Search Results (Searched for: )

- PCW

19 Jan 2026 15:47 - 19 Jan 2026 15:48

Replied by PCW on topic Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Category: Driver Boards

- cmorley

- cmorley

19 Jan 2026 15:25

- NWE

- NWE

19 Jan 2026 14:53 - 19 Jan 2026 15:21

- m.ruefenacht

- m.ruefenacht

19 Jan 2026 14:24

- sataran

- sataran

19 Jan 2026 14:09 - 19 Jan 2026 14:52

Replied by sataran on topic Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Category: Driver Boards

- bkt

19 Jan 2026 12:27

- tincho80

19 Jan 2026 12:10

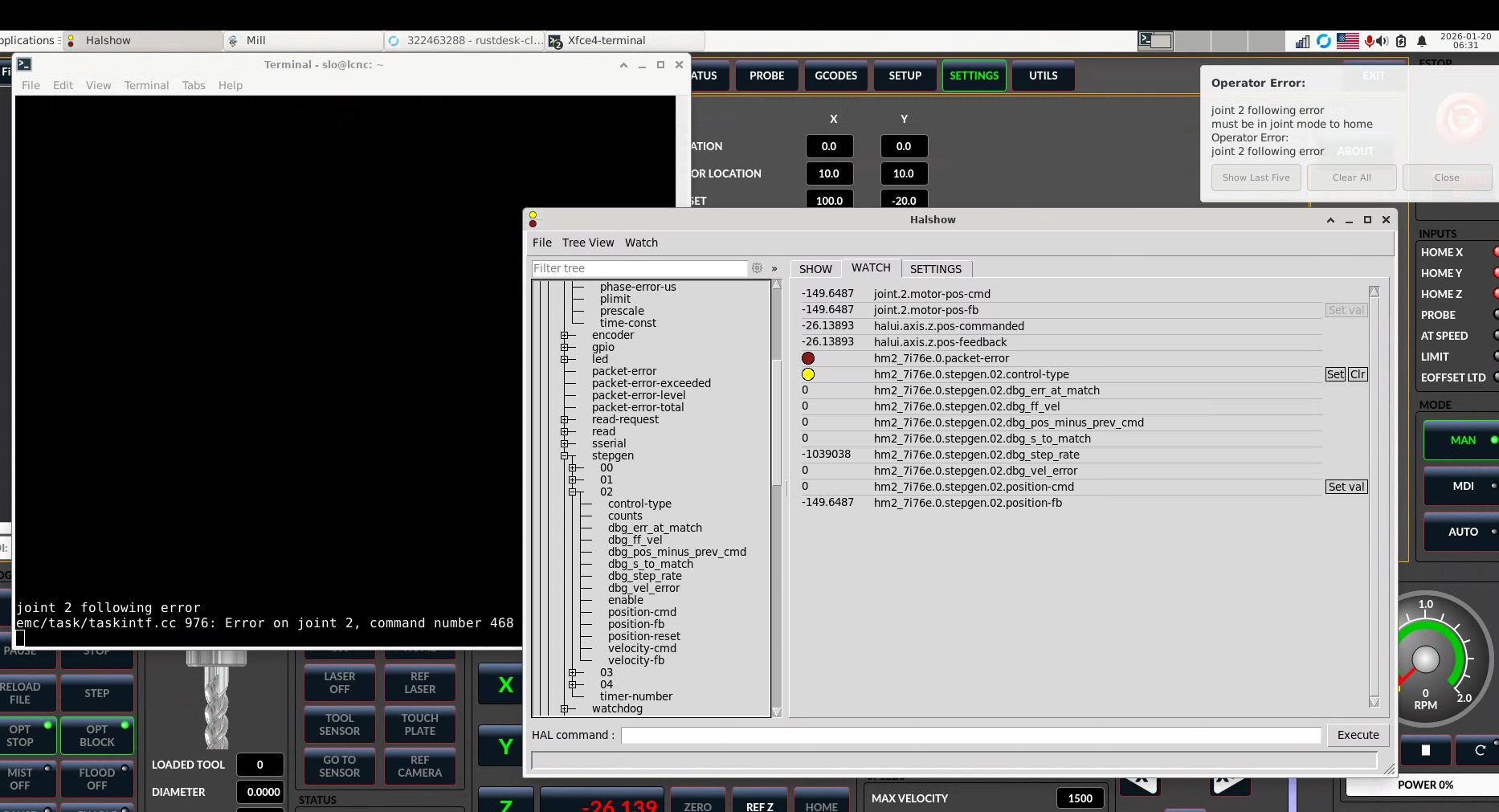

Replied by tincho80 on topic Machine from LinuxCNC 2.8.4 to LinuxCNC 2.9.8 not working anymore

Machine from LinuxCNC 2.8.4 to LinuxCNC 2.9.8 not working anymore

Category: General LinuxCNC Questions

- tincho80

19 Jan 2026 10:28

Replied by tincho80 on topic Machine from LinuxCNC 2.8.4 to LinuxCNC 2.9.8 not working anymore

Machine from LinuxCNC 2.8.4 to LinuxCNC 2.9.8 not working anymore

Category: General LinuxCNC Questions

- billykid

19 Jan 2026 09:35 - 19 Jan 2026 09:43

7i80db16 7i85s 7i37 firmware was created by billykid

7i80db16 7i85s 7i37 firmware

Category: Driver Boards

- SrLange61

19 Jan 2026 09:28

Replied by SrLange61 on topic Latency, error finishing read, and IRQ affinity

Latency, error finishing read, and IRQ affinity

Category: General LinuxCNC Questions

- meister

- meister

19 Jan 2026 09:04

Replied by meister on topic Mesa 7i96 step ausgangsignal =5V , Schrittmotortriber eingang 12V was nun?

Mesa 7i96 step ausgangsignal =5V , Schrittmotortriber eingang 12V was nun?

Category: Deutsch

- cdamm11

- cdamm11

19 Jan 2026 08:55

- harindugamlath

- harindugamlath

19 Jan 2026 08:15

Replied by harindugamlath on topic Servo Driven tool changer - How to set up

Servo Driven tool changer - How to set up

Category: Advanced Configuration

- kello711

19 Jan 2026 04:55

XHC-WHB04B-4 config difference was created by kello711

XHC-WHB04B-4 config difference

Category: Advanced Configuration

- soehlrich

- soehlrich

19 Jan 2026 04:26

Replied by soehlrich on topic Qtdragon_hd Zero button not zeroing

Qtdragon_hd Zero button not zeroing

Category: General LinuxCNC Questions

Time to create page: 2.196 seconds