Search Results (Searched for: )

- Mark Kraus

- Mark Kraus

17 Jan 2026 23:46

Replied by Mark Kraus on topic Trying to move from UCCNC to Linuxcnc and using 7i96s but having trouble

Trying to move from UCCNC to Linuxcnc and using 7i96s but having trouble

Category: StepConf Wizard

- MaHa

- MaHa

17 Jan 2026 22:31

- PCW

17 Jan 2026 22:18

Replied by PCW on topic need firmware for mesa 7i76eu+7i85+pwm

need firmware for mesa 7i76eu+7i85+pwm

Category: Driver Boards

- grandixximo

17 Jan 2026 22:09 - 17 Jan 2026 22:12

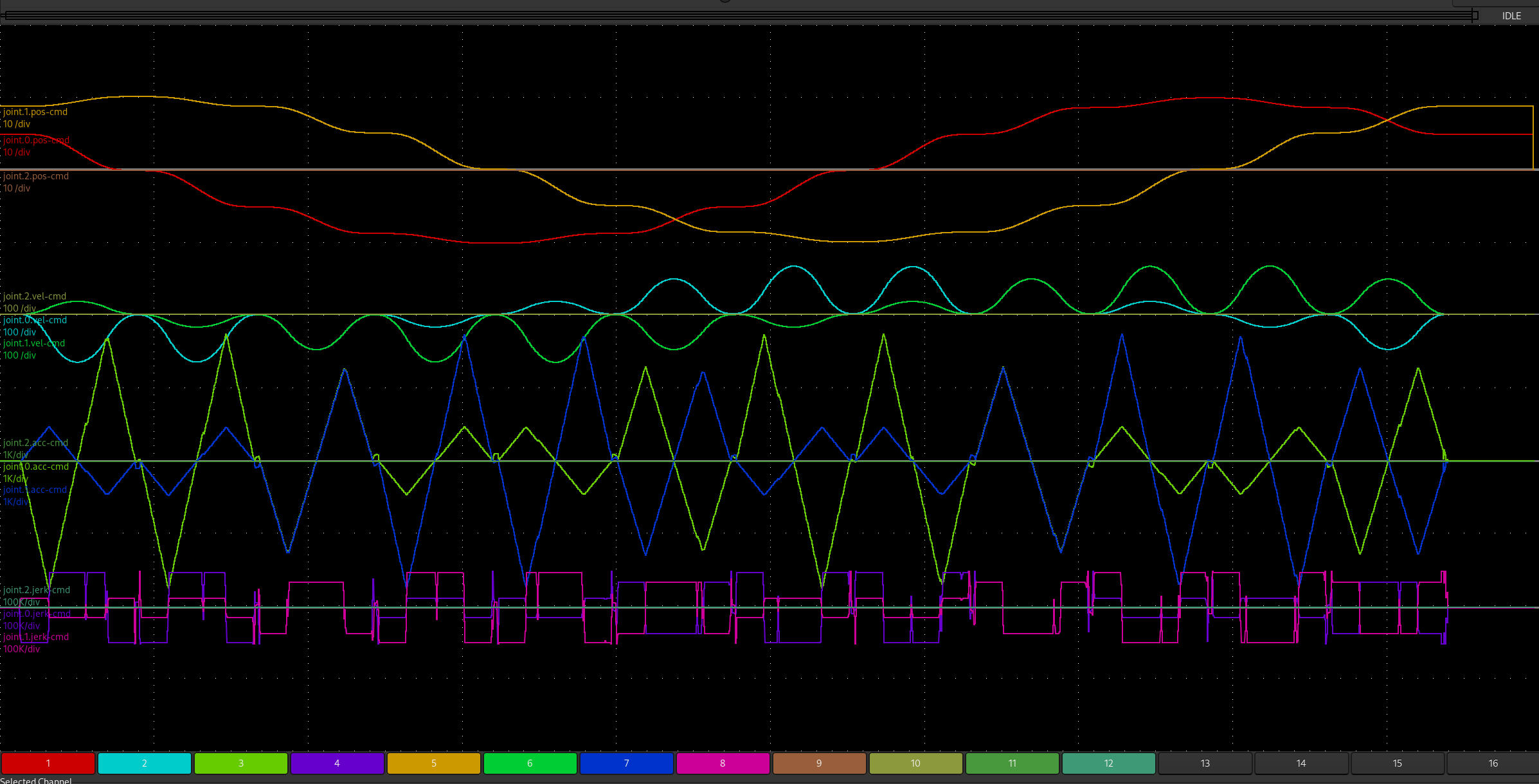

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- advangrootel

- advangrootel

17 Jan 2026 22:05

Replied by advangrootel on topic need firmware for mesa 7i76eu+7i85+pwm

need firmware for mesa 7i76eu+7i85+pwm

Category: Driver Boards

- unknown

- unknown

17 Jan 2026 21:59

Replied by unknown on topic Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Category: Driver Boards

- ruediger123

- ruediger123

17 Jan 2026 21:50

- bnet

17 Jan 2026 21:50

- PCW

17 Jan 2026 21:27

Replied by PCW on topic need firmware for mesa 7i76eu+7i85+pwm

need firmware for mesa 7i76eu+7i85+pwm

Category: Driver Boards

- rodw

17 Jan 2026 20:43

- ruediger123

- ruediger123

17 Jan 2026 20:30

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- advangrootel

- advangrootel

17 Jan 2026 20:12

need firmware for mesa 7i76eu+7i85+pwm was created by advangrootel

need firmware for mesa 7i76eu+7i85+pwm

Category: Driver Boards

- Lili

- Lili

17 Jan 2026 20:07

Replied by Lili on topic Single LC10E-600W Driver Not Responding

Single LC10E-600W Driver Not Responding

Category: EtherCAT

- reboots

- reboots

17 Jan 2026 18:10 - 17 Jan 2026 18:14

Replied by reboots on topic How do I lubricate correctly?

How do I lubricate correctly?

Category: Milling Machines

- bobwolf

- bobwolf

17 Jan 2026 16:42

Time to create page: 0.317 seconds