Search Results (Searched for: )

- gekonko

16 Jan 2025 09:14

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

Error message "Radius to end of arc differs....etc etc"

Category: General LinuxCNC Questions

- Gautham

- Gautham

16 Jan 2025 09:12

Replied by Gautham on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- besriworld

- besriworld

16 Jan 2025 08:35

Replied by besriworld on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- chrischan

- chrischan

16 Jan 2025 08:26

Replied by chrischan on topic Maus funktioniert nicht bei Spindel Start

Maus funktioniert nicht bei Spindel Start

Category: Deutsch

- Gautham

- Gautham

16 Jan 2025 08:16

Rotating Axis Controlled by a Ballscrew was created by Gautham

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- rodw

16 Jan 2025 07:56 - 16 Jan 2025 07:57

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- HansU

16 Jan 2025 07:25 - 16 Jan 2025 07:26

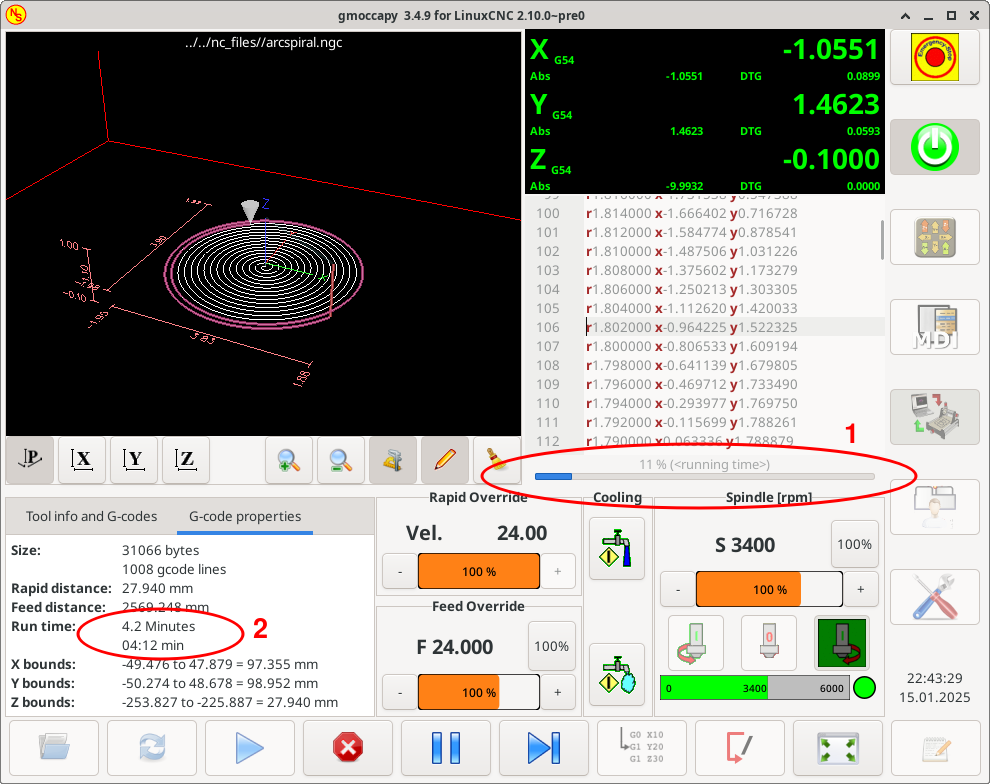

Replied by HansU on topic Gmoccapy 3.5.0 - opinions needed

Gmoccapy 3.5.0 - opinions needed

Category: Gmoccapy

- notJamesLee

- notJamesLee

16 Jan 2025 07:08

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- vre

- vre

16 Jan 2025 06:40

- tcbmetalworks

- tcbmetalworks

16 Jan 2025 06:38

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- rodw

16 Jan 2025 06:23

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- rodw

16 Jan 2025 06:18 - 16 Jan 2025 06:18

- 4ashishkr

- 4ashishkr

16 Jan 2025 04:55

Replied by 4ashishkr on topic Help Needed: Z-Axis Linear Guide Vibrations at Specific Speeds

Help Needed: Z-Axis Linear Guide Vibrations at Specific Speeds

Category: General LinuxCNC Questions

- notJamesLee

- notJamesLee

16 Jan 2025 04:54

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- dschultz

- dschultz

16 Jan 2025 04:43

Replied by dschultz on topic Missing link in homing LC10E

Missing link in homing LC10E

Category: EtherCAT

Time to create page: 0.382 seconds