Search Results (Searched for: )

- tommylight

21 Dec 2024 16:20

- MrDe

- MrDe

21 Dec 2024 16:00

Replied by MrDe on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- CopperHead

- CopperHead

21 Dec 2024 15:36

- JR1050

21 Dec 2024 15:35

- 10K

21 Dec 2024 14:40

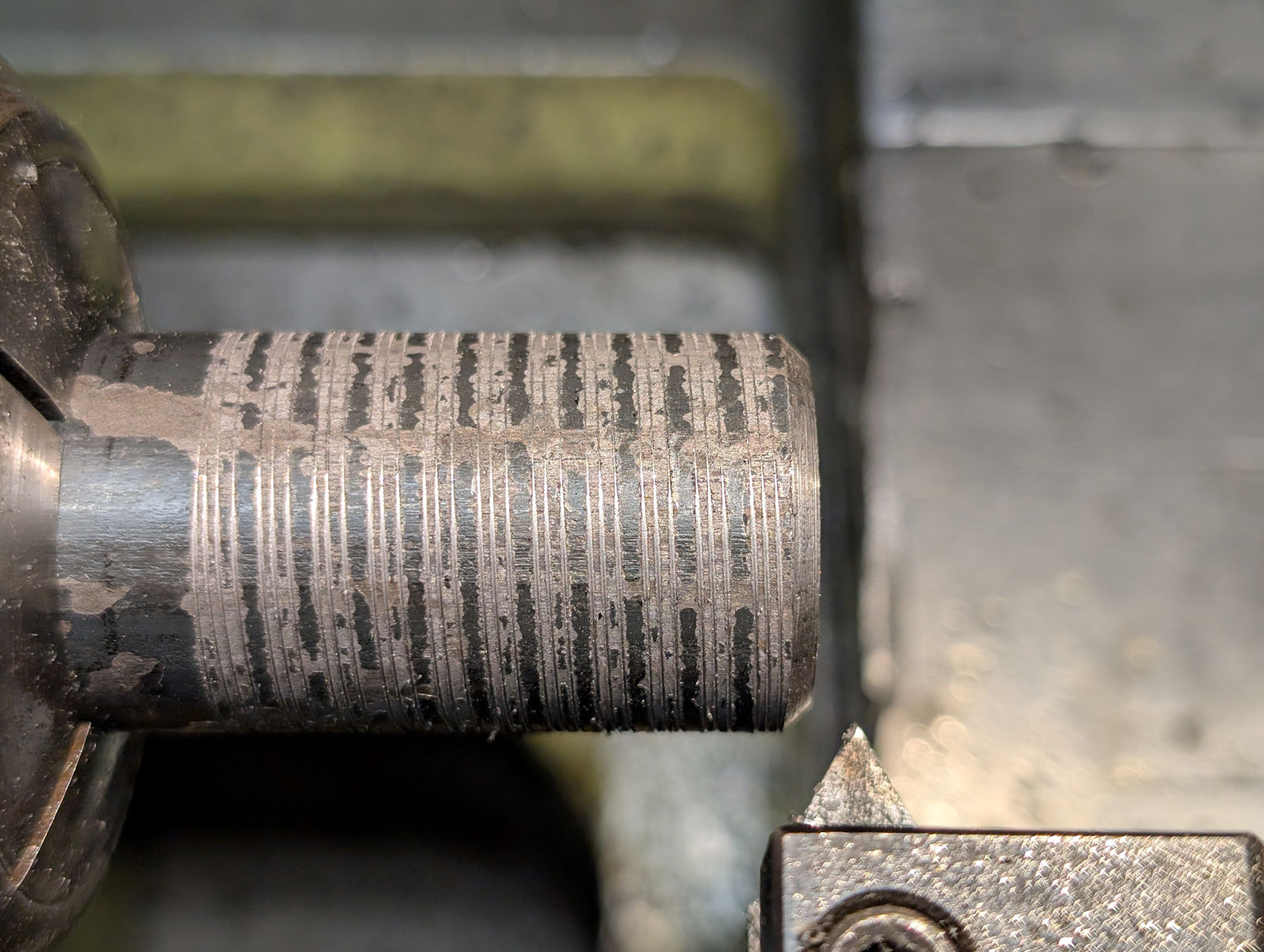

Threading Index Varies With Speed was created by 10K

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- vibram

- vibram

21 Dec 2024 13:29

Replied by vibram on topic Another joint 0 on limit switch error

Another joint 0 on limit switch error

Category: Basic Configuration

- agima2

- agima2

21 Dec 2024 12:23

Replied by agima2 on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- JT

21 Dec 2024 12:20

- Sandro

- Sandro

21 Dec 2024 12:12

- Hossein74Majidi

- Hossein74Majidi

21 Dec 2024 12:01 - 21 Dec 2024 12:05

G Code Syntax Check (Python + Qt Designer) was created by Hossein74Majidi

G Code Syntax Check (Python + Qt Designer)

Category: Qtvcp

- Sandro

- Sandro

21 Dec 2024 11:52

- MaHa

- MaHa

21 Dec 2024 09:19

Replied by MaHa on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- CNC_ANDI

- CNC_ANDI

21 Dec 2024 08:41

- MrDe

- MrDe

21 Dec 2024 07:58 - 21 Dec 2024 08:05

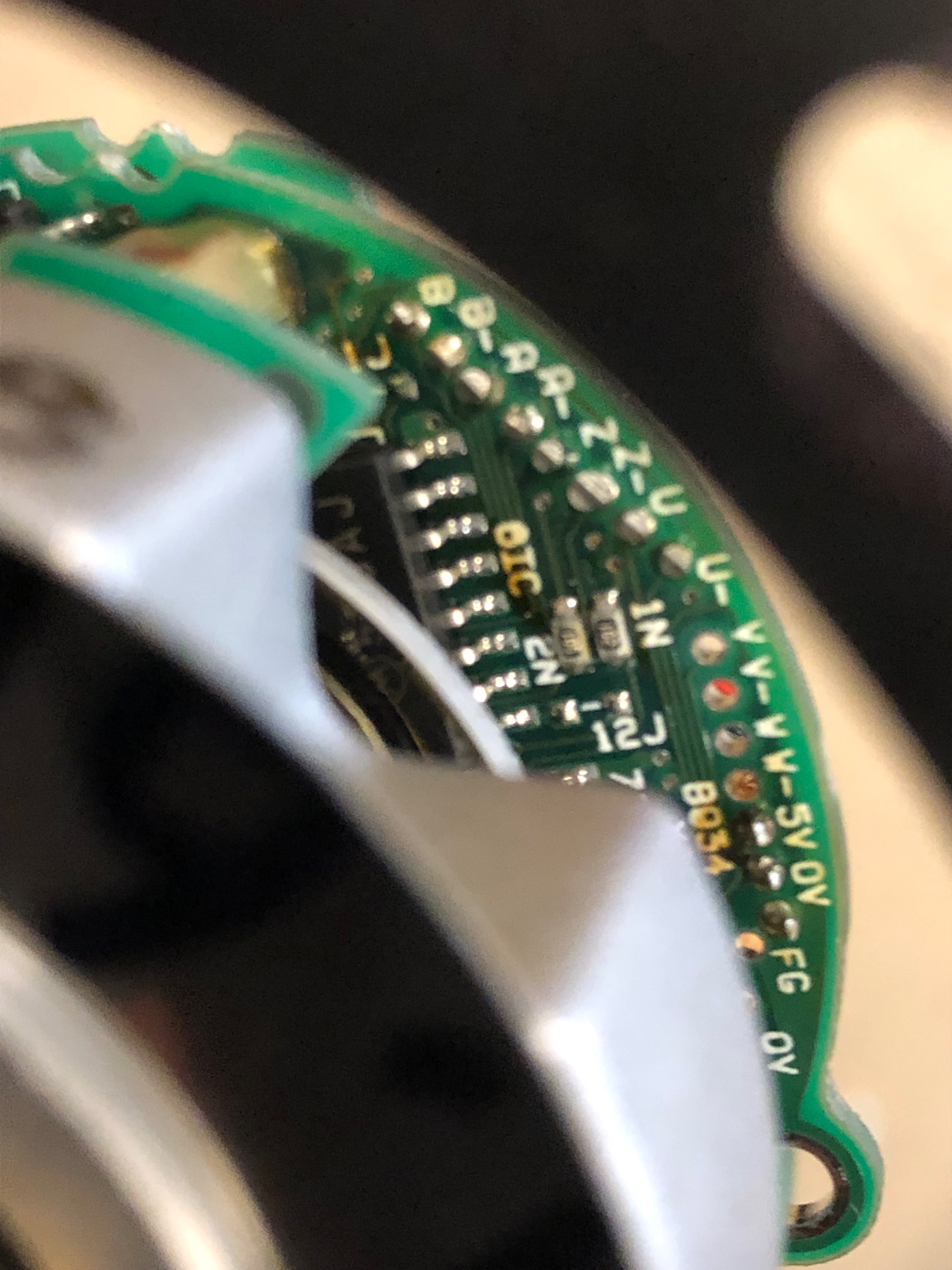

Replied by MrDe on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- IronManDylan

- IronManDylan

21 Dec 2024 06:00

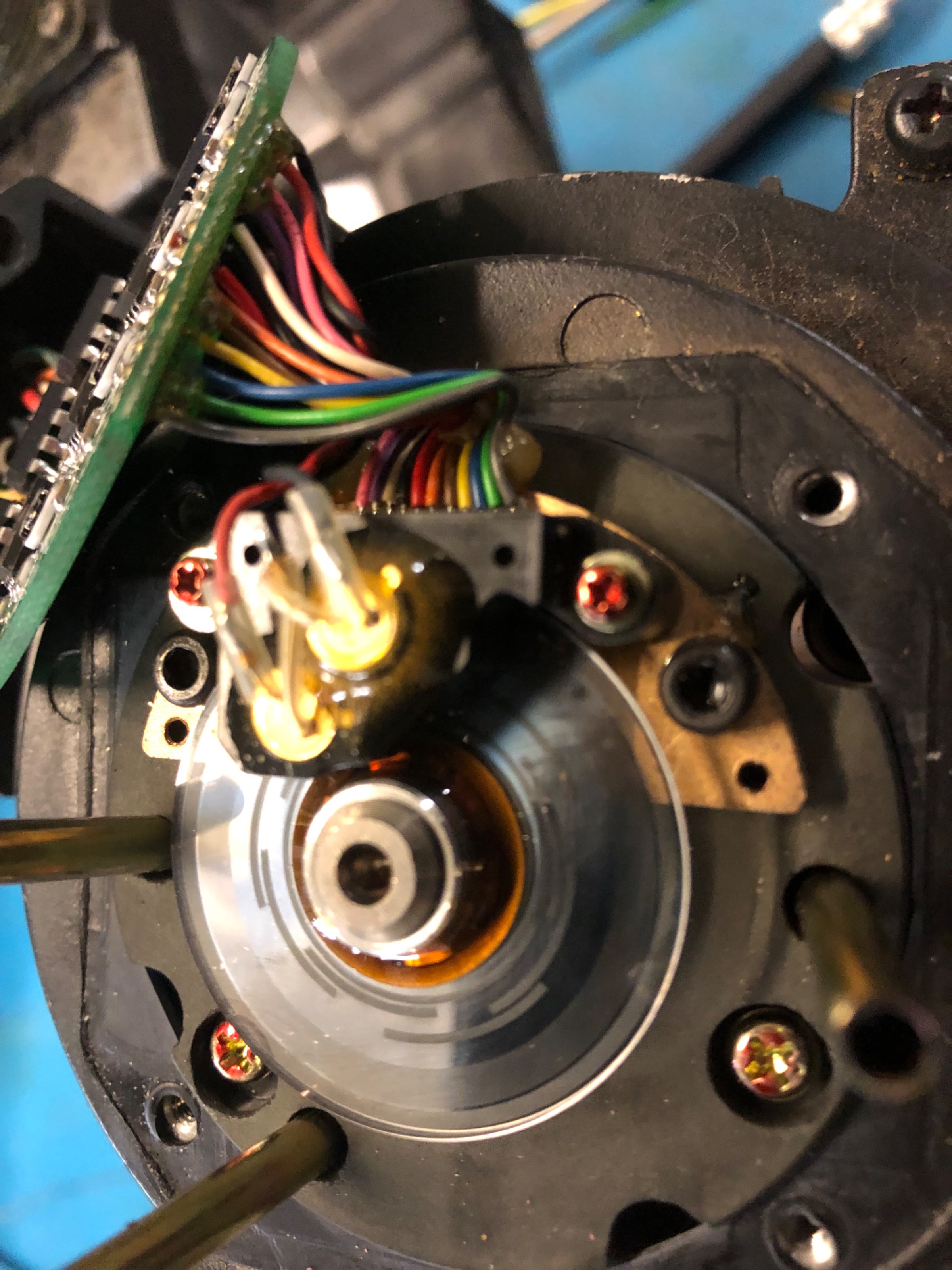

Replied by IronManDylan on topic Fast Hole EDM from Hacked Parts

Fast Hole EDM from Hacked Parts

Category: General LinuxCNC Questions

Time to create page: 0.428 seconds