Search Results (Searched for: )

- rodw

07 Jan 2026 22:50

Replied by rodw on topic Installing ethercat repositories

Installing ethercat repositories

Category: EtherCAT

- unknown

- unknown

07 Jan 2026 21:51

- andypugh

07 Jan 2026 21:49

Replied by andypugh on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- strawberry.blondish

- strawberry.blondish

07 Jan 2026 20:52

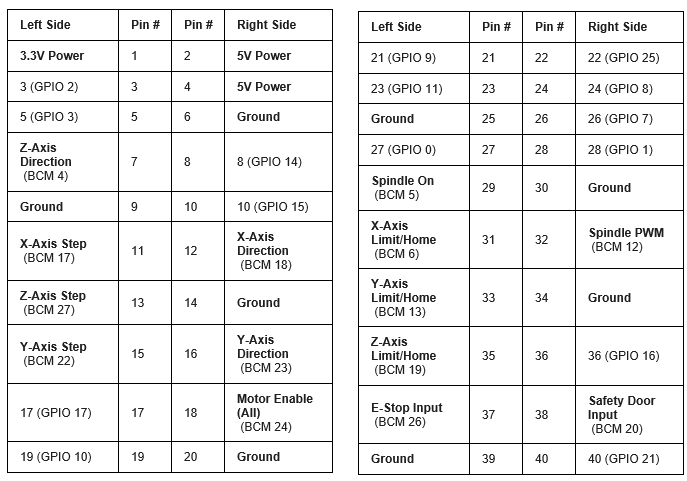

Replied by strawberry.blondish on topic RPi GPIO .hal and .ini from scratch, without hardware, should the GUI open?

RPi GPIO .hal and .ini from scratch, without hardware, should the GUI open?

Category: Basic Configuration

- NickH

- NickH

07 Jan 2026 19:49

Replied by NickH on topic Installing ethercat repositories

Installing ethercat repositories

Category: EtherCAT

- tommylight

07 Jan 2026 19:47

Replied by tommylight on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- tommylight

07 Jan 2026 19:41

Replied by tommylight on topic Installing ethercat repositories

Installing ethercat repositories

Category: EtherCAT

- NickH

- NickH

07 Jan 2026 19:33 - 07 Jan 2026 19:34

Replied by NickH on topic Installing ethercat repositories

Installing ethercat repositories

Category: EtherCAT

- cnbbom

- cnbbom

07 Jan 2026 19:07

Replied by cnbbom on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- vibram

- vibram

07 Jan 2026 18:48

Replied by vibram on topic Spindle Encoder: Float Precision Issues

Spindle Encoder: Float Precision Issues

Category: HAL

- strawberry.blondish

- strawberry.blondish

07 Jan 2026 17:41

RPi GPIO .hal and .ini from scratch, without hardware, should the GUI open? was created by strawberry.blondish

RPi GPIO .hal and .ini from scratch, without hardware, should the GUI open?

Category: Basic Configuration

- PCW

07 Jan 2026 17:32 - 07 Jan 2026 17:32

- NickH

- NickH

07 Jan 2026 17:01 - 07 Jan 2026 22:29

Replied by NickH on topic Installing ethercat repositories

Installing ethercat repositories

Category: EtherCAT

- PCW

07 Jan 2026 16:01

Replied by PCW on topic 7i92M + 7i76 add PWM+PktUART

7i92M + 7i76 add PWM+PktUART

Category: Driver Boards

- PCW

07 Jan 2026 15:52

Replied by PCW on topic Servos drives directly start turning

Servos drives directly start turning

Category: General LinuxCNC Questions

Time to create page: 0.204 seconds