Search Results (Searched for: )

- foam man

- foam man

16 Oct 2024 22:06

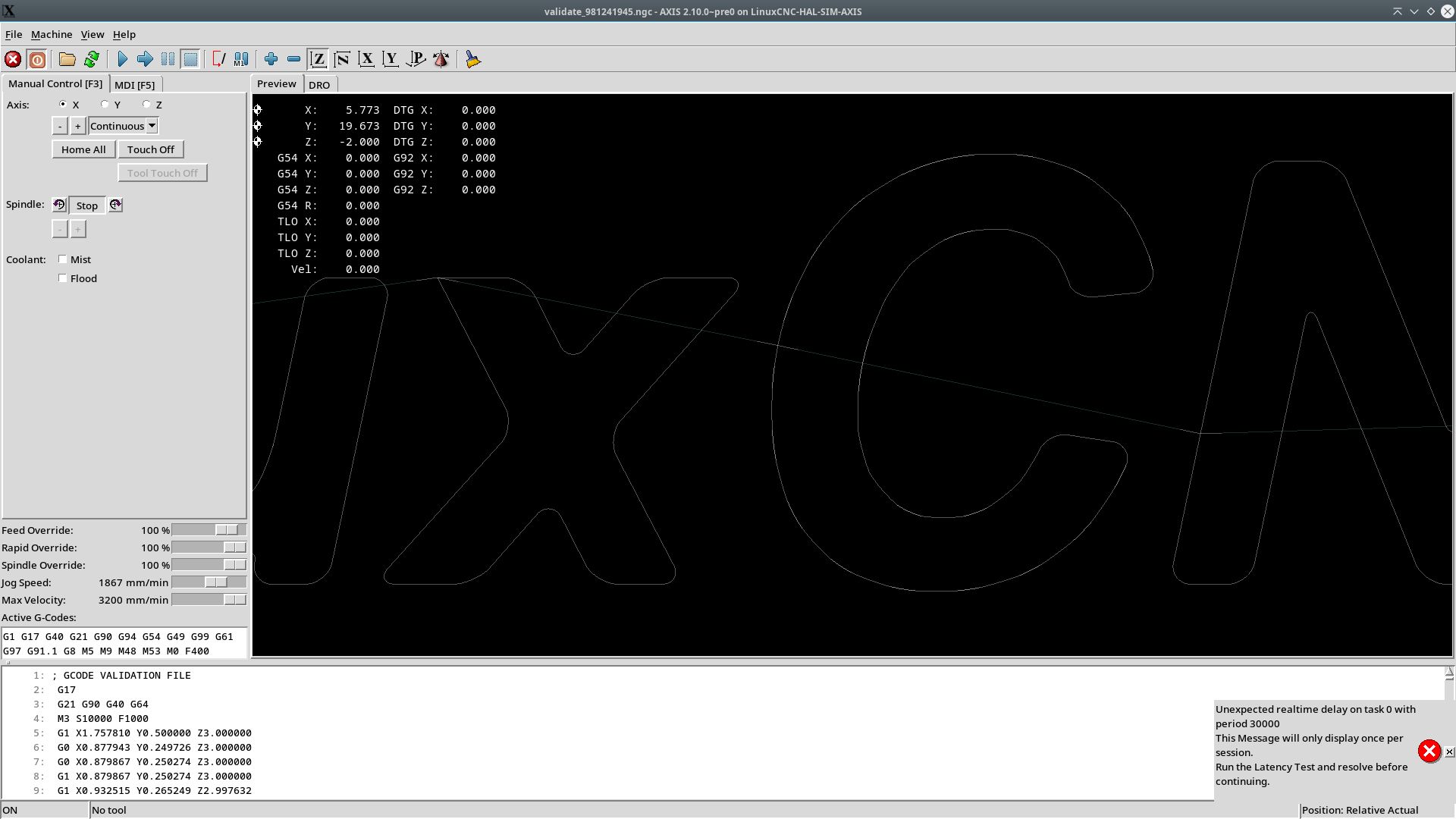

Replied by foam man on topic controller and motors not fully communicating

controller and motors not fully communicating

Category: General LinuxCNC Questions

- tommylight

16 Oct 2024 21:58

- Grotius

16 Oct 2024 21:45

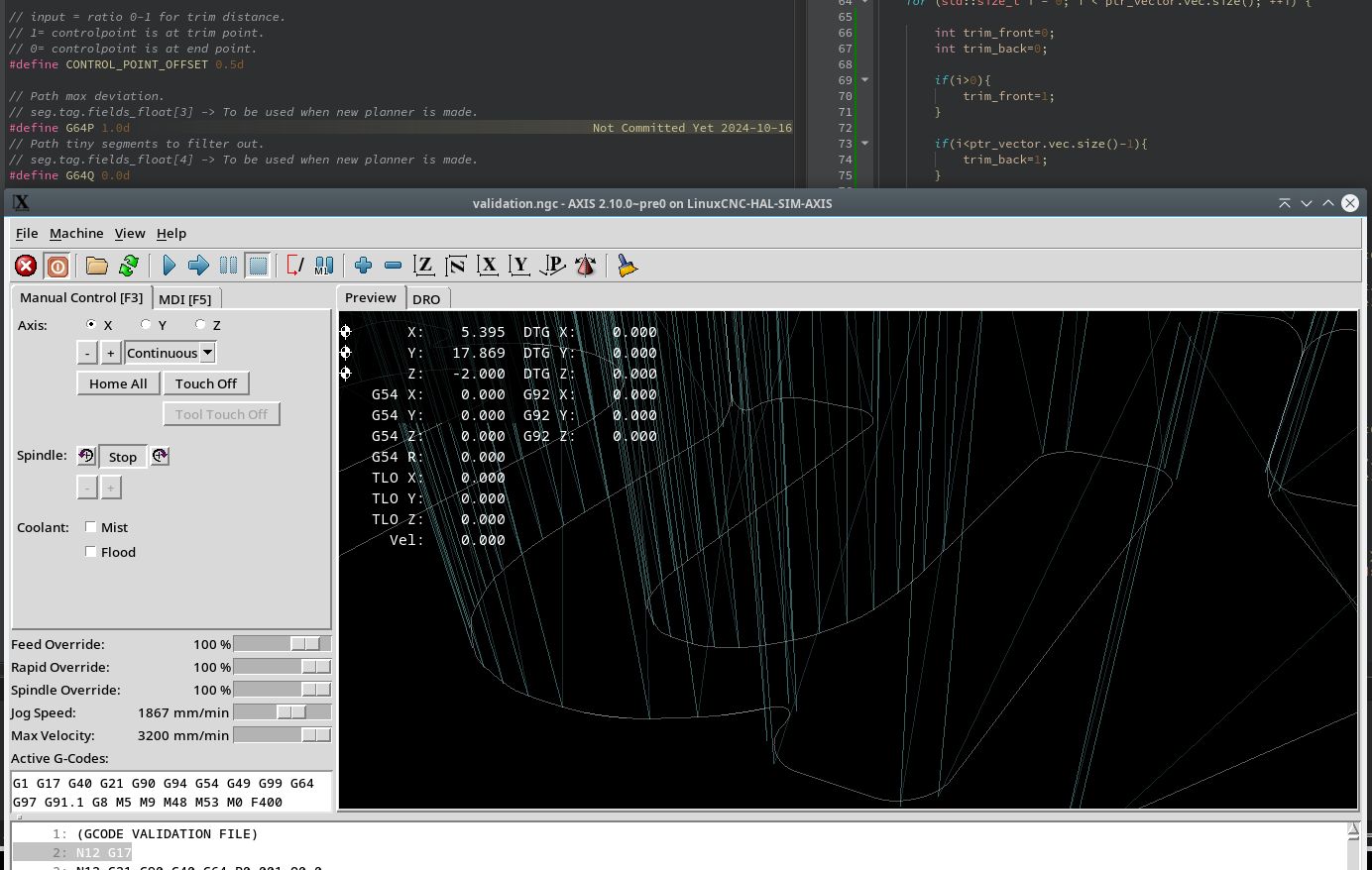

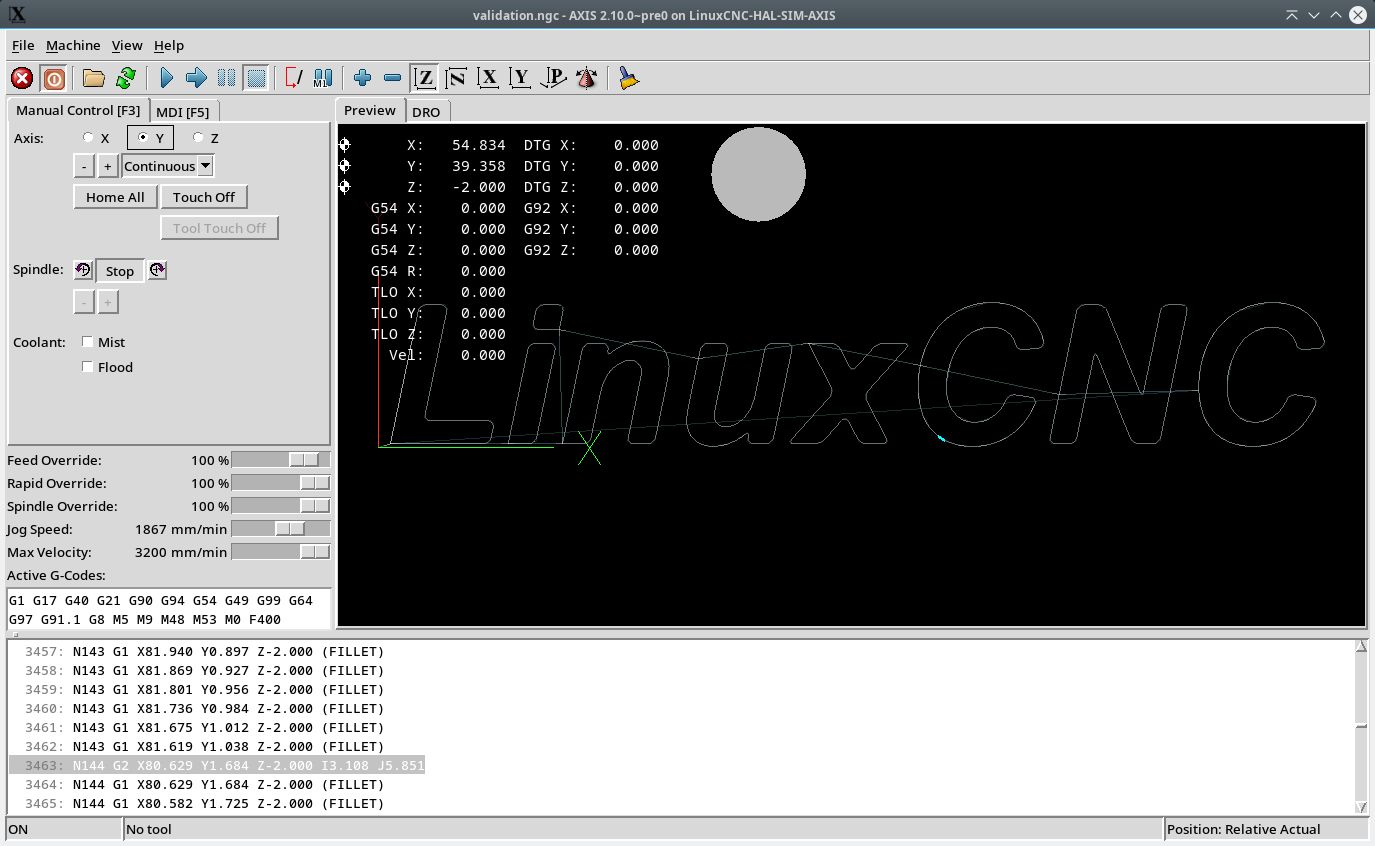

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- tommylight

16 Oct 2024 21:42

Replied by tommylight on topic Make arc in W axis

Make arc in W axis

Category: General LinuxCNC Questions

- Aciera

16 Oct 2024 21:36

Replied by Aciera on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- RLA

- RLA

16 Oct 2024 21:24

- snowgoer540

16 Oct 2024 21:23

Replied by snowgoer540 on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- Grotius

16 Oct 2024 20:44

Replied by Grotius on topic c++ compiling error

c++ compiling error

Category: Advanced Configuration

- Benb

16 Oct 2024 20:27 - 16 Oct 2024 20:30

Replied by Benb on topic linuxcnc-dev is missing?

linuxcnc-dev is missing?

Category: Installing LinuxCNC

- Lcvette

16 Oct 2024 20:09

Replied by Lcvette on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- Dougal9887

- Dougal9887

16 Oct 2024 20:05

Replied by Dougal9887 on topic Are there no increase/decrease spindle speed buttons in Gmoccapy?

Are there no increase/decrease spindle speed buttons in Gmoccapy?

Category: Gmoccapy

- natester

- natester

16 Oct 2024 19:32 - 16 Oct 2024 19:34

Replied by natester on topic Keyboard simulation within a userspace component

Keyboard simulation within a userspace component

Category: Advanced Configuration

- Grotius

16 Oct 2024 19:20

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- bkt

16 Oct 2024 19:14

- tommylight

16 Oct 2024 18:58

Replied by tommylight on topic Welche Tasten haben die Achsen?

Welche Tasten haben die Achsen?

Category: Deutsch

Time to create page: 0.918 seconds