Search Results (Searched for: )

- Neiji_msk

- Neiji_msk

26 Nov 2025 13:23

Servotronix Ethercat problem was created by Neiji_msk

Servotronix Ethercat problem

Category: EtherCAT

- Masiwood123

26 Nov 2025 11:06 - 26 Nov 2025 11:11

Physical buttons to 7i96s+7i77 was created by Masiwood123

Physical buttons to 7i96s+7i77

Category: HAL

- Z3n

- Z3n

26 Nov 2025 10:45 - 26 Nov 2025 10:49

Converting a Brother TC215 to LinuxCNC was created by Z3n

Converting a Brother TC215 to LinuxCNC

Category: Milling Machines

- WKS-3D

26 Nov 2025 08:44

Replied by WKS-3D on topic Suche Fusion Postprozessor für Drehmaschine

Suche Fusion Postprozessor für Drehmaschine

Category: Deutsch

- Pudding1960

- Pudding1960

26 Nov 2025 06:30

- nanowhat

- nanowhat

26 Nov 2025 00:58

Replied by nanowhat on topic Robotic loader motion planning

Robotic loader motion planning

Category: General LinuxCNC Questions

- nanowhat

- nanowhat

26 Nov 2025 00:27

Robotic loader motion planning was created by nanowhat

Robotic loader motion planning

Category: General LinuxCNC Questions

- meister

- meister

25 Nov 2025 22:10 - 25 Nov 2025 22:12

Replied by meister on topic SmartSerial on cheap ESP32-8ch-Relais Card

SmartSerial on cheap ESP32-8ch-Relais Card

Category: Driver Boards

- tommylight

25 Nov 2025 21:45

Replied by tommylight on topic LinuxCNC Hardware Survey

LinuxCNC Hardware Survey

Category: Driver Boards

- tommylight

25 Nov 2025 21:29

Replied by tommylight on topic SmartSerial on cheap ESP32-8ch-Relais Card

SmartSerial on cheap ESP32-8ch-Relais Card

Category: Driver Boards

- zoeper

- zoeper

25 Nov 2025 20:54

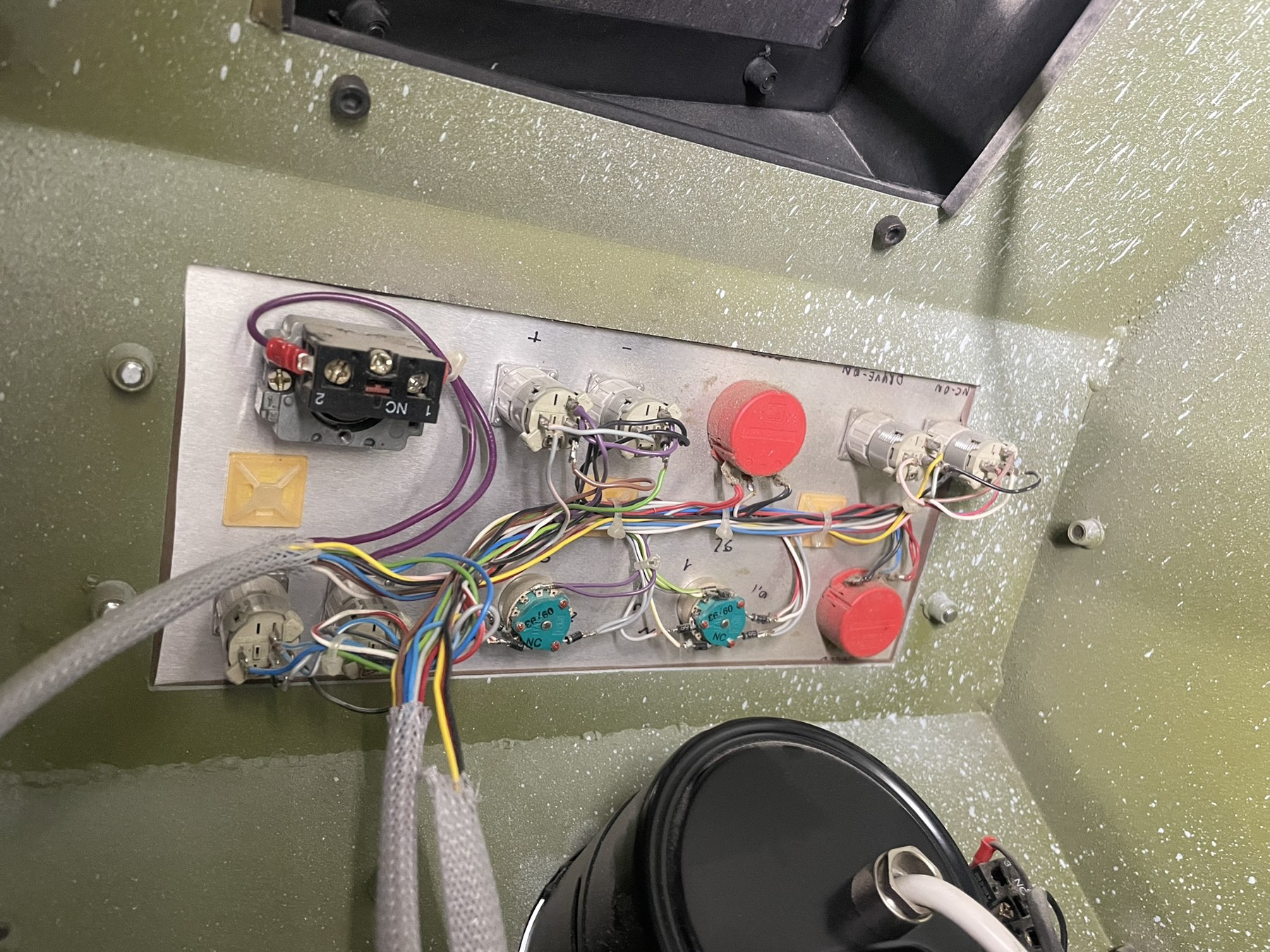

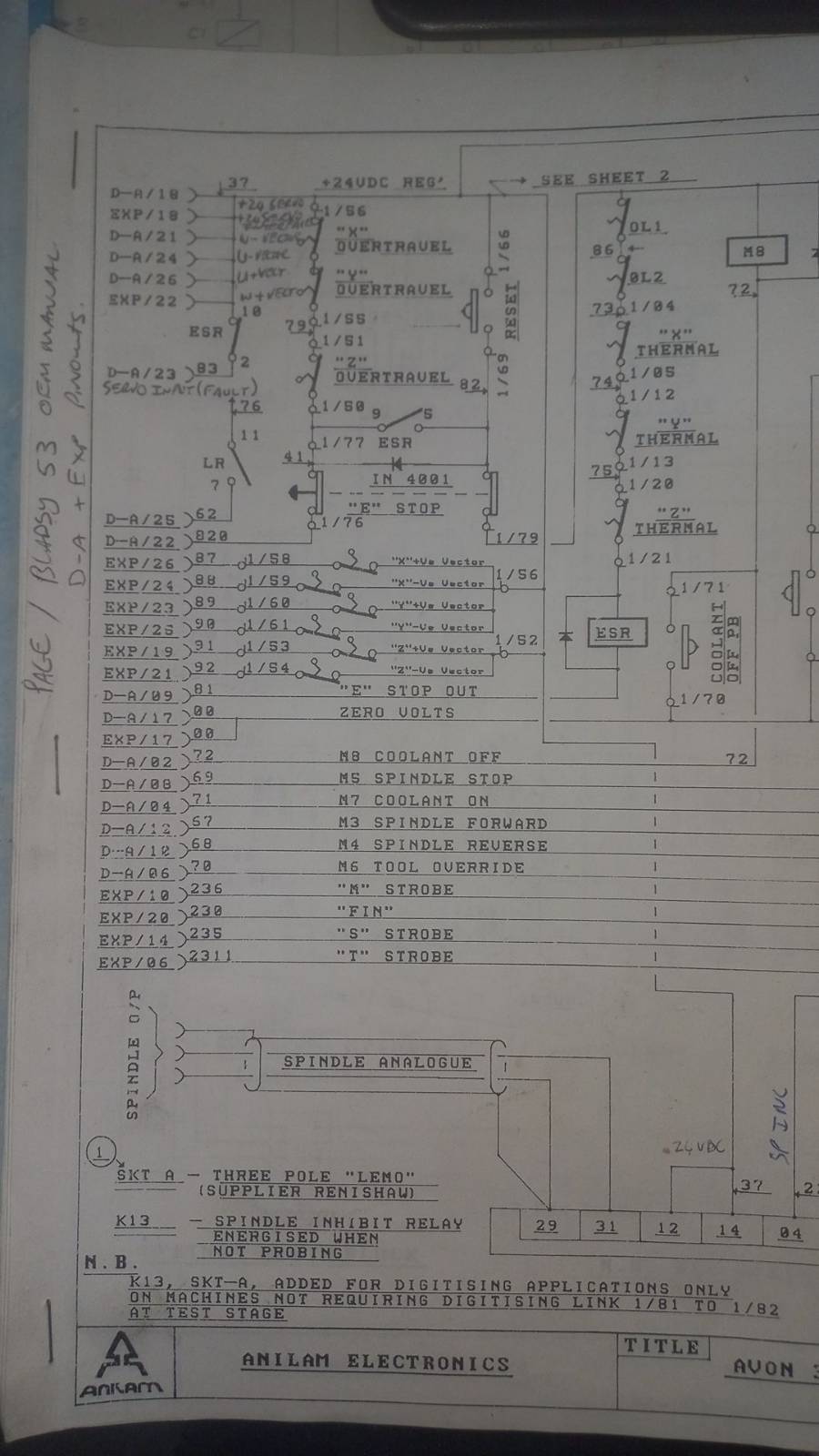

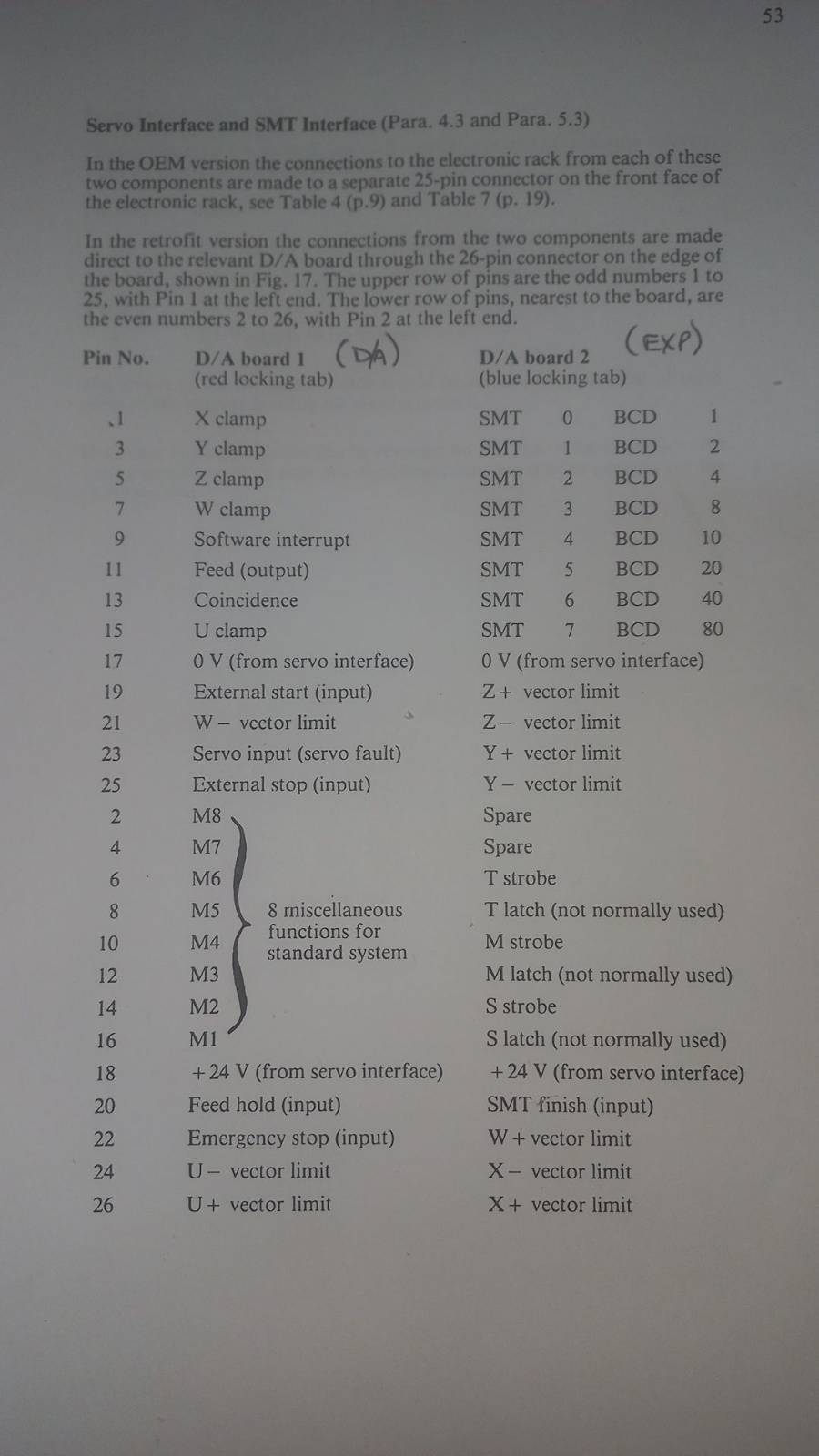

Replied by zoeper on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- Lpkkk

- Lpkkk

25 Nov 2025 19:46 - 25 Nov 2025 20:01

Replied by Lpkkk on topic Huanyang FC01 modbus

Huanyang FC01 modbus

Category: Advanced Configuration

- zoeper

- zoeper

25 Nov 2025 19:43

Replied by zoeper on topic Avon 3000 Mill retrofit

Avon 3000 Mill retrofit

Category: Milling Machines

- rasmus

- rasmus

25 Nov 2025 18:26 - 25 Nov 2025 20:41

Replied by rasmus on topic carousel.comp scale questions.

carousel.comp scale questions.

Category: General LinuxCNC Questions

- langdons

25 Nov 2025 17:18

Replied by langdons on topic carousel.comp scale questions.

carousel.comp scale questions.

Category: General LinuxCNC Questions

Time to create page: 0.277 seconds