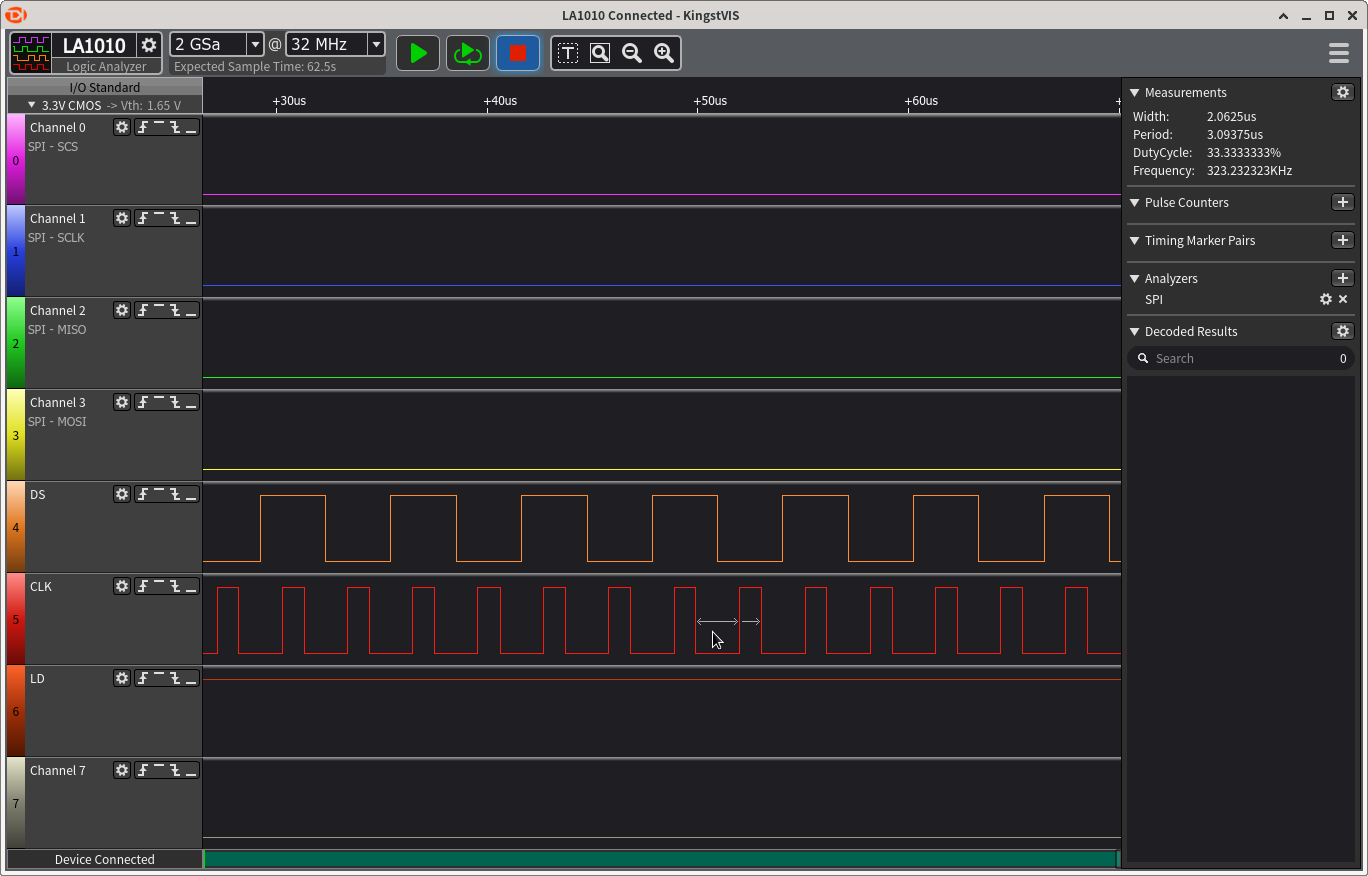

Replied by Tim Bee on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Mr. Mass

25 Jan 2025 08:42

- Joco

25 Jan 2025 08:31

Replied by Joco on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- juliankoenig87

- juliankoenig87

25 Jan 2025 07:00

Replied by juliankoenig87 on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- mudrat

- mudrat

25 Jan 2025 04:21

Replied by mudrat on topic Advanced Search Option Suggestion

Advanced Search Option Suggestion

Category: Forum Questions

- tommylight

25 Jan 2025 03:52

Replied by tommylight on topic LinuxCNC 32 BITS

LinuxCNC 32 BITS

Category: General LinuxCNC Questions

- Toribio1898

- Toribio1898

25 Jan 2025 03:09

Replied by Toribio1898 on topic LinuxCNC 32 BITS

LinuxCNC 32 BITS

Category: General LinuxCNC Questions

- spumco

- spumco

25 Jan 2025 02:48 - 25 Jan 2025 02:51

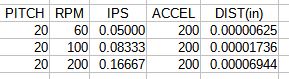

Replied by spumco on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

Time to create page: 1.372 seconds